3 cross pattern what's the right way?

#1

Junior Member

Thread Starter

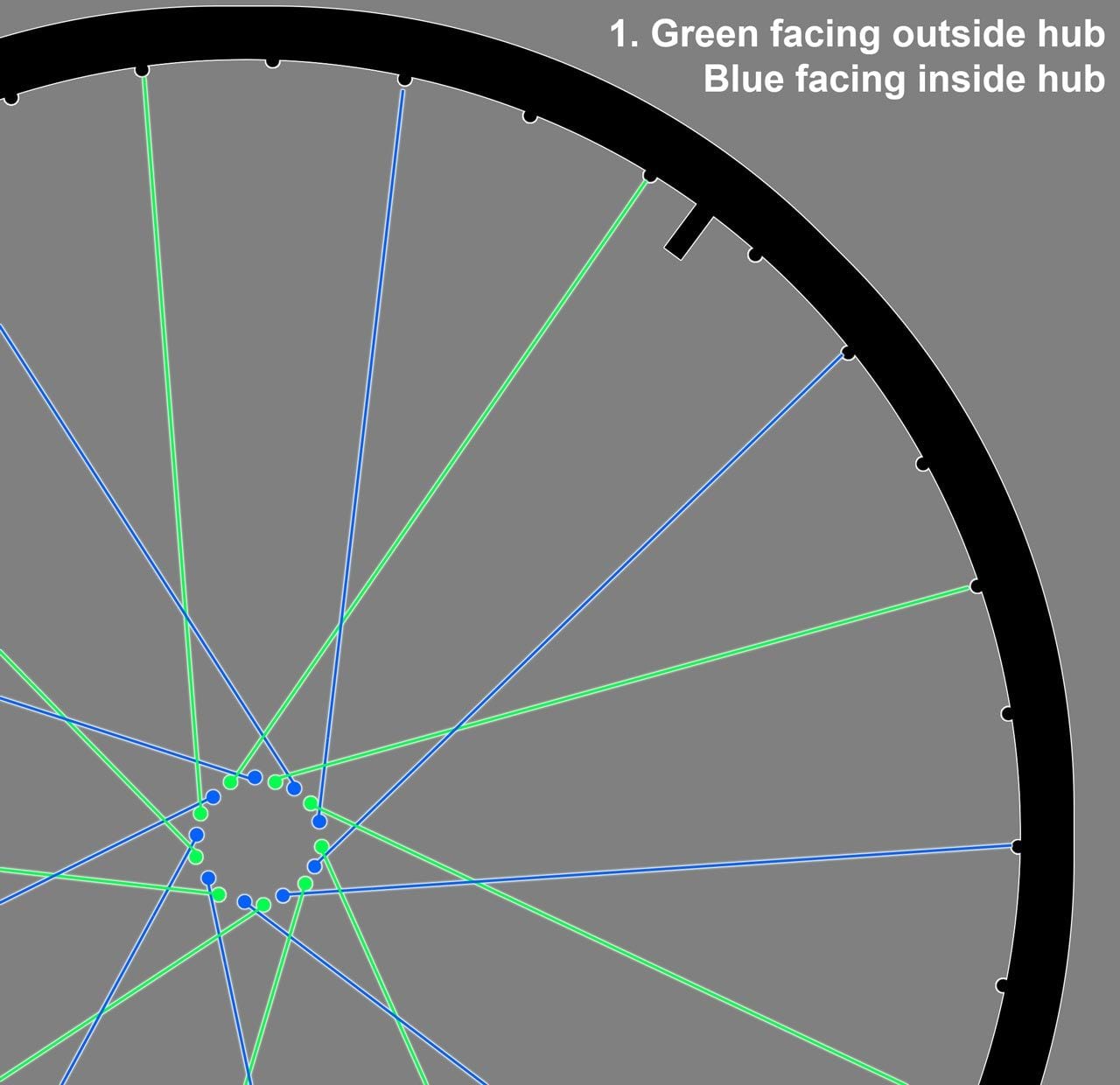

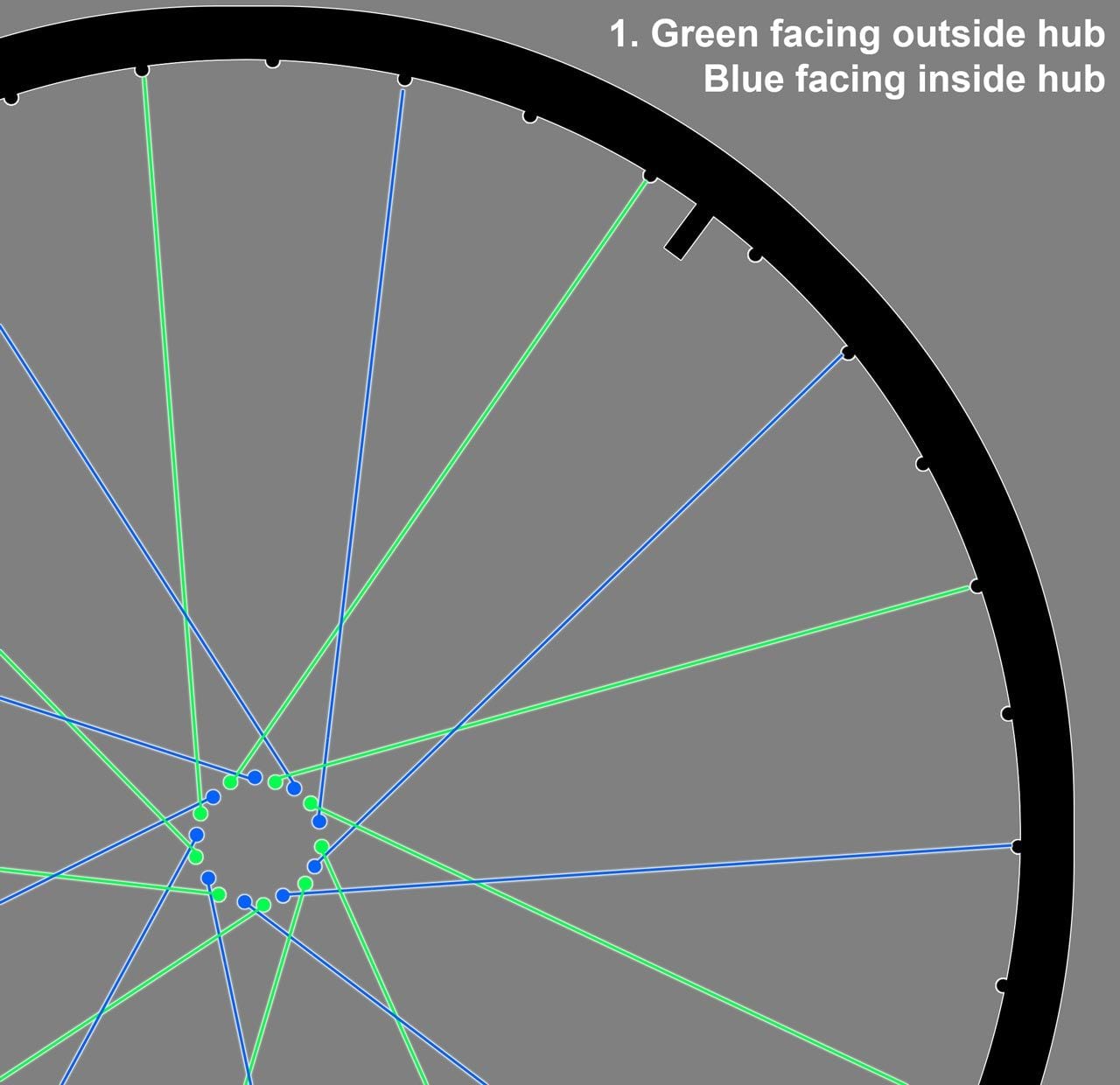

Lacing spokes the right way

I have one wheel that has lacing pattern like #1 and other wheel is lacing pattern #2?

What is the right way to make 3 cross lacing pattern?

Blue spokes cross over green

Green spokes cross over blue

What is the right way to make 3 cross lacing pattern?

Blue spokes cross over green

Green spokes cross over blue

Last edited by PimpMan; 05-05-21 at 01:55 PM.

#2

Senior Member

Join Date: Feb 2004

Location: St Peters, Missouri

Posts: 30,225

Bikes: Catrike 559 I own some others but they don't get ridden very much.

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 1572 Post(s)

Liked 643 Times

in

364 Posts

I've always done it with the heads of the pulling spokes facing out. I also lace all of the heads out spokes on both sides first because that's much easier.

__________________

My greatest fear is all of my kids standing around my coffin and talking about "how sensible" dad was.

My greatest fear is all of my kids standing around my coffin and talking about "how sensible" dad was.

Likes For Retro Grouch:

#3

Senior Member

Join Date: Jul 2013

Location: Nor-Cal

Posts: 3,767

Bikes: lots

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1958 Post(s)

Liked 2,932 Times

in

1,489 Posts

^This^

Your graphic sucks. And what is 'facing' in or out...the heads or the elbows? In #1 if the heads are out and the spokes go 'under, under, over' it would be correct.

Your graphic sucks. And what is 'facing' in or out...the heads or the elbows? In #1 if the heads are out and the spokes go 'under, under, over' it would be correct.

#4

Over the hill

Join Date: Mar 2006

Location: Los Angeles, CA

Posts: 24,368

Bikes: Giant Defy, Giant Revolt

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 995 Post(s)

Liked 1,203 Times

in

689 Posts

Given the limited information, both of those images could hypothetically be the same wheel facing opposite directions. Retro explained it well, but I will mention that many wheels are out there the opposite way or even (cringe) different on each side without issue. Properly seating and stress relieving the spokes, and maybe making sure the stem is in the wider opening, are more important in the long run.

__________________

It's like riding a bicycle

It's like riding a bicycle

#5

Junior Member

Thread Starter

need to make 2 cross spoke pattern for the front wheel (because lack of proper length spokes) i am however having some problem - green spokes stick out trough the rim 4-5mm longer than blue spokes.

Blue spokes angle is -60 degree, green spoke angle is is +20 degree from the hub (compared to radial lacing)

Is this 2 cross pattern diagram wrong?

Blue spokes angle is -60 degree, green spoke angle is is +20 degree from the hub (compared to radial lacing)

Is this 2 cross pattern diagram wrong?

Last edited by PimpMan; 05-05-21 at 01:56 PM.

#6

Tortoise Wins by a Hare!

Join Date: Feb 2006

Location: Looney Tunes, IL

Posts: 7,398

Bikes: Wabi Special FG, Raleigh Roper, Nashbar AL-1, Miyata One Hundred, '70 Schwinn Lemonator and More!!

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1549 Post(s)

Liked 941 Times

in

504 Posts

2 cross will require shorter spokes than 3, but all should be the same length within each pattern. If your green spokes are sticking out farther some of the spokes are in the wrong holes or the hub is twisted that way.

#7

Senior Member

Join Date: Feb 2004

Location: St Peters, Missouri

Posts: 30,225

Bikes: Catrike 559 I own some others but they don't get ridden very much.

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 1572 Post(s)

Liked 643 Times

in

364 Posts

Aha! A common laceing mistake is to lace the spokes on one side of the hub one hole off from the spokes on the opposite side. If that's what you've done, you'll have two long spokes followed by two short spokes all around the rim.

__________________

My greatest fear is all of my kids standing around my coffin and talking about "how sensible" dad was.

My greatest fear is all of my kids standing around my coffin and talking about "how sensible" dad was.

#8

Junior Member

Thread Starter

I know there's a mistake, but i just cannot understand what should be changed, mind pointing out on actual picture of the rim?

#9

Really Old Senior Member

These are rear hubs, but the idea is the same.

The spoke holes on the opposite side of the hub are offset.

IF you are working CCW around the rim, the 2nd set has to be in the opposite hole that is offset CCW as in the left pic. Putting it in the hole as in the right pic will result in the long/short spoke scenario.

The spoke holes on the opposite side of the hub are offset.

IF you are working CCW around the rim, the 2nd set has to be in the opposite hole that is offset CCW as in the left pic. Putting it in the hole as in the right pic will result in the long/short spoke scenario.

Likes For Bill Kapaun:

#11

Junior Member

Thread Starter

Used all 184mm spokes, nipples screwed in equally just to cover the spoke thread, wheel is almost true, however some spokes go inside rim further than others!

Already tried to tighten them its same story they do not tighten at equal lengths (equal number of turns some spokes not tighten at all while others turn all the way).

Used same spoke length as this wheel was built with before i taken it apart and i put new hub that is exactly the same as old one.

This rim is very bad design - it has sharp inner wall and nipple hole is about 4mm thick so nipple fixed at 90 degree angle from the rim.

Already tried to tighten them its same story they do not tighten at equal lengths (equal number of turns some spokes not tighten at all while others turn all the way).

Used same spoke length as this wheel was built with before i taken it apart and i put new hub that is exactly the same as old one.

This rim is very bad design - it has sharp inner wall and nipple hole is about 4mm thick so nipple fixed at 90 degree angle from the rim.

Last edited by PimpMan; 05-08-21 at 01:12 AM.

#12

Junior Member

Thread Starter

I made it over and same issue, rim is trued and all spoke nipples are screwed just to cover the spoke thread.

Heads out spokes go inside rim too far.

I put all the heads out spokes first on both sides, then added heads in spokes on both sides.

Heads out spokes go inside rim too far.

I put all the heads out spokes first on both sides, then added heads in spokes on both sides.

Last edited by PimpMan; 05-08-21 at 04:49 AM.

#13

Junior Member

Thread Starter

Finished with 281mm spokes all good perfect except spokes are kind of too short, only 6 turns into the spoke nipple. I guess i will replace the spokes to 284mm one by one now...

#15

Junior Member

Thread Starter

Okay after installing 281mm spokes and tightening them all to equal number of turns until spokes are tight i switched to 284mm spokes one by one tightening each one and it worked great all went into same number of turns each.

Yes it is.

What pic you mean exactly?

What pic you mean exactly?

Last edited by PimpMan; 05-28-21 at 10:30 AM.

#16

Senior Member

Join Date: Jul 2013

Location: Nor-Cal

Posts: 3,767

Bikes: lots

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1958 Post(s)

Liked 2,932 Times

in

1,489 Posts

What? No...it's every 4th hole...for every 'cross' pattern, even for radial. It's either over, over, under OR under, under, over depending on which side of the flange you're on.

#17

Junior Member

Thread Starter

For asymmetrical rear hub with 7 speed freewheel i need to set dishing towards the center of fork not center of hub hub so tension between each side spokes is different.

Somewhere i read "tension for spokes ideally needs to same prevent breaking" is that same tension for all spokes on one side of the rim or every spoke on the rim needs to be same tension?

Obviously if i set same tension i will loose dishing, so if i say use 181 mm spokes on one side and 184mm spokes on other side then i can set equal tension?

Somewhere i read "tension for spokes ideally needs to same prevent breaking" is that same tension for all spokes on one side of the rim or every spoke on the rim needs to be same tension?

Obviously if i set same tension i will loose dishing, so if i say use 181 mm spokes on one side and 184mm spokes on other side then i can set equal tension?

#18

Senior member

Join Date: Oct 2004

Location: Oakville Ontario

Posts: 8,115

Mentioned: 25 Post(s)

Tagged: 0 Thread(s)

Quoted: 942 Post(s)

Liked 656 Times

in

370 Posts

For asymmetrical rear hub with 7 speed freewheel i need to set dishing towards the center of fork not center of hub hub so tension between each side spokes is different.

Somewhere i read "tension for spokes ideally needs to same prevent breaking" is that same tension for all spokes on one side of the rim or every spoke on the rim needs to be same tension?

Obviously if i set same tension i will loose dishing, so if i say use 181 mm spokes on one side and 184mm spokes on other side then i can set equal tension?

Somewhere i read "tension for spokes ideally needs to same prevent breaking" is that same tension for all spokes on one side of the rim or every spoke on the rim needs to be same tension?

Obviously if i set same tension i will loose dishing, so if i say use 181 mm spokes on one side and 184mm spokes on other side then i can set equal tension?

Likes For Dan Burkhart:

#19

Senior Member

Join Date: Mar 2008

Posts: 8,688

Mentioned: 46 Post(s)

Tagged: 0 Thread(s)

Quoted: 1074 Post(s)

Liked 295 Times

in

222 Posts

Rim being centered between hub flanges is kinda accidental, and not overly important for the function of the bike as a whole. Rim centered between locknuts/dropouts is generally more important.

Different spoke length will NOT let you achieve equal tension on an assymmetric hub.

On an assymetric hub there are basically two things you can do to even out tension:

1) different spoke counts

2) offset/assymmetric rim

There is one more trick, but that doesn’t actually address tension, it influences load or strain.

If you use a thinner spoke on the less tensioned side, then the tension-by-cross section area becomes the same/similar, which is good for spoke longevity.

Basically, if the NDS has 60% tension compared to the DS, then you should use spokes with 60% of the cross section area.

That will keep both sides spokes working equally hard.

Likes For dabac:

#20

Senior Member

Join Date: May 2019

Location: Bloomington, IN

Posts: 2,940

Bikes: Paramount, Faggin, Ochsner, Ciocc, Basso

Mentioned: 115 Post(s)

Tagged: 0 Thread(s)

Quoted: 1301 Post(s)

Liked 1,902 Times

in

1,137 Posts

PimpMan,

I just finished giving pictures and descriptions about my wheel build for my Paramount in the thread "Paramount Build". I describe most of the how and why for the way I build my wheels. They were good enough for our team to finish three Race Across America trips. Along with countless wheels built for the Little 500 race and a lot in the local LBS where I worked. Check it out and if you still have questions, you can contact me by phone or e-mail. Just let me know, Smiles, MH

I just finished giving pictures and descriptions about my wheel build for my Paramount in the thread "Paramount Build". I describe most of the how and why for the way I build my wheels. They were good enough for our team to finish three Race Across America trips. Along with countless wheels built for the Little 500 race and a lot in the local LBS where I worked. Check it out and if you still have questions, you can contact me by phone or e-mail. Just let me know, Smiles, MH

#21

Junior Member

Thread Starter

So far i figured it out following recipe for perfectly adjusted front rim:

1. Assemble the wheel leaving tiny portion of thread visible outside nipple for every spoke.

2. Tighten each nipple equal number of 360 degree turns (e.g. 6 turns out of 12 total).

3. Keep adding equal number of 90 degree turns to each nipple until you get equal tension of about 100 kgf (1000 N) for every spoke (remove spoke tension)

4. True the wheel (remove spoke tension)

5. Adjust the spokes again until you get equal tension of about 100 kgf (1000 N) for every spoke (remove spoke tension)

6. Keep repeating step #4 and #5 until you get equal tension for every spoke while rim stay's true.

Problem is that step #6 has to be repeated too many times, is there a faster way or can you advice any better sequence for wheel building?

1. Assemble the wheel leaving tiny portion of thread visible outside nipple for every spoke.

2. Tighten each nipple equal number of 360 degree turns (e.g. 6 turns out of 12 total).

3. Keep adding equal number of 90 degree turns to each nipple until you get equal tension of about 100 kgf (1000 N) for every spoke (remove spoke tension)

4. True the wheel (remove spoke tension)

5. Adjust the spokes again until you get equal tension of about 100 kgf (1000 N) for every spoke (remove spoke tension)

6. Keep repeating step #4 and #5 until you get equal tension for every spoke while rim stay's true.

Problem is that step #6 has to be repeated too many times, is there a faster way or can you advice any better sequence for wheel building?

Last edited by PimpMan; 05-28-21 at 10:31 AM.