Applications for 3D Printing in C&V?

#51

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,053

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3015 Post(s)

Liked 3,792 Times

in

1,406 Posts

And in full disclosure, rapid CNC is quite affordable. I use the link below. I just sent for a fully custom stem and with the 20% they knocked off, it came in at $90. You can't get a stem from the LBS for that.

https://www.rapiddirect.com/

https://www.rapiddirect.com/

Likes For iab:

#52

Senior Member

Join Date: May 2019

Location: Burien WA

Posts: 511

Bikes: Cannondale Synapse, LeMond Victoire, Bianchi Campione d'Italia, Kona Hei Hei, Ritchey Ultra, Schwinn "Paramount" PDG, '83 Trek 640

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 268 Post(s)

Liked 325 Times

in

211 Posts

And in full disclosure, rapid CNC is quite affordable. I use the link below. I just sent for a fully custom stem and with the 20% they knocked off, it came in at $90. You can't get a stem from the LBS for that.

https://www.rapiddirect.com/

https://www.rapiddirect.com/

#53

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,053

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3015 Post(s)

Liked 3,792 Times

in

1,406 Posts

#54

Senior Member

Join Date: May 2019

Location: Burien WA

Posts: 511

Bikes: Cannondale Synapse, LeMond Victoire, Bianchi Campione d'Italia, Kona Hei Hei, Ritchey Ultra, Schwinn "Paramount" PDG, '83 Trek 640

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 268 Post(s)

