How to pick target spoke tension?

#1

Full Member

Thread Starter

How to pick target spoke tension?

I'm building a set set of wheels for a XC/Downcountry bike project. I'm using DT240 hubs, Pillar 1420 spokes, and LightCarbon UAD935-XC rims. Seems the weakest point is the rims though they say max spoke tension is 145kgf. That seems pretty tight, and I also don't know if it being an MTB wheel has any impact, so not sure what tension to aim for. I'd appreciate some guidance. Thanks!

#2

Senior Member

I'm building a set set of wheels for a XC/Downcountry bike project. I'm using DT240 hubs, Pillar 1420 spokes, and LightCarbon UAD935-XC rims. Seems the weakest point is the rims though they say max spoke tension is 145kgf. That seems pretty tight, and I also don't know if it being an MTB wheel has any impact, so not sure what tension to aim for. I'd appreciate some guidance. Thanks!

Last edited by Duragrouch; 02-23-24 at 05:02 AM.

Likes For Duragrouch:

#3

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

Correct spoke tension depends mainly on the spoke gauge and number of spokes.

While it's become trendy to build to higher tensions, what really matters is minimum tension, with any additional tension above that becoming counter-productive.

You need enough tension to stretch each spoke to where it won't go slack when unloaded. So thicker spokes call for more tension. Because fewer spokes will increase rim flex, that also calls for more tension. Likewise, heavier loads will need slightly more tension. In the end it becomes a judgement call based on the specific factors.

However minimum tensions are typically fairly low. For example, on a 32h wheel using 2.0/1.8/2.0 spokes it's less than 60kgf.

Keep in mind that the rim's maximum tension rating is just that, and not a suggested or ideal tension. In the past no such rating was ever needed because no skilled builder used tensions high enough to damage rims.

While it's become trendy to build to higher tensions, what really matters is minimum tension, with any additional tension above that becoming counter-productive.

You need enough tension to stretch each spoke to where it won't go slack when unloaded. So thicker spokes call for more tension. Because fewer spokes will increase rim flex, that also calls for more tension. Likewise, heavier loads will need slightly more tension. In the end it becomes a judgement call based on the specific factors.

However minimum tensions are typically fairly low. For example, on a 32h wheel using 2.0/1.8/2.0 spokes it's less than 60kgf.

Keep in mind that the rim's maximum tension rating is just that, and not a suggested or ideal tension. In the past no such rating was ever needed because no skilled builder used tensions high enough to damage rims.

Last edited by FBinNY; 02-23-24 at 06:08 AM.

Likes For FBinNY:

#4

I am potato.

Join Date: Jun 2015

Location: Pacific Northwest

Posts: 3,116

Bikes: Only precision built, custom high performance elitist machines of the highest caliber. 🍆

Mentioned: 29 Post(s)

Tagged: 0 Thread(s)

Quoted: 1790 Post(s)

Liked 1,630 Times

in

934 Posts

Max tension is just that, the maximum. When you sit upon the bike or add rack, or panniers, or even ride the tension of every spoke in the wheel goes up in relation to the load, except the 1 or 2 directly between the hub and the ground those de-tension. Building to the maximum, takes away any operating margin between build tension and actual maximum where component failure occured. Building to the minimum allows the 1 or 2 spokes between the hub and the ground to detention enough to flex the j-bends like a paper clip or the nipple to unscrew as the rim struggles and fails to avoid being shaped like the letter "D."

A better question is: What is the target tension? Generally it is somewhere between 100 and 120kg/f depending on many factors. At 145kg/f, if you could even get there, would probably round out and destroy every nipple in the attempt.

A better question is: What is the target tension? Generally it is somewhere between 100 and 120kg/f depending on many factors. At 145kg/f, if you could even get there, would probably round out and destroy every nipple in the attempt.

Last edited by base2; 02-23-24 at 07:43 AM.

#5

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

Undertensioning CANNOT cause the elbow flex you describe. Simply put, the spoke cannot be pushed toward the elbow. Once it hits zero tension, the nipple gets pushed back into the rim instead, which is why undertensioned wheels progressively get worse.

Elbow flex is not a function of tension and is the same at any tension. Elbows flex and break regardless of tension, primarily because of the builder's failure to properly set and stress relieve them.

In short. Low tension does not increase spoke breakage, nor does higher tension magically reduce it.

Last edited by FBinNY; 02-23-24 at 08:54 AM.

#6

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,904

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2604 Post(s)

Liked 1,933 Times

in

1,213 Posts

Good question. Long answer: as FBinNY says, the goal is to keep the bottom spokes from going slack while riding. Rear wheels, because of the cassette assymetry, are usually the hardest. For an aluminum box rim, somewhere around 60 kgf on the non-drive side of the rear wheel is usually sufficient. The rim flexes just enough that the NDS spokes do not go slack with my roughly 120 kg wheel load, IME. (Yes, I'm a clyde.) However, during the wheel build, I'm usually reduced to limiting drive-side spoke tension to 105-115 kgf; by the time the wheel is trued and centered, 60-75 kgf on the NDS seems to work well.

Now you come in with your weight (unknown to me), weight distribution by wheel, carbon composite rim, and lower spoke count. How much does your rim flex? If it's absolutely rigid, you'll want to increase DS tension so the NDS spoke tension is higher than the wheel load. Lower spoke count also means there's a longer load path to adjacent spokes when your real-world wheel starts to flex. If you're a clydesdale sitting upright while riding, you may have to push DS tension as high as it will go. This may also push the limit of your hub, particularly if it's machined rather than forged. Nevertheless, I'd aim to leave some margin between your target spoke tension and the manufacturer's maximum spec, so maybe shoot for 125-130 kgf. If you're a lighter rider, you may need as little as 100-110 kgf tension to keep the loaded spokes from de-tensioning while riding.

Tl/dr? Short answer: 121.7 kgf. The Magic 8 Ball has spoken.

Now you come in with your weight (unknown to me), weight distribution by wheel, carbon composite rim, and lower spoke count. How much does your rim flex? If it's absolutely rigid, you'll want to increase DS tension so the NDS spoke tension is higher than the wheel load. Lower spoke count also means there's a longer load path to adjacent spokes when your real-world wheel starts to flex. If you're a clydesdale sitting upright while riding, you may have to push DS tension as high as it will go. This may also push the limit of your hub, particularly if it's machined rather than forged. Nevertheless, I'd aim to leave some margin between your target spoke tension and the manufacturer's maximum spec, so maybe shoot for 125-130 kgf. If you're a lighter rider, you may need as little as 100-110 kgf tension to keep the loaded spokes from de-tensioning while riding.

Tl/dr? Short answer: 121.7 kgf. The Magic 8 Ball has spoken.

Likes For pdlamb:

#7

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,904

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2604 Post(s)

Liked 1,933 Times

in

1,213 Posts

Undertensioning CAN NOT cause the elbow flex you describe. Simply put, the spoke cannot be pushed toward the elbow. Once it hits zero tension, the nipple gets pushed back into the rim instead, which is why undertensioned wheels progressively get worse.

Elbow flex is not a function of tension and is the same at any tension. Elbows break regardless of tension, primarily because of the builder's failure to properly set and stress relieve them.

In short. Low tension does not increase spoke breakage, nor does higher tension magically reduce it.

Elbow flex is not a function of tension and is the same at any tension. Elbows break regardless of tension, primarily because of the builder's failure to properly set and stress relieve them.

In short. Low tension does not increase spoke breakage, nor does higher tension magically reduce it.

Build the wheel right, folks!

#8

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

I'm going to split a hair here, so bear with me/pardon me. I agree with everything you've written, FOR A WELL-BUILT WHEEL. However, if the builder doesn't adjust the spoke line, typically by bending the spoke across the hub rim, the spoke can spring back to its original shape if it goes completely slack. Then the failure mode @base2 describes can occur.

Build the wheel right, folks!

Build the wheel right, folks!

However the zero tension flex, should it happen, won't cause failure because, by it's very nature, it occurs below the fatigue limit.

FWIW, I spend a decent of time fighting the myth that higher tension means better wheels. To me it's analogous to saying we can strengthen bridges by parking cement trucks along the span.

Last edited by FBinNY; 02-23-24 at 09:38 AM.

Likes For FBinNY:

#9

Senior Member

Join Date: Oct 2023

Location: New Jersey

Posts: 571

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 366 Post(s)

Liked 273 Times

in

175 Posts

In my (limited) experience, within a certain window, there is no benefit or detriment to a higher or lower tension. The goal is to hit near the center of the window, but you have a lot of wiggle room.

Relative tension between individual spokes matters a lot more.

Relative tension between individual spokes matters a lot more.

#10

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

I'd love to hear one coherent explanation for the importance of relative tension. Caveat, excluding that it makes it easier to keep each spoke within the minimum/maximum range.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#11

Senior Member

Join Date: Oct 2023

Location: New Jersey

Posts: 571

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 366 Post(s)

Liked 273 Times

in

175 Posts

If a spoke is out of relative tension, that is also indicative of problems elsewhere.

