Which way to round to even-numbered length of spokes?

#1

Senior Member

Thread Starter

Join Date: Jul 2015

Posts: 586

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 120 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Which way to round to even-numbered length of spokes?

If my spoke calculation gives me 291mm, but I can only buy 290 or 292mm, which way is better to go, too high or too low?

Or does it not really matter?

Too high would leave more jagged edge of the spoke sticking out, but I'll have a double-walled rim, so it's not a huge concern unless the spoke breaks. I could also probably file that edge down when it's sticking out of the nipple.

Too high also means I might run out of thread to pull the spoke in more.

- Is it possible to buy a spoke with more then 10mm thread on it? Or is 10mm plenty, even for being 1mm off?

Too short means the spoke end might still be in the threads of the nipple, not sticking out. Plenty of thread on the spoke left. Is that a concern if there's spoke lock lube on it?

I'm kind of leaning towards 1mm too short being better. Or it might not really matter for a 1mm difference either way.

Another possibility might be to take a 292mm spoke and file off 1mm, then rethread it if needed. But then I'd need a threading tool which is over $100.

Or does it not really matter?

Too high would leave more jagged edge of the spoke sticking out, but I'll have a double-walled rim, so it's not a huge concern unless the spoke breaks. I could also probably file that edge down when it's sticking out of the nipple.

Too high also means I might run out of thread to pull the spoke in more.

- Is it possible to buy a spoke with more then 10mm thread on it? Or is 10mm plenty, even for being 1mm off?

Too short means the spoke end might still be in the threads of the nipple, not sticking out. Plenty of thread on the spoke left. Is that a concern if there's spoke lock lube on it?

I'm kind of leaning towards 1mm too short being better. Or it might not really matter for a 1mm difference either way.

Another possibility might be to take a 292mm spoke and file off 1mm, then rethread it if needed. But then I'd need a threading tool which is over $100.

#2

Senior Member

Join Date: May 2003

Location: Mountain Brook. AL

Posts: 4,002

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

Quoted: 303 Post(s)

Likes: 0

Liked 136 Times

in

104 Posts

Makes no difference really with a double walled rim. On a rear wheel you could use both, with the shorter ones on the drive

side and longer ones on the non-drive side

See also: https://www.bikeforums.net/bicycle-me...confusion.html

side and longer ones on the non-drive side

See also: https://www.bikeforums.net/bicycle-me...confusion.html

Last edited by sch; 02-27-17 at 09:41 AM.

#3

Senior Member

Join Date: Jul 2013

Location: Somewhere in TX

Posts: 2,266

Bikes: BH, Cervelo, Cube, Canyon

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 212 Post(s)

Likes: 0

Liked 6 Times

in

6 Posts

I usually round down because the spokes I use will stretch about 1mm at full tension.

However, I have almost 5mm of extra nipple thread with the nipples I use, so it really doesn't matter. If my spoke lengths are within 4mm for the whole wheel, I just order one spoke length.

However, I have almost 5mm of extra nipple thread with the nipples I use, so it really doesn't matter. If my spoke lengths are within 4mm for the whole wheel, I just order one spoke length.

#4

Senior Member

Join Date: Mar 2008

Posts: 8,688

Mentioned: 46 Post(s)

Tagged: 0 Thread(s)

Quoted: 1074 Post(s)

Liked 295 Times

in

222 Posts

Well...

Do you know where in the nipple you're aiming for?

Bottom of screwdriver slot - 1 mm extra is fine.

slight risk of trouble with an 1.5 mm spoke on the DS.

Flush with nipple head - still likely to be fine for 2.0 and 1.8 spokes. Almost guaranteed trouble with 1.5 mm DS spokes.

OTOH If your aim is flush with nipple head, then -1 won't be a problem.

If a spoke is a little long its always possible to add a washer under the nipple or drill out a few turns of thread.

Do you know where in the nipple you're aiming for?

Bottom of screwdriver slot - 1 mm extra is fine.

slight risk of trouble with an 1.5 mm spoke on the DS.

Flush with nipple head - still likely to be fine for 2.0 and 1.8 spokes. Almost guaranteed trouble with 1.5 mm DS spokes.

OTOH If your aim is flush with nipple head, then -1 won't be a problem.

If a spoke is a little long its always possible to add a washer under the nipple or drill out a few turns of thread.

