Who is Hambini?

#26

Senior Member

Follow the links in the Flo statement. https://flocycling.com/blogs/blog/fl...ni-accusations

His cursing is brilliant ... brings a smile... but I have to fast forward every video to get past the "hambini fans" portion... it's a little loud sometimes.

#27

Senior Member

#28

Senior Member

I hadn’t seen it before but in one of my emails to bbinfinite I made the comment that I “did not want to get in the middle of a religious war between you and Hambini”, not knowing that apparently there actually has been a bit of one. So I guess now I know why I was getting somewhat snarky replies from Gary Mailhiot at BBinfinite, who is actually named in the Hambini video.

#29

Senior Member

Josh is saying that humans vary too much.. that is ok to say... Hambini by the same token can say his human did not. We dont know.

#30

TeeOhPea 2tha DeeOhGee

I wish his clips opened with a summary / brief for those of us who don't need to see all the evidence. I don't have 40 minutes to wait for his case to unfold. By the time he reaches the end, I've skipped so much I have no idea what he's saying. I get the sense it could be something compelling, but who has the time? He's entertaining, so I get suckered again, but ultimately the cycle repeats.

#31

Senior Member

Join Date: Feb 2018

Posts: 1,410

Bikes: 2017 Specialized Allez Sprint Comp

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 850 Post(s)

Liked 344 Times

in

247 Posts

you dont have to agree with the data but that does not automatically make it fake... you can hate on the methods all you want....but it seems you are saying it's 100% fabricated... like he just threw some bad numbers for FLO and that's that.

Josh is saying that humans vary too much.. that is ok to say... Hambini by the same token can say his human did not. We dont know.

Josh is saying that humans vary too much.. that is ok to say... Hambini by the same token can say his human did not. We dont know.

Likes For smashndash:

#32

Senior Member

you dont have to agree with the data but that does not automatically make it fake... you can hate on the methods all you want....but it seems you are saying it's 100% fabricated... like he just threw some bad numbers for FLO and that's that.

Josh is saying that humans vary too much.. that is ok to say... Hambini by the same token can say his human did not. We dont know.

Josh is saying that humans vary too much.. that is ok to say... Hambini by the same token can say his human did not. We dont know.

#33

Senior Member

#34

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

I have not read the book. Only seen some snippets/debates online.

Don’t mean to turn this into a debate but:

“Other than its tension the bicycle wheel is the same as any other wheel such as a wooden wagon wheel. The spoke under the hub is shortened in compression by a load on the axle, while the upper spokes remain unaffected by the load.”

Maybe I’m just dumb but I don’t see a lack of tension as the same thing as compression. We don’t have to discuss this any further, but I think this could be fairly easily resolved if someone heavily loaded a wheel and then cut the spoke at the bottom, and nothing happened. If that spoke were truly a load bearing structure, then something would happen. Regardless, you’re right that this has been debated endlessly and there’s no resolving it.

Don’t mean to turn this into a debate but:

“Other than its tension the bicycle wheel is the same as any other wheel such as a wooden wagon wheel. The spoke under the hub is shortened in compression by a load on the axle, while the upper spokes remain unaffected by the load.”

Maybe I’m just dumb but I don’t see a lack of tension as the same thing as compression. We don’t have to discuss this any further, but I think this could be fairly easily resolved if someone heavily loaded a wheel and then cut the spoke at the bottom, and nothing happened. If that spoke were truly a load bearing structure, then something would happen. Regardless, you’re right that this has been debated endlessly and there’s no resolving it.

Lack of tension is not compression. If an unloaded wheel spoke has 100 kgf tension, it may be that the bottom three spokes on the wheel are loaded at, say 80-90kgf when under load. This just means that (for both wheels) 60-120kg of downward force, from the bottom spokes pulling down, is removed from the hub. The upward force of the remaining spokes is what supports you. One quibble I have with how Jobst explained it was that he said words to the effect that the top spokes don't increase their tension to support you. I would have said something like "There's a force balance on the unbalanced wheel where all the spokes pull evenly and the up and down forces even out. When the wheel is loaded, the spokes near where the wheel touches the ground are unloaded a bit. This means that some spokes aren't pulling down as much as in the unloaded wheel. The difference in force is what supports you. Note that it IS the force of the top spokes from which the hub (and bike) are suspended that is supporting your weight."

