Stuck broken bolt - advice?

#1

Full Member

Thread Starter

Join Date: Apr 2019

Location: Denver Metro, CO

Posts: 392

Bikes: 1972 Fuji The Finest | 1990 Bianchi Giro | 1999 LeMond Buenos Aires

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 151 Post(s)

Liked 303 Times

in

134 Posts

Stuck broken bolt - advice?

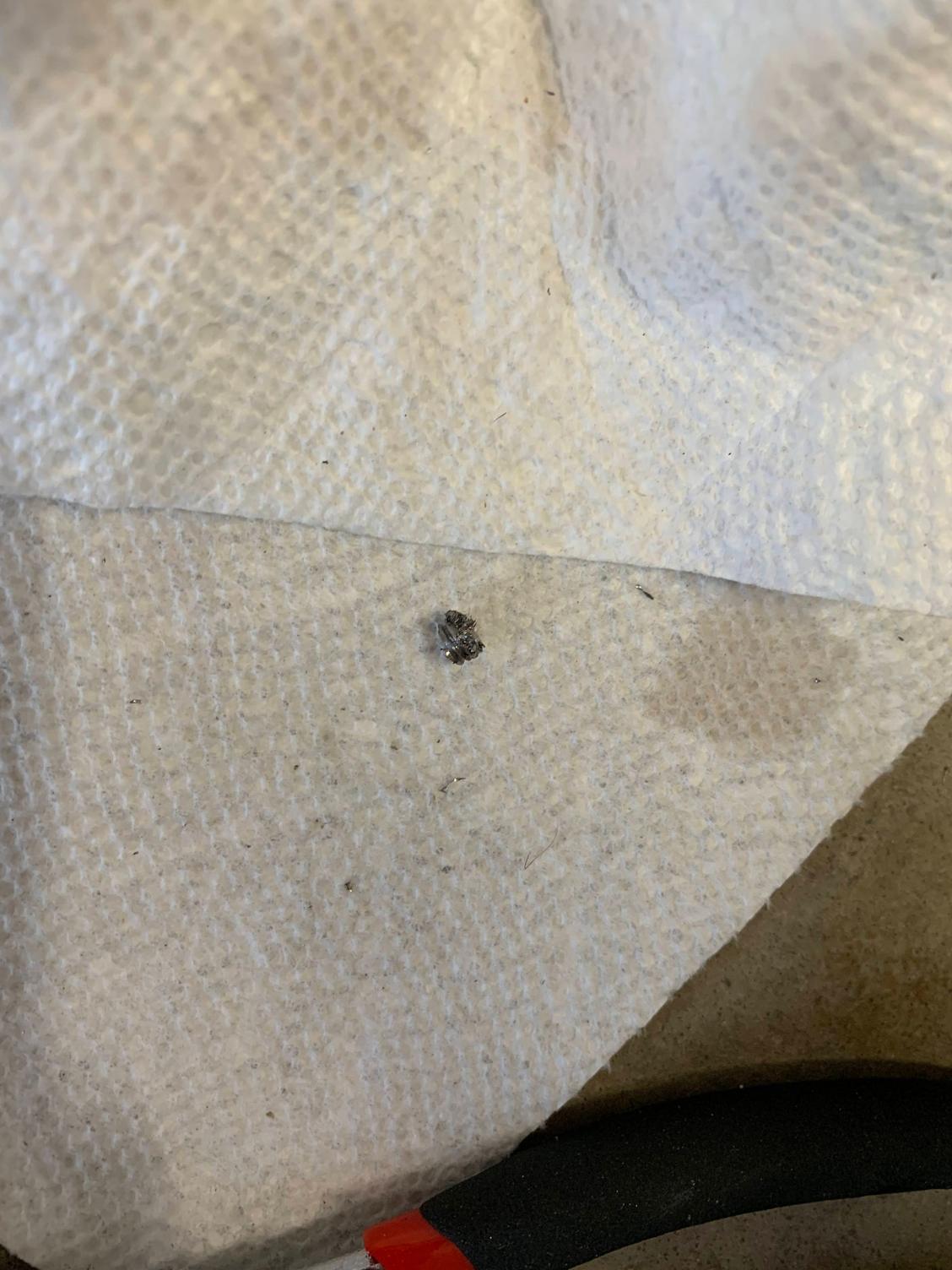

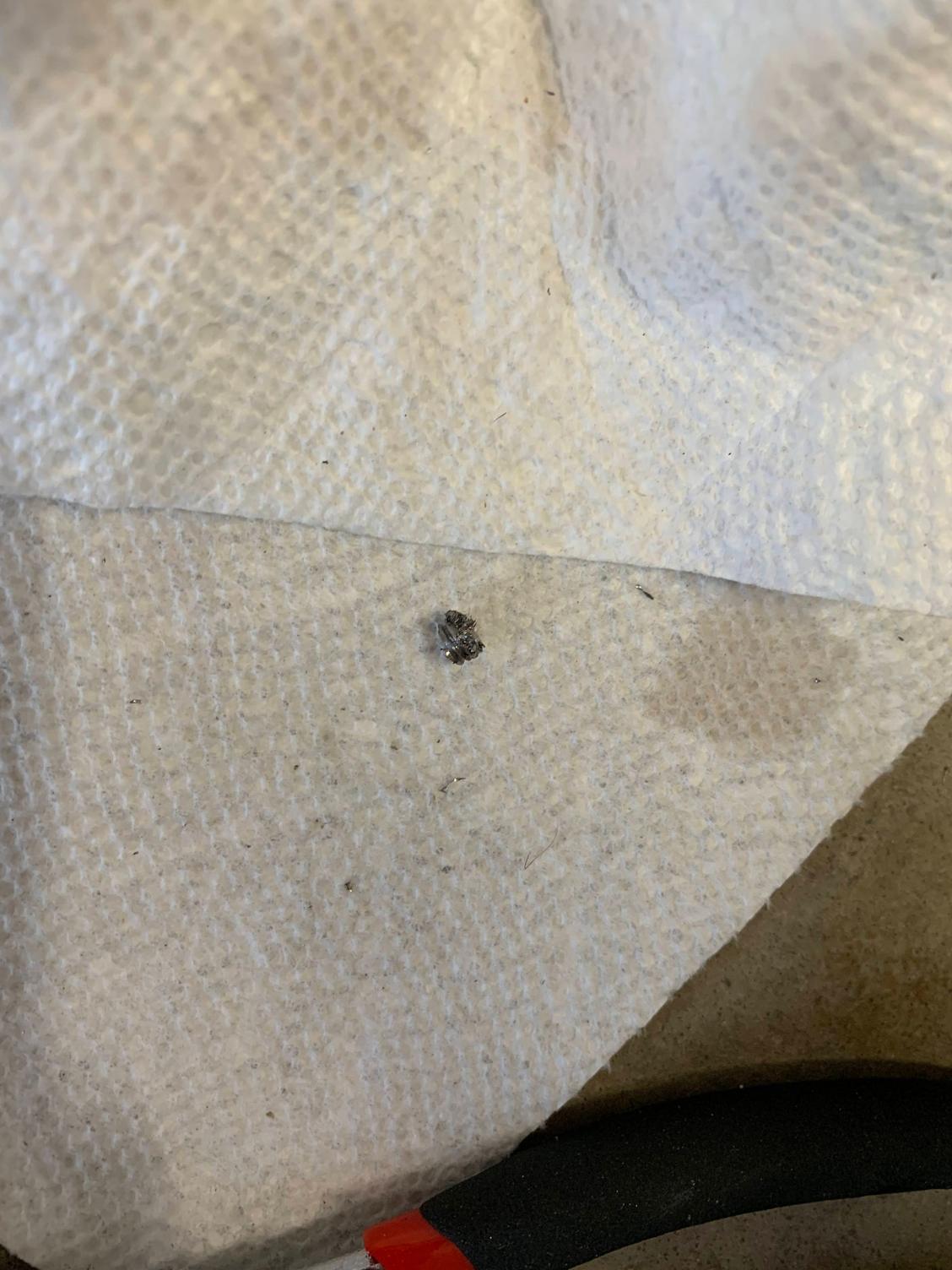

Although I should've known better, I went and snapped a bolt head removing a fender stay screw during fender fitting. I should've run the tap through it first, alas I did not and it was pretty tight and of course I decided to use my limited muscle instead of my limited brainpower.

