What is the range of dimensions for 44mm head tubes before reaming

#1

Randomhead

Thread Starter

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,393

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,693 Times

in

2,515 Posts

What is the range of dimensions for 44mm head tubes before reaming

I have a paragon and a columbus head tube to measure. I didn't break out the expanding hole gauges, so I might be off a little. They were both about 43.46. Anyone have one that's wildly different from this?

I'm going to be making a tube holder for my fixture. It's for the bottom holder, so it's going to be a puck, not a cone. I don't think it matters to me if it's a few microns undersize.

I need to make a cone for the top, my current cone only goes up to 1 1/8"

I'm going to be making a tube holder for my fixture. It's for the bottom holder, so it's going to be a puck, not a cone. I don't think it matters to me if it's a few microns undersize.

I need to make a cone for the top, my current cone only goes up to 1 1/8"

#2

Senior Member

Join Date: Dec 2019

Posts: 955

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

I've used a few regular size Reynolds HTs now and they're all exactly 34mm ID. No reaming required but sometimes a bit of loctite is. Not really a fan of this but since I don't own the reamer the right size it actually works out quite well for me. The 44mm ones in the catalogue say "43.95id" which I'm sure is exactly what they are.

I'm thinking of making an improved jig and plan on aluminium cones for everything now that I have a minilathe. But I won't make any big enough for MTB HTs. If/when I do another one of those I'll probably use the wooden ones I made the last time.

I'm thinking of making an improved jig and plan on aluminium cones for everything now that I have a minilathe. But I won't make any big enough for MTB HTs. If/when I do another one of those I'll probably use the wooden ones I made the last time.

Likes For guy153:

#3

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

I measured a paragon (43.74mm) and one of the tapered ones (43.76mm) with telescoping bore thingies and a verified micrometer. My puck is 43.42mm measured with the micrometer. I face both ends of the tube on the lathe and hope the top cone centers it enough to make up the few thousandths that it's undersized around the periphery. I tack on the centerline so I don't think the gap hurts me. If I was to make a new lower puck, I'd make it slightly bigger than my current. I would also add some way to align the top and bottom holders for the headtube. As mine is now, I have to do a bit of re-alignment if I move the cones/pucks to soak the flux off of them.

Drew Guldalian's new fixture uses an expanding mandrel for the lower puck which seems pretty smart.

Post up some pics!

Drew Guldalian's new fixture uses an expanding mandrel for the lower puck which seems pretty smart.

Post up some pics!

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

Likes For duanedr:

#4

Randomhead

Thread Starter

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,393

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,693 Times

in

2,515 Posts

That's interesting about paragon, the one 44mm head tube I looked up said 43.5. Maybe they went a little bigger on some parts, because 1/2 mm is a lot of material to remove.

I don't think Reynolds aiming for the exact dimension is a good idea. I wouldn't have thought anyone would do that. Certainly Reynolds BITD was undersize. Maybe their production customers wanted to do less reaming.

Facing the columbus head tube is a good idea. It looks good, but can't hurt to be sure. I'm pretty sure the Paragon head tube I have is square, I might mess it up more than anything if I tried to true it.

I don't think Reynolds aiming for the exact dimension is a good idea. I wouldn't have thought anyone would do that. Certainly Reynolds BITD was undersize. Maybe their production customers wanted to do less reaming.

Facing the columbus head tube is a good idea. It looks good, but can't hurt to be sure. I'm pretty sure the Paragon head tube I have is square, I might mess it up more than anything if I tried to true it.

#5

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

That's interesting about paragon, the one 44mm head tube I looked up said 43.5. Maybe they went a little bigger on some parts, because 1/2 mm is a lot of material to remove.

I don't think Reynolds aiming for the exact dimension is a good idea. I wouldn't have thought anyone would do that. Certainly Reynolds BITD was undersize. Maybe their production customers wanted to do less reaming.

Facing the columbus head tube is a good idea. It looks good, but can't hurt to be sure. I'm pretty sure the Paragon head tube I have is square, I might mess it up more than anything if I tried to true it.

I don't think Reynolds aiming for the exact dimension is a good idea. I wouldn't have thought anyone would do that. Certainly Reynolds BITD was undersize. Maybe their production customers wanted to do less reaming.

Facing the columbus head tube is a good idea. It looks good, but can't hurt to be sure. I'm pretty sure the Paragon head tube I have is square, I might mess it up more than anything if I tried to true it.

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

Likes For duanedr:

#6

Randomhead

Thread Starter

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,393

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,693 Times

in

2,515 Posts

How much do you leave for the headset?