Liked 325 Times

in

211 Posts

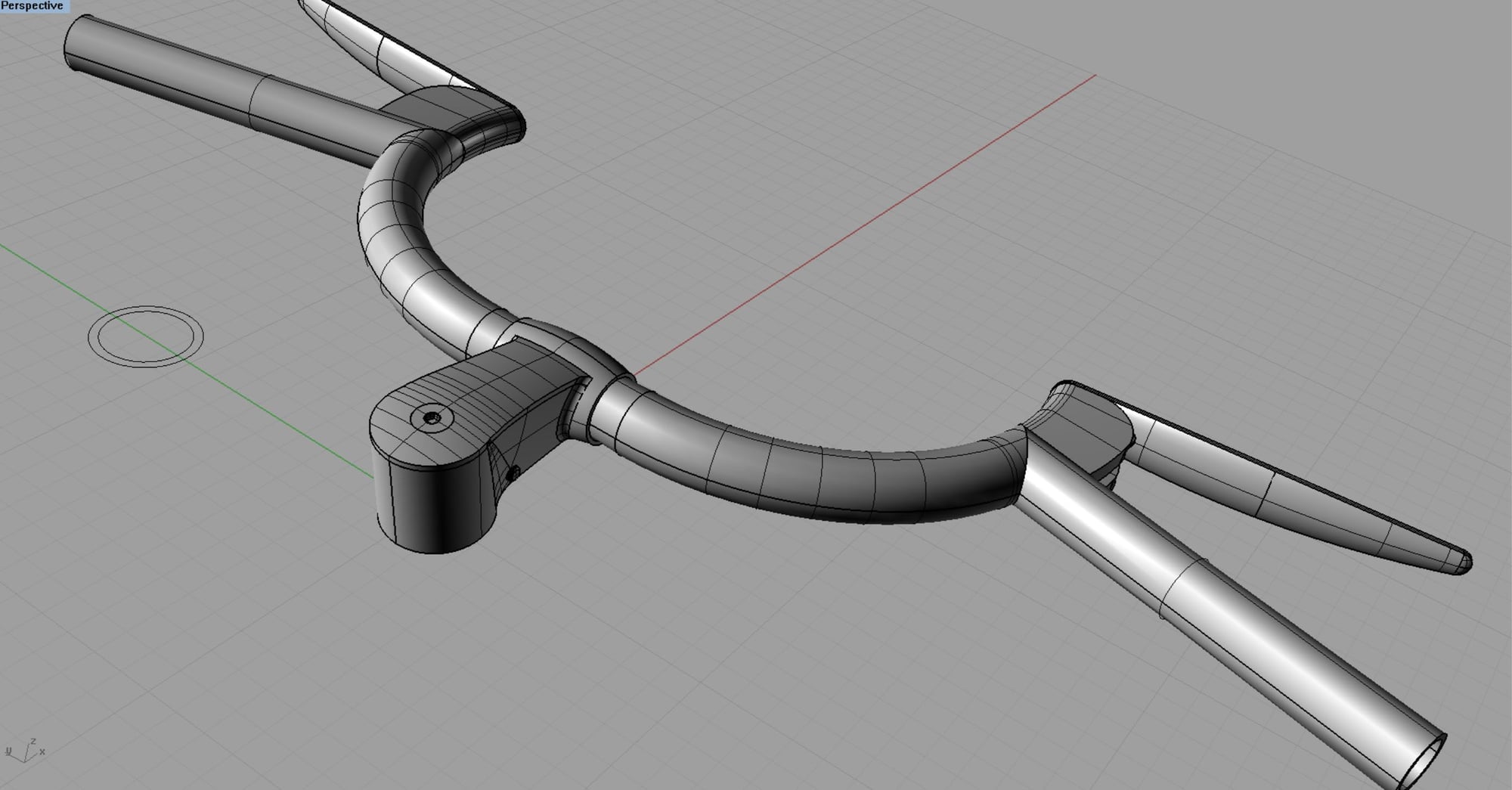

Wow, nice!

#55

Senior Member

Join Date: Aug 2017

Location: Germany

Posts: 1,090

Bikes: 80s Alan Super Record, 79' Somec Special, 90s Rossin(?) Columbus Ego Triathlon, previously: Bianchi SBX Reparto Corse (stolen) and so on...

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 391 Post(s)

Liked 812 Times

in

602 Posts

Excl. levers I assume?

Last edited by Lattz; 12-29-22 at 04:27 PM.

#56

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,053

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3015 Post(s)

Liked 3,792 Times

in

1,406 Posts

No levers. Bars are just bent 0.875 6061 tubes. That's done already.

Likes For iab:

#57

Senior Member

Join Date: Aug 2017

Location: Germany

Posts: 1,090

Bikes: 80s Alan Super Record, 79' Somec Special, 90s Rossin(?) Columbus Ego Triathlon, previously: Bianchi SBX Reparto Corse (stolen) and so on...

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 391 Post(s)

Liked 812 Times

in

602 Posts

#58

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,053

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3015 Post(s)

Liked 3,792 Times

in

1,406 Posts

All of it is 6061 and will be welded to make it a one piece setup. Back in the day I suspect the bars were brazed to the stem and the levers brazed to the bars. Instead of chrome, I'll just polish the aluminium.

Likes For iab:

#59

Full Member

I didn't do any work with 3D printed metal, but anyone who has any experience at all with metal fabrication knows the difference between cast vs stamped vs forged metal and should be immediately skeptical of the idea that you can 3D print a replacement for just any metal part any more than you can cast a part and not have to machine it afterwards.

That said, metal printing is a real thing, structurally speaking. But it's a whole different ball game compared to the usual consumer desktop stuff. Early metal printing was sintering, with high porosity and about the weakest fabrication technique going; modern ones are closer to precision casting, in the sense that metal particles are fused in place, with high temperatures and low porosity. Even then, the products require heat treatment to gain full strength. I doubt that a printed part will be as strong as a forged part if it is equally easy to forge the part -- but a printed part may be just as strong if not stronger because you can do things with printing that you cannot with forging. Material handling is also different, using metal powder. The much higher temperatures involved and finely divided nature of the metal also mean that you need to do this under inert gas conditions, for both strength and safety reasons (metal fires burn very hot). Design for metal printing is also generally much more sophisticated. You would specify metal if strength is a consideration, which means that the design needs attention to the stresses that the part will see, which is not generally the case for plastic printing (which I've done a fair bit of). Most of us probably do not have the mechanical engineering experience in design or the software to make maximum use of metal printing.

#60

Junior Member

<snip>You would specify metal if strength is a consideration, which means that the design needs attention to the stresses that the part will see, which is not generally the case for plastic printing (which I've done a fair bit of). Most of us probably do not have the mechanical engineering experience in design or the software to make maximum use of metal printing.

ESPECIALLY the last sentence, though I would substitute "3D printing" in place of "metal printing". I've printed a lot of files off of Thingiverse and so many of them are poor designs, often with little thought given to how the part will be made. People don't understand/consider how the printer works when making design choices and add insignificant details that create the need for supports or whatever. Early on in my 3D printing experience, I was trying out different things trying to get better results on a Go Pro tool I had gotten a file for. I eventually realized it was the model itself that was a bit rough. I had essentially been wasting my time making higher resoution prints of a low resolution model.

That said, I spent 30 some years in development engineering and have a lot of "design for manufacturing" burned into my brain, so some of this stuff probably irks me more than the average bear. If the printer is being used to make Star Wars character chess pieces I suppose a lot of it doesn't matter.

To those considering getting a 3D printer - they are not toasters. You don't just choose a file, press a button, and get a print. The printer itself will need to be calibrated. Every material you use will require a different technique/setting than the last. You have to make a lot of decisions when setting up the file to print, and there is a TON of misinformation out there on how to make it all work.

If you aren't a tinkerer who likes to get into the details of how things work, consumer level 3D printers probably aren't for you. They are not at all "plug and play" machines.

Ok, so I got a bit off track with my ramblings. If we're talking about what's possible with 3D printing, sure, there is a lot of potential out there. But if you're having it custom made, the idea of "it just needs to be drawn up and printed" is more involved than a lot of people think. Sure, the final part consists of about 15 cents worth of plastic. But the hours it takes to get to the point of being able to turn a little plastic into that part is not (always) insignificant. I've had simple parts that I've drawn and printed in under an hour. I've also had "simple" parts that I work on for a lot of hours to get right.

There's this "simple" TPU strap I've been working on for instance, I'm on design iteration 14 and have printed four of them... I think #5 might do it, but I should recalibrate some things first, an issue has come up with the print quality. I think changing the nozzle and bed temps should help, but the retraction distance and speed should be looked at too. I never really finalized that after switching to an all metal hot end. The z-offset could probably be better though to be honest I'm not all that happy with how level the bed is so it's something of a compromise from one are to the other. I might also change the print bed material to get better adhesion, and...

#61

Full Member

At work, we've started to have fixture parts printed directly in silicone, a relatively new capability as far as I'm aware. The parts are not cheap, but I'd bet they're pretty durable based on how far I can fold them compared to other printed elastomers. I can't really justify testing the tear strength as the parts are too dear. I think it would be appropriate for brake hoods. Black is available in 60A hardness. As costs come down I can see replacement hoods being reasonable.

#62

Senior Member

Join Date: Sep 2007

Location: Reston VA

Posts: 561

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 85 Post(s)

Liked 74 Times

in

55 Posts

The top tube rear brake cable guides on old Cannondales are notorious for failing. I bought some 3D printed ones and epoxied them to the frame. Worked fine. Overpriced though.

Likes For Whit51:

#63

Bianchi Goddess

Join Date: Apr 2009

Location: Shady Pines Retirement Fort Wayne, In

Posts: 27,858

Bikes: Too many to list here check my signature.

Mentioned: 192 Post(s)

Tagged: 2 Thread(s)

Quoted: 2930 Post(s)

Liked 2,923 Times

in

1,491 Posts

I was just looking at some pics of a beautiful Banesto Pinarello and unfortunately it has this Veloce brakes with the hideous yellow cap after the chrome peeled away. I don't know how many people are using these brakes on their classic rides but if you could make this cap is lots of accent colors there might be a market. If you had a Bianchi you could get Celeste green ones, or maybe deep red for your Saronni Colnago or Basso. It would be sacrilege but perhaps you could even do a Cobalt blue.

__________________

“One morning you wake up, the girl is gone, the bikes are gone, all that's left behind is a pair of old tires and a tube of tubular glue, all squeezed out"

Sugar "Kane" Kowalczyk

“One morning you wake up, the girl is gone, the bikes are gone, all that's left behind is a pair of old tires and a tube of tubular glue, all squeezed out"

Sugar "Kane" Kowalczyk

#64

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,053

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3015 Post(s)

Liked 3,792 Times

in

1,406 Posts

I was just looking at some pics of a beautiful Banesto Pinarello and unfortunately it has this Veloce brakes with the hideous yellow cap after the chrome peeled away. I don't know how many people are using these brakes on their classic rides but if you could make this cap is lots of accent colors there might be a market. If you had a Bianchi you could get Celeste green ones, or maybe deep red for your Saronni Colnago or Basso. It would be sacrilege but perhaps you could even do a Cobalt blue.

Paint?

Likes For iab: