How to pick target spoke tension?

#26

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

Side note to this thread.

I note what may be a correlation between age and perspective about things like spoke tension.

It might be interesting to see if there's a dichotomy between those who were experienced (skilled?) wheel builders before 1981 and those who learned later.

I note what may be a correlation between age and perspective about things like spoke tension.

It might be interesting to see if there's a dichotomy between those who were experienced (skilled?) wheel builders before 1981 and those who learned later.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#27

Full Member

Thread Starter

#28

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,817

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 838 Post(s)

Liked 1,258 Times

in

663 Posts

Post your plot when done.

/markp

Likes For mpetry912:

#29

Full Member

Thread Starter

#30

Senior Member

I prioritize rim trueness first, with priority of radial first over lateral, and then adjust lateral easily, then try to even spoke tension as much as possible without affecting the rim true. Sometimes it's just a matter of adjusting laterally opposing pairs together, and with the spoke threads being relatively fine, doesn't take much to make them more even tension without noticing any rim runout. (I just ring, no tension meter, but I should get one, though accuracy may be difficult with short, straight-gauge spokes on 20" rims, spokes are inherently laterally stiffer.) My view is, as long as at good minimums so the bottom spokes don't go too loose under rolling, that's not the issue; It's about the other spokes (top and side) bearing the stress/strain as equally as possible. That's always a good thing, as lowering peak stress even a little, can have a big improvement in fatigue life. But if they have to be a bit unequal for a true rim (or a lot for an old rim), I'll accept that. Qualifier: Not a pro, not a wheelbuilder, just an engineer.

Last edited by Duragrouch; 02-23-24 at 11:03 PM.

#31

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

If one wants to think like an engineer, one has to start by identifying the problem.

Spokes consistently break at the elbows, and no place else. So, that's where one needs to focus. All the argument about tension are a distraction.

Think about WHY elbows fail, and address that first in order to build lasting wheels.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#32

Senior Member

Join Date: Oct 2023

Location: New Jersey

Posts: 571

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 366 Post(s)

Liked 273 Times

in

175 Posts

Side note to this thread.

I note what may be a correlation between age and perspective about things like spoke tension.

It might be interesting to see if there's a dichotomy between those who were experienced (skilled?) wheel builders before 1981 and those who learned later.

I note what may be a correlation between age and perspective about things like spoke tension.

It might be interesting to see if there's a dichotomy between those who were experienced (skilled?) wheel builders before 1981 and those who learned later.

Edit: Did they even have those spring tension gauges back in the day?

Last edited by ScottCommutes; 02-24-24 at 11:01 AM.

#33

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

Yep, we were all too stupid to know you can't do it that way.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#34

Senior Member

Join Date: Oct 2023

Location: New Jersey

Posts: 571

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 366 Post(s)

Liked 273 Times

in

175 Posts

I posted in another thread about tuning a piano. I can tune a piano - it isn't crazy hard. However, my tuning won't stay in tune, because I inadvertently leave a subtle twist in the pins themselves. I lack the feel to know when I'm twisting a pin vs. when I'm turning a pin. In other words, I leave unnecessary tension that (over time) gradually works itself out. My intuition tells me that a bike wheel would be similar.

#35

Full Member

Thread Starter

I wonder if this is a reason wheel building had(has?) the reputation of being such a black art. It had to be done mostly by feel and intuition, and needed extensive experience. Now we have better tools, digital tensionometers, and online resources to break down the data. I'm a numbers person so the latter greatly helps me get a feel for what's going on, others it may just confuse the issue. At least it helps someone like me to be able to build a reasonably good wheel.

#36

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

Twist was more of a problem BITD, when we were using 15g DB spokes for race wheels. So it was SOP to tell a client to ride a few hard miles then come back for a touch up.

These days, twist is less of an issue when building new, but still something one needs to learn to feel, especially when truing older wheels. Basically the spoke initially twists before the nipple actually does anything, then you need to relax it back. So every adjustment is akin to 3 steps forward and two back.

When I taught building, this was thd hardest thing, because it's all about touch.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#37

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

Those who learned before the internet, focused on skills rather than "better tools". Our better tools were the little tricks learned from masters.

