How hard is it to build a wheel with a dynamo?

#1

Full Member

Thread Starter

How hard is it to build a wheel with a dynamo?

I’m considering building my own wheel with a dynamo to power some new lights (Schmidt Edelux II for the front, SON for the rear). I’m not sure what dynamo to get, and it will ultimately go on this Linus bike (https://www.linusbike.com/collection...13276107898903). I’ve never built a wheel before, but have done a fair amount of work on my bikes.

How hard would it be? Is it worth it? Any tips?

How hard would it be? Is it worth it? Any tips?

Last edited by Alligator; 05-31-21 at 07:10 PM. Reason: Added photo of the bike.

#2

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,684 Times

in

2,508 Posts

There are lots of resources online for learning to build a wheel. It's not something you can easily digest into a forum post.

There is a vendor of dyno wheels on ebay that people like, idc1947. You can get pre-built dyno wheels from other sources. I think that's the way to go unless you really want to start building wheels regularly.

There is a vendor of dyno wheels on ebay that people like, idc1947. You can get pre-built dyno wheels from other sources. I think that's the way to go unless you really want to start building wheels regularly.

#3

I am potato.

Join Date: Jun 2015

Location: Pacific Northwest

Posts: 3,104

Bikes: Only precision built, custom high performance elitist machines of the highest caliber. 🍆

Mentioned: 28 Post(s)

Tagged: 0 Thread(s)

Quoted: 1782 Post(s)

Liked 1,620 Times

in

926 Posts

It's the same as any other wheel build. Hub, rim, a bit of math or an online calculator, spokes. Add in a bit of time & a truing stand. That's it.

Son hubs are great if money isn't a concern. Shutter Precision is good if you don't mind drop shipping from China at ⅓ to ¼ the cost. I've never been impressed by Shimanos' dynamo offerings, but have never really been disappointed either.

You'll want to get a 6 volt, 3 watt hubs if you have a choice about things. Even with modern LED's that don't draw very much, the extra capacity over lesser offerings leaves precious "head space" at slower speeds or USB charging options available for the future.

Anyone who says they can detect a noticable drag from a hub dynamo is lying. It's imperceptible at best in real world riding.

Go nuts!

Son hubs are great if money isn't a concern. Shutter Precision is good if you don't mind drop shipping from China at ⅓ to ¼ the cost. I've never been impressed by Shimanos' dynamo offerings, but have never really been disappointed either.

You'll want to get a 6 volt, 3 watt hubs if you have a choice about things. Even with modern LED's that don't draw very much, the extra capacity over lesser offerings leaves precious "head space" at slower speeds or USB charging options available for the future.

Anyone who says they can detect a noticable drag from a hub dynamo is lying. It's imperceptible at best in real world riding.

Go nuts!

#4

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,172

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 47 Post(s)

Tagged: 0 Thread(s)

Quoted: 3450 Post(s)

Liked 1,449 Times

in

1,130 Posts

It is like building any other wheel, maybe easier than a rear wheel because building a dished rear wheel takes a bit more time to master.

If you can't true up a wheel, learn that first. If you see a cheap or free wheel at a coop or on the curb in the garbage, grab it and try to learn truing up wheels from that.

A good tutorial on wheel building at:

https://www.sheldonbrown.com/wheelbuild.html

I worked in a bike shop decades ago. We did not have a lot of extra truing stands around, so I learned how to true up wheels in the bike frame. I still do not have a truing stand and have no real need for one. A couple of my wheels I had a friend that volunteers time at a bike charity to check the tension on my spokes, I do not have a tension gauge. I think for a beginner it is probably adequate to get the spokes as tight as they are on similar wheels by feel, but getting a gauge or access to one would be better, you be the judge on that.

