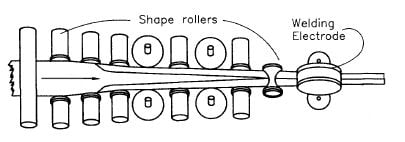

Seamed tubing is usually produced in this manner. A strip of sheet steel from a roll is fed through a series of roller dies until it forms a cylinder which then goes under a rotating electrode die which creates a welded joint. The external flashing can be removed by a number of processes including scarfing, turning, drawing or grinding. External seams are usually invisible in tubing.

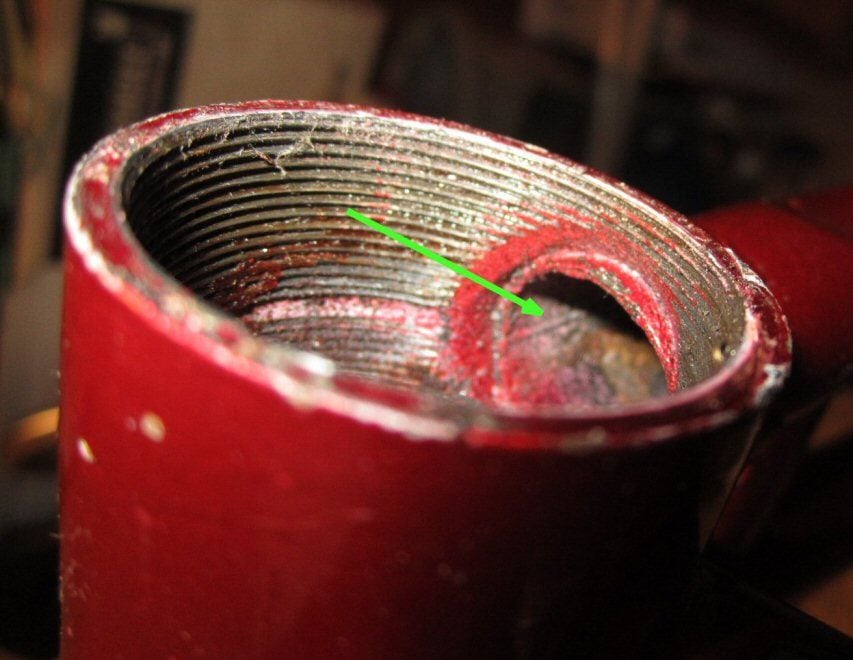

Unless a seamed tube has been drawn over a mandrel there is almost always a visible internal seam.

Seamed chain stay.

Seamed head tube.

I've seen splits like on the OP's Moto before in really cheap tubing used for junk applications but never in bicycle tubes.

Because that's a highly stressed area, a hammersmithing repair would just be a band-aid.

verktyg