In another thread, I posted a method to build quality wheels quickly and easily without the tools many have come to rely on. it's highly abbreviated but the big picture is clear.

Those willing to throw off the training wheels might give it a shot.

Likes For FBinNY:

#38

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

Well that's not true. If "everybody" did a great job of building wheels, we would have very few occasions to discuss wheels going out of true and breaking spokes apart from overt damage.

__________________

RUSA #7498

Originally Posted by noglider

People in this forum are not typical.

Last edited by ThermionicScott; 02-24-24 at 12:15 PM.

#39

Senior Member

Join Date: Oct 2023

Location: New Jersey

Posts: 571

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 366 Post(s)

Liked 273 Times

in

175 Posts

This thread is especially timely for me because while my rear wheel is true, the axle and bearings are shot. I'm trying to decide whether I should take the wheel apart and install a new hub (that I have), or go ahead and spread the bike to 135mm to accept a brand new wheel (that I also have).

#40

Full Member

Thread Starter

I think you've found the essence of the difference between older and newer builders. It's in the culture.

Those who learned before the internet, focused on skills rather than "better tools". Our better tools were the little tricks learned from masters.

In another thread, I posted a method to build quality wheels quickly and easily without the tools many have come to rely on. it's highly abbreviated but the big picture is clear.

Those willing to throw off the training wheels might give it a shot.

Those who learned before the internet, focused on skills rather than "better tools". Our better tools were the little tricks learned from masters.

In another thread, I posted a method to build quality wheels quickly and easily without the tools many have come to rely on. it's highly abbreviated but the big picture is clear.

Those willing to throw off the training wheels might give it a shot.

Likes For Ryan_M:

#41

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,817

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 838 Post(s)

Liked 1,258 Times

in

663 Posts

Not sure if your unit will output a measurement that can be read via USB.

/markp

#42

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,817

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 838 Post(s)

Liked 1,258 Times

in

663 Posts

This thread is especially timely for me because while my rear wheel is true, the axle and bearings are shot. I'm trying to decide whether I should take the wheel apart and install a new hub (that I have), or go ahead and spread the bike to 135mm to accept a brand new wheel (that I also have).

/markp

#43

Senior Member

Join Date: Oct 2023

Location: New Jersey

Posts: 571

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 366 Post(s)

Liked 273 Times

in

175 Posts

Yeah, that is a possibility, I have the parts from the other hub that I could grab. They would work. I think the reason the bike bends axles is because they don't sit squarely in the dropouts, so I need to fix that as well.

#44

Senior Member

This is not an attack, but a reminder.

If one wants to think like an engineer, one has to start by identifying the problem.

Spokes consistently break at the elbows, and no place else. So, that's where one needs to focus. All the argument about tension are a distraction.

Think about WHY elbows fail, and address that first in order to build lasting wheels.

If one wants to think like an engineer, one has to start by identifying the problem.

Spokes consistently break at the elbows, and no place else. So, that's where one needs to focus. All the argument about tension are a distraction.

Think about WHY elbows fail, and address that first in order to build lasting wheels.

I do know that on the DeHavilland Comet, the problem was not just a design issue, but failure to detect that issue in pre-production testing, and this was because they used the same sample for both "proof" (over) load testing, and then fatigue testing. The overload stress-relieved the area of design deficiency, thus no failure in fatigue. Actual production airplanes did not undergo that proof loading, put into service, failed in fatigue and explosive decompression. It had been thought that double-testing the same sample would be worst case, but it was not.

So I know there is value in stress-relieving.

I'll look at your link for your wheelbuilding instructions. EDIT: Oh, yes, I had already seen that post.

Last edited by Duragrouch; 02-24-24 at 08:54 PM.

