How to tell the frame's material

#1

Large Member ;)

Thread Starter

Join Date: Oct 2008

Location: Costa Mesa, CA

Posts: 379

Bikes: I currently own a Giant Brass 1 dirt jumping bike. I love it. I bought it December 1st, 2008.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

How to tell the frame's material

I am looking to buy a used steel road bike, but I don't know how to tell the difference between Steel, Aluminum, and Chromoly. I heard from a friend that Chromoly welds are nearly invisible, Aluminum welds are thin, and Steel welds are fat. Is this true? Will a magnet stick to Chromoly? Thank you.

#2

Decrepit Member

Hmmm... How can I answer your question, which is a quite reasonable one, without sounding like a kindergarten teacher?

All steels are alloys containing iron, carbon, and other elements like molybdenum, chromium, manganese, nickel, phosphorus, zirconium, vanadium, and others. The simplest steels are basic carbon alloys, and some very low end bikes are made of carbon steel tubing. Because carbon steel isn't particularly strong, the tubing is usually straight gauge rather than butted (butted means the tubing wall is thicker at the end than it is in the middle), and the tubing wall is usually fairly thick. So, carbon steel frames tend to be relatively heavy. A stronger steel alloy is chromium molybdenum (or, chromoly). Since chromoly is stronger than plain carbon steel, it can be drawn with thinner walls, particularly in the middle of the tube, resulting in weight savings. So, chromoly is steel; it's just stronger than carbon steel, so it can be made lighter. A magnet will stick to chromoly.

I think your friend, when he says steel welds are fat, is probably referring to a tube joining method called fillet brazing. It isn't welding, but uses brass filler to create a smooth relatively large radius joint between tubes. Brazing is done at a lower temperature than welding, and in a brazed joint the tubing itself doesn't approach a temperature which would melt it.

Welding, on the other hand, involves melting the tubes at the joint so the tubes essentially become one piece. Most welded bike frames today, whether steel, titanium, or aluminum, use TIG (Tungsten Inert Gas) welding. In TIG welding, a tungsten electrode heats the metal you are welding and gas (most commonly Argon) protects the weld puddle from airborne contaminants. TIG welding produces clean, precise welds on any metal.

This is an example of fillet brazed joints (these are by framebuilder Dave Kirk):

This seat tube cluster is a beautiful example of TIG welding (by framebuilder Carl Strong):

Hope this helps.

All steels are alloys containing iron, carbon, and other elements like molybdenum, chromium, manganese, nickel, phosphorus, zirconium, vanadium, and others. The simplest steels are basic carbon alloys, and some very low end bikes are made of carbon steel tubing. Because carbon steel isn't particularly strong, the tubing is usually straight gauge rather than butted (butted means the tubing wall is thicker at the end than it is in the middle), and the tubing wall is usually fairly thick. So, carbon steel frames tend to be relatively heavy. A stronger steel alloy is chromium molybdenum (or, chromoly). Since chromoly is stronger than plain carbon steel, it can be drawn with thinner walls, particularly in the middle of the tube, resulting in weight savings. So, chromoly is steel; it's just stronger than carbon steel, so it can be made lighter. A magnet will stick to chromoly.

I think your friend, when he says steel welds are fat, is probably referring to a tube joining method called fillet brazing. It isn't welding, but uses brass filler to create a smooth relatively large radius joint between tubes. Brazing is done at a lower temperature than welding, and in a brazed joint the tubing itself doesn't approach a temperature which would melt it.

Welding, on the other hand, involves melting the tubes at the joint so the tubes essentially become one piece. Most welded bike frames today, whether steel, titanium, or aluminum, use TIG (Tungsten Inert Gas) welding. In TIG welding, a tungsten electrode heats the metal you are welding and gas (most commonly Argon) protects the weld puddle from airborne contaminants. TIG welding produces clean, precise welds on any metal.

This is an example of fillet brazed joints (these are by framebuilder Dave Kirk):

This seat tube cluster is a beautiful example of TIG welding (by framebuilder Carl Strong):

Hope this helps.

Likes For Scooper:

#3

Large Member ;)

Thread Starter

Join Date: Oct 2008

Location: Costa Mesa, CA

Posts: 379

Bikes: I currently own a Giant Brass 1 dirt jumping bike. I love it. I bought it December 1st, 2008.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

That was the best answer I have ever received to a question. Thank you.

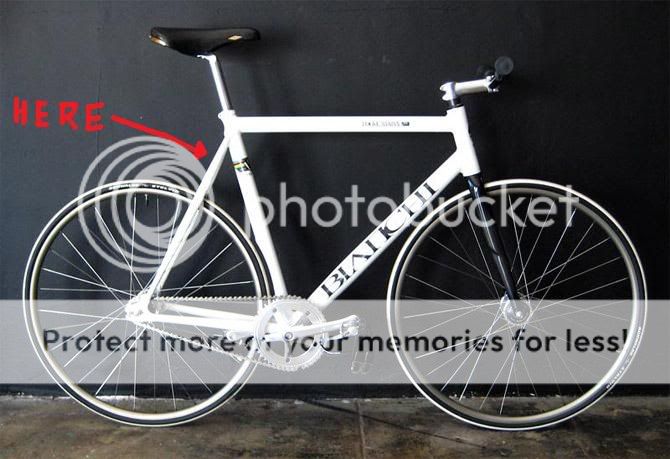

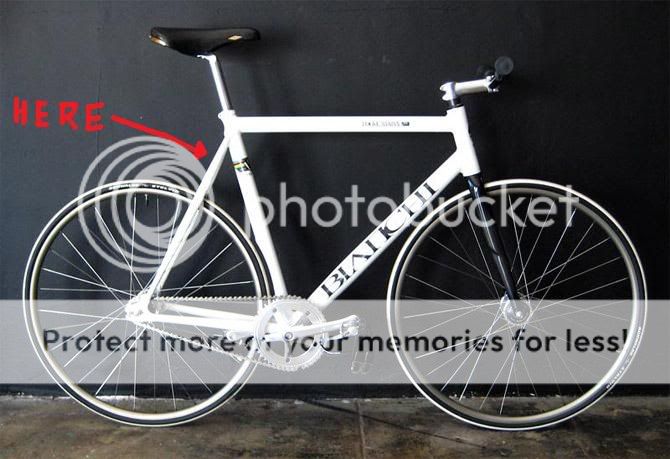

Now for another question: I have a small air cooled welder at my house that can (at the moment) only weld steel. I have practiced welding steel square tubing together, and made a nice big cube. Would I be able to use that welder to weld chromoly? I am wanting to attempt the double reduction drivetrain on a single speed road bike. Would the welds from that welder hold up to the stress? I was going to get a bottom bracket from any bike I could find and weld it here:

And by bottom bracket, I mean just as pictured. Maybe less of the tubes though:

I am going to switch the front chainring to the left side of the bike, and have a freewheel on the left side of the crank (which is in the newly welded bottom bracket). On the right side of the crank will be a chainring the size of the front one, and it will be chained to the freewheel that is attached to the back wheel. What do you guys think of my plan?

Now for another question: I have a small air cooled welder at my house that can (at the moment) only weld steel. I have practiced welding steel square tubing together, and made a nice big cube. Would I be able to use that welder to weld chromoly? I am wanting to attempt the double reduction drivetrain on a single speed road bike. Would the welds from that welder hold up to the stress? I was going to get a bottom bracket from any bike I could find and weld it here:

And by bottom bracket, I mean just as pictured. Maybe less of the tubes though:

I am going to switch the front chainring to the left side of the bike, and have a freewheel on the left side of the crank (which is in the newly welded bottom bracket). On the right side of the crank will be a chainring the size of the front one, and it will be chained to the freewheel that is attached to the back wheel. What do you guys think of my plan?

#4

Decrepit Member

I don't know anything about your welder or your welding skills, so I can't comment on your plan other than to say welding thin walled bicycle tubing without cooking the tubing is a learned skill that takes lots of practice.

As far as your gearing idea is concerned, IMHO it's a worthwhile challenge. This youtube video shows a derailleur equipped bike with an added crank similar to what I think you're considering.

https://www.youtube.com/watch?v=FgIL6eHHgZU

As far as your gearing idea is concerned, IMHO it's a worthwhile challenge. This youtube video shows a derailleur equipped bike with an added crank similar to what I think you're considering.

https://www.youtube.com/watch?v=FgIL6eHHgZU

#5

Large Member ;)

Thread Starter

Join Date: Oct 2008

Location: Costa Mesa, CA

Posts: 379

Bikes: I currently own a Giant Brass 1 dirt jumping bike. I love it. I bought it December 1st, 2008.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

#6

Newbie

Join Date: Dec 2020

Posts: 2

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

easy how to tell what metal a frame is made from ....

I am looking to buy a used steel road bike, but I don't know how to tell the difference between Steel, Aluminum, and Chromoly. I heard from a friend that Chromoly welds are nearly invisible, Aluminum welds are thin, and Steel welds are fat. Is this true? Will a magnet stick to Chromoly? Thank you.

or its painted or specialty coated or covered in stickers the tap touch ring method works easy enough mild high carbon steel rings a dull ting thumping sound chrome moly rings clear and true its much denser and thinner tubing for lighter weight frames it rings much clearer and sharper than mild hicarb steel and aluminum is easy to ring test its very very dull and may not even ring with a dull bong dong sound

some magnesium alloys with aluminum can ring depending on how its made cast or extruded or spun all light weight alloys usually will not ring unless hardened or annealed with a heat treating process . just a dull ting at best so the handiest tool to use a finger nail or marble or a hardened nut from an axle to tap the tubing right in the center so no guessing by looking closely at a nice weld trying to guess what the hell that metal is........ if it rings clear and true chrome moly if it is rather dull ding ting not ring its high carbon steel or a mild steel if its 6061 aluminum thump knock bong dull to nothing sound that dissipates rapidly those are the ost common types of tubing used for bike frames ... good luck

#7

Newbie

Join Date: Dec 2020

Posts: 2

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

as far as welding chrome moly steel it is heat treated so must be pre heated to make a proper strong weld and not over anneal the weld area and cause stress fractures or failure of the structure of the tubing distorting and embrittling those areas to the point of failure when loaded so a good weld is just that done right with all the right equipment and materials that you currently do not have at hand it appears many machine shops will do small spot jobs like what you need to have done to you frame call around google it yeehaw

#8

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,890

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4789 Post(s)

Liked 3,915 Times

in

2,546 Posts

OK the easy way if you don't know how too weld and identifying several types of welds that can appear very different on alloyed metals.

or its painted or specialty coated or covered in stickers the tap touch ring method works easy enough mild high carbon steel rings a dull ting thumping sound chrome moly rings clear and true its much denser and thinner tubing for lighter weight frames it rings much clearer and sharper than mild hicarb steel and aluminum is easy to ring test its very very dull and may not even ring with a dull bong dong sound

some magnesium alloys with aluminum can ring depending on how its made cast or extruded or spun all light weight alloys usually will not ring unless hardened or annealed with a heat treating process . just a dull ting at best so the handiest tool to use a finger nail or marble or a hardened nut from an axle to tap the tubing right in the center so no guessing by looking closely at a nice weld trying to guess what the hell that metal is........ if it rings clear and true chrome moly if it is rather dull ding ting not ring its high carbon steel or a mild steel if its 6061 aluminum thump knock bong dull to nothing sound that dissipates rapidly those are the ost common types of tubing used for bike frames ... good luck

or its painted or specialty coated or covered in stickers the tap touch ring method works easy enough mild high carbon steel rings a dull ting thumping sound chrome moly rings clear and true its much denser and thinner tubing for lighter weight frames it rings much clearer and sharper than mild hicarb steel and aluminum is easy to ring test its very very dull and may not even ring with a dull bong dong sound

some magnesium alloys with aluminum can ring depending on how its made cast or extruded or spun all light weight alloys usually will not ring unless hardened or annealed with a heat treating process . just a dull ting at best so the handiest tool to use a finger nail or marble or a hardened nut from an axle to tap the tubing right in the center so no guessing by looking closely at a nice weld trying to guess what the hell that metal is........ if it rings clear and true chrome moly if it is rather dull ding ting not ring its high carbon steel or a mild steel if its 6061 aluminum thump knock bong dull to nothing sound that dissipates rapidly those are the ost common types of tubing used for bike frames ... good luck

Welcome to the forum! I'm not a framebuilder. Retired engineer and have had 3 frames made for me and others modified.

Ben

Likes For 79pmooney:

#9

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

as far as welding chrome moly steel it is heat treated so must be pre heated to make a proper strong weld and not over anneal the weld area and cause stress fractures or failure of the structure of the tubing distorting and embrittling those areas to the point of failure when loaded so a good weld is just that done right with all the right equipment and materials that you currently do not have at hand it appears many machine shops will do small spot jobs like what you need to have done to you frame call around google it yeehaw

The cromoly itself is sometimes heat treated sometimes not but either way you just go ahead and weld it.

You can only weld it with TIG (and a fair bit of practice) because you need a high level of control because the metal is so thin.

Some low end bikes made of thicker carbon steel are actually MIG welded and this may be the lumpy welds the OP was talking about. If you have a cheap frame like that it's a good starting point for a tall bike or a cargo bike project etc and will easier to weld to.

#10

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,686 Times

in

2,509 Posts

Apparently it's not uncommon for recumbent bikes to be mig welded at least in places. I'm not sure why that is, but maybe they are using heavy wall tubing in certain spots.

#11

Senior Member

Join Date: Apr 2005

Location: Ann Arbor, MI

Posts: 16,866

Bikes: 1980 Masi, 1984 Mondonico, 1984 Trek 610, 1980 Woodrup Giro, 2005 Mondonico Futura Leggera ELOS, 1967 PX10E, 1971 Peugeot UO-8

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1854 Post(s)

Liked 661 Times

in

504 Posts

The OP original question was "How can I tell whether a given frame is made of steel, aluminum, or magnesium?" The most straightforward response (yeah, it's dead, but ... this is still important) is to note that even 10 years later, there are very few magnesium frames. Steel can be distinguished from aluminum by using a magnet. If a magnet pulls itself to the surface of the frame, it's a steel frame, period. If not it is almost certainly aluminum or carbon composite, not magnesium.

Reviewing the welds is great if you have that knowledge and skill, though my gut says it is either not possible or is error-prone.

Reviewing the welds is great if you have that knowledge and skill, though my gut says it is either not possible or is error-prone.

#12

Senior Member

Join Date: Apr 2005

Location: Ann Arbor, MI

Posts: 16,866

Bikes: 1980 Masi, 1984 Mondonico, 1984 Trek 610, 1980 Woodrup Giro, 2005 Mondonico Futura Leggera ELOS, 1967 PX10E, 1971 Peugeot UO-8

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1854 Post(s)

Liked 661 Times

in

504 Posts

You don't need to preheat cromoly when it's less than about 3mm thick, which is basically everything on a bike. I don't think anyone preheats when welding bike frames.

The cromoly itself is sometimes heat treated sometimes not but either way you just go ahead and weld it.

You can only weld it with TIG (and a fair bit of practice) because you need a high level of control because the metal is so thin.

Some low end bikes made of thicker carbon steel are actually MIG welded and this may be the lumpy welds the OP was talking about. If you have a cheap frame like that it's a good starting point for a tall bike or a cargo bike project etc and will easier to weld to.

The cromoly itself is sometimes heat treated sometimes not but either way you just go ahead and weld it.

You can only weld it with TIG (and a fair bit of practice) because you need a high level of control because the metal is so thin.

Some low end bikes made of thicker carbon steel are actually MIG welded and this may be the lumpy welds the OP was talking about. If you have a cheap frame like that it's a good starting point for a tall bike or a cargo bike project etc and will easier to weld to.

Last edited by Road Fan; 12-26-20 at 07:40 AM.

#13

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,054

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

Depends on what/how the welds are lumpy. Many feel that the "stack of dimes" weld bead is the perfect weld yet the bead is quite lumpy. Just that the lumps are specifically shaped. Some companies do some after welding filing/grinding of the bead and remove any lumps. Neither method says anything about weld penetration, undercutting or tube distortions though. Judging a weld from a photo of the joint's outsides is lacking in complete info and thus is only partially valid. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#14

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,686 Times

in

2,509 Posts

I don't know if you would call them lumpy, but aluminum welds aren't as smooth at welds on Ti or steel. Except for Cannondale-style cosmetic welds, which aren't that common.

#15

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

Perfectly good MIG welds just tend to look a bit more lumpy than TIG welds because the process is inherently a bit more messy and out of control.

Some people can do very nice MIG welds that almost look like TIG (and they do a bit of puddle manipulation to get the "stack of dimes" look).

But on low end bikes you will often see just regular MIG welds as you might get on a trolley jack or something. Nothing wrong with that, it's a good welding process for that wall thickness.

Some people can do very nice MIG welds that almost look like TIG (and they do a bit of puddle manipulation to get the "stack of dimes" look).

But on low end bikes you will often see just regular MIG welds as you might get on a trolley jack or something. Nothing wrong with that, it's a good welding process for that wall thickness.