No longer inspecting frames for crash damage

#76

Full Member

Join Date: Dec 2014

Location: New Hampshire

Posts: 485

Bikes: Pinarello Gavia TSX; Bianchi Intenso

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 164 Post(s)

Likes: 0

Liked 92 Times

in

62 Posts

Seems most CF failures will be catastrophic, so I see no reason for the LBS to get involved unless they happen to represent the vendor. Just not worth the liability issue. Now, once upon a time manufacturer's representatives made the rounds of their dealers and the LBS could tell the customer that they are willing to show it to him for referral to the factory, but I suspect this doesn't happen as much anymore.

As for a ferrous frame failing, I have snapped chainstays and rear dropouts of Columbus frames and both times were able to "limp" home. With the former, I actually thought I had broken an axle rather than the chainstay until I got home. I also had an alu frame "tear" at the BB junction. Tore like a Coke can as these alu frames have such thin walls. At least it was detectable.

As for a ferrous frame failing, I have snapped chainstays and rear dropouts of Columbus frames and both times were able to "limp" home. With the former, I actually thought I had broken an axle rather than the chainstay until I got home. I also had an alu frame "tear" at the BB junction. Tore like a Coke can as these alu frames have such thin walls. At least it was detectable.

#77

Junior Member

Join Date: May 2019

Posts: 17

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I had an industrial ct scanner at one of my previous jobs and it would still be pretty easy to miss something. Often the scan was very good and you could see exactly what you were looking for and sometimes you really couldn't see a lot.

#78

Junior Member

I am not a competitive cyclist, I use my bike for transportation to save wear and tear on an old car, and because I am in my 70's it is dangerous to skimp on exercise. While a carbon frame has promise for light weight and racing, if it can suffer dangerous structural failures I prefer the reliability of a steel mountain bike frame. Not only is it more affordable, it is more dependable. I appreciate this forum educating me about

#79

Senior Member

But actually, false analogy. You can build something of very high quality, without imaging equipment, through careful quality control during construction, yet be unable to determine the extent of damage after an impact, without imaging equipment.

I'm not an expert on such equipment. But fiberglass composite boat hulls are subject to osmotic blistering (water penetrates the glass composite via osmosis, unless there is a vinylester or epoxy barrier top coat), and boat inspectors can detect this, I think using ultrasound equipment. If so, that might also be a means for detecting carbon composite skin damage. But even if you have that information, to determine safety, you must then perform a finite element analysis of a computer solid model that includes the damage, under design loads, unless the engineers have already clearly defined "allowable" structural defects in terms of location, size, and orientation on the structure (frame).

#80

Senior Member

Join Date: Aug 2014

Posts: 2,433

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 741 Post(s)

Liked 412 Times

in

230 Posts

I am not a competitive cyclist, I use my bike for transportation to save wear and tear on an old car, and because I am in my 70's it is dangerous to skimp on exercise. While a carbon frame has promise for light weight and racing, if it can suffer dangerous structural failures I prefer the reliability of a steel mountain bike frame. Not only is it more affordable, it is more dependable. I appreciate this forum educating me about

#81

Senior Member

Metals are homogeneous and isotropic, exhibiting the same strengths and stiffness in all directions. Composites (carbon fiber, fiberglass, et all) are anisotropic, providing different strength and stiffness depending on the orientation of the fibers in the resin matrix, which is one of their advantages; A carbon frame can have the down tube wrapped at 45 degrees off the long axis in both directions to provide excellent torsional stiffness (to prevent twisting under hard climbing), yet some longitudinal bending flex for better ride quality. For damage to a composite, the amount of discontinuities in the fibers determines structural integrity. Metals are generally more tolerant, though not all; some metals are particularly "notch sensitive", and even surface scratches can propagate under high stresses or high cycle fatigue loads. For composites, a damaged section that is "soft" (damaged resin matrix) may still transmit loads fine under local tension, but buckle under local compression; the engineering term for this is "you can't push on a rope".

Last edited by Duragrouch; 06-03-19 at 06:28 PM.

#82

I eat carbide.

Join Date: Jan 2006

Location: Elgin, IL

Posts: 21,627

Bikes: Lots. Van Dessel and Squid Dealer

Mentioned: 25 Post(s)

Tagged: 0 Thread(s)

Quoted: 1325 Post(s)

Liked 1,306 Times

in

560 Posts

Why people with absolutely no say or skin in the game would ever wander here to put their 2 cents in is beyond me.

Crash damage and inspection of crash damage of carbon frames is nothing new. You can not do it fully in a shop setting. Period. Any shop that says they can is either lying or ignorant. You decide which of those two is better.

Rukus Composites has really broken a lot of ground in actual frame inspection techniques. Their processes and techniques started in the aerospace industry. It is a decided process - not up for debate. When the aerospace industry is wrong/ planes fall from the sky.

Rukus has gone on record as stating that they honestly don't know how anyone who is not using ultrasound or x-ray can ever make a determination that something isn't compromised.

This means your shop is not doing an accurate inspection of a frame if they say they can. This means your OEM factory is not doing an accurate inspection of anything they make if they don't take it back in house and do an ultrasound or x-ray on it. I don't know of any OEM in the business who doesn't simply say, "If in doubt then don't ride it. If warranty and I approve it then I will fix/replace it. If out of warranty then go pound sand. I will not say it is safe to ride." Most now at least offer a crash or discounted replacement.

For us with rims - OE factory warranty or we simply replace at cost. I will never tell you something is safe if you told me you wrecked it. That said, I personally ride on stuff that has a questionable history. Why? Because I can and it's my choice. I'm not an idiot. I can usually tell if there is or will be a problem but I am never going on record with anyone to say something is safe if I am not 100% sure it is. Even then I will hedge my bets.

Rukus has begun to work with shops to bring them up to speed. They started running tech workshops at PBMA (Pro Bicycle Mechanics Association) events to help teach mechanics what they could do beyond the visual and tapping on the frame. They're a pretty dedicated group that has more than enough work. They're interested in the answers.

So...there's no conspiracy. Your shop is simply not equipped to do a thorough crash investigation. Asking them to do just that will yield all sorts of results from "no" to "absolutely and that frame is just fine". None of those results are provable without doing a thorough exam that no shop in this country can do so anything said is meaningless anyway. You're the one that has to ride it. You're the one that was on it during the wreck. If it was a big wreck that had bruises appearing on you in weird places days afterwards then guess what? The frame went through the same ordeal. If you ran into the back of a car and the wheel is fine, fork looks fine and downtube look fine and there's no dent on the car and you were able to stay on the bike....then odds are it's fine. You acceptance of that is your balance of how you value your safety getting in a wreck vs the money to replace. You're the one that makes the choice. Replying on a shop to tell you what to do is your own negligence. Be your own advocate.

Crash damage and inspection of crash damage of carbon frames is nothing new. You can not do it fully in a shop setting. Period. Any shop that says they can is either lying or ignorant. You decide which of those two is better.

Rukus Composites has really broken a lot of ground in actual frame inspection techniques. Their processes and techniques started in the aerospace industry. It is a decided process - not up for debate. When the aerospace industry is wrong/ planes fall from the sky.

Rukus has gone on record as stating that they honestly don't know how anyone who is not using ultrasound or x-ray can ever make a determination that something isn't compromised.

This means your shop is not doing an accurate inspection of a frame if they say they can. This means your OEM factory is not doing an accurate inspection of anything they make if they don't take it back in house and do an ultrasound or x-ray on it. I don't know of any OEM in the business who doesn't simply say, "If in doubt then don't ride it. If warranty and I approve it then I will fix/replace it. If out of warranty then go pound sand. I will not say it is safe to ride." Most now at least offer a crash or discounted replacement.

For us with rims - OE factory warranty or we simply replace at cost. I will never tell you something is safe if you told me you wrecked it. That said, I personally ride on stuff that has a questionable history. Why? Because I can and it's my choice. I'm not an idiot. I can usually tell if there is or will be a problem but I am never going on record with anyone to say something is safe if I am not 100% sure it is. Even then I will hedge my bets.

Rukus has begun to work with shops to bring them up to speed. They started running tech workshops at PBMA (Pro Bicycle Mechanics Association) events to help teach mechanics what they could do beyond the visual and tapping on the frame. They're a pretty dedicated group that has more than enough work. They're interested in the answers.