I might open up the Paragon since I have to borrow a reamer

I might open up the Paragon since I have to borrow a reamer

#7

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

Well, when I say 'I trim off as much as I can', I'm not really being literal - just that I try to get the taper further down so the transition isn't in the middle of the DT. That miter is already a pain. You also don't want the reamer to cut into the taper!

The last one I did (still waiting to be taken to paint) has about 16mm from the lower edge of the HT to the start of the taper on the outside of the HT. It looks like I trimmed off about 6-7mm based on the other one I have. My measurements say Chris King and FSA headsets require 8-9mm inside depth for the seat .

I bored a Paragon in the mill with a boring head before I got the 44mm reamers. My little mill (I refer to it as my Barbie EZ-Mill ) could just barely get a 90mm headtube done! It wasn't too bad to indicate it in and cut it though - a bigger mill would make it a breeze really.

) could just barely get a 90mm headtube done! It wasn't too bad to indicate it in and cut it though - a bigger mill would make it a breeze really.

The last one I did (still waiting to be taken to paint) has about 16mm from the lower edge of the HT to the start of the taper on the outside of the HT. It looks like I trimmed off about 6-7mm based on the other one I have. My measurements say Chris King and FSA headsets require 8-9mm inside depth for the seat .

I bored a Paragon in the mill with a boring head before I got the 44mm reamers. My little mill (I refer to it as my Barbie EZ-Mill

) could just barely get a 90mm headtube done! It wasn't too bad to indicate it in and cut it though - a bigger mill would make it a breeze really.

) could just barely get a 90mm headtube done! It wasn't too bad to indicate it in and cut it though - a bigger mill would make it a breeze really.

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

Likes For duanedr:

#8

Senior Member

Join Date: Dec 2019

Posts: 955

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

I used a Columbus tapered tube. I only cut the narrower end and left the bottom as it was. I took it to a local place where they make motorbikes hoping he could face the top on a lathe (I didn't have my minilathe at the time). He couldn't, saying he would have needed to make a plug to go inside the tube to hold it properly at the chuck (which sounds completely believable), but he managed to do a very good job with a belt sander, a machine table and a square.

I then had to modify my coping template calculator software to be able to handle joining the DT right onto the tapered part (you input the ratio of diameter change to length change across the taper). This part actually worked really well especially as I was fresh out of tapered holesaws.

The way the Columbus tubes work is you then braze some inserts into the top and bottom that support the actual bearings. This possibly makes facing a bit less critical. I chose to braze (silver solder with MAPP, not pretty but they aren't going anywhere) those in after welding the frame concerned that the welding might melt the braze. But I think this was the wrong way around. The HT distorted a bit during welding to the point where it was compressing the inserts and the bearings didn't want to go in. This needed some last minute squishing in a vice to correct. Brazing them in first would have added support to the tube and reduced distortion in the first place and probably nothing would have melted. Those HTs are pretty much on the 50:1 diameter:wall limit considered the rule of thumb for coke-canning.

I then had to modify my coping template calculator software to be able to handle joining the DT right onto the tapered part (you input the ratio of diameter change to length change across the taper). This part actually worked really well especially as I was fresh out of tapered holesaws.

The way the Columbus tubes work is you then braze some inserts into the top and bottom that support the actual bearings. This possibly makes facing a bit less critical. I chose to braze (silver solder with MAPP, not pretty but they aren't going anywhere) those in after welding the frame concerned that the welding might melt the braze. But I think this was the wrong way around. The HT distorted a bit during welding to the point where it was compressing the inserts and the bearings didn't want to go in. This needed some last minute squishing in a vice to correct. Brazing them in first would have added support to the tube and reduced distortion in the first place and probably nothing would have melted. Those HTs are pretty much on the 50:1 diameter:wall limit considered the rule of thumb for coke-canning.

#9

Senior Member

Join Date: Jan 2013

Location: South Jersey

Posts: 2,265

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 714 Post(s)

Liked 798 Times

in

475 Posts

I don't remember the exact measurement, but Paragon 44mm head tubes are the smallest ID of any that I've used. I think I have one in my shop that I can measure later today. Some of the straight walled tube that is made for 44mm head tube stock is very close to 43.95 on the ID, so I don't like to use that stuff.

Any pucks that I make get a 1 degree taper that is only the target OD at the very bottom(Paragon's have a good size chamfer on the ends, so you can go slightly oversized) This makes it so that your part doesn't get stuck on the puck from distortion and makes it easier to get the frame back into the jig after welding/brazing.

Any pucks that I make get a 1 degree taper that is only the target OD at the very bottom(Paragon's have a good size chamfer on the ends, so you can go slightly oversized) This makes it so that your part doesn't get stuck on the puck from distortion and makes it easier to get the frame back into the jig after welding/brazing.

Likes For dsaul:

#10

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

Yes, the top is the same as a standard 1-1/8" HT so standard reamers/facers work to get that straight once it's cut. I chuck it up on the section that will be cut off and then just use a parting bit to part off the HT I want to use.

The way the Columbus tubes work is you then braze some inserts into the top and bottom that support the actual bearings. This possibly makes facing a bit less critical. The way the Columbus tubes work is you then braze some inserts into the top and bottom that support the actual bearings. This possibly makes facing a bit less critical. I chose to braze (silver solder with MAPP, not pretty but they aren't going anywhere) those in after welding the frame concerned that the welding might melt the braze. But I think this was the wrong way around. The HT distorted a bit during welding to the point where it was compressing the inserts and the bearings didn't want to go in. This needed some last minute squishing in a vice to correct.

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

Likes For duanedr:

Likes For dsaul:

#12

Senior Member

Join Date: Dec 2019

Posts: 955

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

I think with headsets so long as the steering turns and doesn't go wobbly at any point in its travel you're all right. It's not a joint that's spinning continuously like a wheel or a bottom bracket. But I will also never criticize anyone for aiming for perfection however unnecessary as this is a good thing.

I think with headsets so long as the steering turns and doesn't go wobbly at any point in its travel you're all right. It's not a joint that's spinning continuously like a wheel or a bottom bracket. But I will also never criticize anyone for aiming for perfection however unnecessary as this is a good thing.

#13

Randomhead

Thread Starter

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,393

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,693 Times

in

2,515 Posts

My lbs has the cutters to face the 45 degree cups. But they still can't tap a t47 bb.

#14

Newbie

I used a BFS machined 44 mm headtube on my recent creation. Their drawing, which I believe was under P/N TBE-HT-50-44-90, shows the bore for the headset at 43.50 mm +.01/-00. After brazing it is still pretty close to this, but a bit out of round. Too much heat on my part, I'm sure... This headtube is nice in that it tapers to a larger ID after 15 mm for the headset bore. I plan to bore it in my mill since I don't have a reamer setup. I will just bore through to the larger diameter. That happens this weekend. Let you know how it turns out!

Likes For Devin Rickey:

#15

Senior Member

Join Date: Dec 2019

Posts: 955

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

I used a BFS machined 44 mm headtube on my recent creation. Their drawing, which I believe was under P/N TBE-HT-50-44-90, shows the bore for the headset at 43.50 mm +.01/-00. After brazing it is still pretty close to this, but a bit out of round. Too much heat on my part, I'm sure... This headtube is nice in that it tapers to a larger ID after 15 mm for the headset bore. I plan to bore it in my mill since I don't have a reamer setup. I will just bore through to the larger diameter. That happens this weekend. Let you know how it turns out!

#16

Senior Member

Join Date: Jan 2013

Location: South Jersey

Posts: 2,265

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 714 Post(s)

Liked 798 Times

in

475 Posts

I'll bet that you've never reamed a Paragon head tube with that method. .5mm doesn't seem like much, but it would be an eternity to remove with emery cloth. Its a bit of work even with a sharp Park tools reamer.

#17

Newbie

I used a similar method on the seat tube. 120 grit on a 1/2" rat tail file, but didn't need to remove much material... Not elegant, but it worked. Agree with Unterhausen, .5 mm is too much to remove with sandpaper!

Likes For Devin Rickey:

Likes For guy153:

#19

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

After thinking about this quite a bit since I bored that frame a few years ago, it seems one has the ability to machine out a little post-brazing frame twist if you needed to. The same would apply to PressFit BB but I don't think many use those with steel construction (do they?). How one would indicate that 'corrected' axis into the boring set up would be a fun puzzle!

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

#20

Randomhead

Thread Starter

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,393

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,693 Times

in

2,515 Posts

I used to think about boring a press fit bb shell before the advent of T47. Not sure I would try to align a frame that way though.

#21

Newbie

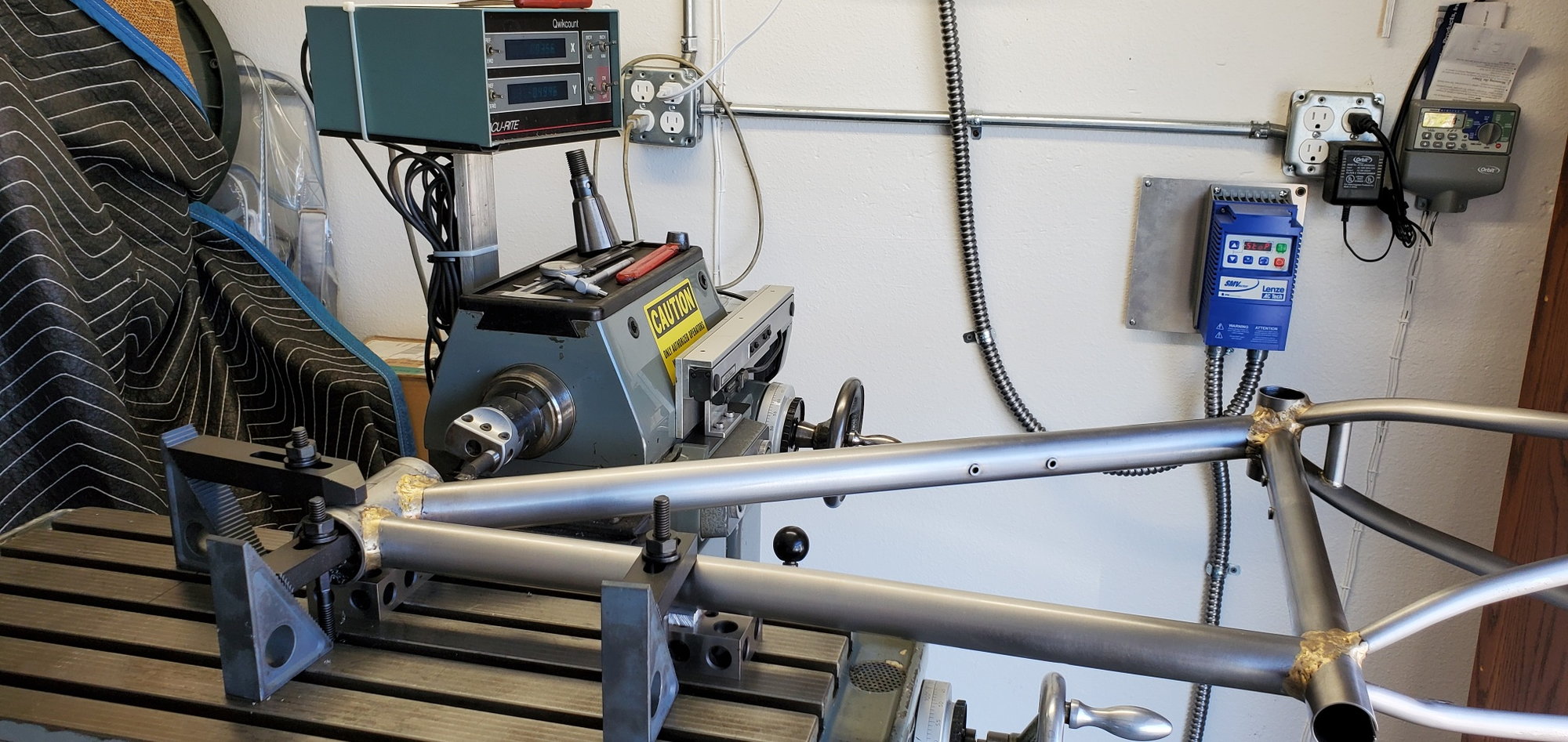

On the Deckel with the vertical spindle removed. I love having a flexible machine!

The boss was disinterested...

Got the head tube machining done this afternoon. It came out fine, but I was happy for every micron of the 0.5 mm of machining stock! My "too much heat" newbie brazing didn't do the head tube any favors... Had a very small (~8 mm) area that didn't clean up on the top bore, but I doubt that will be a problem. Today's experience may fortify my resolve to get a reamer setup!

Last edited by Devin Rickey; 10-11-21 at 04:05 PM. Reason: Adding photos

Likes For Devin Rickey:

#22

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

I don't think as part of a standard process it would make sense but sometimes the mind wanders when the minutes drag. if one found they had 1mm of twist in the front, at the end of their HT alignment bar, they could in theory pull that out by boring based on perpendicularity to rear axle. I haven't done the trig to see how much one could remove within the 0.5mm of material that has to be removed anyway but it seems like 1mm could be covered.

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com