The rear jig is done, finally. A bit more involved than the front one. More tube support points and planes of function at play and more surfaces to clean up.

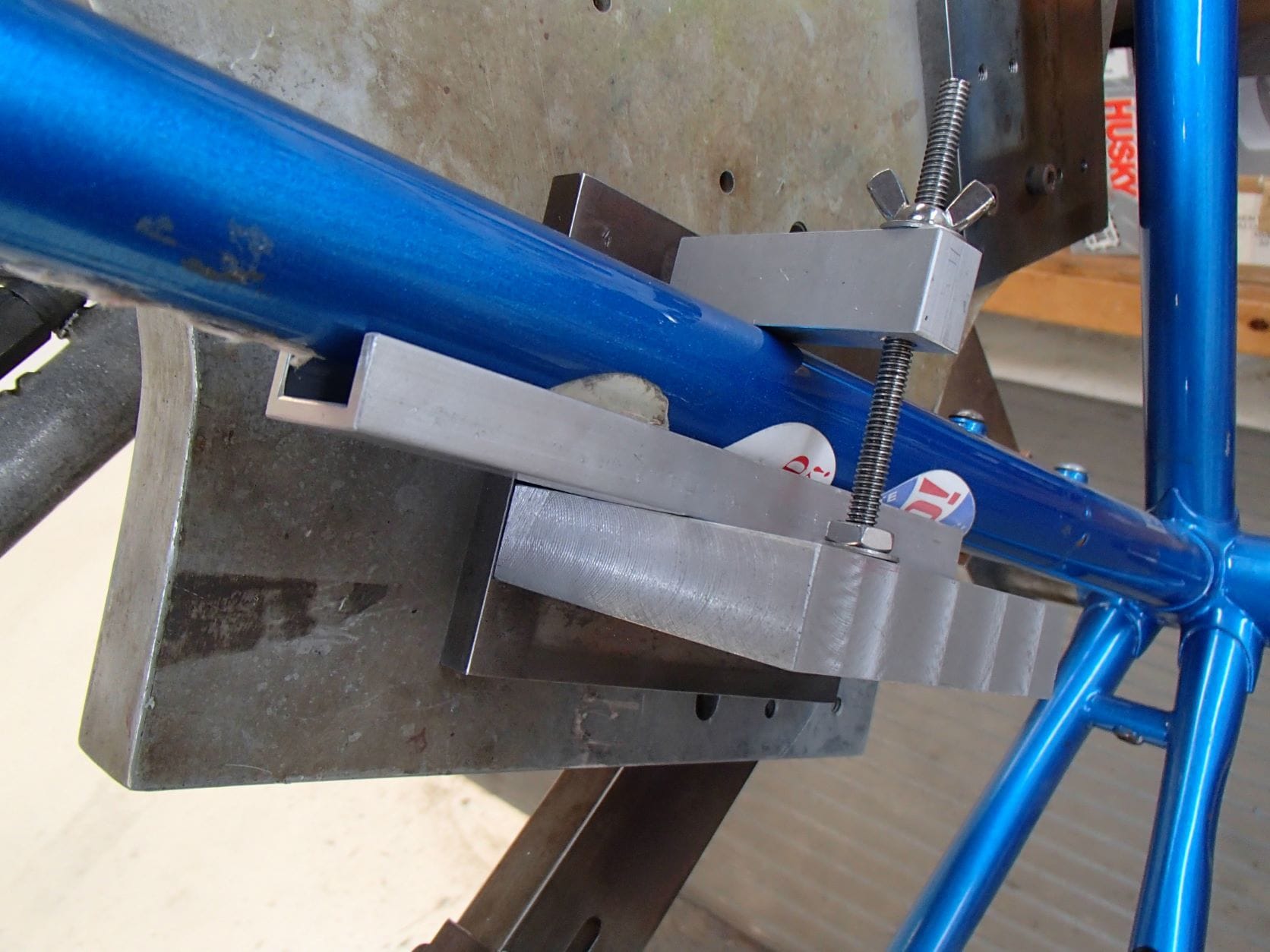

I decided to reduce the added stand off to 5/8", somewhat driven by the rear triangle/axle support design. New drop out "studs" to expand the spread to 137mm. The one detail that took some thinking about was the DT support.

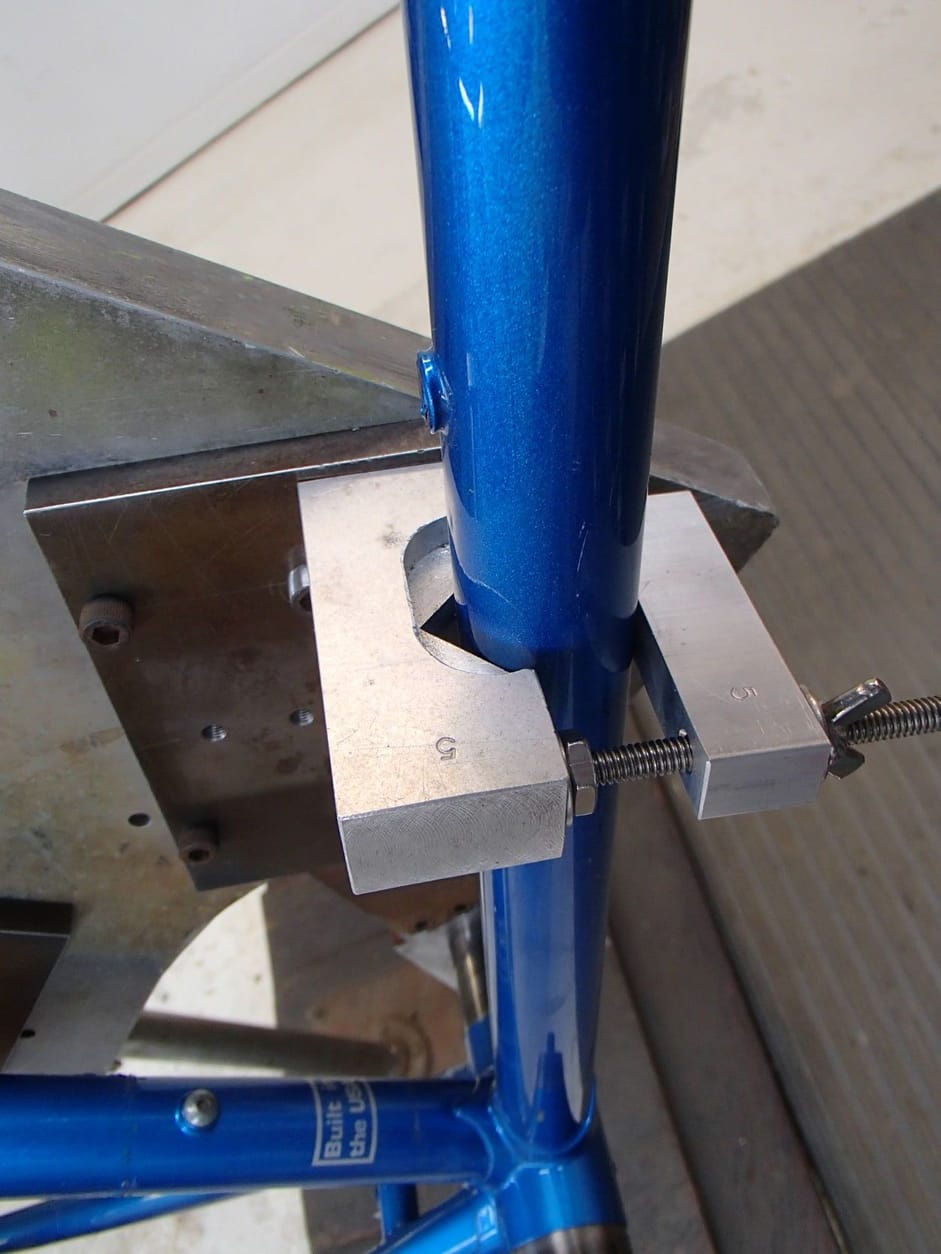

The top and seat tube support clamps can slide and pivot on the jig's base plate, as was the case with the front end jig. Thus the only critical dimension is the tubes' stand off from the plate. But the DT support is fixed in place and with the want of varying tube diameters that the tube being held on its inner side meant that I couldn't align the tube support WRT the BB and have this alignment be consistent across the varying diameters. I finally came up with the idea of a single point contact with the tube, allowing the tube to rock a bit against the support. At first I was going to turn an hour glass shaped stud. In the end I decided to just use a flat support "V" with a fairly thin section, not knife like but close enough. Now the DT can remain centered at the shell, be held parallel to the jig base plate and have a clamp to contain the DT. The rest of the frame will rock this or that way to allow the DT and support to touch. The rest of the jig can be adjusted to suits the other contact points. Remember these jigs have no scales or angles, all tube to tube dimensions/angles are by mitering, a venier protractor and careful set up.

All in all I think the results are pretty nice. Soon I'll start up a frame with these jigs before offering them for sale, likely months from now. Andy

Note the cut away of the "V" to reduce the contact surface to a more point like amount.

These two supports are nearly the same as with the front end jig's

The BB support shaft can slide side to side. It's held in place with a set screw on the bottom of its mount.

The two drop out stand offs are of unequal lengths due to the jig's design. I stamped which side is which and the overall axle width. You can see the bright silver 5/8" spacer I placed in the sliding clamp to bring the rear end in line as before. The other tube supports are located with this amount in mind.