If you build up a wheel for that bike, that bike has rim brakes. Consider paying a couple extra dollars to get a hub that can also work on disc brakes, that makes the wheel more likely to be used on another bike if you trade up later. And for that reason, I suggest you put your old wheel from that bike in storage in case you sell that bike later, you can keep the complete new wheel. But do not forget you have the old wheel, a friend of mine had a new dynohub wheel built up four years ago, I advised him to have a complete new wheel built and keep his old front wheel in case he later got rid of the bike. He recently sold the bike but forgot he had the original wheel for it in storage, so he now has an old used wheel and no dyno fitted wheel, that was a big ooooops.

That said, the world is going to through axles. So, to truly future proof a wheel build, it would be best to build up a through axle wheel with adapter to work on a conventional quick release fork. But that is more costly. I built up another dynohub wheel in late winter for a rim brake bike. I paid about three Euros more for a disc hub, but I chose not to pay the much larger fee to buy the through axle dynohub and the adapter to use that on a rim brake bike.

Wiring up the lights, Peter White website has very good information on wiring. He is the USA distributor for some of the dynohubs and European light companies. That said, I usually buy that sort of thing from Germany internet sellers, much cheaper but they have a big up front shipping fee so you want to minimize the number of orders if possible.

Good luck.

If you can't true up a wheel, learn that first. If you see a cheap or free wheel at a coop or on the curb in the garbage, grab it and try to learn truing up wheels from that.

A good tutorial on wheel building at:

https://www.sheldonbrown.com/wheelbuild.html

I worked in a bike shop decades ago. We did not have a lot of extra truing stands around, so I learned how to true up wheels in the bike frame. I still do not have a truing stand and have no real need for one. A couple of my wheels I had a friend that volunteers time at a bike charity to check the tension on my spokes, I do not have a tension gauge. I think for a beginner it is probably adequate to get the spokes as tight as they are on similar wheels by feel, but getting a gauge or access to one would be better, you be the judge on that.

If you build up a wheel for that bike, that bike has rim brakes. Consider paying a couple extra dollars to get a hub that can also work on disc brakes, that makes the wheel more likely to be used on another bike if you trade up later. And for that reason, I suggest you put your old wheel from that bike in storage in case you sell that bike later, you can keep the complete new wheel. But do not forget you have the old wheel, a friend of mine had a new dynohub wheel built up four years ago, I advised him to have a complete new wheel built and keep his old front wheel in case he later got rid of the bike. He recently sold the bike but forgot he had the original wheel for it in storage, so he now has an old used wheel and no dyno fitted wheel, that was a big ooooops.

That said, the world is going to through axles. So, to truly future proof a wheel build, it would be best to build up a through axle wheel with adapter to work on a conventional quick release fork. But that is more costly. I built up another dynohub wheel in late winter for a rim brake bike. I paid about three Euros more for a disc hub, but I chose not to pay the much larger fee to buy the through axle dynohub and the adapter to use that on a rim brake bike.

Wiring up the lights, Peter White website has very good information on wiring. He is the USA distributor for some of the dynohubs and European light companies. That said, I usually buy that sort of thing from Germany internet sellers, much cheaper but they have a big up front shipping fee so you want to minimize the number of orders if possible.

Good luck.

#5

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,888

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2589 Post(s)

Liked 1,920 Times

in

1,204 Posts

Lots of questions in a short post, but I'll throw in a few answers and some more comments.

Is is worth it? If you're commuting regularly, a dyno light setup is da bomb. You'll never need to worry about "did I remember to charge my lights?" or "I wonder if the backup blinky batteries are still good" again.

TBH, I've never built a dyno wheel, but I've re-trued a couple when spokes loosened. Dyno drag on the bike is un-noticeable. Dyno "humps" on the truing stand are noticeable. It's slightly more difficult than working on a free-spinning hub.

Buy or build is probably going to be a wash, cost-wise, if you're starting from scratch on wheel tools. Labor on the one hand, truing stand, spoke wrench, and perhaps a tensiometer on the other. I'd buy and read a copy of Brandt's "The Bicycle Wheel" before starting. You can get most of the same information from Sheldon Brown's web site, but this old dinosaur has benefitted from having a physical book to refer to. (Although nowadays you may be able to get by with a tablet, though I'd hate to have to clean oil, grease and shellac from the tablet face.)

Building up your first wheel, you should probably plan on a couple evenings. The challenging parts are lacing the wheel, and then final true and tension balancing, and those take more concentration than anything else.

Which hub? I've got a Shimano and a Schmidt. I got the Schmidt for my backup (rain bike) commuter. The Schmidt is supposedly better for moisture intrusion, although the Shimano's probably seen similar amounts of rain. I haven't seen much difference in 10 and 9 years, respectively, between the two. The Shimano is marginally easier to disconnect when I have a flat.

Is is worth it? If you're commuting regularly, a dyno light setup is da bomb. You'll never need to worry about "did I remember to charge my lights?" or "I wonder if the backup blinky batteries are still good" again.

TBH, I've never built a dyno wheel, but I've re-trued a couple when spokes loosened. Dyno drag on the bike is un-noticeable. Dyno "humps" on the truing stand are noticeable. It's slightly more difficult than working on a free-spinning hub.

Buy or build is probably going to be a wash, cost-wise, if you're starting from scratch on wheel tools. Labor on the one hand, truing stand, spoke wrench, and perhaps a tensiometer on the other. I'd buy and read a copy of Brandt's "The Bicycle Wheel" before starting. You can get most of the same information from Sheldon Brown's web site, but this old dinosaur has benefitted from having a physical book to refer to. (Although nowadays you may be able to get by with a tablet, though I'd hate to have to clean oil, grease and shellac from the tablet face.)

Building up your first wheel, you should probably plan on a couple evenings. The challenging parts are lacing the wheel, and then final true and tension balancing, and those take more concentration than anything else.

Which hub? I've got a Shimano and a Schmidt. I got the Schmidt for my backup (rain bike) commuter. The Schmidt is supposedly better for moisture intrusion, although the Shimano's probably seen similar amounts of rain. I haven't seen much difference in 10 and 9 years, respectively, between the two. The Shimano is marginally easier to disconnect when I have a flat.

#6

Senior Member

Join Date: Apr 2021

Posts: 4,083

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 2332 Post(s)

Liked 2,097 Times

in

1,314 Posts

Is it worth it financially? No.

Very good wheel builders might charge $60 labor to build a wheel. I think minimally you need a stand, Jobst Brandt's book, and a tensiometer. All together will cost more than 60 bucks. Of course, one could make a truing stand, read online, and try to learn to tone of 125kg. I think most new DIY builders under tension wheels and reason a meter might be needed. You can get away without a dishing tool, just flip it in the stand.

Is it worth it from a personal satisfaction?

I used to build my own wheels and sometimes still do. I think a front wheel is easy to build. I get satisfaction knowing I can do all the repairs on my bike or can easily build up a new one. I have a few tools that will never pay for themselves. If your motivation is along those lines, yes, it is probably worth it. From a cost perspective? very doubtful

Very good wheel builders might charge $60 labor to build a wheel. I think minimally you need a stand, Jobst Brandt's book, and a tensiometer. All together will cost more than 60 bucks. Of course, one could make a truing stand, read online, and try to learn to tone of 125kg. I think most new DIY builders under tension wheels and reason a meter might be needed. You can get away without a dishing tool, just flip it in the stand.

Is it worth it from a personal satisfaction?

I used to build my own wheels and sometimes still do. I think a front wheel is easy to build. I get satisfaction knowing I can do all the repairs on my bike or can easily build up a new one. I have a few tools that will never pay for themselves. If your motivation is along those lines, yes, it is probably worth it. From a cost perspective? very doubtful

#7

Palmer

Join Date: Mar 2007

Location: Parts Unknown

Posts: 8,599

Bikes: Mike Melton custom, Alex Moulton AM, Dahon Curl

Mentioned: 37 Post(s)

Tagged: 0 Thread(s)

Quoted: 1657 Post(s)

Liked 1,803 Times

in

1,050 Posts

You'll earn your spurs building a true, well tensioned wheel using an old (1938-1982) Sturmey Dynohub.

#8

aka Tom Reingold

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,484

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7335 Post(s)

Liked 2,433 Times

in

1,420 Posts

I say do it! I now have two bikes with dynamo hubs.

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Likes For noglider:

#9

Senior Member

Building is not difficult. I have build several wheels. With and without dynamos. A truing stand is really handy when you do so. As for the dynamo: I have two bikes with Shimano dynamos and one bike with a SON 28. Yes the SON is quieter and has less resistance but it is not that noticeable. The expensive parts can be the spokes when you build yourself. My local bike store charged $1.50 per spoke. At 36 spokes this added up to over $60 with tax just for the spokes. Add the rim and a decent dynamo the price can easily exceed $150 for the whole wheel.

Also check ebay for complete wheels. I found a 700c wheel with a Shimano hub dynamo here in the US some time ago. It was brand new. The seller took it off a new bike. Came with a cheap front light and all the cables. I paid $70 for it. Yes the rim might look a bit different than the other rim but I did not care at that price.

Also check ebay for complete wheels. I found a 700c wheel with a Shimano hub dynamo here in the US some time ago. It was brand new. The seller took it off a new bike. Came with a cheap front light and all the cables. I paid $70 for it. Yes the rim might look a bit different than the other rim but I did not care at that price.

#10

aka Tom Reingold

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,484

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7335 Post(s)

Liked 2,433 Times

in

1,420 Posts

Building a wheel with a dynamo hub is a tiny, tiny bit more difficult than with a normal hub, only because it's heavier. Sometimes I hold the whole wheel up by one spoke, and I have to support the weight of the extra 500 grams. Not a big deal.

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

#11

Senior Member

This guy on ebay sells complete 700C wheels with hub dynamo for $125. It is hard to get a wheel built at that price. Free shipping out of CA.

https://www.ebay.com/itm/28417102098...4AAOSwcTJgGoH0

https://www.ebay.com/itm/28417102098...4AAOSwcTJgGoH0

Likes For Harhir:

#12

aka Tom Reingold

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,484

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7335 Post(s)

Liked 2,433 Times

in

1,420 Posts

This guy on ebay sells complete 700C wheels with hub dynamo for $125. It is hard to get a wheel built at that price. Free shipping out of CA.

https://www.ebay.com/itm/28417102098...4AAOSwcTJgGoH0

https://www.ebay.com/itm/28417102098...4AAOSwcTJgGoH0

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

#13

Zoom zoom zoom zoom bonk

Join Date: Sep 2006

Location: New Zealand

Posts: 4,624

Bikes: Giant Defy, Trek 1.7c, BMC GF02, Fuji Tahoe, Scott Sub 35, Kona Rove, Trek Verve+2

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 551 Post(s)

Liked 722 Times

in

366 Posts

This guy on ebay sells complete 700C wheels with hub dynamo for $125. It is hard to get a wheel built at that price. Free shipping out of CA.

https://www.ebay.com/itm/28417102098...4AAOSwcTJgGoH0

https://www.ebay.com/itm/28417102098...4AAOSwcTJgGoH0

#14

Junior Member

Jobst Brandt’s book is really great for understanding how bicycle wheels work, but as a novice wheel builder, I found Roger Musson’s book more useful. It’s a more practical step-by-step guide. I’m glad I have both, but if I had to pick one, Musson’s is easier to follow.

#15

Senior Member

There seems to be a consensus that the SON dynamo hubs are the best. I've built two wheels with Kasai dynamos and have had not problems. At $137 from Rivendell they are half the price of a SON dynamo.

