Broken spokes...

#26

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

One caveat: Go find an old wheel (check a local co-op) and dismantle it, then use it to practice lacing and tensioning before you build up with more expensive spokes. I used this four part series of articles from Bicycling magazine to teach myself how to build wheels nearly 40 years ago. It’s the basis for a class I teach on wheel building as well. You can pretty much ignore the first of the series which are about wheel parts and selection but the three other parts are still applicable

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#27

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

Any time someone reports broken spokes, people start thinking along the lines of "better" spokes or "stronger" rims, sometimes higher spoke count, but the main factor in creating a strong wheel is how they're built. Chances are you have perfectly fine wheels. When someone says they started breaking spokes and they had someone replace all of them, it's not actually the new spokes that solved the problem, it's the fact that the wheel was rebuilt better. Most experienced wheelbuilders (as well as many articles and videos) will tell you that spoke tension is the single most important factor in how strong the wheel is. Even low-end DT 2.0 spokes and single-wall rims can be built into a strong wheel that doesn't break spokes.

You bought a bike online and most wheels these days are machine-built, which can be hit or miss. Replace all the spokes if you must, but you could probably save yourself a lot of money by just making sure your existing wheels are properly built. Personally I never just install and ride on "out of the box" wheels - they need to be put on a stand and checked for true and tension. That's the part that didn't happen with your bike.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#28

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1083 Post(s)

Liked 687 Times

in

441 Posts

That’s just not true. Yes, tension is important but it’s just not the end all/be all of a strong wheel. The article I linked to in post 13 doesn’t mention tension at all. The article is written by Ric Hjertberg who is the founder of Wheelsmith who knows a thing or two about building wheels. People who claim that tension is all that is needed for building a strong wheel or boast about never having broken a spoke probably aren’t large riders or riders who carry large loads or aren’t large riders that carry large loads. Personally, I know how to build wheels with high tension and I still broke spokes on a very regular basis. I carried…and used…several spokes on all my bikes all the time up until the early 2000s. I don’t carry spokes any more nor do I need to because I started building all my wheels with triple butted spokes in the early 2000s. I didn’t use any different tension before or after going to more durable spokes. The only thing that changed was the spoke.

...

...

It's not about having high tension, it's about having the correct tension and that the spoke tension is balanced. There are readily available charts that can be referenced for different types of wheels and spokes, including in the article I linked to, here: The Complete Guide To Wheel Spokes Tension. I would encourage you to check out that article and pay attention specifically to the section describing absolute tension vs relative tension. There are other charts if you don't like that source - fire up your Google machine. Most experts and online sources will say that +/- 20 percent is what you're shooting for. Park Tool even has a free app so you don't have to do any math. So there are a lot of folks that seem to believe it's pretty important.

I agree the quality of materials is always important, but do we have reason to believe that the OP is exceeding the weight limits of his bicycle? Chances are the stock wheels are perfectly acceptable, and all he needs is to have the wheels rebuilt by a pro. If he wants to change spokes while he's at it, that's fine - it's his bike and his money. Sort of like replacing a derailleur because the bike doesn't shift well, when all it really needs is to be adjusted properly.

Last edited by Jeff Neese; 10-29-23 at 12:28 PM.

#29

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

This argument about the MOST IMPORTANT consideration is pointless.

Wheels are a system, incorporating elements, chosen and assembled by the builder. Each contributes to the end product, but has to be considered in the context of the other elements.

You cannot magically make spokes stronger with tension changes. Nor can you build a more durable wheel simply by increase spoke gauge. Lastly, even the best builder can work magic with poor or poorly matched components.

Focusing on one consideration and calling it MOST IMPORTANT is as meaningful as arguing whether it's the b use of color or brushstrokes that are more important in impressionist paintings.

Wheels are a system, incorporating elements, chosen and assembled by the builder. Each contributes to the end product, but has to be considered in the context of the other elements.

You cannot magically make spokes stronger with tension changes. Nor can you build a more durable wheel simply by increase spoke gauge. Lastly, even the best builder can work magic with poor or poorly matched components.

Focusing on one consideration and calling it MOST IMPORTANT is as meaningful as arguing whether it's the b use of color or brushstrokes that are more important in impressionist paintings.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#30

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,563 Times

in

1,026 Posts

There's no particular reason that a wheel built with 32 3x 14g spokes, a 470g aero rim and a 28c tire should be breaking heads-out spokes - except that the spoke tension is either uneven or low.