#7

Really Old Senior Member

On a double wall rim, I round up, since a "bit" long won't matter.

You have about 2mm more above the screw driver slot before running out of threads.

The NDS spoke will protrude less, but it also has less tension, so IF it's a TINY bit short, that's the side you want it on.

You have about 2mm more above the screw driver slot before running out of threads.

The NDS spoke will protrude less, but it also has less tension, so IF it's a TINY bit short, that's the side you want it on.

#8

Senior Member

Thread Starter

Join Date: Jul 2015

Posts: 586

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 120 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

"So if your objective is to have at least that protrusion, you would always round up. "

It's looking like it's not going to matter either way. Personal preference.

I'm leaning towards rounding up.

If the calcuations give me this....

290.8 NDS

289.4 DS

... then 290 and 292mm. That happens to be what I already bought for the 32 spoke wheel I'm on now.

I did think the spokes for a 36 wheel would be slightly shorter. It's less of a difference than I thought, maybe 2mm (whatever it is, I don't care what the current wheel perfect spoke length is now since my current wheel is on death row).

I did think the spokes for a 36 wheel would be slightly shorter. It's less of a difference than I thought, maybe 2mm (whatever it is, I don't care what the current wheel perfect spoke length is now since my current wheel is on death row).I think a lot of my spokes already protrude just a little. That's been fine. For the inner tube getting punctured, I was thinking a spoke would have to go through the second rim (doubtful? but possible if it's all lined up) but then it also has to go through the rim tape. I imagine the most a broken spoke would do is tap on the rim tape. And then I shouldn't have any broken spokes if it's a wheel build with all new parts and everything is trued and dished.

That could give me the option of using a washer too if I really didn't like how it stuck out.

#9

Senior Member

Join Date: Dec 2015

Location: San Diego

Posts: 702

Bikes: 1978 Bruce Gordon, 1977 Lippy, 199? Lippy tandem, Bike Friday NWT, 1982 Trek 720, 2012 Rivendell Atlantis, 1983 Bianchi Specialissima?

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 345 Post(s)

Liked 174 Times

in

106 Posts

Do yourself a favor and get ONE of the several different wheel building guides that are out there and follow it step by step. You will wind up with a fine wheel.

#10

Senior Member

Join Date: Jul 2013

Location: Somewhere in TX

Posts: 2,266

Bikes: BH, Cervelo, Cube, Canyon

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 212 Post(s)

Likes: 0

Liked 6 Times

in

6 Posts

The slotted nipples are so 1980. DT, Sapim, Pillar, and CN all make square drive or torx nipples that will work on all but the shallowest of rims. They will let you go about 4mm past the minimum, which is 8 turns, and are only limited when the unthreaded portion of the spoke bottoms out on the nipple threads.

#11

Senior Member

Join Date: Nov 2010

Location: Deep South

Posts: 1,335

Bikes: Cannondale SR's and ST's from the '80's

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 340 Post(s)

Likes: 0

Liked 46 Times

in

20 Posts

Why not purchase from a source that will cut to order in 1mm increments??

Rounding to the next mm is seldom a problem.

Rounding to the next mm is seldom a problem.

#12

bike whisperer

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,537

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1523 Post(s)

Liked 716 Times

in

508 Posts

If using brass nipples, round down. If using ally, round up.

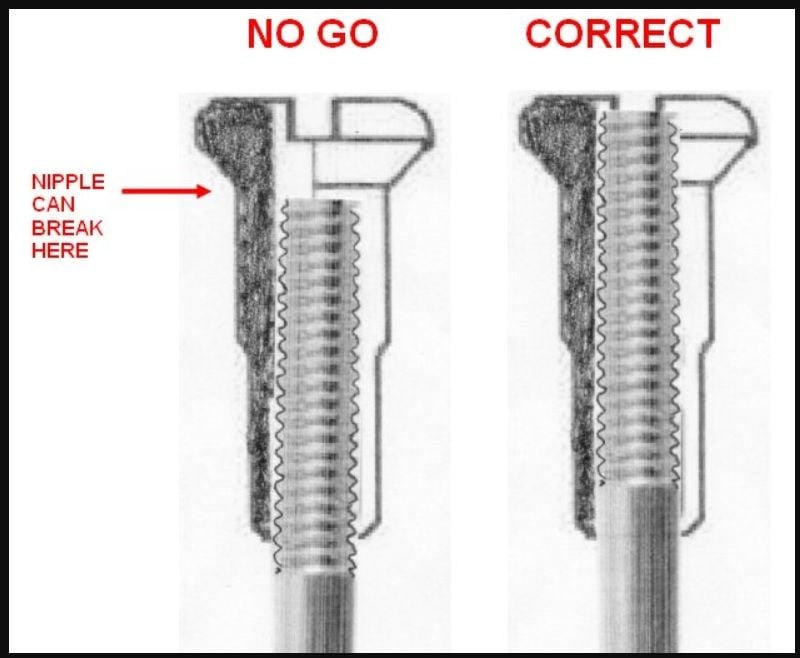

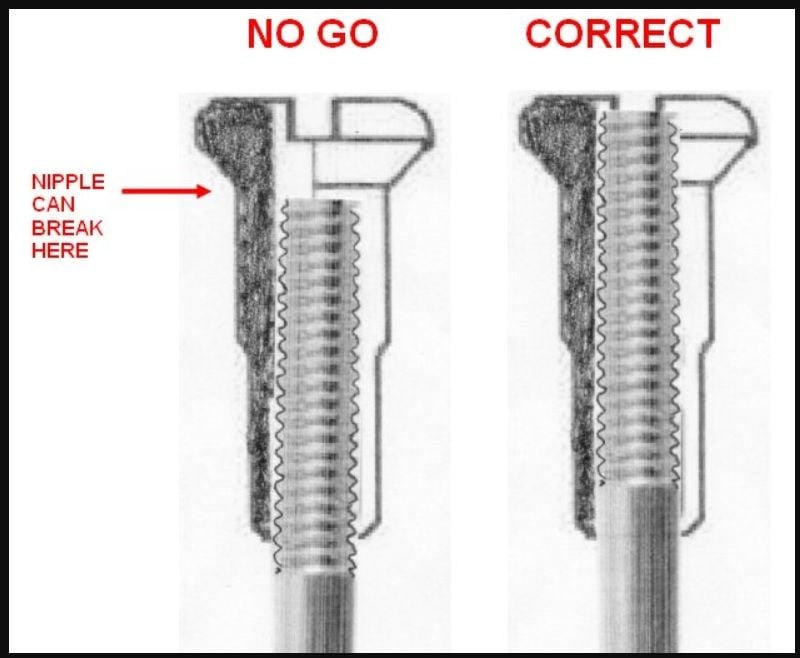

The two bad things you're trying to avoid are, being too short to make it through the head so the nipple doesn't break, and running out of thread.

A brass nipple is less likely to break if the spoke's a little short, and if you run out of thread in an ally nipple, you can just mash it for a thread or two, which will help them stay tight.

The two bad things you're trying to avoid are, being too short to make it through the head so the nipple doesn't break, and running out of thread.

A brass nipple is less likely to break if the spoke's a little short, and if you run out of thread in an ally nipple, you can just mash it for a thread or two, which will help them stay tight.

__________________

Sheldon Brown's bike info ~~~ Park Tools repair help

Half-step triple, using double gear ~~~ 6400 STI rebuild walkthrough ~~~ Want 8/9/10s @126mm OLD? OCR. ~~~ Shimano cassette body overhaul ~~~ Ergopower Escape wear repair ~~~ PSA: drivetrain wear

List of US/Canada bike co-ops ~~~ Global list

Sheldon Brown's bike info ~~~ Park Tools repair help

Half-step triple, using double gear ~~~ 6400 STI rebuild walkthrough ~~~ Want 8/9/10s @126mm OLD? OCR. ~~~ Shimano cassette body overhaul ~~~ Ergopower Escape wear repair ~~~ PSA: drivetrain wear

List of US/Canada bike co-ops ~~~ Global list

#13

Senior Member

Join Date: Apr 2010

Location: Mountain View, CA USA and Golden, CO USA

Posts: 6,341

Bikes: 97 Litespeed, 50-39-30x13-26 10 cogs, Campagnolo Ultrashift, retroreflective rims on SON28/PowerTap hubs

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 550 Post(s)

Liked 325 Times

in

226 Posts

You're probably better off with longer spokes if you measured your rims, your calculator is aiming for the bottom of the nipple slot, and either you aren't using 1.5mm spokes or the calculator accounted for 1mm of stretch.

In that situation, 1mm extra means they'll end at the top of the nipple with 1.5mm of thread remaining before they bottom, and leave almost 2mm extra so you don't break nipples because they don't reach the head.

With a high spot in the rim (like at the joint), 1mm short of the slot can break nipples especially when they're made of alloy.

OTOH, with 1.5mm cross section drive side spokes you'll get about 1mm of stretch. If the calculator didn't account for that you'll only have 0.5mm before running out of threads drive side and front and would want to go 1mm shorter so with stretch they end at the slot bottom.

Another possibility might be to take a 292mm spoke and file off 1mm, then rethread it if needed. But then I'd need a threading tool which is over $100.

#14

Junior Member

Join Date: Jan 2015

Location: UK

Posts: 14

Bikes: Cervelo R5 Di2, Cervelo S5, Cervelo S1.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

If my spoke calculation gives me 291mm, but I can only buy 290 or 292mm, which way is better to go, too high or too low?

Or does it not really matter?

Too high would leave more jagged edge of the spoke sticking out, but I'll have a double-walled rim, so it's not a huge concern unless the spoke breaks. I could also probably file that edge down when it's sticking out of the nipple.

Too high also means I might run out of thread to pull the spoke in more.

- Is it possible to buy a spoke with more then 10mm thread on it? Or is 10mm plenty, even for being 1mm off?

Too short means the spoke end might still be in the threads of the nipple, not sticking out. Plenty of thread on the spoke left. Is that a concern if there's spoke lock lube on it?

I'm kind of leaning towards 1mm too short being better. Or it might not really matter for a 1mm difference either way.

Another possibility might be to take a 292mm spoke and file off 1mm, then rethread it if needed. But then I'd need a threading tool which is over $100.

Or does it not really matter?

Too high would leave more jagged edge of the spoke sticking out, but I'll have a double-walled rim, so it's not a huge concern unless the spoke breaks. I could also probably file that edge down when it's sticking out of the nipple.

Too high also means I might run out of thread to pull the spoke in more.

- Is it possible to buy a spoke with more then 10mm thread on it? Or is 10mm plenty, even for being 1mm off?

Too short means the spoke end might still be in the threads of the nipple, not sticking out. Plenty of thread on the spoke left. Is that a concern if there's spoke lock lube on it?

I'm kind of leaning towards 1mm too short being better. Or it might not really matter for a 1mm difference either way.

Another possibility might be to take a 292mm spoke and file off 1mm, then rethread it if needed. But then I'd need a threading tool which is over $100.

#15

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

I agree. round up. Spokes that do not have full thread engagement in the nip will cause the nip to fracture. True, the brass ones are less fragile. but I round UP to the next MM.

and I measure ERD and spokes. Don't trust published measurements you found on the internets

/markp

and I measure ERD and spokes. Don't trust published measurements you found on the internets

/markp

Likes For mpetry912:

#16

Junior Member

FWIW, he recommends rounding to the nearest 1mm, which would round both your 289.4 and 290.8 to 290.