Having a dynamo is so convenient; You always have light when you want it.

Having a dynamo is so convenient; You always have light when you want it.

#16

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,684 Times

in

2,508 Posts

I'm not sure why people keep posting in this thread, OP never came back.

#17

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,546

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 980 Post(s)

Liked 580 Times

in

398 Posts

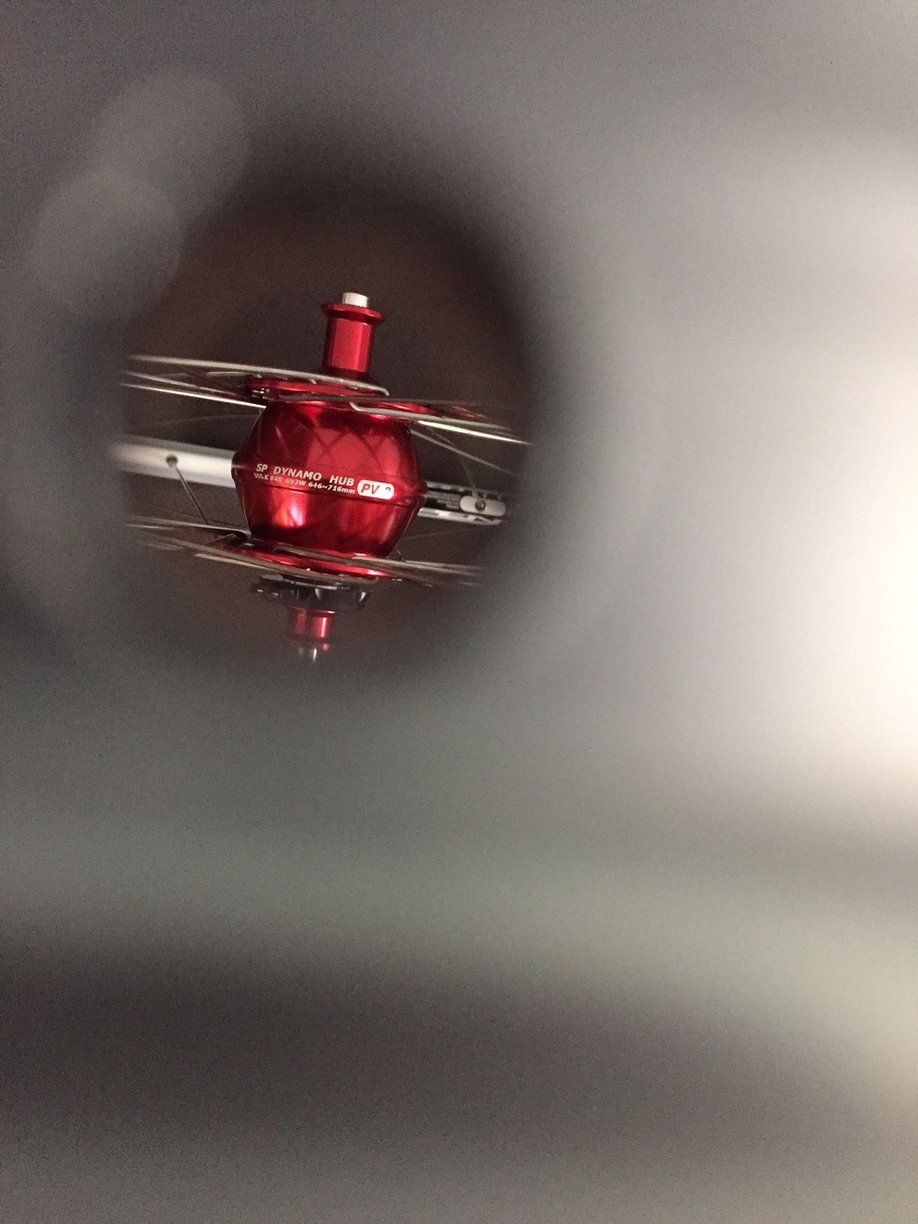

I started using dynohubs on my folding bikes before getting involved with building wheels with them. Eventually I built a wheel for my road bike using a Shutter Precision hub I got on sale (probably because it's red...). I had several thousand miles of good performance out of a later-generation Joule hub on my Tern folder. This hub was also made by SP, so when the rim wore out, I built a new wheel with the existing hub. I used a different rim, so new spokes were required. This hub has almost 10,000 miles on it now.