Any ideas on getting this out? Just tried freeze-off penetrant and pliers/vice grips, as I expected I couldn't really get a grip on the end. I was thinking of filing a slot for a screwdriver attempt, a stripped screw kit where you kind of drill into it (can do one or the other, but not both), instead of a slot filing flats on the sides for pliers to grip, or if that all fails just drilling it out and resigning myself to nut and bolt on this side.

Any ideas on getting this out? Just tried freeze-off penetrant and pliers/vice grips, as I expected I couldn't really get a grip on the end. I was thinking of filing a slot for a screwdriver attempt, a stripped screw kit where you kind of drill into it (can do one or the other, but not both), instead of a slot filing flats on the sides for pliers to grip, or if that all fails just drilling it out and resigning myself to nut and bolt on this side.

#2

Senior Member

Join Date: Jul 2015

Location: Seal Beach Ca. On the right , next to Long Beach

Posts: 1,815

Bikes: 86' Centurion Ironman

Mentioned: 72 Post(s)

Tagged: 0 Thread(s)

Quoted: 628 Post(s)

Liked 315 Times

in

175 Posts

Looks like you still have a good amount of threads left . Why won't that ever happen to me ? Soake it with your favorite penetrant lube and let it sit for at least a day . I recently bought some Kroil , that stuff is good . Liquid Wrench is good too . After a good soaking , the methods you describe sound good . Also if you can make a setup in a drillpress and then use an Easy-Out that could work . Or just drill it out and re tap . If all fails , there are places that do what they call tap burning . I don't think you will have to resort to the latter . You got this !

Likes For markwesti:

#3

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,878

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4782 Post(s)

Liked 3,899 Times

in

2,536 Posts

Being lazy. I'd look long and hard at that bolt and my best, cleanest edged and sharpest toothed vise grips. If I went for it, it's a one shot deal. Side of grips against the dropout, a hard, bolt mashing squeeze, then turn. Might start by center-punching the bolt. After the visegrips, that might be difficult but pre-punched, you might be able to start a drill for an easy-out if the vise grips fail.

Edit: I see you've tried visegrips but not as aggressively as my approach. I'd squeeze until the teeth are beyond the threads and into the bolt shank. Ie, nothing subtle! And this calls for good vice grips. If yours aren't , don't.

Edit: I see you've tried visegrips but not as aggressively as my approach. I'd squeeze until the teeth are beyond the threads and into the bolt shank. Ie, nothing subtle! And this calls for good vice grips. If yours aren't , don't.

Last edited by 79pmooney; 02-08-22 at 11:36 AM.

Likes For 79pmooney:

#4

Senior Member

Join Date: May 2016

Location: Yucatán. México

Posts: 6,167

Bikes: 79 Trek 930 is back on the road, 80 Trek 414, 84 Schwinn Letour Luxe,87 Schwinn Prelude, 92 Schwinn Paramount PDG 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3160 Post(s)

Liked 1,814 Times

in

1,147 Posts

Do you have an easy-out?

Otherwise I'm with 79pmooney

Otherwise I'm with 79pmooney

Likes For seedsbelize2:

#5

Senior Member

Join Date: Dec 2005

Posts: 17,138

Mentioned: 481 Post(s)

Tagged: 0 Thread(s)

Quoted: 3800 Post(s)

Liked 6,614 Times

in

2,592 Posts

Might be easiest to file flats on two sides of that stub and then try with vise grips or an adjustable wrench or put the flats in your bench vise and turn the frame—all after a 24-hour soak in penetrating fluid.

Likes For nlerner:

#6

Senior Member

Join Date: May 2008

Location: Fredericksburg, Va

Posts: 9,578

Bikes: '65 Frejus TDF, '73 Bottecchia Giro d'Italia, '83 Colnago Superissimo, '84 Trek 610, '84 Trek 760, '88 Pinarello Veneto, '88 De Rosa Pro, '89 Pinarello Montello, '94 Burley Duet, 97 Specialized RockHopper, 2010 Langster, Tern Link D8

Mentioned: 73 Post(s)

Tagged: 0 Thread(s)

Quoted: 1606 Post(s)

Liked 2,209 Times

in

1,102 Posts

If you can find dry ice, apply then try to remove. Apply Kroil or equivalent then the next step would be an easy out. Then vice grips.

What does the other side look like?

What does the other side look like?

__________________

Bikes don't stand alone. They are two tired.

Bikes don't stand alone. They are two tired.

Likes For SJX426:

#7

Senior Member

I have easy out bits, but the alternative would be is to cut a line with a dremal and use a screwdriver

__________________

Semper fi

Semper fi

#8

Senior Member

Join Date: Jan 2019

Location: Toledo Ohio

Posts: 1,493

Bikes: 1964 Huffy Sportsman, 1972 Fuji Newest, 1973 Schwinn Super Sport (3), 1982 Trek 412, 1983 Trek 700, 1989 Miyata 1000LT, 1991 Bianchi Boardwalk, plus others

Mentioned: 21 Post(s)

Tagged: 0 Thread(s)

Quoted: 582 Post(s)

Liked 697 Times

in

393 Posts

If cutting a slot for a screwdriver, any old screwdriver will probably not work. For real tough screws I get out my gunsmithing screwdrivers. The tip has parallel sides at the slot. I think for some reason this is called hollow ground screwdrivers. A regular screwdriver has the sides forming a very slight wedge shape and like to lever out of the slot and damage it. The parallel side tips of the hollow ground screwdriver can apply way more torque if you can really lean into it.

Likes For sd5782:

#9

Edumacator

Join Date: Jan 2018

Location: Goose Creek, SC

Posts: 6,745

Bikes: '87 Crestdale, '87 Basso Gap, '92 Rossin Performance EL-OS, 1990 VanTuyl, 1980s Losa, 1985 Trek 670, 1982 AD SLE, 1987 PX10, etc...

Mentioned: 59 Post(s)

Tagged: 0 Thread(s)

Quoted: 2427 Post(s)

Liked 3,075 Times

in

1,940 Posts

Grandfather did this I remember...he built airplanes as a machinist/tech. maybe someone can vouch.

he found a drill that was well short of thread size and drill a hole...then he’d enlarge the hole and thin the walls of the bolt gradually and carefully...Then vice grip and twist gingerly. If there was enough metal left, it decompressed the bolt against the wall of threads.

he found a drill that was well short of thread size and drill a hole...then he’d enlarge the hole and thin the walls of the bolt gradually and carefully...Then vice grip and twist gingerly. If there was enough metal left, it decompressed the bolt against the wall of threads.

__________________

1987 Crest Cannondale, 1987 Basso Gap, 1992 Rossin Performance EL, 1990ish Van Tuyl, 1985 Trek 670, 1982 AD SLE, 2003 Pinarello Surprise, 1990ish MBK Atlantique, 1987 Peugeot Competition, 1987 Nishiki Tri-A, 1981 Faggin, 1996 Cannondale M500, 1984 Mercian, 1982 AD SuperLeicht, 1985 Massi (model unknown), 1988 Daccordi Griffe , 1989 Fauxsin MTB, 1981 Ciocc Mockba, 1992 Bianchi Giro, 1977 Colnago Super

1987 Crest Cannondale, 1987 Basso Gap, 1992 Rossin Performance EL, 1990ish Van Tuyl, 1985 Trek 670, 1982 AD SLE, 2003 Pinarello Surprise, 1990ish MBK Atlantique, 1987 Peugeot Competition, 1987 Nishiki Tri-A, 1981 Faggin, 1996 Cannondale M500, 1984 Mercian, 1982 AD SuperLeicht, 1985 Massi (model unknown), 1988 Daccordi Griffe , 1989 Fauxsin MTB, 1981 Ciocc Mockba, 1992 Bianchi Giro, 1977 Colnago Super

Likes For jdawginsc:

#10

Senior Member

Looks like there is room for vice grips. Soak with penetrating oil and have at it with the vice grips.

