Originally Posted by

merziac

Yet again,

No, I'm sorry, you are confused.

The length of the wrench determines the torque and is calculated from the handle at the end.

The left hand is just steadying the socket and it says so in the text, the physics dictate the torque is is calibrated to the length of the lever, not correct or accurate from anywhere else, only from the black handle part.

Again, quote from the link, article.

"Apply force to the handle only."

"The torque is calculated based on force being applied to the handle. Applying force on other parts of the wrench will result in a different torque value being applied."

Any fulcrum or lever is dependent especially on length so it obviously matters where force is applied so the value changes if it is not correctly applied at the proper handle.

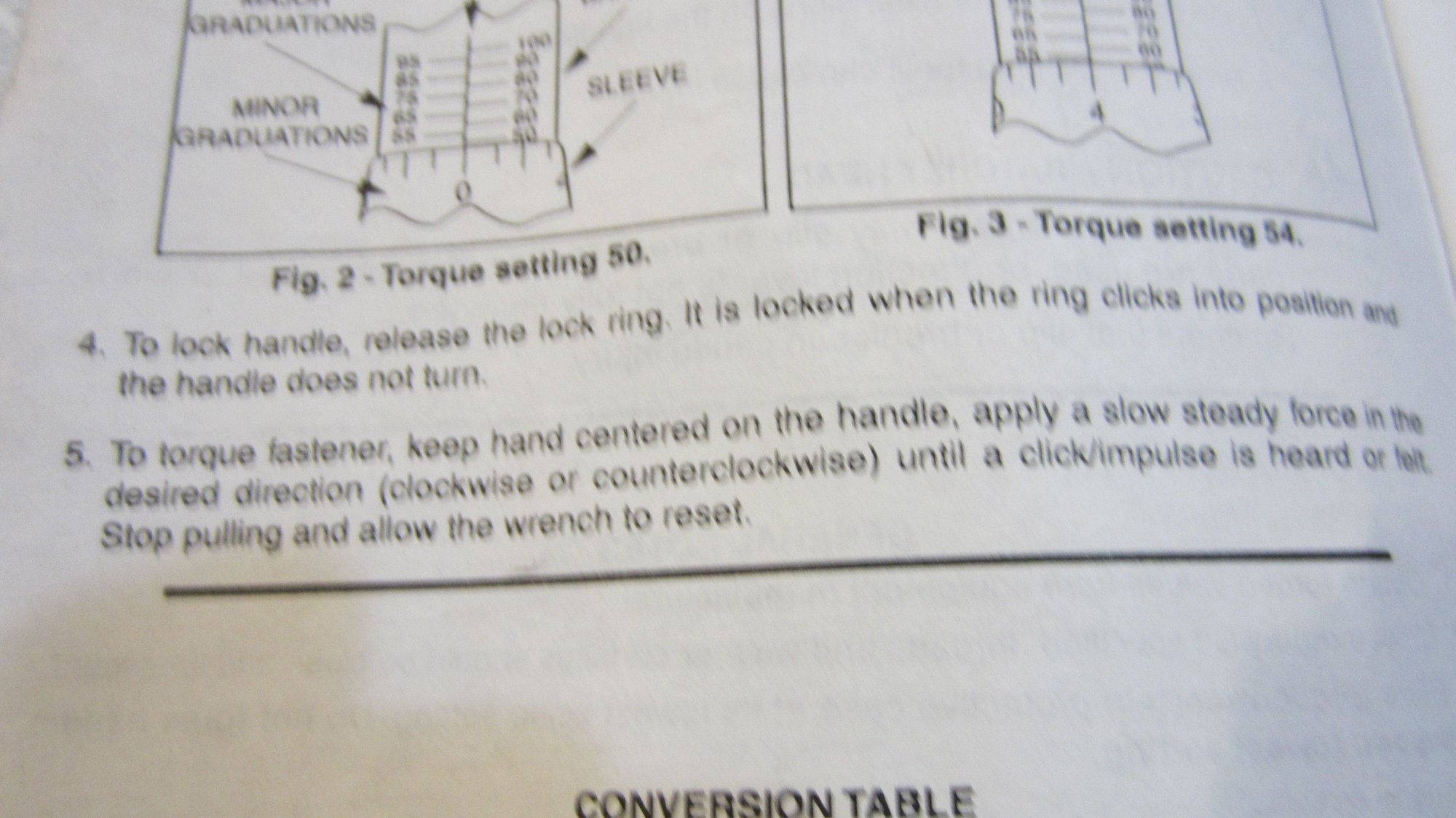

Here are instructions from SnapOn and Matco.

Again, this is simple physics. Everything south of the hinge is "handle", because it has no parts that move when pressure is applied. The user will notice more or less force required depending on where they hold the handle, but the device that measures torque does not and cannot know where your hand was placed. All it knows is that force of some sort was placed somewhere below the hinge, and that force exceeds the setting of the torque wrench mechanism. It can't read your mind or tell where your hand was.

This is no different than a teeter-totter. The child at one end will only come off the ground if weight is applied to somewhere on the other side of the pivot. That can be a similar weight at the far end, or twice the weight closer in.. But the child can't measure the force/weight - they can only express if they start rising off the ground. The wrench clicking is like the child. Really basic physics.