I agree with the poster above: Hambini is a technically smart guy that doesn't give enough of a ***k to explain things to others who differ even slightly, and he kind of takes the same approach as some politicians today to anyone who questions his infallibility. He expects his words to be taking without question. Undercuts his message, some of which is useful. If I had the exact problem that one of his videos addressed, I'd watch it. Otherwise, very tiring. Better things to do.

Last edited by WizardOfBoz; 10-29-19 at 08:42 AM.

#35

Senior Member

The main thing that gives me pause about AC is the preload despite what Enduro says. My SRAM cranks have an adjuster collar that provides very minimal adjustment, but I am just not confident that it is capable of exerting sufficient preload for AC bearings.

Likes For Moe Zhoost:

#37

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,355

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6215 Post(s)

Liked 4,213 Times

in

2,362 Posts

+1 Having been involved in a long drawn out discussion on wheel dynamics, this is the key to my problem with Brandt's point. He (and others) look on a decrease in tension as an increase in compression as if they are directly opposite forces. They aren't. For compression to occur, especially in a tensioned bicycle wheel, tension has to be zero and vice versa.

Additionally, there is also nothing to "compress" when it comes to a spoke. Put a single spoke in a rim (or piece of rim) and hang a hub from it. Hold on to the rim and turn it upside down. The hub will fall through the rim along the spoke until the hub hits the rim. The end of the spoke doesn't "stand" on anything so it can't be compressed.

Additionally, there is also nothing to "compress" when it comes to a spoke. Put a single spoke in a rim (or piece of rim) and hang a hub from it. Hold on to the rim and turn it upside down. The hub will fall through the rim along the spoke until the hub hits the rim. The end of the spoke doesn't "stand" on anything so it can't be compressed.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#38

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

Bikes do not require 0.002mm runout. Even if you are racing. They do require fairly low runout and to get this for AC bearings is not hard. We successfully preloaded AC bearings in decades of very fine BB and wheel AC bearings. Think Dura Ace and Campagnolo. Think Eddy Merckx. I have my old paramount BB from nearly 40 years ago and it's pristine. Today, at least for Dura Ace cranks, you put the hollowtech NDS arm on, and use a little thumb wrench to snug up the thing. If the crank doesn't have play and spins pretty freely, tighten the clamping bolts and yer done.

AC bearings are much easier to adjust and more tolerant of improper preload than deep groove radials. AC bearings are MEANT to resist angular force. The design of DGR bearings make them very susceptible to wear if they experience side loads (or too-high a preload).

ACs are better bearings for BB service, and are easier to adjust and are more tolerate of improper adjustment that DGRs. Look at Enduro's warranty record. I believe them.

Last edited by WizardOfBoz; 10-29-19 at 08:44 AM.

#39

Junior Member

Join Date: Oct 2019

Location: Midlands, UK

Posts: 12

Bikes: 20+ from 1990's steel & magnesium!, to modern day alloy and carbon. MTB, CX & road

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

A wise old Owl once told me:

AC bearings can last longer in BB30 applications because they have higher load ratings than radial ball bearings. This is down to the filling method of the radial balls (look up Conrad filling method). So an AC of the same size will have more balls and a higher load rating than a radial bearing. So basically nothing to do with axial loads and/or preload. AC has slight rigidity benefit too as the 'effective centres' of the bearing are further apart. Forces are applied to the bearing where a line drawn through the contact angle bisects the axle centreline. However AC is only effective with fixed mechanical adjustment (e.g.screw thread). If your BB is preloading the bearings with a wavy spring then it wont be an AC under a radial load.

