here is one little insite that master wheelbuilder Ric Hjertberg (Wheelfanatyk) shared with me.

it's fine to adjust lateral runout by tightening and loosening spokes on opposite sides of the hub, working in groups of 2 or 4

and you can tighten or loosen spokes (again working in groups of 2 or 4) to reduce "up and down" variations and bring the rim into perfect circularity

And to adjust the dish, you'll tighten all spokes on one side of the hub to put the rim into the plane that is equidistant between the axle endpieces.

you're trying to arrive at a state where the wheel is 1) straight laterally 2) perfectly round 3) dished accurately and 4) evenly and sufficiently tensioned

What experienced wheelbuilders are able to do - in the final stages of truing - is to find one spoke that affects both lateral and vertical deviation and adjust that one spoke to address both.

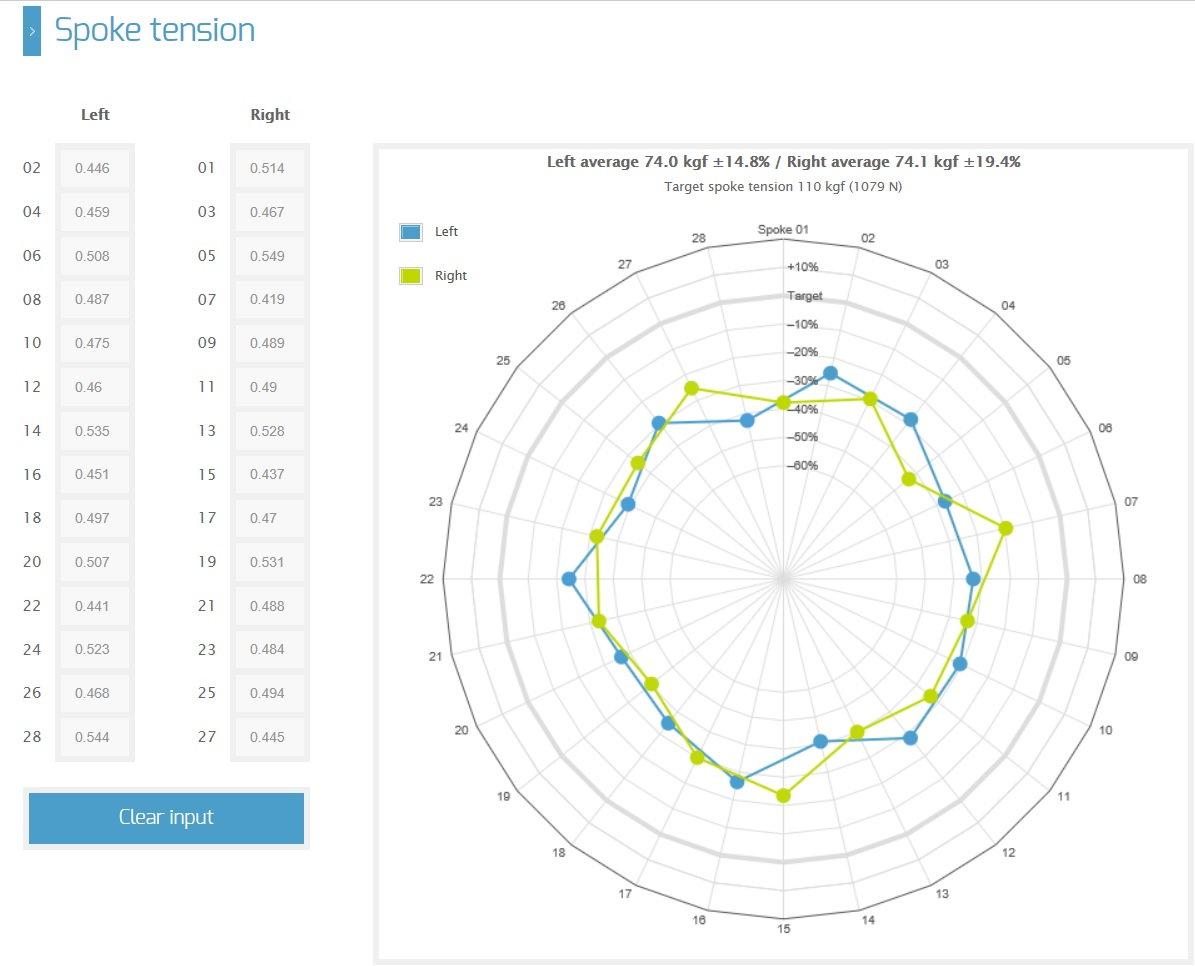

this can approach an art form. Like tuning a piano. But "that one spoke" will generally be an outlier in terms of tension, either too low or too high. in this way a skilled wheelbuilder can reduce the variation in spoke tension, which makes for wheels that stay true for a long time. And Ric's instrumentation can show you the spoke tension of the entire wheel at a glance.

/markp