#45

Full Member

Thread Starter

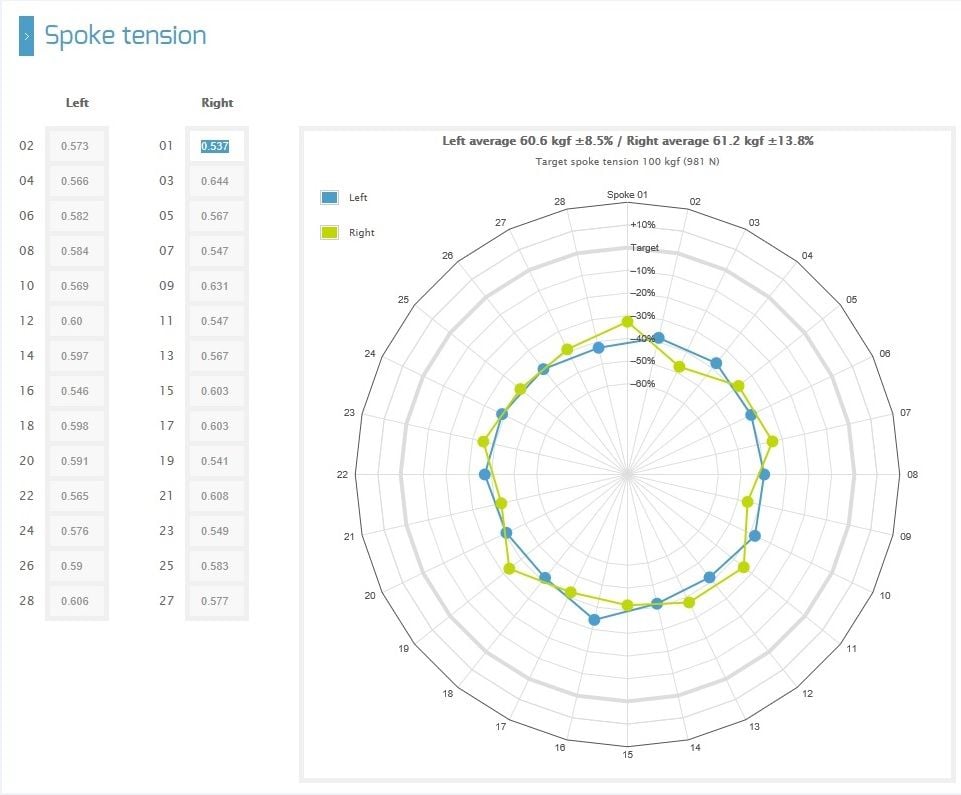

FBinNY I'd like to hear your feedback on this - so far. I saw you mentioned in another thread about maintaining length, this is only my third wheel set build and I'm pretty sure I did that in past builds but regardless did it this time, counting turns. It gave me some sporadic tensions but the wheel looked reasonable for a starting point, I doubt the rim has any give to it so that may amplify the tension differences. Just to see what would happen I started going only by numbers, trying to smooth out the tensions. FWIW this is the front wheel with asymetric carbon rims that feels stiff AF. I wanted to get things semi in order before tensionsioning more. The radial true isn't horrible at ~0.6mm. Lateral true is trash at probably 1.5mm but that I will address later. Spoke tension deviation is 11% on the right and 18% on the left. not good, but at least it's not erratic. I thought that was under control enough to start approaching final tension.

I know this isn't how you build wheels but I'd still like to hear your opinion. Thanks!

#46

Full Member

Join Date: Oct 2022

Location: UK, New Forest

Posts: 269

Bikes: 1980 Gitane sprint,1977 Motobécane C4, 1977 Carlton Clubman, 1959 Claud Butler European

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 69 Post(s)

Liked 122 Times

in

78 Posts

Easy now. I delve into building wheels because I like the tools, making my own equipment. And the analytics. It's not always about the fastest route to a end product. I like fussing over it, looking at pretty graphs, and chasing numbers. It gives me my OCD fix. I also make telescope optics by hand and enjoy the analysis and getting as close to perfection as I can where tolerances are measured in the 10s of nanometers. I've made enough of those to last me years, so this is the new thing.

Then look at Islandix system. Ciao

#47

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,931 Times

in

2,556 Posts

I posted in another thread about tuning a piano. I can tune a piano - it isn't crazy hard. However, my tuning won't stay in tune, because I inadvertently leave a subtle twist in the pins themselves. I lack the feel to know when I'm twisting a pin vs. when I'm turning a pin. In other words, I leave unnecessary tension that (over time) gradually works itself out. My intuition tells me that a bike wheel would be similar.

Or - build the wheel. Ride it a hundred miles or so. Re-true, making it a point to turn past the (say) quarter turn you need, then back to unwind the spoke. Lots of ways to get correctly tensioned spokes without twist. Some put "flags" on their spokes so they can see it. I like the idea but flagging every spoke and removing them all sounds like a lit of work I don't have patience for.

#48

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,931 Times

in

2,556 Posts

Thanks! I'll look into that at some point but I ended up writing my own thing in Excel. It's obviouly not as polished and looks romper roomish but I like being able to manipulate the data. This is what I'm looking at.

FBinNY I'd like to hear your feedback on this - so far. I saw you mentioned in another thread about maintaining length, this is only my third wheel set build and I'm pretty sure I did that in past builds but regardless did it this time, counting turns. It gave me some sporadic tensions but the wheel looked reasonable for a starting point, I doubt the rim has any give to it so that may amplify the tension differences. Just to see what would happen I started going only by numbers, trying to smooth out the tensions. FWIW this is the front wheel with asymetric carbon rims that feels stiff AF. I wanted to get things semi in order before tensionsioning more. The radial true isn't horrible at ~0.6mm. Lateral true is trash at probably 1.5mm but that I will address later. Spoke tension deviation is 11% on the right and 18% on the left. not good, but at least it's not erratic. I thought that was under control enough to start approaching final tension.

I know this isn't how you build wheels but I'd still like to hear your opinion. Thanks!

FBinNY I'd like to hear your feedback on this - so far. I saw you mentioned in another thread about maintaining length, this is only my third wheel set build and I'm pretty sure I did that in past builds but regardless did it this time, counting turns. It gave me some sporadic tensions but the wheel looked reasonable for a starting point, I doubt the rim has any give to it so that may amplify the tension differences. Just to see what would happen I started going only by numbers, trying to smooth out the tensions. FWIW this is the front wheel with asymetric carbon rims that feels stiff AF. I wanted to get things semi in order before tensionsioning more. The radial true isn't horrible at ~0.6mm. Lateral true is trash at probably 1.5mm but that I will address later. Spoke tension deviation is 11% on the right and 18% on the left. not good, but at least it's not erratic. I thought that was under control enough to start approaching final tension.

I know this isn't how you build wheels but I'd still like to hear your opinion. Thanks!

Edit: This is a reason I am such a fan of tensioning by ear. (Granted, I can hear pitch.) I tune pair of spokes to be equal. Go around the rims listening for ones that stand out. All easy and fast just hitting the spokes with the wrench. Sometimes the sound is ambiguous. Then I pluck the spoke with my finger. But even needing to both of those is a lot faster than putting the tension tool on.

Last edited by 79pmooney; 02-25-24 at 08:18 AM.

#49

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

....

FBinNY I'd like to hear your feedback on this ......

I know this isn't how you build wheels but I'd still like to hear your opinion. Thanks!

FBinNY I'd like to hear your feedback on this ......

I know this isn't how you build wheels but I'd still like to hear your opinion. Thanks!

I hate the entire notion of using tension as a basis during the build. (confirming tension on finished, or near finished wheels is perfectly reasonable).

IMO trying to track tension while building is like trying to drive with your wife and mother-in-law in the car.

Whatever you prefer, pick one priority and deal with that. That's not to say that you never want to do a reality check. As I'm finishing a wheel, I'll spin it and ping the spokes (good use of expired Visa card) listening for outliers and sometimes tweak a few.

My experience is that pinging spokes is much faster and comparably accurate to using a tension meter. But, as I keep saying, good shop practice is the key.

‐------------

Since you asked specifically, please don't be offended when I characterize this as a well documented, poorly built wheel.

Put the meter away, spin it pinging the spokes, find the worst outliers, and tweak the crossed pairs to better equalize the tension between them. Don't go nuts, just deal with the low hanging fruits.

Likes For FBinNY:

#50

Full Member

Thread Starter

LOL nope, not offended at all. I appreciate you giving me your honest opinion. Before I move on with our discussion, can I ask if you're able to play an instrument?