Now if you take a radial bearing with a higher radial clearance (C3) and apply preload it becomes an AC albeit with a low contact angle (typically 10~12deg). A bearing with lower clearance or 'standard' clearance CN will have a lower contact angle when preloaded. So C3 clearance will give you a marginal theoretical benefit but misses the main advantage of an AC which is the higher load rating. However the extra clearance in a C3 can be helpful if the machining of your BB is not very accurate and the two bearing positions are misaligned relative to each other.

OK so now lets have a look at precision bearings. Actually the P classes are ISO (Euro & Asia) and ABEC are ANSI (USA) but they are directly comparable P0 (ABEC-1) is standard then P6,P5,P4 & P2 (ABEC-3,5.7 & 9) are all improvements. Now consider that a BB30 bearing size 6806; the standard clearance, standard precision version of which is rated to run at max 15,000rpm and will do so all day long if so required. Now consider that the main benefit of higher precision bearings comes when you wish to exceed the max speed rating of a 'standard' bearing. Then consider that very few cyclists can get anywhere near a 200rpm cadence (yes that is 1.3% of the available speed capability!) Also higher precision bearings demand higher precision from the mating axle and housing journals so fitting them to standard parts has no benefit at all.

No matter how fast you think you are ALL BEARINGS IN BICYCLES OPERATE AT LOW SPEED. That is also why ceramics offer absolutely no tangible benefits for cyclists.

More than 50% of the drag in an unloaded bearing will come from the seals. This will reduce to less than 50% under load because mechanical drag is proportional to load and seal drag is constant. Now the 50% figure will apply to full contact seals (for example NTN seals have two contact lips at each side - which is why they last so well). This can be reduced by using low friction seals (single contact lip), non-contact seals or metal shields. There is no getting away from the fact that seal drag and sealing efficiency are directly related. As soon as you get any dirt inside a bearing you will massively increase the drag torque. This is down to the tolerances and clearances; again using the BB30 size 6806 as an example a CN version will have a radial clearance of 5~20microns (1 micron = 0.001mm) the C3 version 13~28microns. Now consider that a human hair has an thickness somewhere between 50 and 250microns; probably best to keep your helmet and shorts on when servicing your bearings!

If you want to give your cartridge bearings the best start in life try running them in before you fit them. Because bicycle application speeds are so slow the correct grease distribution does not happen. Therefore fix up your electric drill to spin them for 10 minutes at a few thousand rpm. This will help distribute the grease which has many benefits; reduced drag in bearing and seal, improved sealing efficiency, better corrosion protection & better lubrication.

Apologies if this is a bit heavy going but hopefully some of you will understand the key points here. Regarding the OP question I agree with most of the conclusions that Hambini reaches regarding bearings in the videos I have seen on YT.

AC bearings can last longer in BB30 applications because they have higher load ratings than radial ball bearings. This is down to the filling method of the radial balls (look up Conrad filling method). So an AC of the same size will have more balls and a higher load rating than a radial bearing. So basically nothing to do with axial loads and/or preload. AC has slight rigidity benefit too as the 'effective centres' of the bearing are further apart. Forces are applied to the bearing where a line drawn through the contact angle bisects the axle centreline. However AC is only effective with fixed mechanical adjustment (e.g.screw thread). If your BB is preloading the bearings with a wavy spring then it wont be an AC under a radial load.

Now if you take a radial bearing with a higher radial clearance (C3) and apply preload it becomes an AC albeit with a low contact angle (typically 10~12deg). A bearing with lower clearance or 'standard' clearance CN will have a lower contact angle when preloaded. So C3 clearance will give you a marginal theoretical benefit but misses the main advantage of an AC which is the higher load rating. However the extra clearance in a C3 can be helpful if the machining of your BB is not very accurate and the two bearing positions are misaligned relative to each other.