#17

Newbie

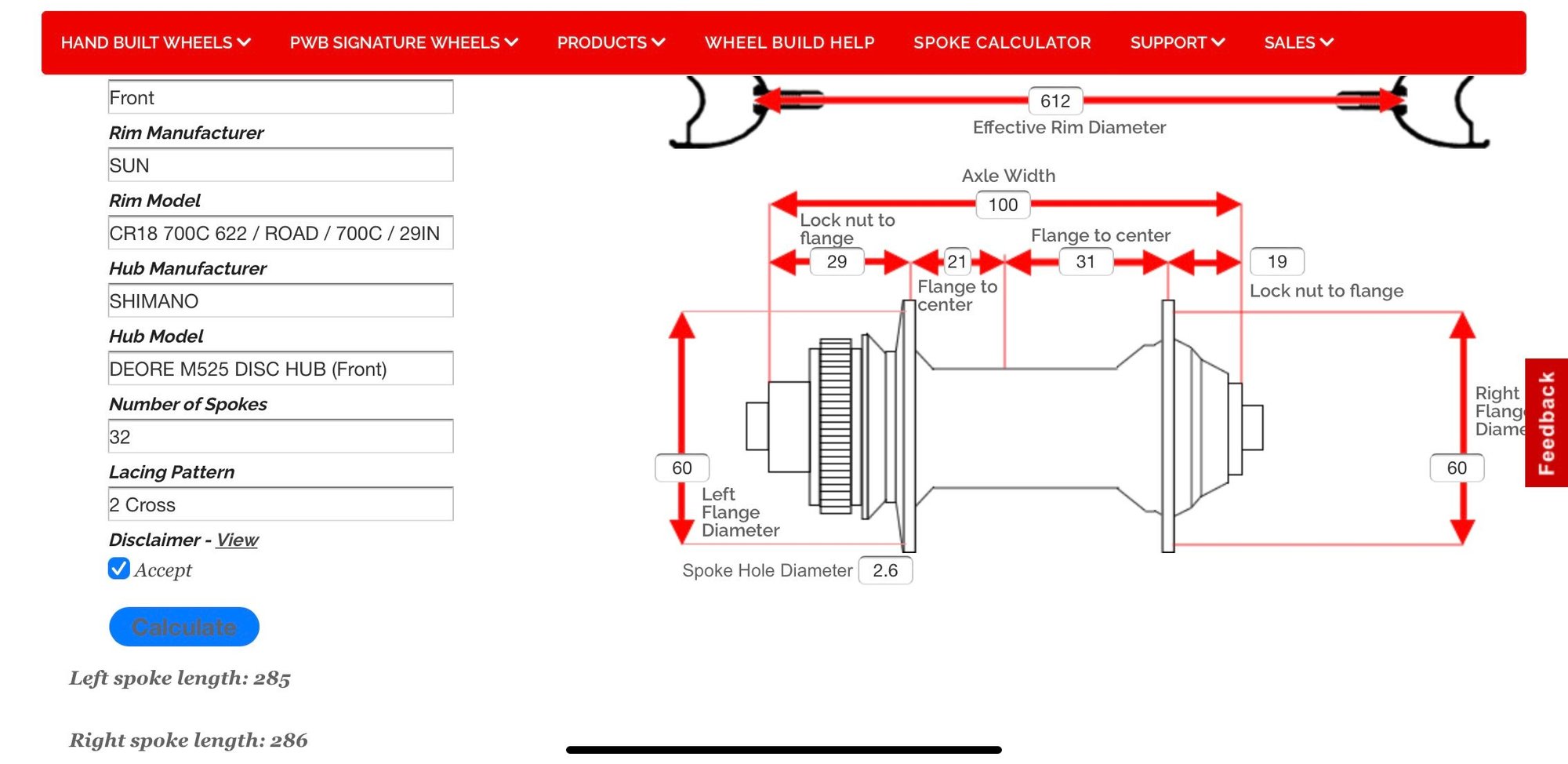

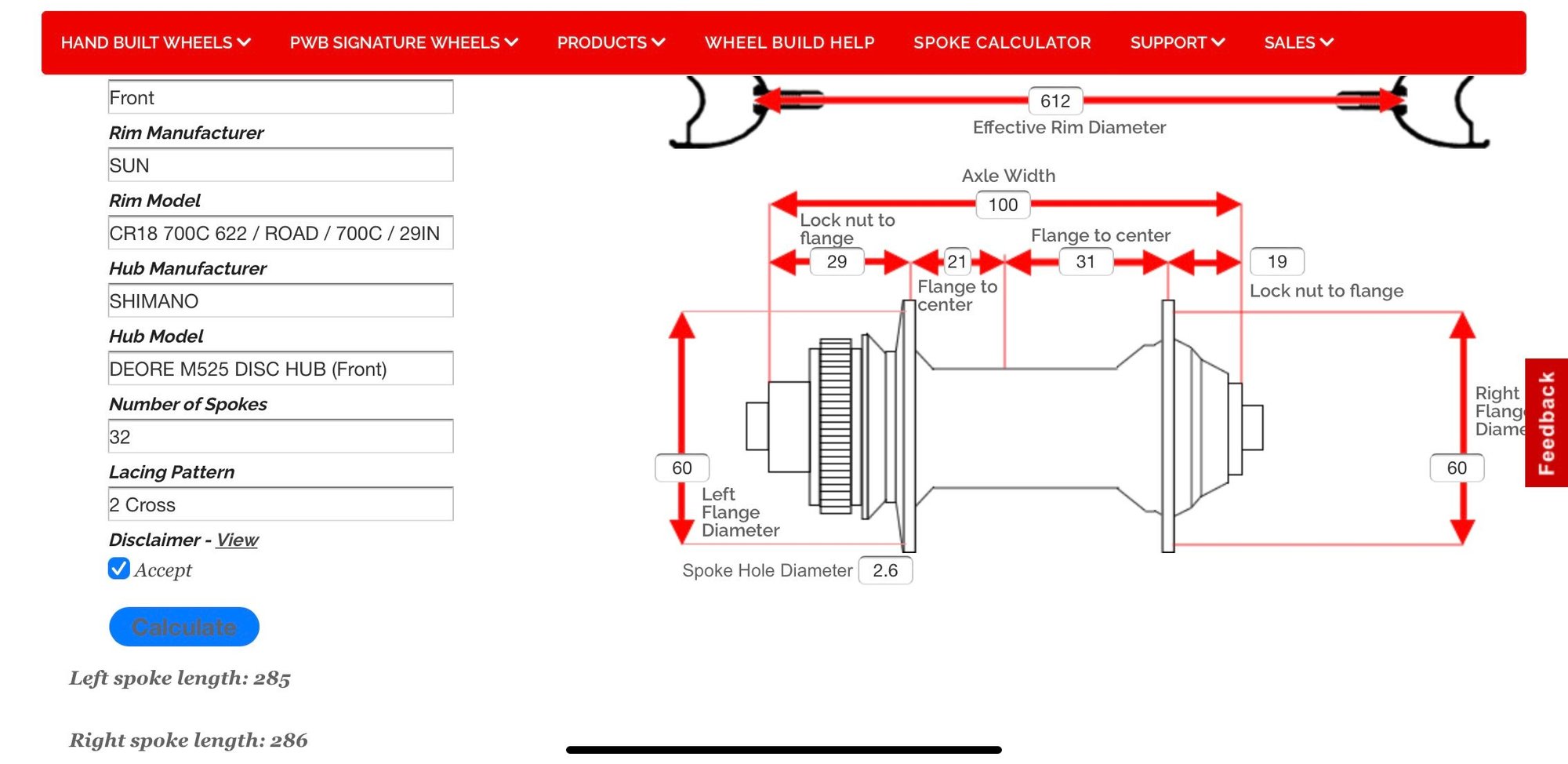

Based on the discussion here I'm assuming it would be unreasonable to think I could use 290mm spokes based on the following 2-cross & 3-cross calculations? By the way, I'm using 12mm brass nipples.

Thanks for any input!

Front 2-cross

Rear 2-cross

Front 3-cross

Rear 3-cross

Thanks for any input!

Front 2-cross

Rear 2-cross

Front 3-cross

Rear 3-cross

#18

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

#19

Newbie

Yea, that's kind of what I suspected... dang. I did my original calculations using 28 spokes instead of 32, duh.

In that case does anybody have a box of 100 14g 286mm j-bend spokes to trade me for my 290mm's? ;^)

In that case does anybody have a box of 100 14g 286mm j-bend spokes to trade me for my 290mm's? ;^)

#20

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,546

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 980 Post(s)

Liked 580 Times

in

398 Posts

This looks like the best advice in the thread. Iíve used Roger Mussonís wheel building ebook and found it reasonably priced and easy to follow. (In fact, Iím just about to lace up a pair of wheels with a new dynamo hub this morning.)

FWIW, he recommends rounding to the nearest 1mm, which would round both your 289.4 and 290.8 to 290.

FWIW, he recommends rounding to the nearest 1mm, which would round both your 289.4 and 290.8 to 290.

About "rounding to the nearest 1 mm"... 289.4 rounds to 289, and 290.8 rounds to 291.

#21

Senior Member

Join Date: Jul 2020

Location: Humboldt County, CA

Posts: 832

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 405 Post(s)

Likes: 0

Liked 430 Times

in

286 Posts

This generalizes. The most common way to arrive at the wrong answer is to start from the wrong question.

--Shannon

Thread

Thread Starter

Forum

Replies

Last Post

totalnewbie

Bicycle Mechanics

2

06-28-15 02:21 PM

speedevil

Bicycle Mechanics

9

09-23-13 11:46 PM

Brian7581

Bicycle Mechanics

13

12-17-11 06:00 PM