CAD templates for cutting lugs?

#1

Junior Member

Thread Starter

Join Date: Sep 2012

Posts: 141

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Liked 0 Times

in

0 Posts

CAD templates for cutting lugs?

I've been thinking about custom styles for my cast lugs. I have access to CAD software, and I wonder if creating a template within that software would be a good idea? My idea is to draw out the rough design on the lugs with a graphic pencil, transfer those sketches onto graph paper, bring those designs in CAD for precision(ish) treatment, and finally, take the CAD print outs back to the lugs for cutting. Do others have any thoughts on this process. Perhaps any way to improve the workflow?

I'm aware of irregularities in the lug ODs, which will make the CAD drawing a little problematic, but I think I'm OK with that right now.

I'm aware of irregularities in the lug ODs, which will make the CAD drawing a little problematic, but I think I'm OK with that right now.

#2

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

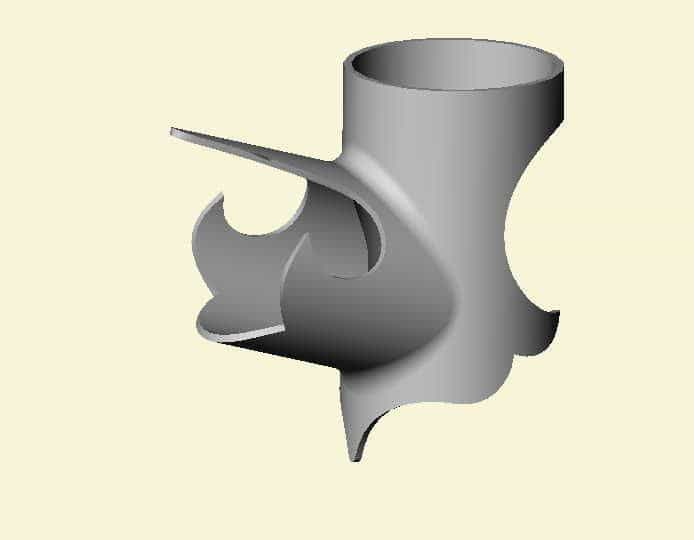

I had some lug designs in solidworks but I never finished them. IIRC, I didn't like the way I cut the profiles. I'm not sure what your plan is, would you try to get them 3d printed?

It's just a cylinder cutting a cylinder, and the outside has a fillet at the intersection. I think you should be able to fillet the intersection in most 3d software, maybe with some hackery involved.

I think it would be interesting to try to use sheet metal tools to make a welded lug like they used to make in the old days. I have always called them "pressed lugs" because of the way they formed the sheet metal. But nowadays you could get them laser cut out of a ductile steel.

It's just a cylinder cutting a cylinder, and the outside has a fillet at the intersection. I think you should be able to fillet the intersection in most 3d software, maybe with some hackery involved.

I think it would be interesting to try to use sheet metal tools to make a welded lug like they used to make in the old days. I have always called them "pressed lugs" because of the way they formed the sheet metal. But nowadays you could get them laser cut out of a ductile steel.

#3

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,985

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,567 Times

in

1,072 Posts

Pacenti lugs started as CAD drawings.

He's a good guy and might answer questions if you ask nicely.

Don't bother trying to contact the Pacenti company though. Kirk's partners bought him out ó forcefully, not a friendly split from what I hear. The new owners will be less inclined to help you.

Mark B in Seattle

He's a good guy and might answer questions if you ask nicely.

Don't bother trying to contact the Pacenti company though. Kirk's partners bought him out ó forcefully, not a friendly split from what I hear. The new owners will be less inclined to help you.

Mark B in Seattle

Likes For bulgie:

#4

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

His partners wouldn't know anyway, Kurt was a long-time framebuilder and the lugs predated them.

I get the impression that Darrell McCulloch of Llewellyn bikes also did the cad for his lugs. He's a good guy, might have something to say about it.

I get the impression that Darrell McCulloch of Llewellyn bikes also did the cad for his lugs. He's a good guy, might have something to say about it.

Likes For unterhausen:

#5

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

So is bikingman just carving existing lugs or is creating a design to be cast into lugs?

Doug Fattic has had a lot of experience in both carving his own lugs as well as teaching his students how to do so. IIRC he suggests drawing on graph paper and then using a copier to change the scale to that of the actual lug's size.

The two lugs sets I have made in the last couple of years were done with brazing two tubes at the right angle and careful sharpie tracing then cutting/filing. For the one offs that I will do in the future this is the easiest way to get a properly angled lug in a shape I want. Andy

Doug Fattic has had a lot of experience in both carving his own lugs as well as teaching his students how to do so. IIRC he suggests drawing on graph paper and then using a copier to change the scale to that of the actual lug's size.

The two lugs sets I have made in the last couple of years were done with brazing two tubes at the right angle and careful sharpie tracing then cutting/filing. For the one offs that I will do in the future this is the easiest way to get a properly angled lug in a shape I want. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#6

Junior Member

Thread Starter

Join Date: Sep 2012

Posts: 141

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Liked 0 Times

in

0 Posts

So is bikingman just carving existing lugs or is creating a design to be cast into lugs?

Doug Fattic has had a lot of experience in both carving his own lugs as well as teaching his students how to do so. IIRC he suggests drawing on graph paper and then using a copier to change the scale to that of the actual lug's size.

The two lugs sets I have made in the last couple of years were done with brazing two tubes at the right angle and careful sharpie tracing then cutting/filing. For the one offs that I will do in the future this is the easiest way to get a properly angled lug in a shape I want. Andy

Doug Fattic has had a lot of experience in both carving his own lugs as well as teaching his students how to do so. IIRC he suggests drawing on graph paper and then using a copier to change the scale to that of the actual lug's size.

The two lugs sets I have made in the last couple of years were done with brazing two tubes at the right angle and careful sharpie tracing then cutting/filing. For the one offs that I will do in the future this is the easiest way to get a properly angled lug in a shape I want. Andy

#7

Junior Member

Thread Starter

Join Date: Sep 2012

Posts: 141

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Liked 0 Times

in

0 Posts

Pacenti lugs started as CAD drawings.

He's a good guy and might answer questions if you ask nicely.

Don't bother trying to contact the Pacenti company though. Kirk's partners bought him out ó forcefully, not a friendly split from what I hear. The new owners will be less inclined to help you.

Mark B in Seattle

He's a good guy and might answer questions if you ask nicely.

Don't bother trying to contact the Pacenti company though. Kirk's partners bought him out ó forcefully, not a friendly split from what I hear. The new owners will be less inclined to help you.

Mark B in Seattle

#8

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

I think I like this idea, but I probably would use inkscape or illustrator to do it. That's what I have done when I made silly patterns for my model airplane skins.

#9

framebuilder

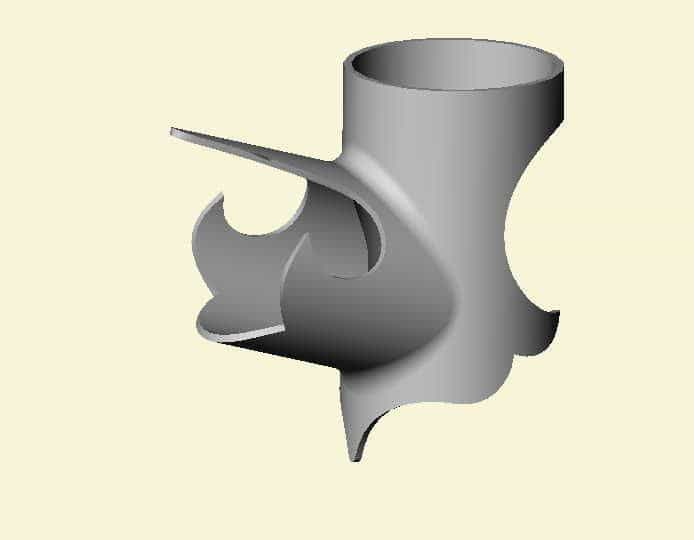

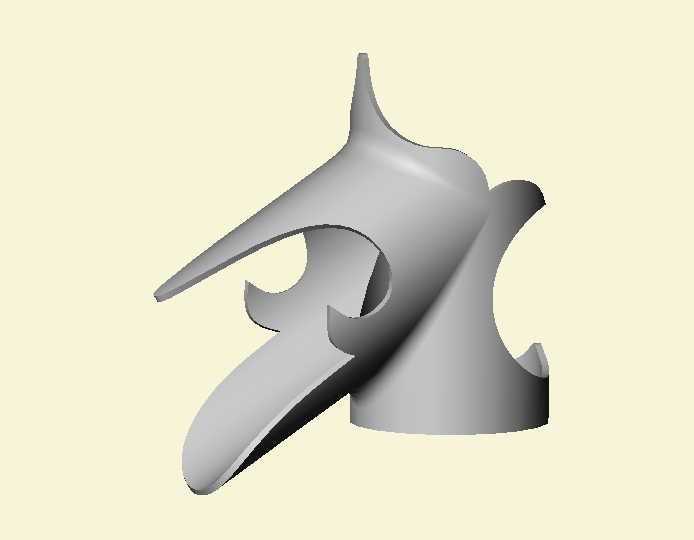

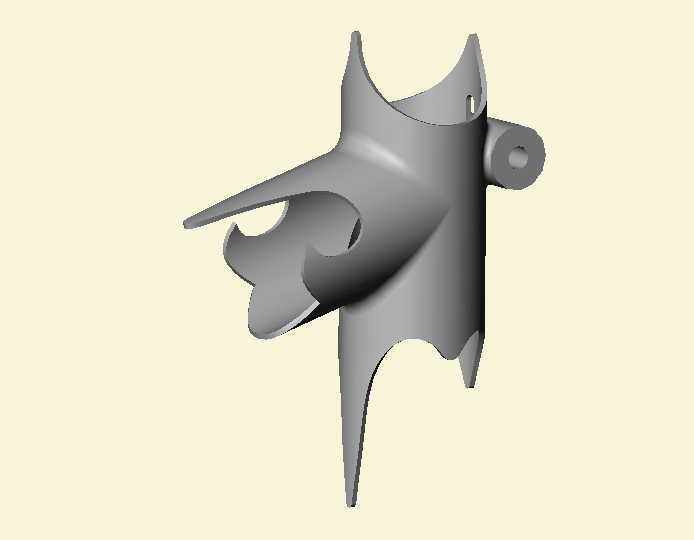

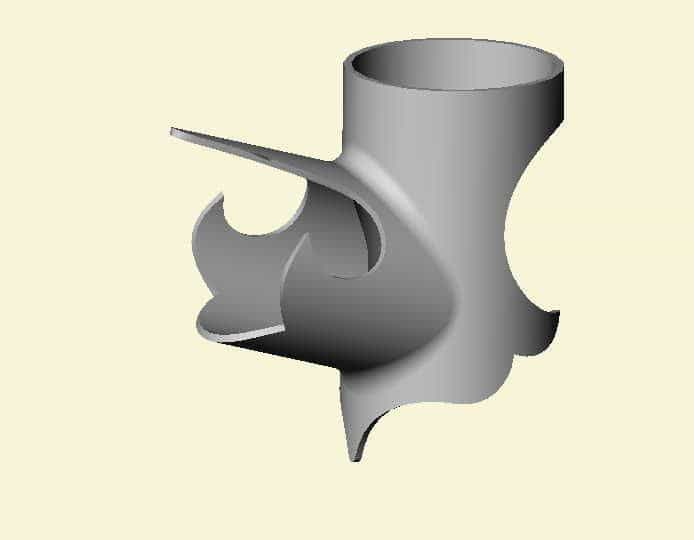

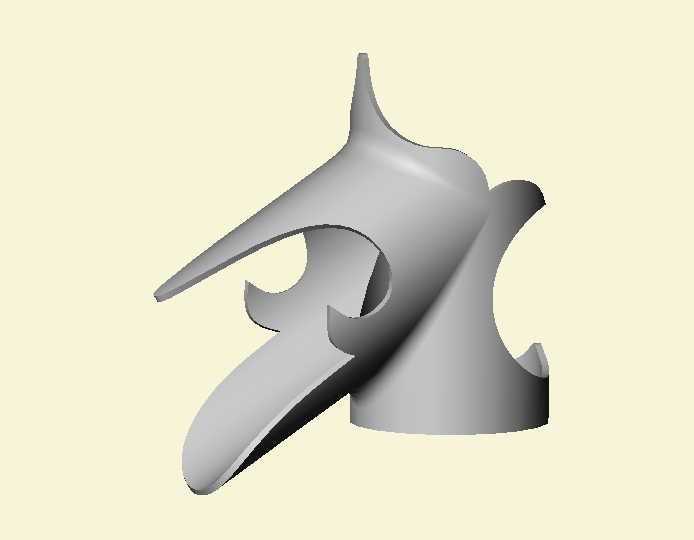

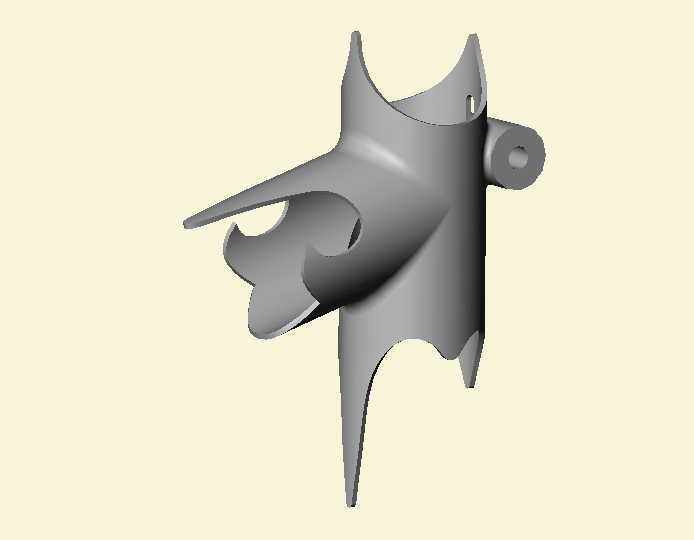

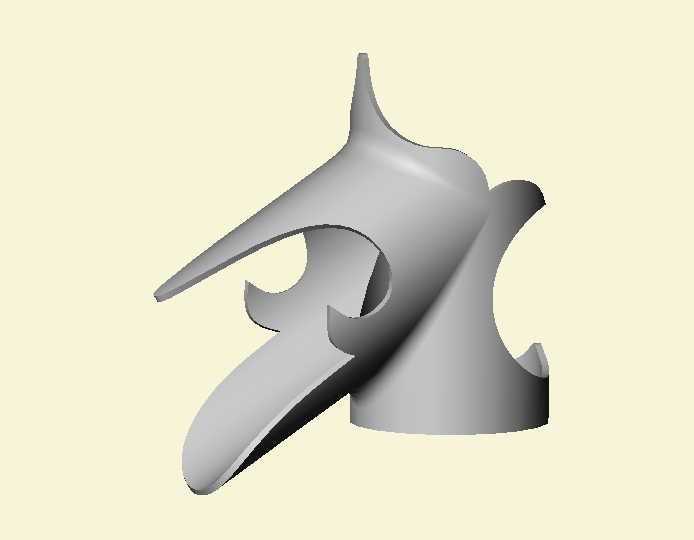

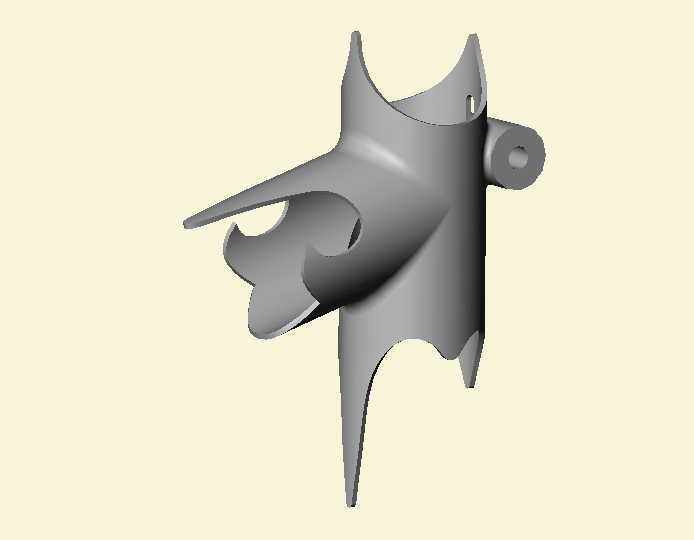

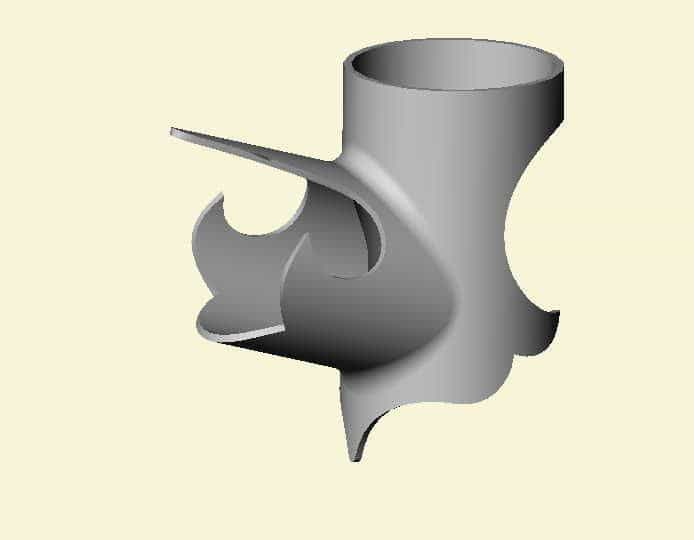

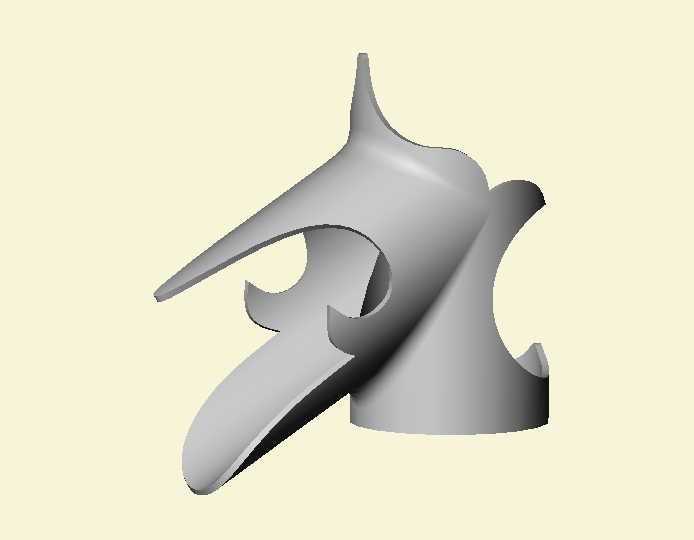

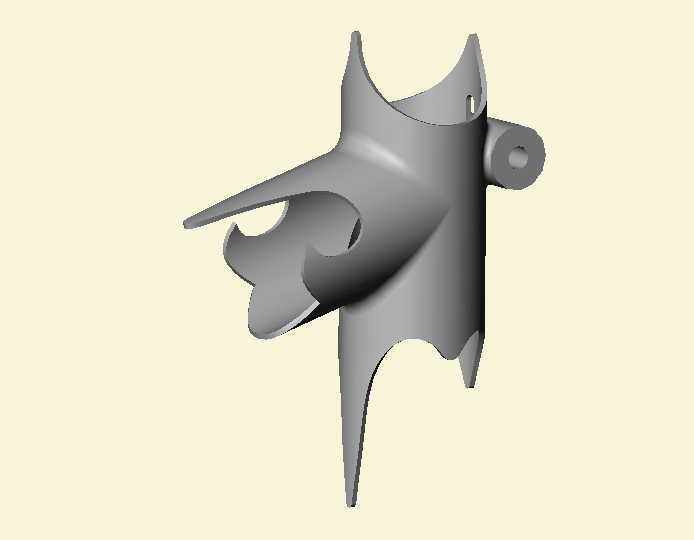

Many of my frame building class students have carved their own lug designs. I'll attach a few pictures to show some of that work. Some designs were pretty complex while others were simple.

#10

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

Like many who initially ask here, soon you'll be the expert we all reference.

The last bit I'll mention is that cast lugs are fairly angle range challenged. I would suggest that any angle changes are taken into account WRT the carving. Andy

The last bit I'll mention is that cast lugs are fairly angle range challenged. I would suggest that any angle changes are taken into account WRT the carving. Andy

__________________

AndrewRStewart

AndrewRStewart

#11

Senior Member

Join Date: Dec 2011

Location: NE Ohio

Posts: 2,595

Bikes: 1992 Serotta Colorado II,Co-Motion Speedster, Giant Escape Hybrid, 1977 Schwinn Super Le Tour

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 455 Post(s)

Likes: 0

Liked 112 Times

in

85 Posts

Doug taught me how to carve lugs during my class. I remember spending 8 hours on a single lug. I still have cramps min my hands!!! But the bike looks great!

Likes For Tandem Tom:

#12

Junior Member

Thread Starter

Join Date: Sep 2012

Posts: 141

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Liked 0 Times

in

0 Posts

I've always been interested in carving personal designs into blank lugs. This inspiration started when I bought a Hechins on Seven Sisters road in London in 1969. Every since I learned how to build frames, I've thought about methods to both design and carve. What I've found that works best for me is to start with a flat graph paper template for each socket. By making the templates twice life size, it is much easier to draw and correct and adjust the proportions. These adjustments seem easier drawing by hand over doing them by CAD. Because each socket has different dimensions, it is easier for me to customize each pattern to fit the available space. I like to use Vellum paper which is somewhat translucent and can be erased many times without damaging it. Once the design has been finalized, I use my laser printer/copy machine to reduce the lug drawing back to life size on either more vellum or label paper. This reduction also sharpens the lines.

Many of my frame building class students have carved their own lug designs. I'll attach a few pictures to show some of that work. Some designs were pretty complex while others were simple.

Many of my frame building class students have carved their own lug designs. I'll attach a few pictures to show some of that work. Some designs were pretty complex while others were simple.

#13

framebuilder

My experience has shown that it is easier to draw and then refine a design than do it all in CAD. Actually Iíve tried to get those experienced in both CAD and art to create a design totally in CAD and they have struggled to get it just right. What I have discovered is that very small changes in the lines can have a fairly significant overall impact. What I do is shade in a thicker line and then erase part of it until the proportions of a thinned line looks right. It is essential to do this at 200% actual size where bigger adjustments have a smaller impact and easier to control. Each lug socket has a different amount of space and shape. That requires some fiddling to get them all to play nicely so they look right together. Of course reducing the drawing to life size and trying it out on a lug can revel if things look right. A curved surface lug gives a different appearance than a larger flat drawing.

Likes For Doug Fattic:

#14

Senior Member

Join Date: Dec 2011

Location: NE Ohio

Posts: 2,595

Bikes: 1992 Serotta Colorado II,Co-Motion Speedster, Giant Escape Hybrid, 1977 Schwinn Super Le Tour

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 455 Post(s)

Likes: 0

Liked 112 Times

in

85 Posts

When I took Doug's class I carved my lugs. A lot of work but I get to enjoy them on every ride!

Likes For Tandem Tom: