Design feature for DIY wheel truing stand

#1

Newbie

Thread Starter

Design feature for DIY wheel truing stand

I'm putting the finishing touches to the design for a wheel truing stand and the one thing I can't get my head round is the fixing mechanism to hold the wheel stable and static in the stand.

Most / some stands have a V-shaped socket which you drop the locknuts into, e.g. Park TS-2.2 (option A)

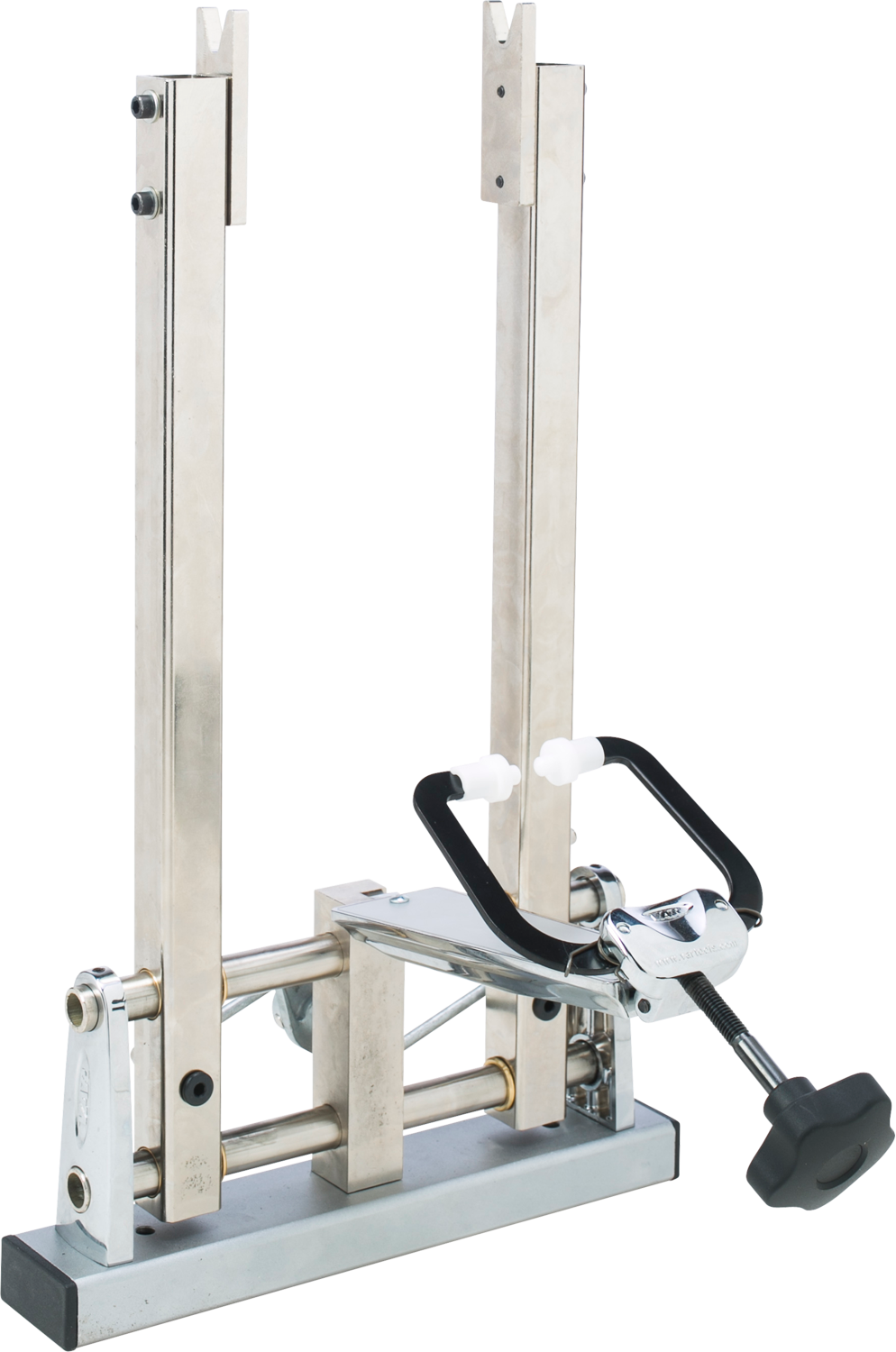

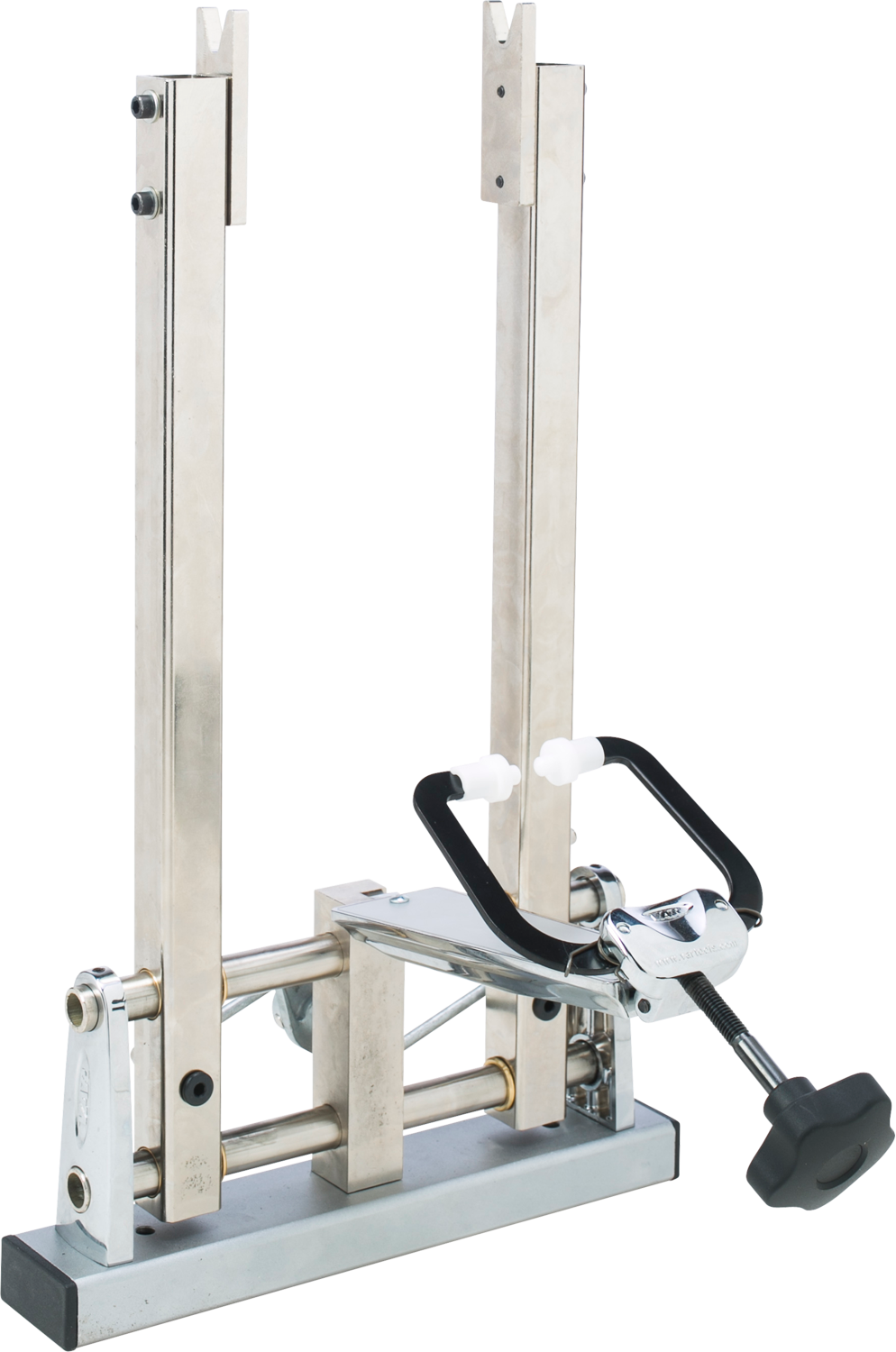

Some stands & my design would better suit the wheel being held by tapered metal shafts which insert into each locknut e.g. VAR Atomic (option B)

This could probably benefit from some pics but I'm eight posts away. Hope you get the gist.

My brain is telling me option B will allow the wheel to wobble around all over the place. Has anyone got any practical experience to confirm or deny this?

Many thanks in advance if you have time to reply.

Most / some stands have a V-shaped socket which you drop the locknuts into, e.g. Park TS-2.2 (option A)

Some stands & my design would better suit the wheel being held by tapered metal shafts which insert into each locknut e.g. VAR Atomic (option B)

This could probably benefit from some pics but I'm eight posts away. Hope you get the gist.

My brain is telling me option B will allow the wheel to wobble around all over the place. Has anyone got any practical experience to confirm or deny this?

Many thanks in advance if you have time to reply.