So...there's no conspiracy. Your shop is simply not equipped to do a thorough crash investigation. Asking them to do just that will yield all sorts of results from "no" to "absolutely and that frame is just fine". None of those results are provable without doing a thorough exam that no shop in this country can do so anything said is meaningless anyway. You're the one that has to ride it. You're the one that was on it during the wreck. If it was a big wreck that had bruises appearing on you in weird places days afterwards then guess what? The frame went through the same ordeal. If you ran into the back of a car and the wheel is fine, fork looks fine and downtube look fine and there's no dent on the car and you were able to stay on the bike....then odds are it's fine. You acceptance of that is your balance of how you value your safety getting in a wreck vs the money to replace. You're the one that makes the choice. Replying on a shop to tell you what to do is your own negligence. Be your own advocate.

__________________

PSIMET Wheels, PSIMET Racing, PSIMET Neutral Race Support, and 11 Jackson Coffee

Podcast - YouTube Channel

Video about PSIMET Wheels

Podcast - YouTube Channel

Video about PSIMET Wheels

#83

I eat carbide.

Join Date: Jan 2006

Location: Elgin, IL

Posts: 21,627

Bikes: Lots. Van Dessel and Squid Dealer

Mentioned: 25 Post(s)

Tagged: 0 Thread(s)

Quoted: 1325 Post(s)

Liked 1,306 Times

in

560 Posts

My 1st carbon frame was bought in 1992, which were the early years of carbon frames, so I have broken a lot of frames. My experience was that the frame will let you know it is breaking. Handling gets weird or it will make creaking noises. Of course cracks are dead giveaways.

The general public is full of ignorance in its full meaning.

__________________

PSIMET Wheels, PSIMET Racing, PSIMET Neutral Race Support, and 11 Jackson Coffee

Podcast - YouTube Channel

Video about PSIMET Wheels

Podcast - YouTube Channel

Video about PSIMET Wheels

#84

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18354 Post(s)

Liked 4,502 Times

in

3,346 Posts

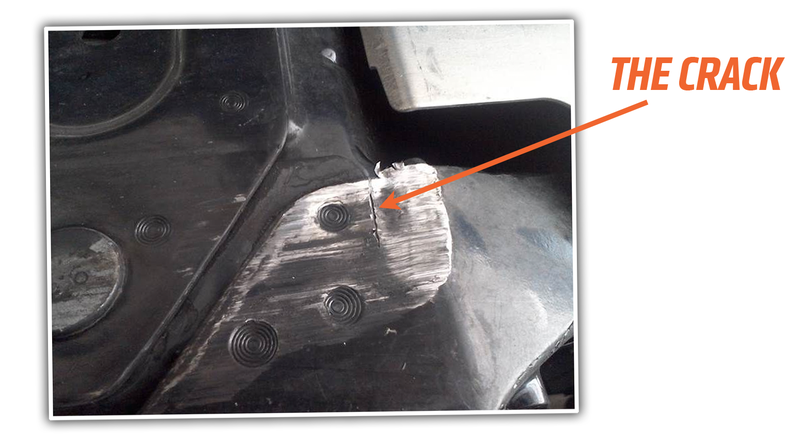

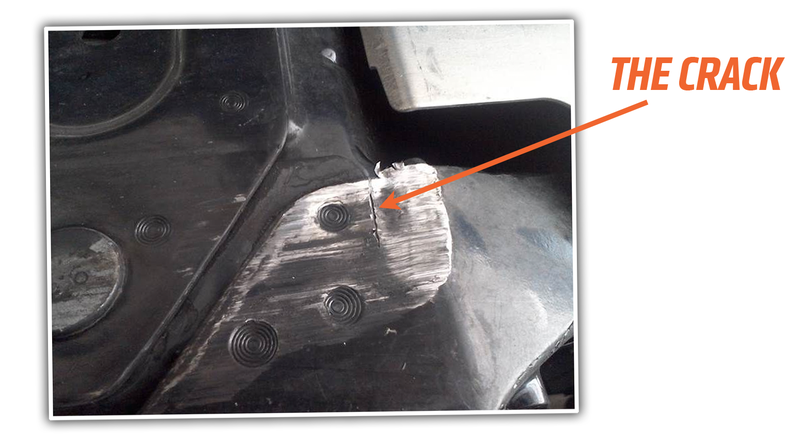

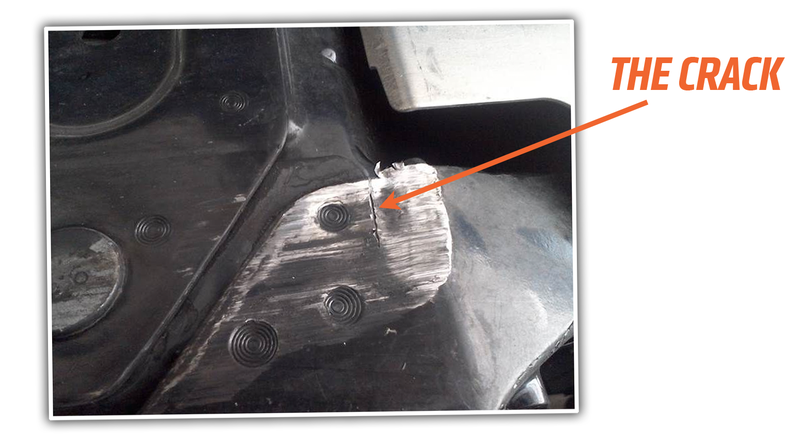

I started browsing auto insurance auctions a bit.

It is interesting how this is also impacting the car business.

In particular, very expensive sports cars are being totaled for "undercarriage damage".

https://jalopnik.com/heres-how-a-cor...-of-1806727930

In this case, there was a visible crack in aluminum, and the choice was made not to do a repair in an auto body shop, what should have been a routine repair if it had been a steel frame.

#85

Senior Member

NDI. Non Destructive Inspection.

you take your bike to b's for inspection, they do inspection or send it out to be inspected, who knows what method of inspection or expertise of b's or outside company is, and are they all using inspection methods (xray, eddy current, ultrasound magnaflux etc) on the specific stress tested points on frame per specifications in the manufactures manual? Thanks, but ill stick to steel frames.

#86

Newbie

Join Date: Mar 2019

Location: Bay Area

Posts: 15

Bikes: 86 Alan, 88 Stumpjumper Comp, 80s Litespeed MTB, 70s Schwinn Paramount

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Liked 0 Times

in

0 Posts

Seems like many people missed the part about the OP's shop now not inspecting any frames, not just carbon frames.

#87

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,631

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4729 Post(s)

Liked 1,531 Times

in

1,002 Posts

Seems there's a lot here that is warning against buying anything made of CF online, since you don't know how the baggage/shipping companies handled the material, nor can simple visual inspection tell you the item(s) are OK. And here I was considering ordering some CF wheels -- silly me.

#88

Junior Member

Join Date: Jun 2019

Posts: 7

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Kind of not the point

The gist of the carbon fiber frame problem in this thread is damage and/or flaws undetectable by any shop without at least an ultrasound scanner. In contrast, before failing, a steel frame would have a visible crack or rust. If the rust were strictly internal , with no visible bubbling of the paint (inside the the chainstay, for example), it would be visible upon inspection when the bottom bracket was overhauled.

#89

Senior Member

Join Date: Sep 2007

Location: Kent, WA

Posts: 495

Bikes: 2005 S-Works SR Equipped,1978 Tom Ritchie Road bike, Kuwahara Tandem

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I'm in the automotive business and I have the same issue with some components. People will ask me if their timing belt/chain is good. I tell clients I can only tell you if they are bad [When they are broken, they are bad]. I cannot say if they are good. That would include a brand new one. If I install a new one, I would say the belt/chain is new.

Most shops do not have the money to buy the equipment and training to determine if something is perfectly ok. If you ever had shop insurance, they probably will not support you when it comes to lawsuits. That is why I cannot install customer supplied parts. That is why I have clients buy their own used parts.

I cannot see any bike shop that can afford to take on the task of checking a bike frame and give it a good bill of health.

Most shops do not have the money to buy the equipment and training to determine if something is perfectly ok. If you ever had shop insurance, they probably will not support you when it comes to lawsuits. That is why I cannot install customer supplied parts. That is why I have clients buy their own used parts.

I cannot see any bike shop that can afford to take on the task of checking a bike frame and give it a good bill of health.

#90

• —

Join Date: Jun 2015

Location: Land of Pleasant Living

Posts: 12,219

Bikes: Shmikes

Mentioned: 59 Post(s)

Tagged: 0 Thread(s)

Quoted: 10152 Post(s)

Liked 5,843 Times

in

3,147 Posts

Naive question and I have nothing to say about any establishment deciding to provide or not to provide this service, but isn't this what liability insurance is for?

#91

Senior Member

Join Date: Nov 2015

Posts: 8,922

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 4717 Post(s)

Liked 1,882 Times

in

998 Posts

Crash damage and inspection of crash damage of carbon frames is nothing new. You can not do it fully in a shop setting. Period. Any shop that says they can is either lying or ignorant. You decide which of those two is better.

Rukus Composites has really broken a lot of ground in actual frame inspection techniques. Their processes and techniques started in the aerospace industry. It is a decided process - not up for debate. When the aerospace industry is wrong/ planes fall from the sky.

Rukus has gone on record as stating that they honestly don't know how anyone who is not using ultrasound or x-ray can ever make a determination that something isn't compromised.

#92

Senior Member

Ruckus, of course, will also repair the frames.

I started browsing auto insurance auctions a bit.

It is interesting how this is also impacting the car business.

In particular, very expensive sports cars are being totaled for "undercarriage damage".

https://jalopnik.com/heres-how-a-cor...-of-1806727930

In this case, there was a visible crack in aluminum, and the choice was made not to do a repair in an auto body shop, what should have been a routine repair if it had been a steel frame.

I started browsing auto insurance auctions a bit.

It is interesting how this is also impacting the car business.

In particular, very expensive sports cars are being totaled for "undercarriage damage".

https://jalopnik.com/heres-how-a-cor...-of-1806727930

In this case, there was a visible crack in aluminum, and the choice was made not to do a repair in an auto body shop, what should have been a routine repair if it had been a steel frame.

#93

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,182

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1562 Post(s)

Liked 1,288 Times

in

859 Posts

There is a guy with a u-tube video of his supercar Audi purchase (for parts-car money) which he then went on to have the aluminum frame strut towers repaired with welding. He then had it "certified" by a state agency who gave stamp of approval for the car's return to the road, since it had been declared "totaled".

It was a challenging repair that required being well thought out, but he saved tens of thousands of dollars versus cost of buying the same car in good used condition.

In other news, I found a free Lincoln Town Car in excellent condition @132k miles but for need of about $3k in simple mechanical repairs, bought a grand worth of new and used parts and more or less broke even on it's likely resale price if I were paying myself about $20 an hour (which it seems I am on my way to having done).

It was a challenging repair that required being well thought out, but he saved tens of thousands of dollars versus cost of buying the same car in good used condition.

In other news, I found a free Lincoln Town Car in excellent condition @132k miles but for need of about $3k in simple mechanical repairs, bought a grand worth of new and used parts and more or less broke even on it's likely resale price if I were paying myself about $20 an hour (which it seems I am on my way to having done).

Last edited by dddd; 06-04-19 at 11:22 AM.

#94

Senior Member

Join Date: Oct 2009

Posts: 2,853

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 1067 Post(s)

Likes: 0

Liked 259 Times

in

153 Posts

There is a guy with a u-tube video of his supercar Audi purchase (for parts-car money) which he then went on to have the aluminum frame strut towers repaired with welding. He then had it "certified" by a state agency who gave stamp of approval for the car's return to the road, since it had been declared "totaled".

It was a challenging repair that required being well thought out, but he saved tens of thousands of dollars versus cost of buying the same car in good used condition.

In other news, I found a free Lincoln Town Car in excellent condition @132k miles but for need of about $3k in simple mechanical repairs, bought a grand worth of new and used parts and more or less broke even on it's likely resale price if I were paying myself about $20 an hour (which it seems I am on my way to having done).

It was a challenging repair that required being well thought out, but he saved tens of thousands of dollars versus cost of buying the same car in good used condition.

In other news, I found a free Lincoln Town Car in excellent condition @132k miles but for need of about $3k in simple mechanical repairs, bought a grand worth of new and used parts and more or less broke even on it's likely resale price if I were paying myself about $20 an hour (which it seems I am on my way to having done).

These are adhered to for "proper" repairs. It would be a brave or stupid engineer that would sign off a repair that was done differently no matter how well it was done.

I had a van with a high tensile steel sub frame that cracked in a non load bearing area. Manufacturer specs said it was not to be welded and the whole (large and expensive) unit needed replacement.

This procedure was not negotiable.

I don't agree with this but that is how it is now, at least where I live.

#96

Senior Member

Join Date: Feb 2019

Location: Indiana

Posts: 592

Bikes: 1984 Fuji Club, Suntour ARX; 2013 Lynskey Peloton, mostly 105 with Ultegra rear derailleur, Enve 2.0 fork; 2020 Masi Giramondo 700c, full Deore with TRP dual piston mech disk brakes

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 324 Post(s)

Liked 81 Times

in

71 Posts

Not that long ago I bent a steel fork when a car hit me and I hit a curb, years ago some bike shops had frame and fork jigs you could take a damaged steel bike to and they they would put the bike back into shape again, well guess what? shops no longer are doing that kind of work because of liability concerns! So now a steel bike, aluminum, titanium and CF bikes will all be thrown out nowadays. I knew several people years ago got steel bike frames and forks bent back and they never had any problems with the bike, but those days are gone, we live in a very litigious world so we throw everything away instead of taking a risk of repairing it.

#97

Senior Member

that people back then knew to to properly do stuff. unlike today.

#98

Senior Member

they built atom bombs, sr71, moon rocket, moon lander all that with common sense and a simply slide ruler. they didn't need any "scanner" to get stuff done.

and i think this is whats missing today: just getting stuff done. by yourself, ringth now.

and i think this is whats missing today: just getting stuff done. by yourself, ringth now.

#99

Senior Member

*All i'm saying is that you dont need to quantify the damage you only need to determine if its cracked or not. and almost anyone can do that if they try.

#100

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18354 Post(s)

Liked 4,502 Times

in

3,346 Posts

Everything in the linked article was completely valid. Having said that, if that was my car, and I was able to buy it dirt cheap from the insurance company or at auction, I would carefully clean the local area down to bare metal and apply a round aluminum patch the same thickness and alloy as the original part, diameter 2X the length of the crack, with aerospace structural adhesive. If the original part was a weldable aluminum alloy like 6061-T6, I would weld the crack, sand flush, and then apply the round patch with structural adhesive. I'd inspect the area monthly or at each oil change.

But, a lot still applies to bikes.

One of the comments on the Corvette article claims to be by a structural engineer (but not familiar with the Vette), and he is suggesting that this part of the frame would be highly structural.

Even if a good frame could be acquired, it could be a massive undertaking to swap frames.

The circles appear to me to be some kind of a spot weld. And, I've seen other photos/videos of Corvette frames that appear to have traditional MIG/TIG welds, so the alloy is "weldable". However, I'd say that Chevrolet likely does a post heat treating of the entire frame after assembly.

Welding 6061 Aluminum is supposed to reduce strength by about 40%.

Then the question comes whether there is 40% redundancy in the frame design???

Take the car to Joe's body shop, and he'll likely jump in with MIG/TIG, have it welded up, and back on the road within an hour (assuming not too much has to be disassembled to prevent heat damage).

Take the car to a Chevy Dealer, and they won't sign off on anything short of 100% complete frame replacement with all new parts.

Now, the people buying $70,000 brand new Corvettes won't necessarily be the ones making their own backyard repairs.

And, give them a choice between a repair on someone else's dime that is "probably OK", vs "100% back to new"... and they just won't accept the "probably ok" repair.

Take away the middle-man, and make them pay up-front, and the Corvette owner may choose the cheap repair, or to attempt to hide the damage and sell it to some unsuspecting buyer.

That selling to an unsuspecting buyer may be a good reason to "brand titles" even if a vehicle is repaired.

So, as a car owner, are you satisfied with the $100 "Joe's body Shop" repair... or the massive undertaking to swap frames? Or, is nothing short of a new car acceptable?