Stronglight Axle Failed!

#1

Senior Member

Thread Starter

Stronglight Axle Failed!

I just acquired a '71 Italvega and was doing some preventive maintenance. The raceway on this lightly used part has been destroyed most likely by water intrusion and subsequent corrosion pitting. The damage is only on the drive side and about half way around the circumference with some coining/smoothing from subsequent usage. The bearings are shiny and the cups are undamaged. Interestingly, the cups were full of fresh grease and quite easy to get off. There was no oxide contamination in the grease either.

The part is marked 118 and came off a bike with a 70mm shell width and Stronglight 49D crankset. If anyone knows where I might find a reasonably priced spare I'm all ears. I understand some other brands are compatible but not sure.

Last edited by Cratecruncher; 12-19-21 at 02:47 PM. Reason: Corrected shell width.

#2

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

I don't see any failure. I do see severe wear (which is not a failure in my world) (failure to me suggests the part was substandard and I don't see that here). What I think is going on is that the wear/ball track (and those pits look very much like what I've seen on so many cones and BB axles) is rather low on the ground bearing curved surface. Way low. Generally, the ball track runs about 1/3 to 1/2 way up that curved surface. I can easily see a too high a preload given the low contact angle involved. Are the cups also Stronglight? If not, then there's a likely reason.

As far as replacements go these axles rarely show up any more and those that do should be suspect untill shown good (WRT the ball track wear). Phil has made their BBs in Stronglight compatible tapers. But their production is hindered by C-19 these days. Andy

As far as replacements go these axles rarely show up any more and those that do should be suspect untill shown good (WRT the ball track wear). Phil has made their BBs in Stronglight compatible tapers. But their production is hindered by C-19 these days. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#3

Senior Member

Thread Starter

Thanks for the reply. Very interesting point about the contact point on the raceway. I've gone back and looked closer. It had eleven 1/4" loose bearings installed in each side. My assumption was water intrusion because of the round pitting and damage only on one side. Not much wear on the bike generally despite it's age. The cups are marked "Strongliight" "Patent" on the drive side. The offside cup has no marks. Before disassembly the bearings felt gritty but not like binding. I wonder if 1/4" bearing is too big??? The phot of the cup below also indicates very low raceway contact that I didn't notice initially.

Hmm. I think I'll pop in on my local bike shop and grab some 7/32" and 5mm bearings. With any luck I can get higher raceway contact and avoid those worn portions of the part. Thanks for that whack on the side of my head Andy!

Hmm. I think I'll pop in on my local bike shop and grab some 7/32" and 5mm bearings. With any luck I can get higher raceway contact and avoid those worn portions of the part. Thanks for that whack on the side of my head Andy!

Last edited by Cratecruncher; 12-19-21 at 02:31 PM.

#4

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

^ If the cups are correct, I wonder if going down a size on the DS bearing balls would help wring more life out of this spindle. (By allowing the balls to ride on the unworn part of the race.)

After pitting a few spindles despite what I thought was good maintenance and adjustment, I've become a big fan of the cartridge style.

After pitting a few spindles despite what I thought was good maintenance and adjustment, I've become a big fan of the cartridge style.

__________________

RUSA #7498

Originally Posted by noglider

People in this forum are not typical.

Last edited by ThermionicScott; 12-19-21 at 02:42 PM.

#5

Senior Member

Join Date: Apr 2012

Location: Middle Earth (aka IA)

Posts: 20,433

Bikes: A bunch of old bikes and a few new ones

Mentioned: 178 Post(s)

Tagged: 0 Thread(s)

Quoted: 5888 Post(s)

Liked 3,471 Times

in

2,079 Posts

1/4 inch ball bearing is the right size. It's not uncommon to open up a bike that old and find that the spindle is shot. Put up a WTB in the C&V for sale forum; something is likely to turn up.

Edit: I'm fairly certain (but the folks in C&V can confirm) that stronglight used thicker cups with Italian BBs so they could run the same spindles that were used in 68 mm BBs (i.e., French, English, and Swiss) which means that there may be a decent supply of 118 mm used spindles.

Alternatively you can find a cartridge style BB. Phil Wood will cost a lot. Also IRD has french and italian threaded cups you can use with their BBs. Also Rene Hearse has french and italian threaded in different lengths.

I'm fairly certain you need JIS if going new and not ISO. I believe that the Japanese copied French axles when they came out with their BBs. This is what it says on the Rene Hearse website (and that is a company that loves to modernize old French parts) and I believe it is correct but you may find contrary info on the web:

https://www.renehersecycles.com/bott...s-demystified/

Edit: I'm fairly certain (but the folks in C&V can confirm) that stronglight used thicker cups with Italian BBs so they could run the same spindles that were used in 68 mm BBs (i.e., French, English, and Swiss) which means that there may be a decent supply of 118 mm used spindles.