#2

Senior Member

Join Date: Aug 2005

Location: Pittsburgh, PA

Posts: 33,656

Bikes: '96 Litespeed Catalyst, '05 Litespeed Firenze, '06 Litespeed Tuscany, '20 Surly Midnight Special, All are 3x10. It is hilly around here!

Mentioned: 39 Post(s)

Tagged: 0 Thread(s)

Quoted: 2026 Post(s)

Likes: 0

Liked 1,096 Times

in

742 Posts

Can your wheel holders be shaped like dropouts and the wheel clamped with a qr skewer or axle nuts?

#3

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,075

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,859 Times

in

2,307 Posts

I've used an Atomic stand, too many years ago What I remember was that solid axles didn't fit, the dishing marks were pretty useless (not that this is a real need), it's rim indicators sucked and the rim diameter adjustment was clumsy. Now back then there were no Parks (not for another year or two in my area), other stands had equally frustrating aspects with the exception of the Preciray (the best overall stand for classic wheels IMO, and one is 20' from me currently).

What I remember was that solid axles didn't fit, the dishing marks were pretty useless (not that this is a real need), it's rim indicators sucked and the rim diameter adjustment was clumsy. Now back then there were no Parks (not for another year or two in my area), other stands had equally frustrating aspects with the exception of the Preciray (the best overall stand for classic wheels IMO, and one is 20' from me currently).

Not asked but this is the interweb…- For me the number 1 aspect of a stand is holding the wheels solidly and in a repeatable manor. No dishing feature is no problem. No dial indicators (the Park, also in my basement have two that I use for giggles after I true a wheel). The ability to position the "working area" of the stand is a plus (do you have to stand up, lean over, reach around stuff...). Enough fitting and size adjustability to handle the wheels that you see (obviously different between a home and shop setting). And last is the stability/solidness of the stand and how it holds the wheel (did I mention that before ).

).

Back to the Atomic- The axle end conical bits were slid into the stand's sliding supports, basically cylinders with marks on them for sort of but not really dishing. When a solid axle was encountered the conical bits were removed and the solid axle was gripped (a poor term for what really was the case) by the now open ended supports. The axle would not seek a consistent position within the supports. Perhaps if the supports were also conical in a concave sense the axle would better center and repeat the wheel's arrangement WRT the rim indicators.

But given how simple and axle diameter accommodating the "V" notch axle fitting design is I don't see the need to reinvent the wheel (poor pun ). One aspect of this from the Preciray are the little links that swing over the axle and with their thumb nuts (set screws) trap the axle into the bottom of the "V". I have no problem using a false through axle with conical sliding ends that trap a big and hollow axle, much like the Park TS-TA. Andy

). One aspect of this from the Preciray are the little links that swing over the axle and with their thumb nuts (set screws) trap the axle into the bottom of the "V". I have no problem using a false through axle with conical sliding ends that trap a big and hollow axle, much like the Park TS-TA. Andy

What I remember was that solid axles didn't fit, the dishing marks were pretty useless (not that this is a real need), it's rim indicators sucked and the rim diameter adjustment was clumsy. Now back then there were no Parks (not for another year or two in my area), other stands had equally frustrating aspects with the exception of the Preciray (the best overall stand for classic wheels IMO, and one is 20' from me currently).

What I remember was that solid axles didn't fit, the dishing marks were pretty useless (not that this is a real need), it's rim indicators sucked and the rim diameter adjustment was clumsy. Now back then there were no Parks (not for another year or two in my area), other stands had equally frustrating aspects with the exception of the Preciray (the best overall stand for classic wheels IMO, and one is 20' from me currently). Not asked but this is the interweb…- For me the number 1 aspect of a stand is holding the wheels solidly and in a repeatable manor. No dishing feature is no problem. No dial indicators (the Park, also in my basement have two that I use for giggles after I true a wheel). The ability to position the "working area" of the stand is a plus (do you have to stand up, lean over, reach around stuff...). Enough fitting and size adjustability to handle the wheels that you see (obviously different between a home and shop setting). And last is the stability/solidness of the stand and how it holds the wheel (did I mention that before

).

).Back to the Atomic- The axle end conical bits were slid into the stand's sliding supports, basically cylinders with marks on them for sort of but not really dishing. When a solid axle was encountered the conical bits were removed and the solid axle was gripped (a poor term for what really was the case) by the now open ended supports. The axle would not seek a consistent position within the supports. Perhaps if the supports were also conical in a concave sense the axle would better center and repeat the wheel's arrangement WRT the rim indicators.

But given how simple and axle diameter accommodating the "V" notch axle fitting design is I don't see the need to reinvent the wheel (poor pun

). One aspect of this from the Preciray are the little links that swing over the axle and with their thumb nuts (set screws) trap the axle into the bottom of the "V". I have no problem using a false through axle with conical sliding ends that trap a big and hollow axle, much like the Park TS-TA. Andy

). One aspect of this from the Preciray are the little links that swing over the axle and with their thumb nuts (set screws) trap the axle into the bottom of the "V". I have no problem using a false through axle with conical sliding ends that trap a big and hollow axle, much like the Park TS-TA. Andy

__________________

AndrewRStewart

AndrewRStewart

#4

Senior Member

Greetings Wesley.

It has probably been said before, if it is for amateur home use...

An old cheap quality bike frame, chopped to suit, and zip ties to begin with. Maybe get more elaborate later with braze on adjustable fixtures. (You're just referencing run-out or confirming 'true'.)

Or use your existing frame.

Works for me.

That is easily sorted.

It has probably been said before, if it is for amateur home use...

An old cheap quality bike frame, chopped to suit, and zip ties to begin with. Maybe get more elaborate later with braze on adjustable fixtures. (You're just referencing run-out or confirming 'true'.)

Or use your existing frame.

Works for me.

I'm eight posts away.

Last edited by slow_runner; 10-10-19 at 08:44 PM.

#5

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,905

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,928 Times

in

2,553 Posts

I've never seen a reason not to have the vee slots. Reasonably repeatable and with hub nuts or QR, solid. Plus the axle size/type doesn't matter at all. Nothing to add or keep track of. I did modify the dishing too I've had for decades so it can be used with the nuts in place. (There are dishing tools out there with that feature. Not my idea.)

Ben

Ben

#6

Newbie

Thread Starter

Greetings Wesley.

It has probably been said before, if it is for amateur home use...

An old cheap quality bike frame, chopped to suit, and zip ties to begin with. Maybe get more elaborate later with braze on adjustable fixtures. (You're just referencing run-out or confirming 'true'.)

Or use your existing frame.

Works for me.

That is easily sorted.

It has probably been said before, if it is for amateur home use...

An old cheap quality bike frame, chopped to suit, and zip ties to begin with. Maybe get more elaborate later with braze on adjustable fixtures. (You're just referencing run-out or confirming 'true'.)

Or use your existing frame.

Works for me.

That is easily sorted.

#7

Newbie

Thread Starter

Thanks for all your replies.

The jig design will accommodate two horizontal shafts in a very simple way. I can make them perfectly aligned in each plane and they will slide in simple bearings to accommodate different hub sizes very easily. They can be clamped rock solid once holding the wheel also. So all of that I'm comfortable with. I'm just not sure if this is actually a good way to hold the wheel so was wondering if anyone had tried it themselves, either DIY or with something like a VAR. I don't think I would have the problem mentioned above with the VAR since I could machine some inserts for thru-axles which would include a "female" socket to accept the pointed shaft.

The jig design won't easily accommodate V sockets, so it would be back to the drawing board if common consensus is that this is the best method to fix the wheel in place.

Cheers, Richard

The jig design will accommodate two horizontal shafts in a very simple way. I can make them perfectly aligned in each plane and they will slide in simple bearings to accommodate different hub sizes very easily. They can be clamped rock solid once holding the wheel also. So all of that I'm comfortable with. I'm just not sure if this is actually a good way to hold the wheel so was wondering if anyone had tried it themselves, either DIY or with something like a VAR. I don't think I would have the problem mentioned above with the VAR since I could machine some inserts for thru-axles which would include a "female" socket to accept the pointed shaft.

The jig design won't easily accommodate V sockets, so it would be back to the drawing board if common consensus is that this is the best method to fix the wheel in place.

Cheers, Richard

#8

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

Looking at this having just relaced and trued some old Schwinn Superior wheels, one observation: The vee slots in the Park work fine, even for the older threaded and keyed axles. Very easy to use and works great is pretty good engineering.

Looking at the old Atomic, it had two cones independently adjustable cones. If I'm looking at that correctly you had to adjust both cones to center it. Bad design - inconvenient. VAR doesn't make that design anymore: their current model, below, uses Vees. They offer cones with stubs and shoulders to allow you to put a wheel into the vee design conveniently (pic further below). Many companies offer a setup for through-axle designs where you have two cones with holes in the center, and a threaded rod through the center. Using a vee design with either seems to me to give you the freedom to use either vees on the wheel nubs or axles, OR to use a cone design. So, with a vee, you have convenience PLUS you can apply cones if you like. Don't even have to remove the QR or nut from the axle with a vee.

Engineering is the application of science to achieve an economically superior outcome. It seems to me that the vee design gives you convenience and flexibility. And certainly avoids having to adjust two cones independently to get the thing centered (not talking about centering to check for disk, just talking about easy centering to allow the wheel to fit into the centering arm with minimal fuss). If you are truly engineering this (that is, taking economic factors like convenience, time to mount the wheel in the stand, time to center the wheel) my vote is Vee. Of course, if this is to be a monument to technology (that is, a sculpture), why not consider maglev support of the wheels?

I'm prejudiced, because my shop hero Perry O. (Racine Cyclery - howdy, Perry!) built thousands of high quality wheels quickly and used (I believe) something like a Park stand with Vees IIRC. If Perry could do it with vees, I'll do it with vees.

https://www.vartools.com/images/phot...686_365_XL.PNG

Looking at the old Atomic, it had two cones independently adjustable cones. If I'm looking at that correctly you had to adjust both cones to center it. Bad design - inconvenient. VAR doesn't make that design anymore: their current model, below, uses Vees. They offer cones with stubs and shoulders to allow you to put a wheel into the vee design conveniently (pic further below). Many companies offer a setup for through-axle designs where you have two cones with holes in the center, and a threaded rod through the center. Using a vee design with either seems to me to give you the freedom to use either vees on the wheel nubs or axles, OR to use a cone design. So, with a vee, you have convenience PLUS you can apply cones if you like. Don't even have to remove the QR or nut from the axle with a vee.

Engineering is the application of science to achieve an economically superior outcome. It seems to me that the vee design gives you convenience and flexibility. And certainly avoids having to adjust two cones independently to get the thing centered (not talking about centering to check for disk, just talking about easy centering to allow the wheel to fit into the centering arm with minimal fuss). If you are truly engineering this (that is, taking economic factors like convenience, time to mount the wheel in the stand, time to center the wheel) my vote is Vee. Of course, if this is to be a monument to technology (that is, a sculpture), why not consider maglev support of the wheels?

I'm prejudiced, because my shop hero Perry O. (Racine Cyclery - howdy, Perry!) built thousands of high quality wheels quickly and used (I believe) something like a Park stand with Vees IIRC. If Perry could do it with vees, I'll do it with vees.

https://www.vartools.com/images/phot...686_365_XL.PNG

Last edited by WizardOfBoz; 10-11-19 at 08:24 AM.

#9

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

This begs a question. I don't deal with through axles on my bikes (all have rim brakes). My understanding is that the wheels in a thru axle bike have axles (for example, 15mm diameter) that go directly through the bearing IDs. If so, then the accessories that have cones and a center rod seem overkill for use in a truing stand. Wouldn't a 15mm diameter rod, shot through the wheel and layed in the vees, be more convenient and (because this is how the axle works, too) just as accurate as the vees?

Or am I thinking about this wrong?

Or am I thinking about this wrong?

#10

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,075

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,859 Times

in

2,307 Posts

It would be a simple added element to have a plate with a "V" notch bolt to the two tubes' ends. When the "V" notched plates were used (either all the time or as needed) the axle would run parallel to the tubes but just a bit higher. The same tube threads that the plates attached via could also contain removeable conical, A La Atomic) inserts of any diameter or point angle you wanted.

This speaks to a design principle of modularity. Having a base/foundation design that can have various adaptors added to as the wheel/axle designs change seems to me to be a good idea. I think of the simple need of shops have in storing parts on their shelves. Many shops use industry provided bins which come in various sizes. The shelving is that base/foundation I mentioned. The differing sized bins are the adaptors. Were I to apply for work at a shop which had only one size storage bin/ability I would question the smarts of the boss Andy

Andy

This speaks to a design principle of modularity. Having a base/foundation design that can have various adaptors added to as the wheel/axle designs change seems to me to be a good idea. I think of the simple need of shops have in storing parts on their shelves. Many shops use industry provided bins which come in various sizes. The shelving is that base/foundation I mentioned. The differing sized bins are the adaptors. Were I to apply for work at a shop which had only one size storage bin/ability I would question the smarts of the boss

Andy

Andy

__________________

AndrewRStewart

AndrewRStewart

#12

Senior Member

Join Date: Sep 2014

Posts: 3,893

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1062 Post(s)

Liked 665 Times

in

421 Posts

I'm building my own truing stand right now. I'll post pics when I'm done. Meanwhile, I'll share one idea. Everybody's got spare axles and cones. I threaded spare cones onto the exposed threads of a QR axle, then threaded spare axles into those. My stand will grab onto those axles. It'll be nice and rigid, and if the threads are the same, should work with solid axles as well.