The reference I use mainly is Roger Musson's Professional Guide to Wheel Building. I also refer to Sheldon Brown, Jobst Brandt and Park Tools, but Musson's book is clear and straightforward and I've annotated my own printed-out copy over the years so I have my own tips and tricks at my fingertips. I don't build wheels often enough to remember all the details between builds!

Built this 7ooc wheel while laid up with a broken ankle. :-)

Hub maker's mark viewed through valve hole.

New rim and spokes on well-used SP hub.

Likes For sweeks:

#18

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,684 Times

in

2,508 Posts

Unless you want to build a number of wheels, even the minimum investment isn't worth it. My favorite wheel building story is when I was working as a mechanic in the '70s, someone came in and wanted to build a wheel. Which was borderline insane, because our charge to build a wheel was way too low. He said, "I'll be able to figure it out because I'm a mechanical engineering grad student." I told him I was a mechanical engineering undergrad, and that he would be back. Surprisingly, he came back when he couldn't figure it out. In his defense, this was before the availability of wheel building books and the internet.

Even with all the info out there nowadays, people don't really build very good wheels a lot of times. This is true of some people that work in bike shops.

Even with all the info out there nowadays, people don't really build very good wheels a lot of times. This is true of some people that work in bike shops.

#19

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,546

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 980 Post(s)

Liked 580 Times

in

398 Posts

For the record, I am not a mechanical engineer... I was a chemistry major.

#20

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,172

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 47 Post(s)

Tagged: 0 Thread(s)

Quoted: 3450 Post(s)

Liked 1,449 Times

in

1,130 Posts

A few years ago I was in a bike shop, I had my Rohloff bike with me.

A mechanic saw it and went over to look at the bike for several minutes. Then he asked why the wheel was built two cross, and before I could answer he said he was going to build a Rohloff wheel for a customer but was waiting for the spokes to come in as they did not stock those shorter spokes, and he of course would do it right with three cross.

I already knew the answer, but I asked the question, had he read the Rohloff instructions for wheel building? He said he had built wheels before, he did not need to read any instructions. I told him if he had read the instructions, he would know why it was two cross. I have no clue what he did, but I suspect that his customer has had lots of broken spokes.

I am not a mechanical engineer, or chemist I am a geological engineer (retired). I worked in a bike shop before I went to college, back in the pre-internet days of punch cards and punched paper tape. I am pretty good at trig, but the few times I thought about the math to figure out spoke lengths, I gave up.

Likes For Tourist in MSN:

#21

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,684 Times

in

2,508 Posts

I probably made the 2x/3x mistake on my last wheel, just made it 3x out of habit. We'll see how that works out. BITD, we always used 3x on high flange hubs and it worked fine, 4x also works fine. There is no doubt 2x is better though.

Most mechanical engineers are not particularly mechanically inclined. Half of the department works in thermal systems. The other half works on dynamics. Very few profs work in anything mechanically related. Structural design is either in the civil engineering department or the aero department. The mechanical engineering department had a "product dissection" lab for a while. It was pretty embarrassing, to be honest. I think at least 1/3 of the class was taking a bike apart and putting it back together. Lots of ruined tools, especially pedal wrenches.

Most mechanical engineers are not particularly mechanically inclined. Half of the department works in thermal systems. The other half works on dynamics. Very few profs work in anything mechanically related. Structural design is either in the civil engineering department or the aero department. The mechanical engineering department had a "product dissection" lab for a while. It was pretty embarrassing, to be honest. I think at least 1/3 of the class was taking a bike apart and putting it back together. Lots of ruined tools, especially pedal wrenches.

#22

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,172

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 47 Post(s)

Tagged: 0 Thread(s)

Quoted: 3450 Post(s)

Liked 1,449 Times

in

1,130 Posts

I probably made the 2x/3x mistake on my last wheel, just made it 3x out of habit. We'll see how that works out. BITD, we always used 3x on high flange hubs and it worked fine, 4x also works fine. There is no doubt 2x is better though.

Most mechanical engineers are not particularly mechanically inclined. Half of the department works in thermal systems. The other half works on dynamics. Very few profs work in anything mechanically related. Structural design is either in the civil engineering department or the aero department. The mechanical engineering department had a "product dissection" lab for a while. It was pretty embarrassing, to be honest. I think at least 1/3 of the class was taking a bike apart and putting it back together. Lots of ruined tools, especially pedal wrenches.

Most mechanical engineers are not particularly mechanically inclined. Half of the department works in thermal systems. The other half works on dynamics. Very few profs work in anything mechanically related. Structural design is either in the civil engineering department or the aero department. The mechanical engineering department had a "product dissection" lab for a while. It was pretty embarrassing, to be honest. I think at least 1/3 of the class was taking a bike apart and putting it back together. Lots of ruined tools, especially pedal wrenches.

I have worked with some mechanical engineers that seemed to be very good at what they did, but they were unable to fix their car door or something simple like that.

Likes For Tourist in MSN:

#23

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,461

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1822 Post(s)

Liked 3,366 Times

in

1,572 Posts

Steve in Peoria

#24

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,172

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 47 Post(s)

Tagged: 0 Thread(s)

Quoted: 3450 Post(s)

Liked 1,449 Times

in

1,130 Posts

That was half a century ago so I do not remember much in detail, but I think wheel building was reserved for about three mechanics that were keepers of the secret arts. Everybody trued wheels, but with the shortage of truing stands, most of use just used the bike frame or fork and rim brake pads as our truing stands. To this day I do not own or use a truing stand. The catalog did not have any spoke wrenches in it, but it had a wide variety of nipple grippers.

#25

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,461

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1822 Post(s)

Liked 3,366 Times

in

1,572 Posts

The bike shop I worked at was Wheel Goods in Minneapolis. If that is the catalog I think you are citing, the shop I worked at produced and sold stuff from that catalog. The owner of the store also had a number of distribution contracts with European manufacturers. If you bought a Raleigh in Iowa or a Gitane in Indiana, the owner of our shop made money. It was a big operation.

That was half a century ago so I do not remember much in detail, but I think wheel building was reserved for about three mechanics that were keepers of the secret arts. Everybody trued wheels, but with the shortage of truing stands, most of use just used the bike frame or fork and rim brake pads as our truing stands. To this day I do not own or use a truing stand. The catalog did not have any spoke wrenches in it, but it had a wide variety of nipple grippers.

That was half a century ago so I do not remember much in detail, but I think wheel building was reserved for about three mechanics that were keepers of the secret arts. Everybody trued wheels, but with the shortage of truing stands, most of use just used the bike frame or fork and rim brake pads as our truing stands. To this day I do not own or use a truing stand. The catalog did not have any spoke wrenches in it, but it had a wide variety of nipple grippers.

The first catalog that I had (and still have) was the 11th edition, dating to around the mid 70's. The catalog doesn't have prices printed in it. Instead, there was a separate price sheet.

The cover of this edition of the catalog:

The wheel building instructions were typical of the era... heavy on text, and light on graphics. Still, that was good enough, and I don't recall struggling with the concepts much. Here are the first two pages ......

Steve in Peoria