Likes For rjhammett:

#11

Senior Member

Join Date: Apr 2011

Location: Maryland, USA

Posts: 2,422

Bikes: Drysdale/Gitane/Zeus/Masi/Falcon/Palo Alto/Raleigh/Legnano

Mentioned: 34 Post(s)

Tagged: 0 Thread(s)

Quoted: 971 Post(s)

Liked 624 Times

in

399 Posts

Lot of tape to protect the finish of the dropout before filing, drilling, etc! Just my opinion...

I learned something new today!  And, even at Amazon, those are not cheap -- but I hate straight-slot screws specifically due to lack of grip, this might be a neat purchase.

And, even at Amazon, those are not cheap -- but I hate straight-slot screws specifically due to lack of grip, this might be a neat purchase.

If cutting a slot for a screwdriver, any old screwdriver will probably not work. For real tough screws I get out my gunsmithing screwdrivers. The tip has parallel sides at the slot. I think for some reason this is called hollow ground screwdrivers. A regular screwdriver has the sides forming a very slight wedge shape and like to lever out of the slot and damage it. The parallel side tips of the hollow ground screwdriver can apply way more torque if you can really lean into it.

And, even at Amazon, those are not cheap -- but I hate straight-slot screws specifically due to lack of grip, this might be a neat purchase.

And, even at Amazon, those are not cheap -- but I hate straight-slot screws specifically due to lack of grip, this might be a neat purchase.

__________________

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

#12

Senior Member

Join Date: Feb 2020

Posts: 2,810

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1105 Post(s)

Likes: 0

Liked 1,324 Times

in

781 Posts

If so then do the file-slot thing first, you want to turn the remainder of the bolt *inwards*, getting away from whatever's binding. Mashing the threads won't let you do that, and if the head-end threads are torn up file them so they won't bind.

If that fails and you decide to drill, cut and file the end of the bolt flush with the dropout, then punch and drill.

Likes For oneclick:

#13

Full Member

Thread Starter

Join Date: Apr 2019

Location: Denver Metro, CO

Posts: 392

Bikes: 1972 Fuji The Finest | 1990 Bianchi Giro | 1999 LeMond Buenos Aires

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 151 Post(s)

Liked 303 Times

in

134 Posts

Thanks for the advice all! Tried some of this last night. Had added more penetrating oil over the last couple days (didn't post until after I'd tried the freeze-out yesterday)

Vice grips just couldn't get enough purchase, either straight on or turned to the side sadly. Again wasn't using my brain, this bolt was way too tight in there to begin with. I guess it's my way back German heritage of getting something guten-tight.

Filed a slot with my thinnest needle file from the set. Tried it shallow and no-go, every screwdriver or bit I had slipped. Filed it down to almost the dropout. Sides just weren't up to the torque (tried turning either way) and they started bowing/twisting out.

EDIT: Seems obvious now, but I wonder if I could've grabbed a thinner M5 nut, carefully threaded it on the remainder, THEN used a small screwdriver bit. Nut would've maybe held the "ears" together. Something to try if there's a next time...

Filed off the slot just about flush and started drilling. Too many dulled and snapped bits from the good set over the 15 years or so I've had them, so I need to run to the store and I'll grab a set of bits for metal. I have a set of Easy-Out type removers, but was going to take a peek at what they have at the store too.

Planning to drill out incrementally and try the extractors I have to the extent possible. May try warming up the whole dropout with the heat gun (expanding under heat), then hitting the hollowed out bolt inside with freeze-off (contraction), then an extractor. Seems like maybe the best combo of everything at my disposal at this point. Due to how tight it was to start, I'm not holding my breath it wont just have to be drilled out completely. But I've got to try right? Oh the indignity of having one threaded mount and one smooth bore!

The opposite side of the snapped bolt is nearly flush with the dropout, not recessed, but not even a full thread showing.

Vice grips just couldn't get enough purchase, either straight on or turned to the side sadly. Again wasn't using my brain, this bolt was way too tight in there to begin with. I guess it's my way back German heritage of getting something guten-tight.

Filed a slot with my thinnest needle file from the set. Tried it shallow and no-go, every screwdriver or bit I had slipped. Filed it down to almost the dropout. Sides just weren't up to the torque (tried turning either way) and they started bowing/twisting out.

EDIT: Seems obvious now, but I wonder if I could've grabbed a thinner M5 nut, carefully threaded it on the remainder, THEN used a small screwdriver bit. Nut would've maybe held the "ears" together. Something to try if there's a next time...

Filed off the slot just about flush and started drilling. Too many dulled and snapped bits from the good set over the 15 years or so I've had them, so I need to run to the store and I'll grab a set of bits for metal. I have a set of Easy-Out type removers, but was going to take a peek at what they have at the store too.

Planning to drill out incrementally and try the extractors I have to the extent possible. May try warming up the whole dropout with the heat gun (expanding under heat), then hitting the hollowed out bolt inside with freeze-off (contraction), then an extractor. Seems like maybe the best combo of everything at my disposal at this point. Due to how tight it was to start, I'm not holding my breath it wont just have to be drilled out completely. But I've got to try right? Oh the indignity of having one threaded mount and one smooth bore!

The opposite side of the snapped bolt is nearly flush with the dropout, not recessed, but not even a full thread showing.

Last edited by AJI125; 02-09-22 at 07:26 AM.

#14

Senior Member

Join Date: May 2008

Location: Fredericksburg, Va

Posts: 9,578

Bikes: '65 Frejus TDF, '73 Bottecchia Giro d'Italia, '83 Colnago Superissimo, '84 Trek 610, '84 Trek 760, '88 Pinarello Veneto, '88 De Rosa Pro, '89 Pinarello Montello, '94 Burley Duet, 97 Specialized RockHopper, 2010 Langster, Tern Link D8

Mentioned: 73 Post(s)

Tagged: 0 Thread(s)

Quoted: 1606 Post(s)

Liked 2,209 Times

in

1,102 Posts

I was hoping some ID thread would be showing that a tap could be applied. Slow and easy at this point.

__________________

Bikes don't stand alone. They are two tired.

Bikes don't stand alone. They are two tired.

#15

Senior Member

Join Date: Sep 2011

Location: Baltimore MD

Posts: 3,330

Bikes: '72 Motobecane Grand Record, '72 Gitane tandem, '72 Raleigh Super Course, '73 Raleigh Gran Sport, '73 Colnago Super, '76 Fiorelli Coppi, '78 Raleigh SBDU Team Pro, '78 Trek 930, '81 Holdsworth Special 650B, '86 Masi GC, ’94 Bridgestone RB-T

Mentioned: 67 Post(s)

Tagged: 0 Thread(s)

Quoted: 786 Post(s)

Liked 516 Times

in

280 Posts

This worked for me with a broken off dropout adjustor screw. I wore a highly magnifying visor (to best center bit on bolt), and used new carbide bits. By the last bit, the remaining threads just fell out. I think the heat from drilling helps loosen things.

__________________

The man who dies with the most toys…is dead. - Rootboy

The man who dies with the most toys…is dead. - Rootboy

#17

Full Member

Thread Starter

Join Date: Apr 2019

Location: Denver Metro, CO

Posts: 392

Bikes: 1972 Fuji The Finest | 1990 Bianchi Giro | 1999 LeMond Buenos Aires

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 151 Post(s)

Liked 303 Times

in

134 Posts

Yeah my thought (after the fact) was file the slot, then thread on the nut to stabilize the sides of the slot, then try to unscrew. I did see some of those welding ideas but figured my skills of JB weld, solder, etc wouldn't be up to the task.

#18

Senior Member

Join Date: Jul 2008

Location: 25 miles northwest of Boston

Posts: 29,545

Bikes: Bottecchia Sprint, GT Timberline 29r, Marin Muirwoods 29er, Trek FX Alpha 7.0

Mentioned: 112 Post(s)

Tagged: 0 Thread(s)

Quoted: 5222 Post(s)

Liked 3,574 Times

in

2,338 Posts

left hand drill bit

straight fluted extractor

proper tap wrench

when you're done you want this in your hand

good luck!

straight fluted extractor

proper tap wrench

when you're done you want this in your hand

good luck!

Likes For rumrunn6:

#19

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,490

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2738 Post(s)

Liked 3,379 Times

in

2,044 Posts

If it's a stainless screw they don't drill easy.

https://ttp-hard-drills.com/drilling-stainless-steel/

https://ttp-hard-drills.com/drilling-stainless-steel/

Likes For dedhed:

#20

Full Member

Thread Starter

Join Date: Apr 2019

Location: Denver Metro, CO

Posts: 392

Bikes: 1972 Fuji The Finest | 1990 Bianchi Giro | 1999 LeMond Buenos Aires

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 151 Post(s)

Liked 303 Times

in

134 Posts

Stainless indeed doesn't drill easy! Took an hour off work (work from home helps) since I was trying freeze out in the garage, and the kids rooms are above the garage (so at night, gotta stay closed).

Took a long time to drill through with the 1/16" bit. Removed a lot, to clean and add some 3in1 as lube (maybe wrong choice?). Actually broke one 1/16" when I was adjusting my position (angle/pressure?). But cobalt bits got through there eventually. Stepping up size went nice and quick. Alignment was pretty good for eyeballing it.

Tried extractors with no luck until after I drilled 9/64" (3.6mm), and the second smallest "easy out" extractor pulled out the first half! Gotta figure out what to do with the back half but so far so good. Looks like it's maybe even broken through so maybe it'll come out easy or I can run a tap through - had a conference call so had to run back inside but hopeful for this evening!

initial 1/16" hole

Back side 1/16" hole

Getting bigger...

Bigger rear side

Success for front half!

Removed chunk

Removed

Took a long time to drill through with the 1/16" bit. Removed a lot, to clean and add some 3in1 as lube (maybe wrong choice?). Actually broke one 1/16" when I was adjusting my position (angle/pressure?). But cobalt bits got through there eventually. Stepping up size went nice and quick. Alignment was pretty good for eyeballing it.

Tried extractors with no luck until after I drilled 9/64" (3.6mm), and the second smallest "easy out" extractor pulled out the first half! Gotta figure out what to do with the back half but so far so good. Looks like it's maybe even broken through so maybe it'll come out easy or I can run a tap through - had a conference call so had to run back inside but hopeful for this evening!

initial 1/16" hole

Back side 1/16" hole

Getting bigger...

Bigger rear side

Success for front half!

Removed chunk

Removed

Likes For AJI125:

#21

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,982

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26373 Post(s)

Liked 10,341 Times

in

7,185 Posts

...for a fender stay mount like that:

1. even if you do go off center and hit some of the threading on one side of the hole, it's usually not enough to matter much. The machine screw that holds that fender stay in place doesn't carry much load with a fender.

2. if you are mounting something that will carry a load, like a rack, and you're worried about the damaged threads, it's not a big deal to drill out the stay eye a size larger and re-tap it to fit a larger machine screw.

But yeah, I usually just assume that if a machine screw is in there tight enough that turning it snapped off the head, drilling is my best bet for removal. In the smaller bit sizes, those bits that are coated with miracle space age titanium nitride don't cost that much more, and seem to last longer in use for me.

1. even if you do go off center and hit some of the threading on one side of the hole, it's usually not enough to matter much. The machine screw that holds that fender stay in place doesn't carry much load with a fender.

2. if you are mounting something that will carry a load, like a rack, and you're worried about the damaged threads, it's not a big deal to drill out the stay eye a size larger and re-tap it to fit a larger machine screw.

But yeah, I usually just assume that if a machine screw is in there tight enough that turning it snapped off the head, drilling is my best bet for removal. In the smaller bit sizes, those bits that are coated with miracle space age titanium nitride don't cost that much more, and seem to last longer in use for me.

__________________

Likes For 3alarmer:

#22

Senior Member

Join Date: Jul 2008

Location: 25 miles northwest of Boston

Posts: 29,545

Bikes: Bottecchia Sprint, GT Timberline 29r, Marin Muirwoods 29er, Trek FX Alpha 7.0

Mentioned: 112 Post(s)

Tagged: 0 Thread(s)

Quoted: 5222 Post(s)

Liked 3,574 Times

in

2,338 Posts

Stainless indeed doesn't drill easy! Took an hour off work (work from home helps) since I was trying freeze out in the garage, and the kids rooms are above the garage (so at night, gotta stay closed).

Took a long time to drill through with the 1/16" bit. Removed a lot, to clean and add some 3in1 as lube (maybe wrong choice?). Actually broke one 1/16" when I was adjusting my position (angle/pressure?). But cobalt bits got through there eventually. Stepping up size went nice and quick. Alignment was pretty good for eyeballing it.

Tried extractors with no luck until after I drilled 9/64" (3.6mm), and the second smallest "easy out" extractor pulled out the first half! Gotta figure out what to do with the back half but so far so good. Looks like it's maybe even broken through so maybe it'll come out easy or I can run a tap through - had a conference call so had to run back inside but hopeful for this evening!

initial 1/16" hole

Back side 1/16" hole

Getting bigger...

Bigger rear side

Success for front half!

Removed chunk

Removed

Took a long time to drill through with the 1/16" bit. Removed a lot, to clean and add some 3in1 as lube (maybe wrong choice?). Actually broke one 1/16" when I was adjusting my position (angle/pressure?). But cobalt bits got through there eventually. Stepping up size went nice and quick. Alignment was pretty good for eyeballing it.

Tried extractors with no luck until after I drilled 9/64" (3.6mm), and the second smallest "easy out" extractor pulled out the first half! Gotta figure out what to do with the back half but so far so good. Looks like it's maybe even broken through so maybe it'll come out easy or I can run a tap through - had a conference call so had to run back inside but hopeful for this evening!

initial 1/16" hole

Back side 1/16" hole

Getting bigger...

Bigger rear side

Success for front half!

Removed chunk

Removed

#23

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,020

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 267 Post(s)

Tagged: 0 Thread(s)

Quoted: 4501 Post(s)

Liked 6,367 Times

in

3,663 Posts

Stainless indeed doesn't drill easy! Took an hour off work (work from home helps) since I was trying freeze out in the garage, and the kids rooms are above the garage (so at night, gotta stay closed).

Took a long time to drill through with the 1/16" bit. Removed a lot, to clean and add some 3in1 as lube (maybe wrong choice?). Actually broke one 1/16" when I was adjusting my position (angle/pressure?). But cobalt bits got through there eventually. Stepping up size went nice and quick. Alignment was pretty good for eyeballing it.

Tried extractors with no luck until after I drilled 9/64" (3.6mm), and the second smallest "easy out" extractor pulled out the first half! Gotta figure out what to do with the back half but so far so good. Looks like it's maybe even broken through so maybe it'll come out easy or I can run a tap through - had a conference call so had to run back inside but hopeful for this evening!

initial 1/16" hole

Back side 1/16" hole

Getting bigger...

Bigger rear side

Success for front half!

Removed chunk

Removed

Took a long time to drill through with the 1/16" bit. Removed a lot, to clean and add some 3in1 as lube (maybe wrong choice?). Actually broke one 1/16" when I was adjusting my position (angle/pressure?). But cobalt bits got through there eventually. Stepping up size went nice and quick. Alignment was pretty good for eyeballing it.

Tried extractors with no luck until after I drilled 9/64" (3.6mm), and the second smallest "easy out" extractor pulled out the first half! Gotta figure out what to do with the back half but so far so good. Looks like it's maybe even broken through so maybe it'll come out easy or I can run a tap through - had a conference call so had to run back inside but hopeful for this evening!

initial 1/16" hole

Back side 1/16" hole

Getting bigger...

Bigger rear side

Success for front half!

Removed chunk

Removed

And they have dedicated ones that are basically the same as but probably tougher.

Lisle 61980 screw extractor set and the like.

#25

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,630

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4677 Post(s)

Liked 5,790 Times

in

2,279 Posts

If push comes to shove and you end up damaging the threads, not all is lost.

I prefer not threading into those dropout eyelets, sometimes I drill out the threads. Best to use a bolt and nylok nut for that application, they'll never loose, and if they seize a hacksaw or dremel will remove them.

I prefer not threading into those dropout eyelets, sometimes I drill out the threads. Best to use a bolt and nylok nut for that application, they'll never loose, and if they seize a hacksaw or dremel will remove them.

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

Likes For gugie: