I have feelings about the "Hand-Hammered" look in fenders and other things

#101

Senior Member

Join Date: Jan 2008

Location: Beaverton, OR

Posts: 14,744

Bikes: Yes

Mentioned: 525 Post(s)

Tagged: 0 Thread(s)

Quoted: 3230 Post(s)

Liked 3,868 Times

in

1,439 Posts

i think it’s a 1976 model. That’s partly based on a story from the guy I got it from (and eventually gave it back to) about when his brother originally bought it, but I think I had another reason for thinking it. I don’t remember what that reason was.

__________________

My Bikes

My Bikes

Likes For Andy_K:

#102

Senior Member

Join Date: Nov 2005

Location: NW Ohio

Posts: 3,419

Bikes: 1984 Miyata 310, 1986 Schwinn Sierra, 2011 Jamis Quest, 1980 Peugeot TH8 Tandem, 1992 Performance Parabola, 1987 Ross Mt. Hood, 1988 Schwinn LeTour, 1988 Trek 400T, 1981 Fuji S12-S LTD, 197? FW Evans

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 531 Post(s)

Liked 1,004 Times

in

514 Posts

Likes For Pompiere:

#103

Senior Member

Join Date: Jan 2016

Posts: 3,448

Mentioned: 33 Post(s)

Tagged: 0 Thread(s)

Quoted: 874 Post(s)

Liked 2,287 Times

in

1,278 Posts

I think a lot of us C&V folks also appreciate the other classic vehicles . This thread has brought out some great images that I have enjoyed tremendously, thanks.

Likes For Kabuki12:

#104

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

...as a way to differentiate themselves and their product was to hand-hammer so you knew the product, whether it be a bowl, a light fixture or fenders were hand crafted by people, not machines.

Now, a stamping machine creates the HH look. And no one seems to care what it represented at one time.

Now, a stamping machine creates the HH look. And no one seems to care what it represented at one time.

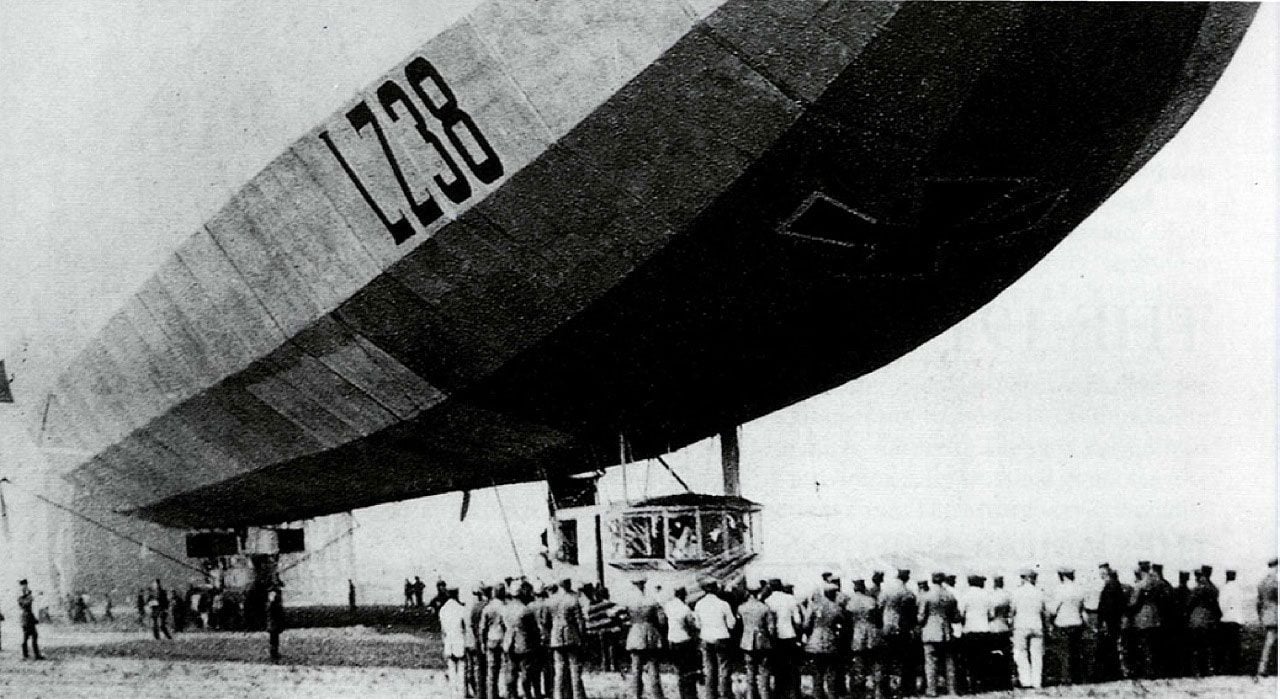

Funny enough, the French company Lefol made a Zeppelin style fender, but possibly because of anti-krautism, they called it "Le Paon" (the peacock).

Legend says that the first Pro's with hammered rivets were Pro's where the rivets were removed, the leather was subjected to some special treatment to soften it up, and then re-riveted to the saddle frame. To make it look nice, larger rivets were needed to cover the area around the holes (no idea why), and the hammering was needed either to get that large rivet flush with the leather or shaped to match the leather's contours or some other reason.

This is my example of a butchered saddle. I think it's from the '50s or so. It started out as a B17, as evidenced by the markings on the leather, so I have placed a stock B17 next to it for scale. The cantle plate shows evidence of being hammered inwards to reduce the width. The leather curls inward under it even without lacing. It is surprisingly comfortable for how it looks. And lighter than any other leather saddle I have, in spite of its steel rails.

So having hand-hammered rivets was a sign of high-performance gear.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Last edited by scarlson; 11-11-22 at 10:49 AM.

#105

Sunshine

Join Date: Aug 2014

Location: Des Moines, IA

Posts: 16,611

Bikes: '18 class built steel roadbike, '19 Fairlight Secan, '88 Schwinn Premis , Black Mountain Cycles Monstercross V4, '89 Novara Trionfo

Mentioned: 123 Post(s)

Tagged: 0 Thread(s)

Quoted: 10955 Post(s)

Liked 7,484 Times

in

4,186 Posts

Apologies if already posted but is my Hand Hammered Wok from The People’s Republic of China a classic or is it just vintage junk?

https://youtu.be/Ff_ObKMjn4w

https://youtu.be/Ff_ObKMjn4w

Likes For mstateglfr:

#106

www.theheadbadge.com

Join Date: Sep 2005

Location: Southern Florida

Posts: 28,513

Bikes: https://www.theheadbadge.com

Mentioned: 124 Post(s)

Tagged: 0 Thread(s)

Quoted: 2422 Post(s)

Liked 4,391 Times

in

2,092 Posts

The problem with this is, I just don't think the hand hammered look ever represented hand craft, in bicycle fenders at least. Hand-hammered aluminum bike fenders came out in the '30s or '40s, same time as your streamline toaster. They were always made by machine, as far as I know.

I can only assume that besides appearance, the patterns may have helped with structural strength, similar to how the stampings on the Citroën van help strengthen the otherwise light and floppy steel. Same reason fender edges are rolled over. Sure, it helps to reduce sharp edges, but a plain aluminum fender would be very noodly without it.

Pic via @THREADLESS1430 at: https://flic.kr/p/mWtGae - really hard to find this picture due to Flickr not being indexed by Google.

-Kurt

Likes For cudak888:

#107

Senior Member

Join Date: Jan 2016

Posts: 3,448

Mentioned: 33 Post(s)

Tagged: 0 Thread(s)

Quoted: 874 Post(s)

Liked 2,287 Times

in

1,278 Posts

I do like the hammered look on my Brooks Team Pro with the oversized rivets. ^ those fenders are works of art , even if machine generated.....luv 'em!

Likes For Kabuki12:

#108

Senior Member

On a somewhat similar theme... how do you feel about corrugated aircraft skins? Functional, or just for looks?

Ford Tri-motor:

Junkers Ju52:

The Junkers was being used as part of a marketing campaign for some high-end luggage that used corrugated metal on the exterior because... no idea why, but apparently it was novel and interesting. ... sorta like curly stays on a Hetchins?...

Steve in Peoria

(no hammered fenders yet),

Ford Tri-motor:

Junkers Ju52:

The Junkers was being used as part of a marketing campaign for some high-end luggage that used corrugated metal on the exterior because... no idea why, but apparently it was novel and interesting. ... sorta like curly stays on a Hetchins?...

Steve in Peoria

(no hammered fenders yet),

I'd guess the reasons for use on the vans pictured later were much the same, particularly if those date to the 1940s or early 1950s (not that familiar with those vehicles). I've read that for a while immediately after World War II, France was severely short in certain structural materials.

The corrugations were oriented in the direction of travel presumably to avoid dramatically increasing wind resistance.

Last edited by Hondo6; 11-11-22 at 12:48 PM. Reason: clarification; corect typo

Likes For Hondo6:

#109

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

I'd guess corrugated steel was used in aircraft work of that era because the corrugations make it stronger in one direction (the direction perpendicular to the corrugations) than an equivalent flat sheet, thus potentially allowing the use of thinner steel - and aircraft engines of the day were still (by a decade or two later's standards) not particularly high-performers. With proper design and given the flight speeds of the day, that might have resulted in a significant weight savings.

By 1932, when the Ju-52 flew first, this technique was already past its prime. Engine performance, construction techniques and wing loading had improved to a point that the better solution was to rivet stiffeners on the inside of a load-carrying skin. Junkers airplanes were very innovative first, but once the company had found a good way of producing robust, low-cost aircraft, it stuck to what it knew. However, Junkers' concept of a steel or aluminum truss plus the corrugated aluminum skin was heavier than the smooth monocoque skin which we still use on today's airplanes, and once aerodynamic drag could be reduced to a point where the drag increase due to the larger wetted surface of the corrugated skin could not be overlooked, even Junkers switched over to smooth skin.

I'd guess the reasons for use on the vans pictured later were much the same, particularly if those date to the 1940s or early 1950s (not that familiar with those vehicles). I've read that for a while immediately after World War II, France was severely short in certain structural materials.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Likes For scarlson:

#110

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,476

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1829 Post(s)

Liked 3,374 Times

in

1,580 Posts

The Rimowa luggage is a different story. A German luggage house that built luggage the traditional way, wood frames, canvas or leather. For kicks they made some pieces from scrap from the Junkers airplane company.

The factory burned down. Going through the debris, they found the only thing still intact was the aluminum luggage and decided that was the direction they were going to go.

The factory burned down. Going through the debris, they found the only thing still intact was the aluminum luggage and decided that was the direction they were going to go.

Looking further on their site, I see that I can get a small piece of luggage for carrying a wine or champagne bottle... for only $1820. It makes a NOS T.A. bottle cage seem like an absolute bargain by comparison.

I should say that the folks who own and operate vintage aircraft are already shoveling large sums of money to keep those aircraft flying, so they probably are a great target market for this sort of prestige luggage.

Steve in Peoria

Likes For steelbikeguy:

#111

Senior Member

It was aluminum, not steel, but you are more or less right. Junkers started making corrugated designs in late WWI, when the engines were even less powerful, and speeds were even lower. Because drag increases with the square of speed, at 100mph the corrugations barely mattered while at 200mph they matter more than a bit more! In addition, the low power of the engines of that time demanded low wing loadings, so surface friction was a minor contribution to the overall drag of aircraft of this time.

By 1932, when the Ju-52 flew first, this technique was already past its prime. Engine performance, construction techniques and wing loading had improved to a point that the better solution was to rivet stiffeners on the inside of a load-carrying skin. Junkers airplanes were very innovative first, but once the company had found a good way of producing robust, low-cost aircraft, it stuck to what it knew. However, Junkers' concept of a steel or aluminum truss plus the corrugated aluminum skin was heavier than the smooth monocoque skin which we still use on today's airplanes, and once aerodynamic drag could be reduced to a point where the drag increase due to the larger wetted surface of the corrugated skin could not be overlooked, even Junkers switched over to smooth skin.

The reason for corrugated steel's use on the Citroën HY van was because it was not like a traditional van of that era. Instead of being body-on-frame construction, it was unibody, like a modern car, giving it a very low loading floor and center of gravity, as well as mechanical simplicity. Unibody construction led to the skin bearing significant load. The van was powered by the same 2L 4-cylinder engine found in the Traction Avant, so weight was also a consideration. To save weight (and cost) and go with a thinner gauge of steel, corrugation was chosen to stiffen the structure. This is why it weighed only 1200kg but could carry 1600kg. Thanks to the stiff construction and welds holding the metal together, the floor inside was strong enough to support a horse or cow.

By 1932, when the Ju-52 flew first, this technique was already past its prime. Engine performance, construction techniques and wing loading had improved to a point that the better solution was to rivet stiffeners on the inside of a load-carrying skin. Junkers airplanes were very innovative first, but once the company had found a good way of producing robust, low-cost aircraft, it stuck to what it knew. However, Junkers' concept of a steel or aluminum truss plus the corrugated aluminum skin was heavier than the smooth monocoque skin which we still use on today's airplanes, and once aerodynamic drag could be reduced to a point where the drag increase due to the larger wetted surface of the corrugated skin could not be overlooked, even Junkers switched over to smooth skin.

The reason for corrugated steel's use on the Citroën HY van was because it was not like a traditional van of that era. Instead of being body-on-frame construction, it was unibody, like a modern car, giving it a very low loading floor and center of gravity, as well as mechanical simplicity. Unibody construction led to the skin bearing significant load. The van was powered by the same 2L 4-cylinder engine found in the Traction Avant, so weight was also a consideration. To save weight (and cost) and go with a thinner gauge of steel, corrugation was chosen to stiffen the structure. This is why it weighed only 1200kg but could carry 1600kg. Thanks to the stiff construction and welds holding the metal together, the floor inside was strong enough to support a horse or cow.

Likes For Hondo6:

#112

Senior Member

Join Date: Nov 2015

Posts: 4,485

Mentioned: 102 Post(s)

Tagged: 0 Thread(s)

Quoted: 1639 Post(s)

Likes: 0

Liked 829 Times

in

538 Posts

okay, we've discussed hammered fenders, but what about other hammered stuff?

I'm just thinking about hammered rivets on Brooks saddles. I've got older Brooks Professionals with medium sized copper rivets that don't have any hammer marks, but also a newer Pro with large, hammered rivets. I've also got a B.17 and a Swift with larger hammered rivets.

Legend says that the first Pro's with hammered rivets were Pro's where the rivets were removed, the leather was subjected to some special treatment to soften it up, and then re-riveted to the saddle frame. To make it look nice, larger rivets were needed to cover the area around the holes (no idea why), and the hammering was needed either to get that large rivet flush with the leather or shaped to match the leather's contours or some other reason.

Of course, that large hammered rivet became an indicator of some sort of prestige or extra value, so it became popular. As such, we find production Brooks models with large hammered rivets to this day. Is it wrong that I think they still look pretty cool?? ... maybe?...

On a somewhat similar theme... how do you feel about corrugated aircraft skins? Functional, or just for looks?

Ford Tri-motor:

Junkers Ju52:

The Junkers was being used as part of a marketing campaign for some high-end luggage that used corrugated metal on the exterior because... no idea why, but apparently it was novel and interesting. ... sorta like curly stays on a Hetchins?...

Steve in Peoria

(no hammered fenders yet),

I'm just thinking about hammered rivets on Brooks saddles. I've got older Brooks Professionals with medium sized copper rivets that don't have any hammer marks, but also a newer Pro with large, hammered rivets. I've also got a B.17 and a Swift with larger hammered rivets.

Legend says that the first Pro's with hammered rivets were Pro's where the rivets were removed, the leather was subjected to some special treatment to soften it up, and then re-riveted to the saddle frame. To make it look nice, larger rivets were needed to cover the area around the holes (no idea why), and the hammering was needed either to get that large rivet flush with the leather or shaped to match the leather's contours or some other reason.

Of course, that large hammered rivet became an indicator of some sort of prestige or extra value, so it became popular. As such, we find production Brooks models with large hammered rivets to this day. Is it wrong that I think they still look pretty cool?? ... maybe?...

On a somewhat similar theme... how do you feel about corrugated aircraft skins? Functional, or just for looks?

Ford Tri-motor:

Junkers Ju52:

The Junkers was being used as part of a marketing campaign for some high-end luggage that used corrugated metal on the exterior because... no idea why, but apparently it was novel and interesting. ... sorta like curly stays on a Hetchins?...

Steve in Peoria

(no hammered fenders yet),

The corrugations on the Ford Trimotor and other planes from that era gave the fuselage and wings additional stiffness.

it might have resulted in less internal framing for tye plane = lighter.

Last edited by Chombi1; 11-11-22 at 01:17 PM.

#113

señor miembro

Join Date: Dec 2018

Location: Pac NW

Posts: 6,622

Bikes: '70s - '80s Campagnolo

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 3885 Post(s)

Liked 6,479 Times

in

3,205 Posts

#114

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,476

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1829 Post(s)

Liked 3,374 Times

in

1,580 Posts

I had to look up the Wiki page for the Trimotor to get the basics.... it was designed sometime before 1925, so I guess they were still figuring out the best ways to construct an all-metal aircraft. It looks like they hadn't figured out that they should be running the control cables inside the fuselage either.

The Ford Trimotor using all-metal construction was not a revolutionary concept, but it was certainly more advanced than the standard construction techniques of the 1920s. The aircraft resembled the Fokker F.VII Trimotor (except for being all-metal which Henry Ford claimed made it "the safest airliner around").[3] Its fuselage and wings followed a design pioneered by Junkers[4] during World War I with the Junkers J.I and used postwar in a series of airliners starting with the Junkers F.13 low-wing monoplane of 1920 of which a number were exported to the US, the Junkers K 16 high-wing airliner of 1921, and the Junkers G 24 trimotor of 1924. All of these were constructed of aluminum alloy, which was corrugated for added stiffness, although the resulting drag reduced its overall performance.

The amount of hand work involved in creating all of those structural elements must have been immense!

No idea of how many hammers were used in this type of construction (just to bring this back to the original topic, sorta).

Steve in Peoria

Likes For steelbikeguy:

#115

Senior Member

Join Date: Nov 2015

Posts: 4,485

Mentioned: 102 Post(s)

Tagged: 0 Thread(s)

Quoted: 1639 Post(s)

Likes: 0

Liked 829 Times

in

538 Posts

Copper pots must been hand hammered to make the pot stronger/stiffer as copper is quite soft.

It kinda makes sense then to do he same to an aluminum fender on a bike.

It kinda makes sense then to do he same to an aluminum fender on a bike.

Likes For semroc:

#117

The Huffmeister

Join Date: Jul 2008

Location: The Le Grande HQ

Posts: 2,735

Bikes: '79 Trek 938, '86 Jim Merz Allez SE, '90 Miyata 1000, '68 PX-10, '80 PXN-10, '73 Super Course, '87 Guerciotti, '83 Trek 600, '80 Huffy Le Grande

Mentioned: 45 Post(s)

Tagged: 0 Thread(s)

Quoted: 1225 Post(s)

Liked 3,543 Times

in

1,407 Posts

#118

Bianchi Goddess

Join Date: Apr 2009

Location: Shady Pines Retirement Fort Wayne, In

Posts: 27,858

Bikes: Too many to list here check my signature.

Mentioned: 192 Post(s)

Tagged: 2 Thread(s)

Quoted: 2930 Post(s)

Liked 2,923 Times

in

1,491 Posts

It was probably the best infomercial ever made. He was selling something by giving you a history lesson and showing how to use it rather than just shouting about how great it and the price. This was all over TV in the late ‘89s

__________________

“One morning you wake up, the girl is gone, the bikes are gone, all that's left behind is a pair of old tires and a tube of tubular glue, all squeezed out"

Sugar "Kane" Kowalczyk

“One morning you wake up, the girl is gone, the bikes are gone, all that's left behind is a pair of old tires and a tube of tubular glue, all squeezed out"

Sugar "Kane" Kowalczyk

#120

www.theheadbadge.com

Join Date: Sep 2005

Location: Southern Florida

Posts: 28,513

Bikes: https://www.theheadbadge.com

Mentioned: 124 Post(s)

Tagged: 0 Thread(s)

Quoted: 2422 Post(s)

Liked 4,391 Times

in

2,092 Posts

This Bottecchia was supposed to get Lefol hammered fenders, but a snafu of shipping and a lucky opportunity via nlerner meant it wound up with plebian Honjo Turtles.

I hope this meets with the OP's approval. If it doesn't, I can provide a pantographed Colnago kickstand as a prayer offering.

-Kurt

I hope this meets with the OP's approval. If it doesn't, I can provide a pantographed Colnago kickstand as a prayer offering.

-Kurt

Last edited by cudak888; 11-11-22 at 07:06 PM.

Likes For cudak888:

#121

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

Griswold! You are a man of culture, I see

There is nothing like frying in a good piece of American iron.

There is nothing like frying in a good piece of American iron.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Likes For scarlson:

#122

Senior Member

Join Date: Oct 2022

Posts: 1,378

Bikes: a couple

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 563 Post(s)

Liked 862 Times

in

455 Posts

They are awesome when you use them with gas and even better with induction heating

#123

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

I love them even with our lousy apartment electric coil stove. The light weight and smooth surface are a revelation after using the modern stuff. I inherited my two Griswold frying pans (one prewar large logo and one postwar small logo) from my grandpa's cousin when he died. They were going to auction them off but I nabbed them along with some of his cuckoo clock collection.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Likes For scarlson:

#124

Bianchi Goddess

Join Date: Apr 2009

Location: Shady Pines Retirement Fort Wayne, In

Posts: 27,858

Bikes: Too many to list here check my signature.

Mentioned: 192 Post(s)

Tagged: 2 Thread(s)

Quoted: 2930 Post(s)

Liked 2,923 Times

in

1,491 Posts

Interestingly a few decades after those seemingly primitive, but beautiful in their own way, tri-motors took to the sky’s the vaunted A-12s and SR-71s also featured corrugated skin panels to assist in heat dissipation and expansion and contraction. I suspect some very large hydraulic hammers beat these into submission

Somewhere in all the documentaries and books I seen on WWII there are pics and even I believe film of German paratroopers riding on the wings of Fokker Tri-motors.

Somewhere in all the documentaries and books I seen on WWII there are pics and even I believe film of German paratroopers riding on the wings of Fokker Tri-motors.

__________________

“One morning you wake up, the girl is gone, the bikes are gone, all that's left behind is a pair of old tires and a tube of tubular glue, all squeezed out"

Sugar "Kane" Kowalczyk

“One morning you wake up, the girl is gone, the bikes are gone, all that's left behind is a pair of old tires and a tube of tubular glue, all squeezed out"

Sugar "Kane" Kowalczyk

Likes For Bianchigirll:

#125

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,509

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2746 Post(s)

Liked 3,390 Times

in

2,053 Posts

I sold this guy some of my grandfather's blacksmith tools when he was starting out now he hand hammers hammers.

https://www.cergolforge.com/?variant=40204869501017

https://www.cergolforge.com/?variant=40204869501017

Likes For dedhed: