Custom frame design is always a collection of compromises with the rider's primary needs trumping other factors that may be desirable but are in conflict. For example stem length vs toe overlap. Most designs are based on good bicycle handling characteristics for a go fast fit cyclist. Lots of studies have refined both fit and handling to improve their competitiveness.. However for some people age or outside of the norm body dimensions and perhaps injury have taken their toll and what might work best when they were younger in a fast pace line will no longer fit them comfortably when they are getting some miles to try and stay at least a little bit fit. These adjustments from prefect have to be made. It is the great advantage of a custom frame (besides making it beautiful).

One of the possible fit adjustments as factors move us away from the ideal is the need to raise the handlebars. Even young urban riders may like them higher than what would make them go the fastest so they can keep an eye out for coming up traffic signs or parked drivers opening their doors. As the handlebars are raised, that results in the need for the seat to go back. A fitting bike can better allow the builder to assess the rider's position. Of particular importance is sliding the saddle back just far enough to take the weight off his hands on his brifters. When the goal is no longer trying to stay with the fast group or to shave another second to two off of your riding circuit, it just makes sense to be as comfortable as possible.

Experience has shown me that this fitting bike is good enough to accurately establish a position within a centimeter or so. Of course it isn't as good as riding a real bike on the road nor as sexy as using a computer to activate server motors that move the seat and handlebars. But it gets the job done. And can often show that a standard production bicycle is not optimum for the newly discovered position. Lots of my customers and students have said they like their bike position just fine but after a fitting and new frame designed around their new position, they most often say: "oh this is better!".

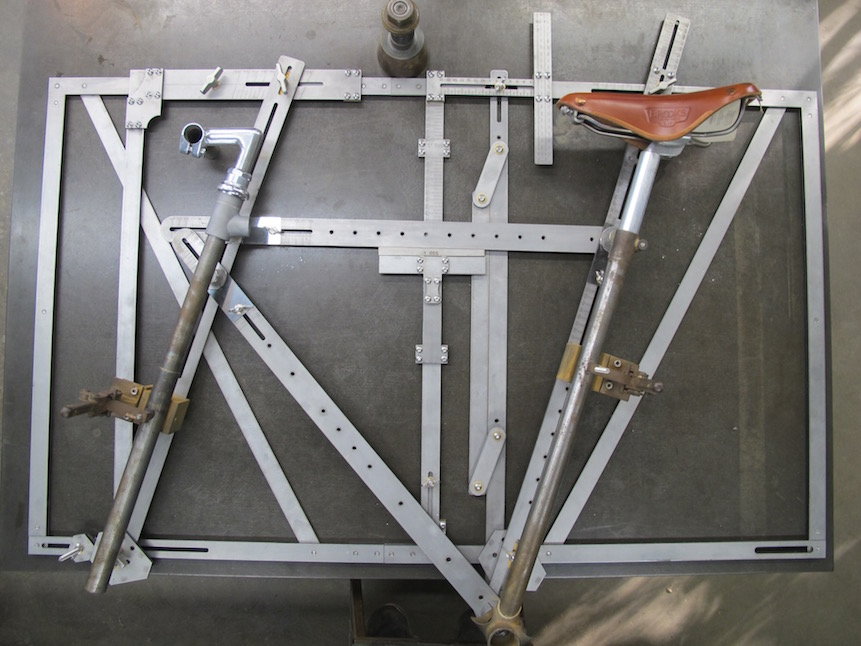

Of course finding a rider's position is only part of the battle. The frame now needs to be designed around that position. It isn't the purpose of this thread to explain about how my fixture helps me design a frame but I'll give you a brief description so you can understand my process. I've spent hundreds/thousands of hours over many years with the help of others designing a fixture to help me convert a bicycle position into a frame design. I have them laser cut and etched out of stainless steel in Ukraine. I don't go out of my way to sell them although I'm sure the company that makes them wishes I did. On the fixture I place the chosen stem and saddle/seatpost in the rider's position and slide the pieces that represent the frame tubes to match those components. During this process, I make the choices that fit the needs of the rider. it is particularly important to me that everything looks proportional so I can, for example, micro adjust the head tube height so there aren't too many spacers or quill stem exposed.

Here is a picture of the fixture holding the stem/saddle to help create a frame design. It's an older version without all of its accessories. It is just for showing how I do a frame design.