Straight gauge 14g spokes are not weak, but they are less forgiving of bad tension then butted spokes which are elastic enough to mask tension problems.

If I were the OP I would get the wheel stress relieved and re-tensioned. It almost certainly has never been trued by a human. And if that doesn't solve the problem, just buy a new Clyde wheel and be done with it, rather than replace spokes.

Straight gauge 14g spokes are not weak, but they are less forgiving of bad tension then butted spokes which are elastic enough to mask tension problems.

If I were the OP I would get the wheel stress relieved and re-tensioned. It almost certainly has never been trued by a human. And if that doesn't solve the problem, just buy a new Clyde wheel and be done with it, rather than replace spokes.

#31

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

IMO the advice to try to save the wheel isn't well thought out.

Consider the time element. 2 broken spokes within less than a hundred miles, maybe less than fifty.

Most people knowledgeable about wheels consider a single broken spoke after a LONG while an isolated event. 2 is kind of a warning of things to come. Generally, the interval between breaks gets shorter, not longer. What you're seeing means that something is fundamentally wrong.

So, let the past guide your expectations.

It's true, that proper reworking of the wheel might help, but it would be disingenuous to assume that, whatever the problem, it's isolated to those 2 spokes.

Time to rip off this band-aid, and start fresh with new, proper build, using new spokes better suited to your needs. If you like this rim, and want to save dough, that's probably OK.

Consider the time element. 2 broken spokes within less than a hundred miles, maybe less than fifty.

Most people knowledgeable about wheels consider a single broken spoke after a LONG while an isolated event. 2 is kind of a warning of things to come. Generally, the interval between breaks gets shorter, not longer. What you're seeing means that something is fundamentally wrong.

So, let the past guide your expectations.

It's true, that proper reworking of the wheel might help, but it would be disingenuous to assume that, whatever the problem, it's isolated to those 2 spokes.

Time to rip off this band-aid, and start fresh with new, proper build, using new spokes better suited to your needs. If you like this rim, and want to save dough, that's probably OK.

#32

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,563 Times

in

1,026 Posts

IMO the advice to try to save the wheel isn't well thought out.

Consider the time element. 2 broken spokes within less than a hundred miles, maybe less than fifty.

Most people knowledgeable about wheels consider a single broken spoke after a LONG while an isolated event. 2 is kind of a warning of things to come. Generally, the interval between breaks gets shorter, not longer. What you're seeing means that something is fundamentally wrong.

So, let the past guide your expectations.

It's true, that proper reworking of the wheel might help, but it would be disingenuous to assume that, whatever the problem, it's isolated to those 2 spokes.

Time to rip off this band-aid, and start fresh with new, proper build, using new spokes better suited to your needs. If you like this rim, and want to save dough, that's probably OK.

Consider the time element. 2 broken spokes within less than a hundred miles, maybe less than fifty.

Most people knowledgeable about wheels consider a single broken spoke after a LONG while an isolated event. 2 is kind of a warning of things to come. Generally, the interval between breaks gets shorter, not longer. What you're seeing means that something is fundamentally wrong.

So, let the past guide your expectations.

It's true, that proper reworking of the wheel might help, but it would be disingenuous to assume that, whatever the problem, it's isolated to those 2 spokes.

Time to rip off this band-aid, and start fresh with new, proper build, using new spokes better suited to your needs. If you like this rim, and want to save dough, that's probably OK.

But the real problem here is time and money. Spokes aren't actually cheap, neither is wheelbuilding. The rim is okay, but nothing stellar. Having a mechanic go over the tension on the wheel will cost $20-30, and may be everything needed to solve the problem. If we start replacing all the spokes, now we are talking $100, and you still end up with the same rim and hub.

For $100 a more appropriate wheel could be purchased that already has a heavy rim and the shop has gone over the tension on. Even if you spend $20 on the current wheel AND then replace it for $100, you've still spent barely than rebuilding it with new spokes.

Just because some of the spokes have broken doesn't mean the rest are so stressed they are about to break. Spokes are made from very tough, plastic, carbon-less stainless steel. They aren't brittle. Stop stressing some of them unnecessarily and they will all last a long time.

#33

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

Certainly spoke tension is not ALL that is needed, but it's the most important thing. Wheels are stronger and stay truer longer. I'm not disputing that better spokes and rims are part of the equation. But even the best spokes and rims are not going to hold up if the wheel is not built properly.

It's not about having high tension, it's about having the correct tension and that the spoke tension is balanced. There are readily available charts that can be referenced for different types of wheels and spokes, including in the article I linked to, here: The Complete Guide To Wheel Spokes Tension. I would encourage you to check out that article and pay attention specifically to the section describing absolute tension vs relative tension. There are other charts if you don't like that source - fire up your Google machine. Most experts and online sources will say that +/- 20 percent is what you're shooting for. Park Tool even has a free app so you don't have to do any math. So there are a lot of folks that seem to believe it's pretty important.

Everyone says “follow the manufacturer’s recommendations” but there aren’t any recommendations that have any value. For example, Velocity says to

Recommended spoke tension

We recommend building to spoke tension between 110kgf and 130kgf. Each rim may behave a bit differently; the mark of an excellent wheel builder is the ability to find the highest tension a rim will allow while maintaining its radial and lateral true.

I agree the quality of materials is always important, but do we have reason to believe that the OP is exceeding the weight limits of his bicycle? Chances are the stock wheels are perfectly acceptable, and all he needs is to have the wheels rebuilt by a pro. If he wants to change spokes while he's at it, that's fine - it's his bike and his money. Sort of like replacing a derailleur because the bike doesn't shift well, when all it really needs is to be adjusted properly.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#34

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

You cannot magically make spokes stronger with tension changes. Nor can you build a more durable wheel simply by increase spoke gauge. Lastly, even the best builder can work magic with poor or poorly matched components.

Facts

#1 - The single biggest weakness for cost conscious wheels is spoke breakage (also for many high performance wheels as well).

#2 - Spokes break overwhelmingly at the elbow (hub), secondarily at the threads (rim)

#3 - Stronger spoke material, larger spoke numbers, and thicker spokes decrease a wheel’s tendency to break them.

#1 - The single biggest weakness for cost conscious wheels is spoke breakage (also for many high performance wheels as well).

#2 - Spokes break overwhelmingly at the elbow (hub), secondarily at the threads (rim)

#3 - Stronger spoke material, larger spoke numbers, and thicker spokes decrease a wheel’s tendency to break them.

Focusing on one consideration and calling it MOST IMPORTANT is as meaningful as arguing whether it's the b use of color or brushstrokes that are more important in impressionist paintings.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#35

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

[Straight gauge 14g spokes are not weak, but they are less forgiving of bad tension than butted spokes which are elastic enough to mask tension problems.

If I were the OP I would get the wheel stress relieved and re-tensioned. It almost certainly has never been trued by a human. And if that doesn't solve the problem, just buy a new Clyde wheel and be done with it, rather than replace spokes.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#36

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,563 Times

in

1,026 Posts

Or that the spokes aren’t strong enough for the task at hand.

Straight gauge spokes are weaker than butted spokes, period. You and most everyone else assumes a tension problem. For OEM wheels, that is something of a concern but if all things are equal, butted spokes are stronger and more durable.

“Just buying a new Clyde wheel” trades one machine built wheel for another one without addressing the problem. e0richt has expressed an interest in building wheels. More power to him. Building with triple butted spoke are only going to marginally reduce the thickness of his wallet while substantially increasing the durability of his wheels. As a bonus, e0richt will learn something valuable in the process.

Straight gauge spokes are weaker than butted spokes, period. You and most everyone else assumes a tension problem. For OEM wheels, that is something of a concern but if all things are equal, butted spokes are stronger and more durable.

“Just buying a new Clyde wheel” trades one machine built wheel for another one without addressing the problem. e0richt has expressed an interest in building wheels. More power to him. Building with triple butted spoke are only going to marginally reduce the thickness of his wallet while substantially increasing the durability of his wheels. As a bonus, e0richt will learn something valuable in the process.

Why wouldn't 32 2mm spokes be strong enough for the task at hand? How many 14g spokes does it take? 36? 48? What is it you see as such a monumental problem that the kind of wheel nearly every bike came with for some 30 years is not strong enough to handle?

You didn't read:

For $100 a more appropriate wheel could be purchased that already has a heavy rim and the shop has gone over the tension on.

#37

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,563 Times

in

1,026 Posts

You need to go away with your half baked ideas about wheel construction.

#38

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1083 Post(s)

Liked 687 Times

in

441 Posts

.....

No, there are not “other charts” that detail what the “correct” tension to use for wheel building. There never has been. I’m not even sure there can be because there are simply too many variables. A change in spokes is going to change the tension needed. The Park tool chart itself shows how the tension changes with spoke diameter.

Everyone says “follow the manufacturer’s recommendations” but there aren’t any recommendations that have any value...

No, there are not “other charts” that detail what the “correct” tension to use for wheel building. There never has been. I’m not even sure there can be because there are simply too many variables. A change in spokes is going to change the tension needed. The Park tool chart itself shows how the tension changes with spoke diameter.

Everyone says “follow the manufacturer’s recommendations” but there aren’t any recommendations that have any value...

Linked above, has charts for different types of spokes. Uses the Park Tool TM-1 readings but includes conversion tables.

The Complete Guide To Wheel Spokes Tension

A bit more comprehensive and includes readings for several common tensiometers, for different spokes.

Spoke tension tables - A database of tension meters and spoke tension charts

And for those that just don't want to buy a tensiometer, Sheldon Brown produced this chart detailing specifications by musical pitch. I have heard of people using a guitar tuning app. Obviously professional wheelbuilders have a tensiometer, but this could be helpful for the home DIYer that wants to perform a rough check.

Check Spoke Tension by Ear

These were all from the first page of Google results so these charts and tables aren't hard to find.

Many people go to great lengths to check things on their bike, especially a new mail-order bike, a used bike, or as part of their preseason checkout, but wheels don't seem to be part of that. Folks check tire condition and air pressure, shifting performance, braking, and all sorts of other things before getting on the bike and riding it. It seems that a lot of people don't check spoke tension as part of that, and are then shocked when they start breaking spokes.

Likes For Jeff Neese:

#39

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5791 Post(s)

Liked 2,581 Times

in

1,431 Posts

More evidence of the pointlessness of this argument.**

Part of the issue is semantics, where words like strength, stiffness, an durability are used as proxies for each other despite each having different meanings.

Add that to using improper inferences to make strawman arguments.

I stand by my earlier statement that broad statements about parts outside of the context of the whole is pointless.

**Note. not directed at anyone specifically, but roughly equally at the 3 most actively arguing.

Part of the issue is semantics, where words like strength, stiffness, an durability are used as proxies for each other despite each having different meanings.

Add that to using improper inferences to make strawman arguments.

I stand by my earlier statement that broad statements about parts outside of the context of the whole is pointless.

**Note. not directed at anyone specifically, but roughly equally at the 3 most actively arguing.

#40

Senior Member

Thread Starter

Here are a few:

Linked above, has charts for different types of spokes. Uses the Park Tool TM-1 readings but includes conversion tables.

The Complete Guide To Wheel Spokes Tension

A bit more comprehensive and includes readings for several common tensiometers, for different spokes.

Spoke tension tables - A database of tension meters and spoke tension charts

And for those that just don't want to buy a tensiometer, Sheldon Brown produced this chart detailing specifications by musical pitch. I have heard of people using a guitar tuning app. Obviously professional wheelbuilders have a tensiometer, but this could be helpful for the home DIYer that wants to perform a rough check.

Check Spoke Tension by Ear

These were all from the first page of Google results so these charts and tables aren't hard to find.

Many people go to great lengths to check things on their bike, especially a new mail-order bike, a used bike, or as part of their preseason checkout, but wheels don't seem to be part of that. Folks check tire condition and air pressure, shifting performance, braking, and all sorts of other things before getting on the bike and riding it. It seems that a lot of people don't check spoke tension as part of that, and are then shocked when they start breaking spokes.

Linked above, has charts for different types of spokes. Uses the Park Tool TM-1 readings but includes conversion tables.

The Complete Guide To Wheel Spokes Tension

A bit more comprehensive and includes readings for several common tensiometers, for different spokes.

Spoke tension tables - A database of tension meters and spoke tension charts

And for those that just don't want to buy a tensiometer, Sheldon Brown produced this chart detailing specifications by musical pitch. I have heard of people using a guitar tuning app. Obviously professional wheelbuilders have a tensiometer, but this could be helpful for the home DIYer that wants to perform a rough check.

Check Spoke Tension by Ear

These were all from the first page of Google results so these charts and tables aren't hard to find.

Many people go to great lengths to check things on their bike, especially a new mail-order bike, a used bike, or as part of their preseason checkout, but wheels don't seem to be part of that. Folks check tire condition and air pressure, shifting performance, braking, and all sorts of other things before getting on the bike and riding it. It seems that a lot of people don't check spoke tension as part of that, and are then shocked when they start breaking spokes.

#41

Senior Member

Thread Starter

I am not above buying a new wheel. (I eventually did that for the trek 7100 in order to ride that one with no spoke mishaps after that)

but even if I do purchase the new wheel it would be to continue riding that bike while I work on this wheel. I want to learn more about wheels and

lacing etc,

I have been watching some youtube videos on wheel construction especially by a channel name aliclarkson that talks about the different

lacing patterns and truing, tensioning, stressing the wheel. I also have been watching some of the park tool videos which I find interesting as well.

but even if I do purchase the new wheel it would be to continue riding that bike while I work on this wheel. I want to learn more about wheels and

lacing etc,

I have been watching some youtube videos on wheel construction especially by a channel name aliclarkson that talks about the different

lacing patterns and truing, tensioning, stressing the wheel. I also have been watching some of the park tool videos which I find interesting as well.

#42

Senior Member

Join Date: Dec 2015

Location: San Diego

Posts: 704

Bikes: 1978 Bruce Gordon, 1977 Lippy, 199? Lippy tandem, Bike Friday NWT, 1982 Trek 720, 2012 Rivendell Atlantis, 1983 Bianchi Specialissima?

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 346 Post(s)

Liked 175 Times

in

107 Posts

I am not above buying a new wheel. (I eventually did that for the trek 7100 in order to ride that one with no spoke mishaps after that)

but even if I do purchase the new wheel it would be to continue riding that bike while I work on this wheel. I want to learn more about wheels and

lacing etc,

I have been watching some youtube videos on wheel construction especially by a channel name aliclarkson that talks about the different

lacing patterns and truing, tensioning, stressing the wheel. I also have been watching some of the park tool videos which I find interesting as well.

but even if I do purchase the new wheel it would be to continue riding that bike while I work on this wheel. I want to learn more about wheels and

lacing etc,

I have been watching some youtube videos on wheel construction especially by a channel name aliclarkson that talks about the different

lacing patterns and truing, tensioning, stressing the wheel. I also have been watching some of the park tool videos which I find interesting as well.

#43

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

Image 5-11-18 at 1.41 PM by Stuart Black, on Flickr

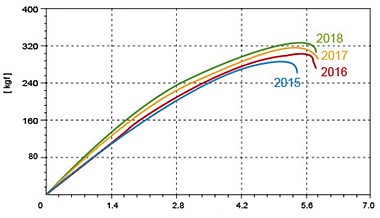

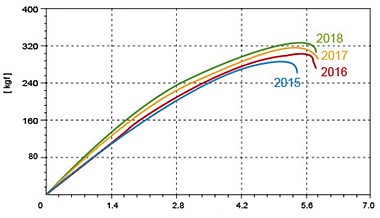

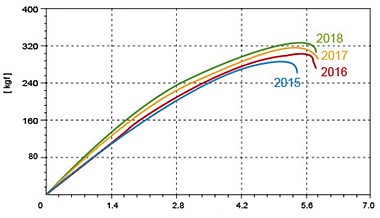

Image 5-11-18 at 1.41 PM by Stuart Black, on FlickrThe 1415 spoke is a 2.0/1.8/2.0mm double butted spoke with a breaking strength of 308 kgf. That’s an strength increase of 14%

Image 5-11-18 at 1.44 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.44 PM by Stuart Black, on FlickrThe 2018 spoke is a 2.2/1.8/20mm spoke with a breaking strength of 340kgf. That’s a 26% increase over the straight spoke. Pillar also makes a 2.3/1.8/2.0mm spoke with a breaking strength of 400 kgf which is a 48% increase in strength over the 2.0mm spoke.

Image 5-11-18 at 1.43 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.43 PM by Stuart Black, on FlickrThere is a very real gain in strength over “regular” spokes that make these kind of spokes worth using.

Why wouldn't 32 2mm spokes be strong enough for the task at hand? How many 14g spokes does it take? 36? 48?

What is it you see as such a monumental problem that the kind of wheel nearly every bike came with for some 30 years is not strong enough to handle?

You didn't read:

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Last edited by cyccommute; 10-30-23 at 10:52 AM.

Likes For cyccommute:

#44

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

I thought you had me on your ignore list.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#45

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

Here are a few:

Linked above, has charts for different types of spokes. Uses the Park Tool TM-1 readings but includes conversion tables.

The Complete Guide To Wheel Spokes Tension

A bit more comprehensive and includes readings for several common tensiometers, for different spokes.

Spoke tension tables - A database of tension meters and spoke tension charts

And for those that just don't want to buy a tensiometer, Sheldon Brown produced this chart detailing specifications by musical pitch. I have heard of people using a guitar tuning app. Obviously professional wheelbuilders have a tensiometer, but this could be helpful for the home DIYer that wants to perform a rough check.

Check Spoke Tension by Ear

These were all from the first page of Google results so these charts and tables aren't hard to find.

Many people go to great lengths to check things on their bike, especially a new mail-order bike, a used bike, or as part of their preseason checkout, but wheels don't seem to be part of that. Folks check tire condition and air pressure, shifting performance, braking, and all sorts of other things before getting on the bike and riding it. It seems that a lot of people don't check spoke tension as part of that, and are then shocked when they start breaking spokes.

Linked above, has charts for different types of spokes. Uses the Park Tool TM-1 readings but includes conversion tables.

The Complete Guide To Wheel Spokes Tension

A bit more comprehensive and includes readings for several common tensiometers, for different spokes.

Spoke tension tables - A database of tension meters and spoke tension charts

And for those that just don't want to buy a tensiometer, Sheldon Brown produced this chart detailing specifications by musical pitch. I have heard of people using a guitar tuning app. Obviously professional wheelbuilders have a tensiometer, but this could be helpful for the home DIYer that wants to perform a rough check.

Check Spoke Tension by Ear

These were all from the first page of Google results so these charts and tables aren't hard to find.

Many people go to great lengths to check things on their bike, especially a new mail-order bike, a used bike, or as part of their preseason checkout, but wheels don't seem to be part of that. Folks check tire condition and air pressure, shifting performance, braking, and all sorts of other things before getting on the bike and riding it. It seems that a lot of people don't check spoke tension as part of that, and are then shocked when they start breaking spokes.

Here’s an example. I built a wheel yesterday using a Mavic XC317 disc rim. Can you find a recommended spoke tension for that rim? I certainly can’t. Any number I’ve found for any rim is the same as the Velocity where they use a range but what does that mean? 135kgf for a rim doesn’t say much. Should all the spokes be that tension? That wouldn’t work for a dished wheel. Since the tensions are different for different sides of the dish, what is the value to be used?

The ICAN article that you linked actually does give a value but says that the tension can be ±20% of their recommendations. Let’s look at the implications of that wild ass guess. There is a CN494 spoke that they use with the “ICAN standard hub”. They recommend nondrive side tension of 51 kgf and drive side tension of 96 kgf. That would be a reading of 17 and 23 on the Park TM-1 meter. But ±20% means that the tension can vary from 40kgf to 61kgf on the nondrive side and 76.8kgf to 115 kgf. I have experience with the TM-1 and know that a reading of about 14 on the nondrive side would make for spokes that are too loose.

Additionally, as someone who made a living measuring stuff, I gotta say that ±20% is a piss poor measurement. It’s just a wild ass guess. If I submitted a measurement with that kind of variance, I’d have been scolded and/or fired.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#46

Senior Member

Thread Starter

In which case I think you will find $12 for this, https://www.wheelpro.co.uk/wheelbuilding/book.php, money well spent. So much easy reading information for so little.

#47

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

I am not above buying a new wheel. (I eventually did that for the trek 7100 in order to ride that one with no spoke mishaps after that)

but even if I do purchase the new wheel it would be to continue riding that bike while I work on this wheel. I want to learn more about wheels and

lacing etc,

but even if I do purchase the new wheel it would be to continue riding that bike while I work on this wheel. I want to learn more about wheels and

lacing etc,

I have been watching some youtube videos on wheel construction especially by a channel name aliclarkson that talks about the different

lacing patterns and truing, tensioning, stressing the wheel. I also have been watching some of the park tool videos which I find interesting as well.

lacing patterns and truing, tensioning, stressing the wheel. I also have been watching some of the park tool videos which I find interesting as well.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#48

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,365

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,219 Times

in

2,366 Posts

strength

- 1.

the quality or state of being physically strong. - 2.

the capacity of an object or substance to withstand great force or pressure.

durability

- the ability to withstand wear, pressure, or damage.

stiffness

- 2.

the quality of being severe or strong

Even in a scientific context, strength and durability are used interchangeably.

I stand by my earlier statement that broad statements about parts outside of the context of the whole is pointless.

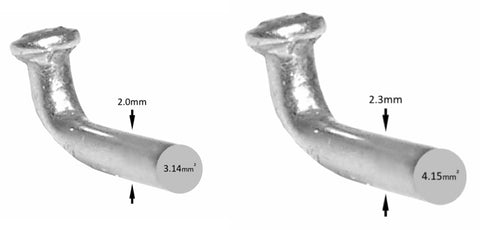

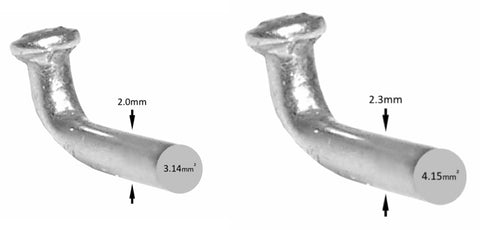

How Much Better Are They?

Remember that a spoke’s fatigue resistance is proportional NOT to its diameter but to its cross sectional area.

32% greater cross section area through the J-bend. 32% longer lasting.

32% greater cross section area through the J-bend. 32% longer lasting.

That’s a whopping 32% increase for a paltry 7g/wheel. Equivalent to adding 10 spokes to the wheel. Experience shows this one feature can nearly eliminate spoke breakage. Combine with larger tires and you have a solution for every under-built, over-used, or over-loaded wheel.

Remember that a spoke’s fatigue resistance is proportional NOT to its diameter but to its cross sectional area.

32% greater cross section area through the J-bend. 32% longer lasting.

32% greater cross section area through the J-bend. 32% longer lasting.That’s a whopping 32% increase for a paltry 7g/wheel. Equivalent to adding 10 spokes to the wheel. Experience shows this one feature can nearly eliminate spoke breakage. Combine with larger tires and you have a solution for every under-built, over-used, or over-loaded wheel.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Last edited by cyccommute; 10-30-23 at 11:04 AM.

Likes For cyccommute:

#49

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1083 Post(s)

Liked 687 Times

in

441 Posts

The ICAN article that you linked actually does give a value but says that the tension can be ±20% of their recommendations. Let’s look at the implications of that wild ass guess. There is a CN494 spoke that they use with the “ICAN standard hub”. They recommend nondrive side tension of 51 kgf and drive side tension of 96 kgf. That would be a reading of 17 and 23 on the Park TM-1 meter. But ±20% means that the tension can vary from 40kgf to 61kgf on the nondrive side and 76.8kgf to 115 kgf. I have experience with the TM-1 and know that a reading of about 14 on the nondrive side would make for spokes that are too loose.

Additionally, as someone who made a living measuring stuff, I gotta say that ±20% is a piss poor measurement. It’s just a wild ass guess. If I submitted a measurement with that kind of variance, I’d have been scolded and/or fired.

And a spec of +/-20% isn't just a wild-ass guess. There are a lot of things that can operate with that range of tolerance. Depending on where they're used in the circuit, capacitors can easily have that tolerance, for example, as well as many other electrical components. I think some of my bicycle tires might have a wider range of inflation between minimum and maximum.

#50

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,563 Times

in

1,026 Posts

It’s not the shaft that is important. Breakage midspoke is very rare no matter what the thickness of the spoke. Breakage at the threads is also rare. The overwhelming point of breakage is at the elbow of the spoke. Read the Hjertberg link. But someone has actually measured the strength of spokes of various gauges. Pillar actually provides graphs with actual results. For example the P14, straight gauge spoke has a breaking strength of 270kgf

Image 5-11-18 at 1.41 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.41 PM by Stuart Black, on Flickr

The 1415 spoke is a 2.0/1.8/2.0mm double butted spoke with a breaking strength of 308 kgf. That’s an strength increase of 14%

Image 5-11-18 at 1.44 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.44 PM by Stuart Black, on Flickr

The 2018 spoke is a 2.2/1.8/20mm spoke with a breaking strength of 340kgf. That’s a 26% increase over the straight spoke. Pillar also makes a 2.3/1.8/2.0mm spoke with a breaking strength of 400 kgf which is a 48% increase in strength over the 2.0mm spoke.

Image 5-11-18 at 1.43 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.43 PM by Stuart Black, on Flickr

There is a very real gain in strength over “regular” spokes that make these kind of spokes worth using.

To your first question, because they aren’t. Broken spokes are the most common failure problem for bicyclists. Derailer adjustment is most likely the greatest problem but when it comes to something breaking, there is no other item that breaks more consistently on a bicycle than spokes. To your second question, yes. 36 2.0mm spokes would be the minimum for most heavy riders. 40 2.0mm spokes would be better. 48 2.0mm spokes would be the best. Or you could build a 32spoke wheel with triple butted spokes and, according to Hjertberg, have a wheel that is the equivalent of a 42 spoke wheel. Since 48, 40, and even 36 spoke hubs and rims can be difficult to find, building with stronger spokes makes sense.

The fact that spoke breakage is a huge problem for many riders. My wife and daughter have never broken a spoke…even on loaded tours. As someone who is dragging 200 lbs pretty hard and rides carrying touring loads on a regular basis, spoke breakage has been something that I have experienced on a frequent basis. I’ve experienced spoke breakage on a frequent basis on bikes that weren’t carrying touring loads. Going to triple butted spokes stopped that problem dead in its tracks.

I did read. I don’t agree. A heavier rim is just that…heavier. It’s not stronger.

Image 5-11-18 at 1.41 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.41 PM by Stuart Black, on FlickrThe 1415 spoke is a 2.0/1.8/2.0mm double butted spoke with a breaking strength of 308 kgf. That’s an strength increase of 14%

Image 5-11-18 at 1.44 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.44 PM by Stuart Black, on FlickrThe 2018 spoke is a 2.2/1.8/20mm spoke with a breaking strength of 340kgf. That’s a 26% increase over the straight spoke. Pillar also makes a 2.3/1.8/2.0mm spoke with a breaking strength of 400 kgf which is a 48% increase in strength over the 2.0mm spoke.

Image 5-11-18 at 1.43 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.43 PM by Stuart Black, on FlickrThere is a very real gain in strength over “regular” spokes that make these kind of spokes worth using.

To your first question, because they aren’t. Broken spokes are the most common failure problem for bicyclists. Derailer adjustment is most likely the greatest problem but when it comes to something breaking, there is no other item that breaks more consistently on a bicycle than spokes. To your second question, yes. 36 2.0mm spokes would be the minimum for most heavy riders. 40 2.0mm spokes would be better. 48 2.0mm spokes would be the best. Or you could build a 32spoke wheel with triple butted spokes and, according to Hjertberg, have a wheel that is the equivalent of a 42 spoke wheel. Since 48, 40, and even 36 spoke hubs and rims can be difficult to find, building with stronger spokes makes sense.

The fact that spoke breakage is a huge problem for many riders. My wife and daughter have never broken a spoke…even on loaded tours. As someone who is dragging 200 lbs pretty hard and rides carrying touring loads on a regular basis, spoke breakage has been something that I have experienced on a frequent basis. I’ve experienced spoke breakage on a frequent basis on bikes that weren’t carrying touring loads. Going to triple butted spokes stopped that problem dead in its tracks.

I did read. I don’t agree. A heavier rim is just that…heavier. It’s not stronger.

Elbows break because they aren't seated, as I have told you many times before. I seat my elbows, and the hundreds of wheels I've built have no elbow problems.

Garbage in, garbage out.

Last edited by Kontact; 10-30-23 at 12:21 PM.