Alternatively you can find a cartridge style BB. Phil Wood will cost a lot. Also IRD has french and italian threaded cups you can use with their BBs. Also Rene Hearse has french and italian threaded in different lengths.

I'm fairly certain you need JIS if going new and not ISO. I believe that the Japanese copied French axles when they came out with their BBs. This is what it says on the Rene Hearse website (and that is a company that loves to modernize old French parts) and I believe it is correct but you may find contrary info on the web:

https://www.renehersecycles.com/bott...s-demystified/

Last edited by bikemig; 12-19-21 at 03:06 PM.

Likes For bikemig:

#6

Really Old Senior Member

More likely routine maintenance failed. If you drained the oil out of your engine and drove it to failure, would you blame the engine?

11 1/4" balls per side is correct. Using a different size would be stupid.

Get a new spindle & bearing balls and GREASE, assuming the cups are good.

It may be simpler to just get a cartridge.

There may be a "code" on the spindle to determine the correct size. That would be more informative than your pics.

11 1/4" balls per side is correct. Using a different size would be stupid.

Get a new spindle & bearing balls and GREASE, assuming the cups are good.

It may be simpler to just get a cartridge.

There may be a "code" on the spindle to determine the correct size. That would be more informative than your pics.

#7

Senior Member

Join Date: Oct 2017

Location: NJ

Posts: 625

Bikes: 68 SS, 72 Fuji Finest, 72 PX-10, 77 Pana Pro 7000, 84 Pinnarello Treviso NR, 84 Trek 520, 88 Project KOM, 90 Trek 750, 91 Trek 930

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 184 Post(s)

Liked 204 Times

in

142 Posts

11 BB's may be too many especially if cup is not Stronglight.

#8

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

No, all the loose balled Stronglight BBs (and all the other Euro classic tapered square and cottered ones too) could fit 11 loose balls. Some did use a 9 or even a 7 ball retainer ring (to save assembly costs) but they were always 1/4" diameter balls. (There are a very few exceptions like some rare Campy TI axled units that needed smaller balls, but if you had one of those you should already know that ).

).

The effect of one too many balls is quite unique. The bearing adjustment seems to be too tight but also is loose AND (the give away) is that the one ball too many that wants to ride up on the adjacent balls. This "lump" will want to rotate at half the pace the axle (or crank arm, the rim if a hub) and thus make the ring (or rim if a wheel) look to be "out of true" but the point of wobble shifts with the lumps traveling around in the cup. Andy

).

). The effect of one too many balls is quite unique. The bearing adjustment seems to be too tight but also is loose AND (the give away) is that the one ball too many that wants to ride up on the adjacent balls. This "lump" will want to rotate at half the pace the axle (or crank arm, the rim if a hub) and thus make the ring (or rim if a wheel) look to be "out of true" but the point of wobble shifts with the lumps traveling around in the cup. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#9

Senior Member

Thread Starter

1/4 inch ball bearing is the right size. It's not uncommon to open up a bike that old and find that the spindle is shot.

Edit: I'm fairly certain (but the folks in C&V can confirm) that stronglight used thicker cups with Italian BBs so they could run the same spindles that were used in 68 mm BBs (i.e., French, English, and Swiss) which means that there may be a decent supply of 118 mm used spindles.

Edit: I'm fairly certain (but the folks in C&V can confirm) that stronglight used thicker cups with Italian BBs so they could run the same spindles that were used in 68 mm BBs (i.e., French, English, and Swiss) which means that there may be a decent supply of 118 mm used spindles.

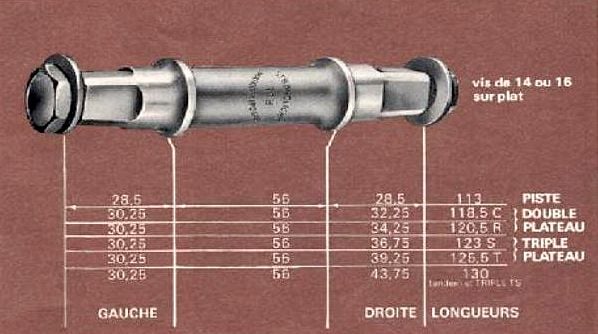

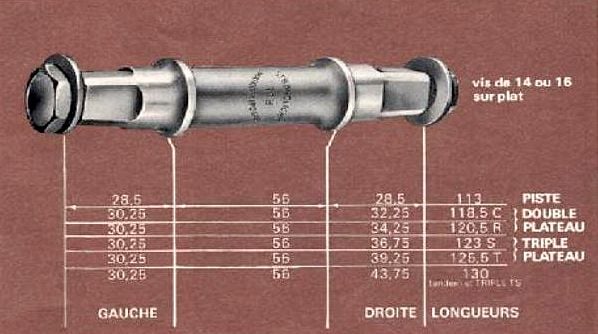

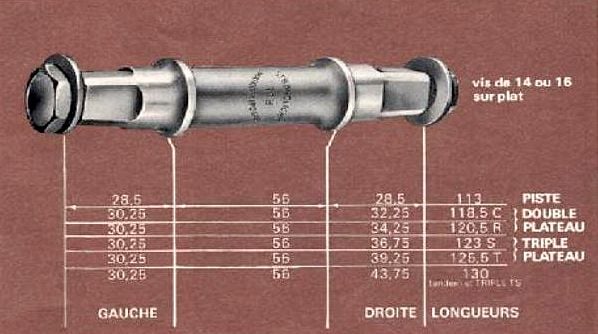

This pick shows the spindles available for different chainring combos and the 118 is likely the most common. My part has "118" clearly stamped on it opposite the "Stronglight Marque Deposee" stamp. The cups are Stronglight. The bike is worth preserving in it's original form so I'd like to replace the spindle with the same or compatible part.

#10

Really Old Senior Member

70mm is Italian.

The 56mm dimension is 52mm for British.

Cup threading is also different than British.

The 56mm dimension is 52mm for British.

Cup threading is also different than British.

#11

Senior Member

Join Date: Apr 2012

Location: Middle Earth (aka IA)

Posts: 20,433

Bikes: A bunch of old bikes and a few new ones

Mentioned: 178 Post(s)

Tagged: 0 Thread(s)

Quoted: 5888 Post(s)

Liked 3,471 Times

in

2,079 Posts

I just acquired a '71 Italvega and was doing some preventive maintenance. The raceway on this lightly used part has been destroyed most likely by water intrusion and subsequent corrosion pitting. The damage is only on the drive side and about half way around the circumference with some coining/smoothing from subsequent usage. The bearings are shiny and the cups are undamaged. Interestingly, the cups were full of fresh grease and quite easy to get off. There was no oxide contamination in the grease either.

The part is marked 118 and came off a bike with a 70mm shell width and Stronglight 49D crankset. If anyone knows where I might find a reasonably priced spare I'm all ears. I understand some other brands are compatible but not sure.

The part is marked 118 and came off a bike with a 70mm shell width and Stronglight 49D crankset. If anyone knows where I might find a reasonably priced spare I'm all ears. I understand some other brands are compatible but not sure.

Forgive me for being confused on this. My bike has a 70mm threaded shell made in Italy in 1971. Would the thicker cup you mention cause the bearing to ride low in the raceways on a 70mm shell? Is this normal? I assumed this bike was initially outfitted with a French caged bearing assembly with metric dimensions and subsequently replaced with loose bearings during a LBS service in the USA. Frankly I'm shocked there is so much wear on the spindle given there is so little wear on the rest of the bike. It's a HARD FAIL where I come from, haha. Seriously, that spindle should be hardened.

This pick shows the spindles available for different chainring combos and the 118 is likely the most common. My part has "118" clearly stamped on it opposite the "Stronglight Marque Deposee" stamp. The cups are Stronglight. The bike is worth preserving in it's original form so I'd like to replace the spindle with the same or compatible part.

This pick shows the spindles available for different chainring combos and the 118 is likely the most common. My part has "118" clearly stamped on it opposite the "Stronglight Marque Deposee" stamp. The cups are Stronglight. The bike is worth preserving in it's original form so I'd like to replace the spindle with the same or compatible part.

So put up a WTB in the C&V for sale forum. If you want more info on how stronglight dealt with Italian bottom brackets, there are people the C&V forum who know more about this than I do so you may want to put up a thread in that forum explaining what you are looking for.

Last edited by bikemig; 12-19-21 at 05:08 PM.

Likes For bikemig:

#12

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

you're going to have a tough time finding a suitable replacement, not only overall length but the correct placement of the bearing track.

I'd be thinking about a phil if you can find one that is the right length

/markp

I'd be thinking about a phil if you can find one that is the right length

/markp

#13

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

I can't think of, or remember, a BB of this style that used metric ball diameters. While I usually avoid absolutes in my replies I would venture that Stronglight never used a metric bearing in their BBs (and headsets for that matter). Andy

__________________

AndrewRStewart

AndrewRStewart

#14

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,546

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 980 Post(s)

Liked 580 Times

in

398 Posts

After wearing out a couple crank axles on my Motobecane Mirage (the first real bicycle I ever bought, in 1974), I replaced the 7-ball retainers with 11 loose 1/4" balls per side. I expect a longer service life this time around.

#15

Senior Member

Thread Starter

I tried to post a WTB thread in the C&V forum section and the website says I don't have that "authorization". Geez.

I'll run the old part flaws clocked opposite the cranking forces for now and continue looking for the right part. I didn't notice any problems with the BB. I just happened to find it while doing routine maintenance. It only takes a few minutes to pull the cranks and open the BB once I get another spindle.

#16

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

I realized after I'd written about two different sizes that there would have been two separate wear marks in the raceways if the part had run two different size bearings. So it must have been 1/4" since the beginning.

I tried to post a WTB thread in the C&V forum section and the website says I don't have that "authorization". Geez.

I'll run the old part flaws clocked opposite the cranking forces for now and continue looking for the right part. I didn't notice any problems with the BB. I just happened to find it while doing routine maintenance. It only takes a few minutes to pull the cranks and open the BB once I get another spindle.

I tried to post a WTB thread in the C&V forum section and the website says I don't have that "authorization". Geez.

I'll run the old part flaws clocked opposite the cranking forces for now and continue looking for the right part. I didn't notice any problems with the BB. I just happened to find it while doing routine maintenance. It only takes a few minutes to pull the cranks and open the BB once I get another spindle.

Good plan for now. I will say that back in the day the French cranks had the rep of being made from a "softer" aluminum. We were instructed to not remove and reinstall crank arms any more times then was needed, least the tapered hole in the arms would be enlarged beyond useful life. Andy

__________________

AndrewRStewart

AndrewRStewart

#17

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,500

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2741 Post(s)

Liked 3,388 Times

in

2,051 Posts

Unless there was a compelling reason to stay with a cup & cone I'd just drop a cartridge in and be done with it. Something like a Shimano UN 26 54, 55 300 or a Tange LN

#18

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,778

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3582 Post(s)

Liked 3,395 Times

in

1,929 Posts

I agree with @Andrew R Stewart that this is typical wear, likely fretting damage from lubrication failure. If the pitting extends all the way around, it's likely due to lack of routine maintenance. If it only extends part way around the race, it suggests that the bottom bracket shell needs facing. Stronglight 118 spindles can be found, but it may take a while. Cartridge bottom brackets may be an easier solution.

N.B., like TA, Stronglight used the same spindle regardless of bottom bracket shell width; cup thickness varied to make up the difference. 1/4" balls were used.

N.B., like TA, Stronglight used the same spindle regardless of bottom bracket shell width; cup thickness varied to make up the difference. 1/4" balls were used.

#19

Senior Member

Join Date: Apr 2012

Location: Middle Earth (aka IA)

Posts: 20,433

Bikes: A bunch of old bikes and a few new ones

Mentioned: 178 Post(s)

Tagged: 0 Thread(s)

Quoted: 5888 Post(s)

Liked 3,471 Times

in

2,079 Posts

+1. Yes stronglight used 1/4 inch bearings for the bottom brackets. I have never worked on a French bike that used metric bearings. I worked in a shop that sold Peugeots and I currently own and ride 4 French bikes.

#20

Senior Member

Join Date: Apr 2005

Location: Northern CA

Posts: 743

Bikes: Cannondale tandems: '92 Road, '97 Mtn. Mongoose 10.9 Ti, Kelly Deluxe, Tommaso Chorus, Cdale MT2000, Schwinn Deluxe Cruiser, Torker Unicycle, among others.

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 279 Post(s)

Liked 206 Times

in

129 Posts

I disagree that this damage was caused by lack of lubrication or contamination. It may have been contributory, but probably not the main cause. And I'm surprised no one mentioned the BB shell condition.

The main cause would be one or both of two things:

1) Bearing developed play.

2) Bottom bracket shell faces not parallel.

The latter causes the former and they work in tandem to cause this damage.

Very few production bicycles have parallel BB shell faces. The manufacturers "say" the BB shells are fine, but one quickly finds out they are NOT when you put a facing tool to them! And no LBS will pull the cranks and BB apart of a $400 bike to do it properly. No way. Like my friend's Ross Shafer-built Salsa. He went through a few XT BBs and was told, "We prep all our frames." by Salsa. I took it apart and quickly learned it had not been. Facing the shell was the solution.

A properly faced shell and installed cup and cone BB should last a long time. Add grade 25 or 20 bearings (as opposed to grade 300 in most bikes) and you can bet the bearing will not fail, despite future grease contamination.

So be sure to get that shell faced!

Personally, I'd try to "machine" that spindle surface smooth again. Can't hurt to try!

The main cause would be one or both of two things:

1) Bearing developed play.

2) Bottom bracket shell faces not parallel.

The latter causes the former and they work in tandem to cause this damage.

Very few production bicycles have parallel BB shell faces. The manufacturers "say" the BB shells are fine, but one quickly finds out they are NOT when you put a facing tool to them! And no LBS will pull the cranks and BB apart of a $400 bike to do it properly. No way. Like my friend's Ross Shafer-built Salsa. He went through a few XT BBs and was told, "We prep all our frames." by Salsa. I took it apart and quickly learned it had not been. Facing the shell was the solution.

A properly faced shell and installed cup and cone BB should last a long time. Add grade 25 or 20 bearings (as opposed to grade 300 in most bikes) and you can bet the bearing will not fail, despite future grease contamination.

So be sure to get that shell faced!

Personally, I'd try to "machine" that spindle surface smooth again. Can't hurt to try!

#21

Full Member

To OP: if you want to stay period correct, you might hunt down a Stronglight 651. It uses cartridge bearings, it's not rare, and if you get the kind with two adjustable cups, you get chainline adjustment.

Looks like this:

#22

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

I disagree that this damage was caused by lack of lubrication or contamination. It may have been contributory, but probably not the main cause. And I'm surprised no one mentioned the BB shell condition.

The main cause would be one or both of two things:

1) Bearing developed play.

2) Bottom bracket shell faces not parallel.

The latter causes the former and they work in tandem to cause this damage.

Very few production bicycles have parallel BB shell faces. The manufacturers "say" the BB shells are fine, but one quickly finds out they are NOT when you put a facing tool to them! And no LBS will pull the cranks and BB apart of a $400 bike to do it properly. No way. Like my friend's Ross Shafer-built Salsa. He went through a few XT BBs and was told, "We prep all our frames." by Salsa. I took it apart and quickly learned it had not been. Facing the shell was the solution.

A properly faced shell and installed cup and cone BB should last a long time. Add grade 25 or 20 bearings (as opposed to grade 300 in most bikes) and you can bet the bearing will not fail, despite future grease contamination.

So be sure to get that shell faced!

Personally, I'd try to "machine" that spindle surface smooth again. Can't hurt to try!

The main cause would be one or both of two things:

1) Bearing developed play.

2) Bottom bracket shell faces not parallel.

The latter causes the former and they work in tandem to cause this damage.

Very few production bicycles have parallel BB shell faces. The manufacturers "say" the BB shells are fine, but one quickly finds out they are NOT when you put a facing tool to them! And no LBS will pull the cranks and BB apart of a $400 bike to do it properly. No way. Like my friend's Ross Shafer-built Salsa. He went through a few XT BBs and was told, "We prep all our frames." by Salsa. I took it apart and quickly learned it had not been. Facing the shell was the solution.

A properly faced shell and installed cup and cone BB should last a long time. Add grade 25 or 20 bearings (as opposed to grade 300 in most bikes) and you can bet the bearing will not fail, despite future grease contamination.

So be sure to get that shell faced!

Personally, I'd try to "machine" that spindle surface smooth again. Can't hurt to try!

Fretting isn't because of grease/lube failure per say but the lube being unable to maintain the tiny gap between the ball and the race. This could very well be from a lack of lube about the bearing but can also be from the lube being pushed out of the way by a very small amount of rotational movement, back and forth, over and over without enough bearing movement to stir up the lube and have it refill the spaces the balls push in it. This is why many headsets get pitting as that bearing often only turns a tiny amount then returns to on center, over and over. IIRC it was Chrysler that had thousands of their car's wheel bearings going bad prematurely. It was found that rail car shipping allowed the cars to slightly rock back and forth enough to push lube away from the bearings and the then metal on metal contact results in micro welding and fracture of these tiny spots, over and over. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#23

Senior Member

In a cup and cone bearing there needs to be a slight amount of preload when the bearing is adjusted. Without it the bearing will prematurely wear out.

Bottom Bracket Bearing adjustment by Jobst Brandt (sheldonbrown.com)

Bottom Bracket Bearing adjustment by Jobst Brandt (sheldonbrown.com)

Last edited by davidad; 12-21-21 at 03:24 PM.