OK so now lets have a look at precision bearings. Actually the P classes are ISO (Euro & Asia) and ABEC are ANSI (USA) but they are directly comparable P0 (ABEC-1) is standard then P6,P5,P4 & P2 (ABEC-3,5.7 & 9) are all improvements. Now consider that a BB30 bearing size 6806; the standard clearance, standard precision version of which is rated to run at max 15,000rpm and will do so all day long if so required. Now consider that the main benefit of higher precision bearings comes when you wish to exceed the max speed rating of a 'standard' bearing. Then consider that very few cyclists can get anywhere near a 200rpm cadence (yes that is 1.3% of the available speed capability!) Also higher precision bearings demand higher precision from the mating axle and housing journals so fitting them to standard parts has no benefit at all.

No matter how fast you think you are ALL BEARINGS IN BICYCLES OPERATE AT LOW SPEED. That is also why ceramics offer absolutely no tangible benefits for cyclists.

More than 50% of the drag in an unloaded bearing will come from the seals. This will reduce to less than 50% under load because mechanical drag is proportional to load and seal drag is constant. Now the 50% figure will apply to full contact seals (for example NTN seals have two contact lips at each side - which is why they last so well). This can be reduced by using low friction seals (single contact lip), non-contact seals or metal shields. There is no getting away from the fact that seal drag and sealing efficiency are directly related. As soon as you get any dirt inside a bearing you will massively increase the drag torque. This is down to the tolerances and clearances; again using the BB30 size 6806 as an example a CN version will have a radial clearance of 5~20microns (1 micron = 0.001mm) the C3 version 13~28microns. Now consider that a human hair has an thickness somewhere between 50 and 250microns; probably best to keep your helmet and shorts on when servicing your bearings!

If you want to give your cartridge bearings the best start in life try running them in before you fit them. Because bicycle application speeds are so slow the correct grease distribution does not happen. Therefore fix up your electric drill to spin them for 10 minutes at a few thousand rpm. This will help distribute the grease which has many benefits; reduced drag in bearing and seal, improved sealing efficiency, better corrosion protection & better lubrication.

Apologies if this is a bit heavy going but hopefully some of you will understand the key points here. Regarding the OP question I agree with most of the conclusions that Hambini reaches regarding bearings in the videos I have seen on YT.

Last edited by seb1466; 10-29-19 at 10:14 AM. Reason: added final sentence

Likes For seb1466:

#40

Senior Member

A wise old Owl once told me:

AC bearings can last longer in BB30 applications because they have higher load ratings than radial ball bearings. This is down to the filling method of the radial balls (look up Conrad filling method). So an AC of the same size will have more balls and a higher load rating than a radial bearing. So basically nothing to do with axial loads and/or preload. AC has slight rigidity benefit too as the 'effective centres' of the bearing are further apart. Forces are applied to the bearing where a line drawn through the contact angle bisects the axle centreline. However AC is only effective with fixed mechanical adjustment (e.g.screw thread). If your BB is preloading the bearings with a wavy spring then it wont be an AC under a radial load..

AC bearings can last longer in BB30 applications because they have higher load ratings than radial ball bearings. This is down to the filling method of the radial balls (look up Conrad filling method). So an AC of the same size will have more balls and a higher load rating than a radial bearing. So basically nothing to do with axial loads and/or preload. AC has slight rigidity benefit too as the 'effective centres' of the bearing are further apart. Forces are applied to the bearing where a line drawn through the contact angle bisects the axle centreline. However AC is only effective with fixed mechanical adjustment (e.g.screw thread). If your BB is preloading the bearings with a wavy spring then it wont be an AC under a radial load..

Bikes do not require 0.002mm runout. Even if you are racing. They do require fairly low runout and to get this for AC bearings is not hard. We successfully preloaded AC bearings in decades of very fine BB and wheel AC bearings. Think Dura Ace and Campagnolo. Think Eddy Merckx. I have my old paramount BB from nearly 40 years ago and it's pristine.

AC bearings are much easier to adjust and more tolerant of improper preload than deep groove radials. AC bearings are MEANT to resist angular force. The design of DGR bearings make them very susceptible to wear if they experience side loads (or too-high a preload).

ACs are better bearings for BB service, and are easier to adjust and are more tolerate of improper adjustment that DGRs. Look at Enduro's warranty record. I believe them.

#41

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

DOS,

Good questions.

First, there's an intrinsic reason why AC bearings have higher ratings for radial loading service. seb1466 described it. If you think how deep groove radial bearings have to be made its this: Inner and outer races are precision ground with grooves for the balls. You can't just make the race concentric and shove in a retainer full of ball bearings, for the same reason that the balls don't fall out in normal use. To install the ball bearings you must make the inner and outer race non-concentric (you move one race so that it touches the other race). This leaves a crescent-moon shaped gap that the bearings will fit in. Note that you can't fill the races totally with the ball bearings touching each other in a DGR. At some point the balls force the races to become concentric and no more can be installed. Once you get the maximum number of balls that fit the inner and outer races are close to concentric. You complete the proces by adding a spacer that keeps the balls apart and equally spaced. The point is, with DGR bearings you MUST have spaces between the balls. The only way to fit more balls into a DGR is to make the "deep groove" not so deep. This makes the next problem discussed much worse.

If you've ever repacked an older hub with cups and cones (that is, AC bearings) you can see that with such bearing you can fill the race with more balls. More balls for the same size bearing mean more area to support load means higher ratings. You could still put a spacer in, but the spacing can be tighter for AC than for DGR bearings.

The increased number of ball bearings explains higher load ratings in radial service.

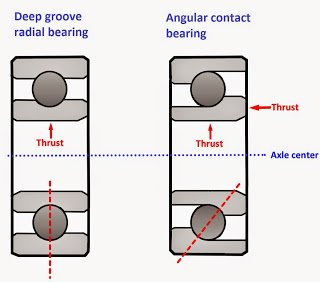

Now, look at how the different designs look:

https://3.bp.blogspot.com/-6SWSy16Ot...e-bearings.jpg

Note that the line that intersects the bearing contact points for AC bearings is angled. This means that a side thrust on the angular contact bearing can be resisted by design. The DGR bearing contact line is perpendicular to axial (side) loads. This means that theoretically the DGR can't resist side loads at all! Practicality intervenes. There is some built-in clearance in the DGR, so (for example, in the pic above) the outer cone shifts less a little bit and the line of contact angles a little bit. For geometric reasons, though, the force on the bearings created by side loads are much higher than in the AC bearings. This can distort the races a bit. Both the clearance and the distortion act to make the DGR bearing a bit more "angular contact" so that it can resist side loads. But again, a side force in a DGR creates way more force on the bearing races than one sees in an AC bearing. And if the groove in the DGR is less deep, the problem is way worse. The upshot is that if you over-preload a DGR bearing its gonna fail faster than its AC counterpart. Also, if you encounter a lot of side forces on the DGR it will fail faster.

Sometimes industrial applications use DGRs when there will be no side loading. Electric motors often have DGRs. But for apps with radial AND side loads you'd always use an AC bearing. For really heavy duty stuff (car, truck, and locomotive axles) you use tapered roller bearings. The loads and speeds on bikes don't require that. For your amusement, a train axle bearing using opposed tapered roller bearings:

PS In rail service, some bearings have spring-loaded devices that give a contact side load on these bearings, to improve service life and peformance.

Good questions.

First, there's an intrinsic reason why AC bearings have higher ratings for radial loading service. seb1466 described it. If you think how deep groove radial bearings have to be made its this: Inner and outer races are precision ground with grooves for the balls. You can't just make the race concentric and shove in a retainer full of ball bearings, for the same reason that the balls don't fall out in normal use. To install the ball bearings you must make the inner and outer race non-concentric (you move one race so that it touches the other race). This leaves a crescent-moon shaped gap that the bearings will fit in. Note that you can't fill the races totally with the ball bearings touching each other in a DGR. At some point the balls force the races to become concentric and no more can be installed. Once you get the maximum number of balls that fit the inner and outer races are close to concentric. You complete the proces by adding a spacer that keeps the balls apart and equally spaced. The point is, with DGR bearings you MUST have spaces between the balls. The only way to fit more balls into a DGR is to make the "deep groove" not so deep. This makes the next problem discussed much worse.

If you've ever repacked an older hub with cups and cones (that is, AC bearings) you can see that with such bearing you can fill the race with more balls. More balls for the same size bearing mean more area to support load means higher ratings. You could still put a spacer in, but the spacing can be tighter for AC than for DGR bearings.

The increased number of ball bearings explains higher load ratings in radial service.

Now, look at how the different designs look:

https://3.bp.blogspot.com/-6SWSy16Ot...e-bearings.jpg

Note that the line that intersects the bearing contact points for AC bearings is angled. This means that a side thrust on the angular contact bearing can be resisted by design. The DGR bearing contact line is perpendicular to axial (side) loads. This means that theoretically the DGR can't resist side loads at all! Practicality intervenes. There is some built-in clearance in the DGR, so (for example, in the pic above) the outer cone shifts less a little bit and the line of contact angles a little bit. For geometric reasons, though, the force on the bearings created by side loads are much higher than in the AC bearings. This can distort the races a bit. Both the clearance and the distortion act to make the DGR bearing a bit more "angular contact" so that it can resist side loads. But again, a side force in a DGR creates way more force on the bearing races than one sees in an AC bearing. And if the groove in the DGR is less deep, the problem is way worse. The upshot is that if you over-preload a DGR bearing its gonna fail faster than its AC counterpart. Also, if you encounter a lot of side forces on the DGR it will fail faster.

Sometimes industrial applications use DGRs when there will be no side loading. Electric motors often have DGRs. But for apps with radial AND side loads you'd always use an AC bearing. For really heavy duty stuff (car, truck, and locomotive axles) you use tapered roller bearings. The loads and speeds on bikes don't require that. For your amusement, a train axle bearing using opposed tapered roller bearings:

PS In rail service, some bearings have spring-loaded devices that give a contact side load on these bearings, to improve service life and peformance.

Last edited by WizardOfBoz; 10-29-19 at 09:30 PM.

Likes For WizardOfBoz:

#42

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

BTW, when you install crank arms there can be spacers that apply preload on the bearings. So you should be able to apply preload with almost any crank design. For Shimano Hollowtech its like preloading the headset. You install bearings and any needed spacers (I don't think I have any in my setup, btw) and then you use the plastic thumbscrew to gently preload. Then you tighten the NDS crank arm.

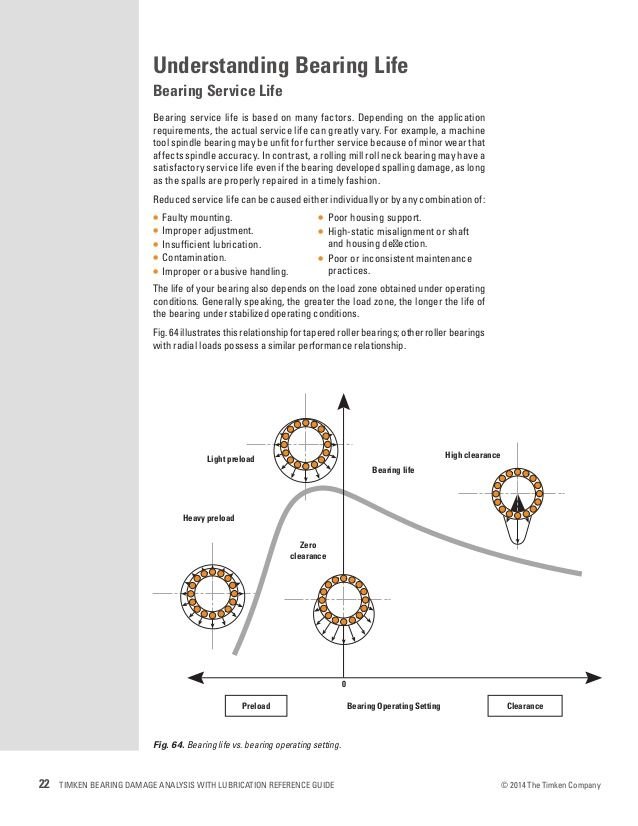

That said, note that in the Timken graph below, the service life difference between no and light preload is minimal. The big hit is if you over-preload, which is easy in DGRs. But the graph below is why I suggest that you 1) snug up the bearing, and 2) apply just a smidge of preload. If you're off a bit, it ain't no biggie.

That said, note that in the Timken graph below, the service life difference between no and light preload is minimal. The big hit is if you over-preload, which is easy in DGRs. But the graph below is why I suggest that you 1) snug up the bearing, and 2) apply just a smidge of preload. If you're off a bit, it ain't no biggie.

#43

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

One last point. When DGR bearings wear, there is a limited amount of adjustment you can to to get rid of the play. With AC bearings, you have a much easier time of adjusting preload to account for wear.

This was pointed out in an article about Chris King bearings (which are AC):

The Chris King Bottom Bracket Review - The Tall Cyclist

This was pointed out in an article about Chris King bearings (which are AC):

The Chris King Bottom Bracket Review - The Tall Cyclist

#44

Senior Member

Thread Starter

Join Date: Sep 2009

Location: Spain

Posts: 185

Bikes: Tommasini, Caad 7 , Seven, Pinarello

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 65 Post(s)

Likes: 0

Liked 15 Times

in

10 Posts

Hi, what is bearings preload ?and to do this befor mounting the cranks? this tool is for Shimano only .thank,s

#45

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,507

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2743 Post(s)

Liked 3,390 Times

in

2,053 Posts

If you want to give your cartridge bearings the best start in life try running them in before you fit them. Because bicycle application speeds are so slow the correct grease distribution does not happen. Therefore fix up your electric drill to spin them for 10 minutes at a few thousand rpm. This will help distribute the grease which has many benefits; reduced drag in bearing and seal, improved sealing efficiency, better corrosion protection & better lubrication.

#46

Senior Member

Load is force applied to a part when in operation.Preload is applying force before operation. In this context it is slight pressure applied to the bearing to remove play by pushing the races closer together. Preload is applied via the installation of the cranks. Shimano cranks have an end cap with a star shape interface; you adjust preload with that before tightening the crank arm pinch bolts.

#47

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

See what they are doing at about 1:40 in the video below.

This may be it in Spanish: de precarga de los rodamientos

#48

Junior Member

Join Date: Oct 2019

Location: Midlands, UK

Posts: 12

Bikes: 20+ from 1990's steel & magnesium!, to modern day alloy and carbon. MTB, CX & road

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Sor forgive my ignorance as I try to understand the angular contact points being made in above two posts. Is the point of the bold text piece of the @seb1466 post that I can use AC bearings with cranks that don't have mechanical preload adjustment, because as @WizardOfBoz points out, preload needs are minimal anyway and AC bearings are tolerant of misalignments, but I will lose the advantage that AC bearings offer in terms of higher load ratings? I am running a pristine 80s Suntour BB on my Paramount and am perfectly comfortable adjusting preload via the adjustable cup because I can feel changes in spindle play and ball bearing movement. With my SRAM cranks, there is no such mechanical adjuster (There is an adjusting collar but I can’t say that it effects bearing load in any way).

#49

Senior Member

Thread Starter

Join Date: Sep 2009

Location: Spain

Posts: 185

Bikes: Tommasini, Caad 7 , Seven, Pinarello

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 65 Post(s)

Likes: 0

Liked 15 Times

in

10 Posts

Load is force applied to a part when in operation.Preload is applying force before operation. In this context it is slight pressure applied to the bearing to remove play by pushing the races closer together. Preload is applied via the installation of the cranks. Shimano cranks have an end cap with a star shape interface; you adjust preload with that before tightening the crank arm pinch bolts.

Last edited by brooklyn6640; 10-30-19 at 07:53 AM.

#50

Junior Member

Join Date: Oct 2019

Location: Midlands, UK

Posts: 12

Bikes: 20+ from 1990's steel & magnesium!, to modern day alloy and carbon. MTB, CX & road

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

A bit more information here to help the discussion. Firstly when considering AC bearings a traditional cup and cone assembly is a slightly different proposition to a AC cartridge bearing (ACBB). The ACBB can be dimensionally interchangeable with a deep groove ball bearing (DGBB) for example in a BB30 bottom bracket (7806 vs 6806).

Regarding preload;

1. All AC bearings need to be adjusted in an axial direction (from the side) due to the asymmetric shape of the raceways. This axial adjustment is referred to a preloading but only actually become a 'preload' once all clearance has been removed. Without some form of preloading AC bearings do not work correctly.

2. DGBB do not need to be adjusted in an axial direction in order to work correctly as the raceways are symmetrical. However the radial clearance in a DGBB also translates into an axial or sideways clearance too. Clearly when you are trying to control chain position for accurate gear section the presence of axial clearance is undesirable. This is why you preload DGBB in a wheel or bottom bracket - it is purely to remove the axial clearance.

Direction of forces:

The sideways (or axial) forces in bottom bracket bearings are negligible. The only axial forces are the preload that you can inadvertently apply through the adjustment system - so you adjust to remove the clearance and not to apply preload (same as a cup and cone).

In a wheel sideways (or axial) forces do occur during cornering. This is a percentage of the radial load it is supporting during normal straight ahead riding. The percentage is determined from the angle of lean and bit of Pythagoras Theorum. However even at significant angles of lean under high loading the axial forces are still lower than the radial forces. This is why many wheel axles successfully use DGBB.

So to summarise:

AC are not selected for bicycle bearings based on their ability to support axial (sideways) forces because the loadings are primarily radial in direction. Only exception is the headset lower bearing ;-)

ACBB offer a higher load rating than a DGBB of the same size.

When preloading ACBB, DGBB or Cup&Cone in bicycles the aim is only to reduce clearance to a minimum or a very light positive preload.

If you set up an AC bearing without preload control (or too much axial clearance) you lose the load rating advantage and get premature wear.

Regarding preload;

1. All AC bearings need to be adjusted in an axial direction (from the side) due to the asymmetric shape of the raceways. This axial adjustment is referred to a preloading but only actually become a 'preload' once all clearance has been removed. Without some form of preloading AC bearings do not work correctly.

2. DGBB do not need to be adjusted in an axial direction in order to work correctly as the raceways are symmetrical. However the radial clearance in a DGBB also translates into an axial or sideways clearance too. Clearly when you are trying to control chain position for accurate gear section the presence of axial clearance is undesirable. This is why you preload DGBB in a wheel or bottom bracket - it is purely to remove the axial clearance.

Direction of forces:

The sideways (or axial) forces in bottom bracket bearings are negligible. The only axial forces are the preload that you can inadvertently apply through the adjustment system - so you adjust to remove the clearance and not to apply preload (same as a cup and cone).

In a wheel sideways (or axial) forces do occur during cornering. This is a percentage of the radial load it is supporting during normal straight ahead riding. The percentage is determined from the angle of lean and bit of Pythagoras Theorum. However even at significant angles of lean under high loading the axial forces are still lower than the radial forces. This is why many wheel axles successfully use DGBB.

So to summarise:

AC are not selected for bicycle bearings based on their ability to support axial (sideways) forces because the loadings are primarily radial in direction. Only exception is the headset lower bearing ;-)

ACBB offer a higher load rating than a DGBB of the same size.

When preloading ACBB, DGBB or Cup&Cone in bicycles the aim is only to reduce clearance to a minimum or a very light positive preload.

If you set up an AC bearing without preload control (or too much axial clearance) you lose the load rating advantage and get premature wear.

Last edited by seb1466; 10-30-19 at 09:08 AM.