Absolute tension can go up or down without affecting the shape of the wheel.

Likes For ScottCommutes:

#12

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

Because it's a circle, each spoke should do an equal share of the work keeping the wheel round. I suppose it's fair to debate what the acceptable tolerance is on that.

If a spoke is out of relative tension, that is also indicative of problems elsewhere.

Absolute tension can go up or down without affecting the shape of the wheel.

If a spoke is out of relative tension, that is also indicative of problems elsewhere.

Absolute tension can go up or down without affecting the shape of the wheel.

To be clear, it's now possible to build round true wheels with uneven tension because rims are stiff enough to permit it. But IMO this doesn't warrant the obsessive pursuit of even tension I keep hearing about.

Is a wheel with very uniform tension somehow better ---- and if so, how? ---- than an equally true with less uniform tension. To wit, what would one consider to be a reasonable tolerance?

FWIW I've never given a thought to tension going back 50+ years. In a way I was lucky by having learned when rims were light and compliant, so true and uniform tension went hand in hand.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#13

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

"Everyone should do their fair share" has a definite emotional appeal. But as long as a spoke doesn't lose enough tension to loosen at the bottom, or gain enough to crack the rim at the top, it can be said to have done its job in full. Shooting for perfectly even tensions is just a "stretch goal" beyond avoiding extremes.

Likes For ThermionicScott:

#14

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

"Everyone should do their fair share" has a definite emotional appeal. But as long as a spoke doesn't lose enough tension to loosen at the bottom, or gain enough to crack the rim at the top, it can be said to have done its job in full. Shooting for perfectly even tensions is just a "stretch goal" beyond avoiding extremes.

It's just a goal, but doesn't make a functional difference. I rank it slightly above lining up the valve and logo on the hub.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#15

Senior Member

Join Date: Oct 2023

Location: New Jersey

Posts: 571

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 366 Post(s)

Liked 273 Times

in

175 Posts

I keep hearing this or something similar, but it's not a cohesive explanation because there's no description of the mechanism involved.

To be clear, it's now possible to build round true wheels with uneven tension because rims are stiff enough to permit it. But IMO this doesn't warrant the obsessive pursuit of even tension I keep hearing about.

Is a wheel with very uniform tension somehow better ---- and if so, how? ---- than an equally true with less uniform tension. To wit, what would one consider to be a reasonable tolerance?

FWIW I've never given a thought to tension going back 50+ years. In a way I was lucky by having learned when rims were light and compliant, so true and uniform tension went hand in hand.

To be clear, it's now possible to build round true wheels with uneven tension because rims are stiff enough to permit it. But IMO this doesn't warrant the obsessive pursuit of even tension I keep hearing about.

Is a wheel with very uniform tension somehow better ---- and if so, how? ---- than an equally true with less uniform tension. To wit, what would one consider to be a reasonable tolerance?

FWIW I've never given a thought to tension going back 50+ years. In a way I was lucky by having learned when rims were light and compliant, so true and uniform tension went hand in hand.

Likes For ScottCommutes:

#16

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

Lets say everything you say is true - I can even agree with you. However, if a rim is stiff enough to work fine even with a slack spoke between two tight ones, why do we even need the loose spoke? If we do actually need it, then it's not that loose and we're back to tolerance. If we don't need it, then it's simply for show.

Your earlier post was spot on. As long as every spoke's tension is within min/max limits everything is OK.

It helps to remember that the ratio between change in length vs. change in tension is constant, regardless of original tension. So each spoke will act similarly even if the tension is different.

Of course, large tension differences mean that the rims local loads will be facing higher local loads in some places, so (as in every mechanical discussion) we have to infer "reasonably".

Last edited by FBinNY; 02-23-24 at 11:04 AM.

#17

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,482

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 967 Post(s)

Liked 1,631 Times

in

1,047 Posts

This is a really good question. Especially with new exotic materials, Carbon, titanium, and unknown alloys. And what can you believe? Is the posted max tension really its max under all conditions? Further more if you are going for an amount of tension based on a mark on the tension meter then is the meter calibrated? Are those real indicators of the tension on you spoke at the place where measured? I dont build wheels from scratch. And I have never handled wheels of exotic materials but I can tell ya this. Pay attention to the Range of tension on your spokes and not so much the actual amount of tension indicated on the meter. Duh... Sounds redundant...

Rats! I dont have enough experience to answer your question... Sorry...

Rats! I dont have enough experience to answer your question... Sorry...

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

#18

I am potato.

Join Date: Jun 2015

Location: Pacific Northwest

Posts: 3,116

Bikes: Only precision built, custom high performance elitist machines of the highest caliber. 🍆

Mentioned: 29 Post(s)

Tagged: 0 Thread(s)

Quoted: 1790 Post(s)

Liked 1,630 Times

in

934 Posts

Ever had an untrue wheel that "just won't get there" until you completely detension and start over? Uneven tension from the get-go is a good suspect as to why.

In short, even spoke tension just builds better, more robust, wheels with longer service life and less hassles further on.

Last edited by base2; 02-23-24 at 11:36 AM.

#19

Senior Member

Elbow flex is not a function of tension and is the same at any tension. Elbows flex and break regardless of tension, primarily because of the builder's failure to properly set and stress relieve them.

In short. Low tension does not increase spoke breakage, nor does higher tension magically reduce it.

#20

Senior Member

Join Date: Oct 2023

Location: New Jersey

Posts: 571

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 366 Post(s)

Liked 273 Times

in

175 Posts

I'm really not trying to argue as you likely know a lot more than me. However, compare the wheel to carpenters building a wall. One carpenter takes care to make sure that each stud is cut exactly the same so that the top plate bears evenly on each. The other carpenter rushes through his stud cutting and has some that are a little short. However, he doesn't worry about it because he figures the top plate is stiff enough to work just fine. That top plate is all he's worried about.

If I had a choice, I would prefer a wall made by the first carpenter. Both walls would probably work just fine at the beginning, but the uneven weight distribution in the second wall has a greater chance of causing problems down the road as the wood expands and contracts and the house settles.

If I had a choice, I would prefer a wall made by the first carpenter. Both walls would probably work just fine at the beginning, but the uneven weight distribution in the second wall has a greater chance of causing problems down the road as the wood expands and contracts and the house settles.

#21

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,932 Times

in

2,557 Posts

I find a really simple approach is to buy that not very expensive Park tension tool and the accompanying chart. Aim for the middle or in the case of highly dished rear wheels, aim to keep both sides in Park's "preferred" tensions. (Checking that the high tensions stay well below the the rim's max.) Pretty brainless and has worked very well for me.

I go for as uniform tensions as I can. This varies a lot depending on the rim. Some are less that true or have side to side kinks at the seam and I ave to vary the tension to get the best compromise between true and even tensions. Other rims like the Ambrosia Futura I built up yesterday are absolutely round and true. And no, I never use the tool to check every spoke. I ping them and tension by ear; using the tool to check say 3 on each side periodically. This wheel, every spoke I checked was between 10 and 11 on the tool; right in the middle of the Park range. (Double sided fix gear hub so basically a front.)

Until yesterday, I had never used the back side of that Park chart. Just the yellow front with all their common straight and butted spokes. Last wheel used rather extreme Sapim bladed spokes. (The trials of using silver spokes to keep them looking right for tubular wheels on old bikes and insisting on thin spokes simply because I love the ride. DT Revs and the equivalent Sapims were available from Wheelbuilder in black only. If I wanted that light, I had to go bladed. Yes I know I cannot feel the difference in spoke weight but I also know that I have come home from rides where the wheels just felt "clumsy and clunky", looked and saw that I was riding straight 14 gauge spoked wheels I'd bought but not yet re-built with the same rims but lighter spokes.)

And another reason for less than the tightest possible spoke tensions - suppose you are riding and one or more spokes break? Will your wheel stay true enough to ride? To ride without crashing before you can stop and put your foot down? Less than max tension improves those odds a lot. Never happen on your bikes you say? True story - doing a town line sprint on my two month old Peter Mooney less than a year after my last race, a newbie followed the county's big sprinter past me. All of us going well over 30 because we'd just come off a bridge. Sign almost in sight. Well that sprinter hooked over to my lane as soon as he cleared me to shed the newbie. Newbie came over also. Put his quick release into my front spokes and cut out 8 consecutives. I'd laced that rim to the (now archaic) CONI standard or spoke tensions; far from tight. And rode the bike to a standstill. At max spoke tension? I'd been the first down of six or so riders.

I go for as uniform tensions as I can. This varies a lot depending on the rim. Some are less that true or have side to side kinks at the seam and I ave to vary the tension to get the best compromise between true and even tensions. Other rims like the Ambrosia Futura I built up yesterday are absolutely round and true. And no, I never use the tool to check every spoke. I ping them and tension by ear; using the tool to check say 3 on each side periodically. This wheel, every spoke I checked was between 10 and 11 on the tool; right in the middle of the Park range. (Double sided fix gear hub so basically a front.)

Until yesterday, I had never used the back side of that Park chart. Just the yellow front with all their common straight and butted spokes. Last wheel used rather extreme Sapim bladed spokes. (The trials of using silver spokes to keep them looking right for tubular wheels on old bikes and insisting on thin spokes simply because I love the ride. DT Revs and the equivalent Sapims were available from Wheelbuilder in black only. If I wanted that light, I had to go bladed. Yes I know I cannot feel the difference in spoke weight but I also know that I have come home from rides where the wheels just felt "clumsy and clunky", looked and saw that I was riding straight 14 gauge spoked wheels I'd bought but not yet re-built with the same rims but lighter spokes.)

And another reason for less than the tightest possible spoke tensions - suppose you are riding and one or more spokes break? Will your wheel stay true enough to ride? To ride without crashing before you can stop and put your foot down? Less than max tension improves those odds a lot. Never happen on your bikes you say? True story - doing a town line sprint on my two month old Peter Mooney less than a year after my last race, a newbie followed the county's big sprinter past me. All of us going well over 30 because we'd just come off a bridge. Sign almost in sight. Well that sprinter hooked over to my lane as soon as he cleared me to shed the newbie. Newbie came over also. Put his quick release into my front spokes and cut out 8 consecutives. I'd laced that rim to the (now archaic) CONI standard or spoke tensions; far from tight. And rode the bike to a standstill. At max spoke tension? I'd been the first down of six or so riders.

#22

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

Every carpenter I know gang cuts all his studs, so they as automatically come out the same. I can't imagine one actually messuring individual studs to check.

Likewise with wheel building. The key lies in good shop practice, vs. testing to achieve good quality control.

I'm not arguing for sloppy builds, or uneven tension. I'm arguing against obsessive focus on tension, and for good methodology which produces very reasonably even tension as part of the process.

My issue is with the mystique and mythology of tension, which I compare with riding a bike with training wheels. As long as the wheels are on, you'll never know how easy it is to ride a bike. Not to mention that you'll be less, not more, likely to fall over.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#23

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

I have to disagree with this. I've been building my own wheels for 40 years. A while back, someone told me he thought I used too much tension. So, with the next set of wheels I built, I tensioned them less than my usual. I started breaking spokes on the rear wheel at the j-bend. After 3 or 4 broken spokes, I increased the tension and haven't broken a spoke since.

However, it's possible that high tension is helping set elbows, whereas you're not doing it well otherwise.

However consider that we've been building light, durable wheels for eons, using tensions much lower than what's trendy these days.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#24

Full Member

Thread Starter

Wow, lots of info and stuff to think about. Thanks everyone!

I appreciate the talk of the loose tension potentially causing fatigue at the J bend but i forgot to mention these hubs are straight pull. Also lacing pattern is governed by the drill pattern, which in this case is 3x. To mirror what gearbasher was saying... I had an OEM wheel that was so grossly undertensioned that a couple of the spokes rattled. I broke 3 spokes in those wheels right at the J bend. This is when I started to get more educated on wheels, I tensioned them up and it's been fine since.

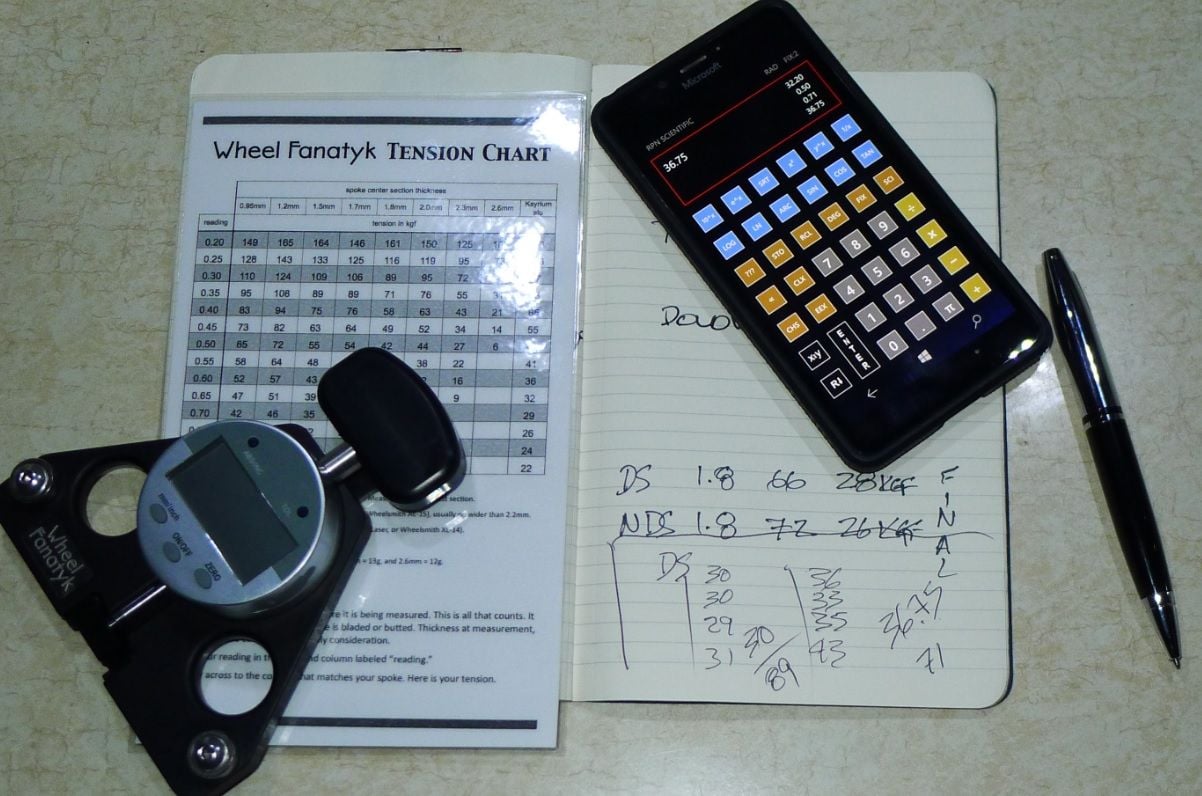

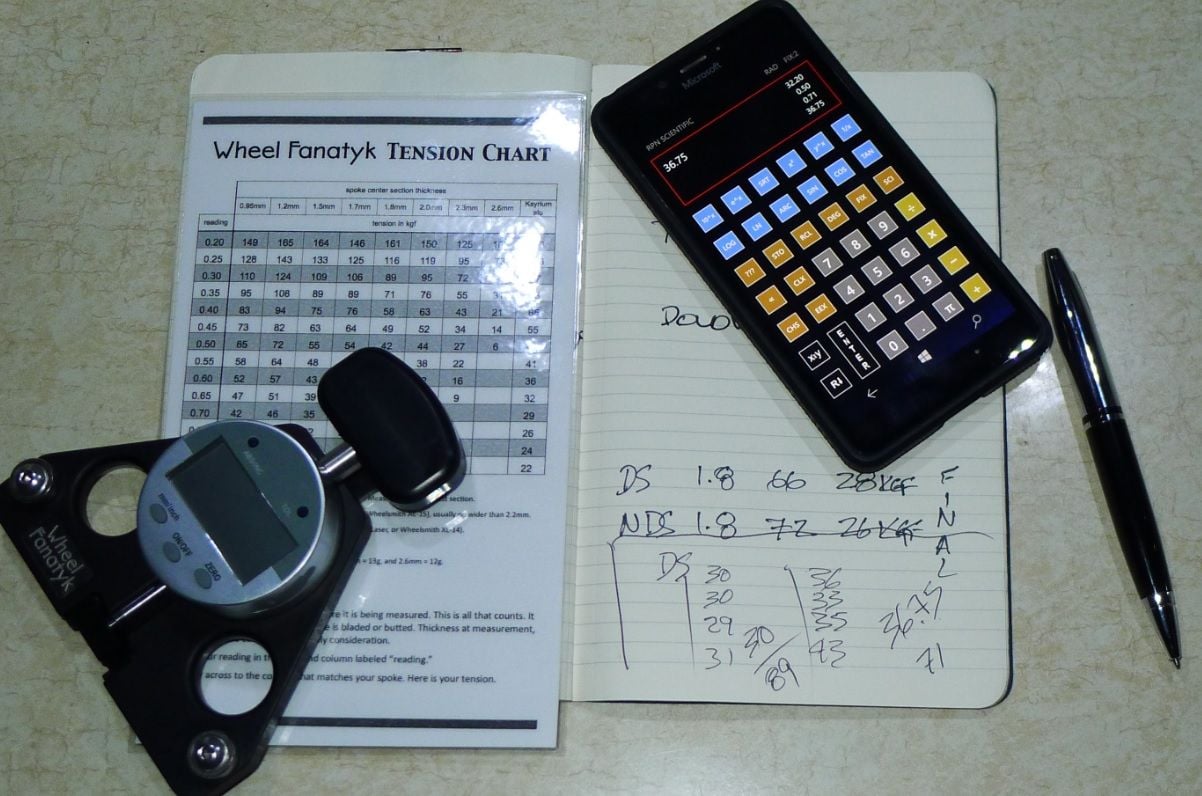

I do have one of those Park tensionometers, or the ZTTO ripoff of it. It's ok I guess but didn't like the inconsistency and ambiguity of the readings. I made a Wheel Fanatyk clone out of bits I had around, I did have to spend ~$12 on a linear rail, so not completely free. It's been tough trying to get any info about their unit but I finally found a picture of someones calibration chart to get a sense of how much deflection I should be seeing. As I suspected my spring is on the weak side making it too sensitive to other factors swamping out the defection of the spoke under tension. I'll go throught the spring bucket tonight and select a better one - and likely have to reprint a new part to accomodate it. Also going to see if I can make a data cable for the digital gauge so I don't have to enter numbers manually in a tension chart calculator. They're at least a few hundred $$$ with foot pedal, @#$% that!!!! Probably need an arduino to translate the SPI interface from the gauge from the research I've done, and some printed bits. Hoping to get it done without having to buy anything, wish me luck!!

I appreciate the talk of the loose tension potentially causing fatigue at the J bend but i forgot to mention these hubs are straight pull. Also lacing pattern is governed by the drill pattern, which in this case is 3x. To mirror what gearbasher was saying... I had an OEM wheel that was so grossly undertensioned that a couple of the spokes rattled. I broke 3 spokes in those wheels right at the J bend. This is when I started to get more educated on wheels, I tensioned them up and it's been fine since.

I do have one of those Park tensionometers, or the ZTTO ripoff of it. It's ok I guess but didn't like the inconsistency and ambiguity of the readings. I made a Wheel Fanatyk clone out of bits I had around, I did have to spend ~$12 on a linear rail, so not completely free. It's been tough trying to get any info about their unit but I finally found a picture of someones calibration chart to get a sense of how much deflection I should be seeing. As I suspected my spring is on the weak side making it too sensitive to other factors swamping out the defection of the spoke under tension. I'll go throught the spring bucket tonight and select a better one - and likely have to reprint a new part to accomodate it. Also going to see if I can make a data cable for the digital gauge so I don't have to enter numbers manually in a tension chart calculator. They're at least a few hundred $$$ with foot pedal, @#$% that!!!! Probably need an arduino to translate the SPI interface from the gauge from the research I've done, and some printed bits. Hoping to get it done without having to buy anything, wish me luck!!

#25

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,817

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 839 Post(s)

Liked 1,258 Times

in

663 Posts

around and around this discussion goes. I'll pick a number, shoot for 100-110 Kgf on the rear drive side and front. Rear non drive will be what it will be.

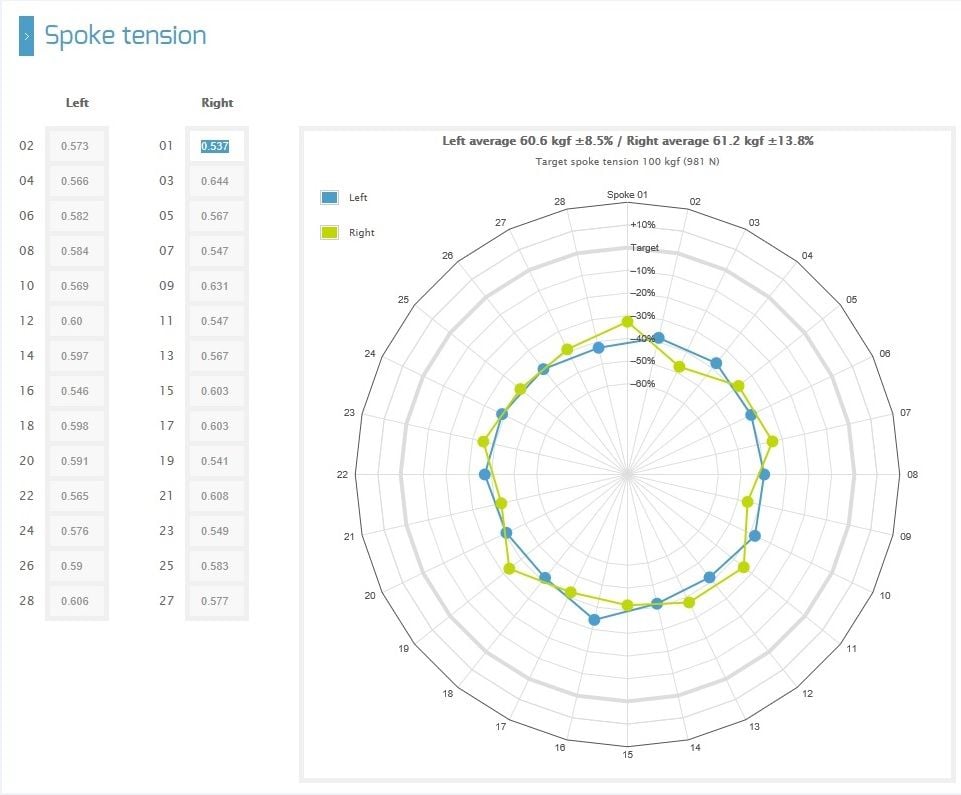

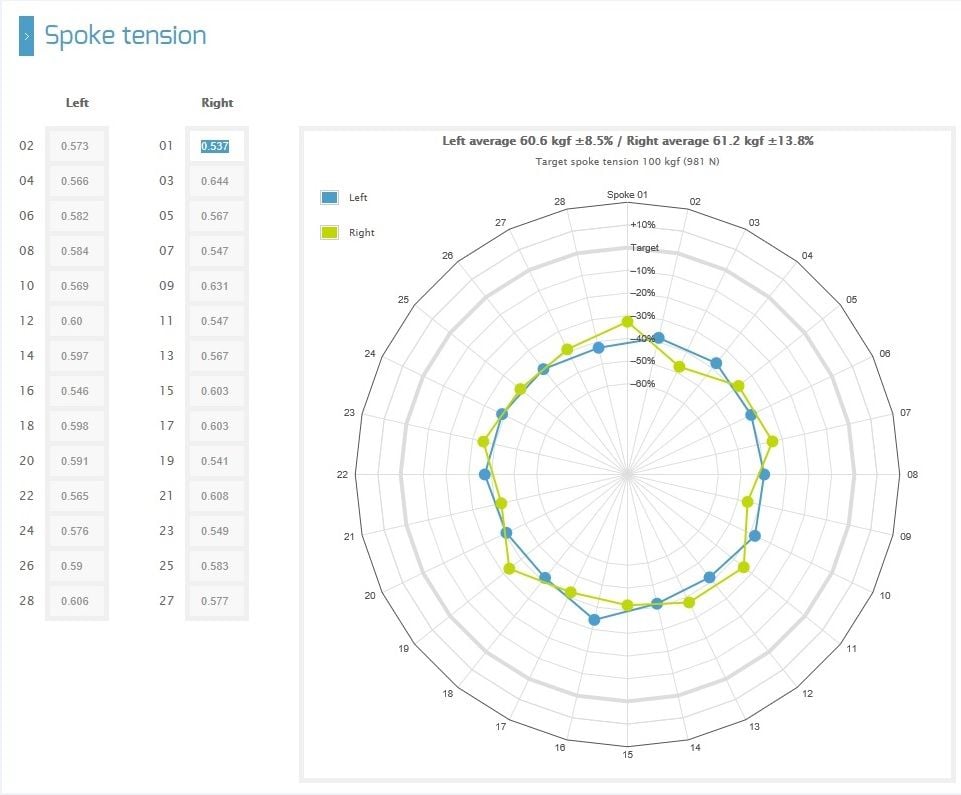

I am not a big fan of winding spoke tensions to the limit. What is far more important is to get the tension as even as possible around the wheel, so using your precision measurement tool there, you can generate a radar plot of spoke tension as shown below.

this thing provides feedback that will keep you humble. Here's a plot from a wheel built for me by master wheelbuilder Spence Wolf in 1987. Campy HF 3X to Mavic MA2, tied and soldered. Look how even the tensions are, nearly 40 years on.

/markp

I am not a big fan of winding spoke tensions to the limit. What is far more important is to get the tension as even as possible around the wheel, so using your precision measurement tool there, you can generate a radar plot of spoke tension as shown below.

this thing provides feedback that will keep you humble. Here's a plot from a wheel built for me by master wheelbuilder Spence Wolf in 1987. Campy HF 3X to Mavic MA2, tied and soldered. Look how even the tensions are, nearly 40 years on.

/markp

Likes For mpetry912: