First time wheel truing

#1

Newbie

Thread Starter

First time wheel truing

Just wrapped up my first adventure into wheel truing. I first tried to do it by ear, got no where, and bought a cheap Chinese tension meter. If the included conversion table is accurate, I ended up ~140kgf on the drive side, and ~80kgf on the non-drive side (rear wheel). Does that look right? I know the drive side should be higher, but 75% difference? Also, my other bike (which is identical, but spokes are untouched) measured ~90kgf on the drive side, and ~56kgf on the non-drive side. How much of the difference is because I freshly tightened the spokes on bike#1, whereas bike#2's spokes stretched over the years? Should I lower the tension on bike#1 to match bike#2? How low can I go before I risk the nipples loosening themselves?

(They're basic single wall rims. Weimann ZAC1900.)

(They're basic single wall rims. Weimann ZAC1900.)

#2

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,893

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2595 Post(s)

Liked 1,923 Times

in

1,207 Posts

140 kgf sounds pretty high to me. I'd try to take it down to 120 kgf tops, 110 would be better.

Non-drive side tension will be what it needs to be to get the dish straight. (That's why some people use linseed oil on NDS spoke threads, they'll often be too slack for tension alone to keep the nipples from rotating.) IIRC my rear wheels run about 115+/-10 DS and 60-70 NDS.

Non-drive side tension will be what it needs to be to get the dish straight. (That's why some people use linseed oil on NDS spoke threads, they'll often be too slack for tension alone to keep the nipples from rotating.) IIRC my rear wheels run about 115+/-10 DS and 60-70 NDS.

Likes For pdlamb:

#3

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

For what it's worth, Weinmann recommends a 120kgf max for most of the single-walled rims I see on their site (couldn't find the 1900.) It's normal for rear wheels to have a healthy difference in tension between sides. Usually the NDS ends up at 50-60% of the DS tension for me. Double-butted spokes resist coming loose a little better, so I'm comfortable with a bit less than the usual 60-70 kgf minimum that a lot of people use for their wheels.

#4

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

How does a 80/140 get a 75% difference?

I agree with both others about the usual tensions and differences.

When you say you "tried it by ear" but couldn't do you mean you couldn't note the different tones of the spokes when plucked? On the same side of the wheel? Seeking the same pluck tone has nothing to do with ultimate tension levels, only relative levels to other similar spokes. Andy

I agree with both others about the usual tensions and differences.

When you say you "tried it by ear" but couldn't do you mean you couldn't note the different tones of the spokes when plucked? On the same side of the wheel? Seeking the same pluck tone has nothing to do with ultimate tension levels, only relative levels to other similar spokes. Andy

__________________

AndrewRStewart

AndrewRStewart

#5

Junior Member

Join Date: May 2022

Posts: 13

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

Jobst Brandt's The Bicycle Wheel gives good justification for the spokes to be absolutely maxed in tension.

I've built perhaps a dozen wheels over the past 50 years and have never used a tensiometer, just truing to straightness.

I've built perhaps a dozen wheels over the past 50 years and have never used a tensiometer, just truing to straightness.

Likes For ajh.me:

#6

Senior Member

Join Date: Feb 2016

Location: SE Wisconsin

Posts: 1,851

Bikes: Lemond '01 Maillot Jaune, Lemond '02 Victoire, Lemond '03 Poprad, Lemond '03 Wayzata DB conv(Poprad), '79 AcerMex Windsor Carrera Professional(pur new), '88 GT Tequesta(pur new), '01 Bianchi Grizzly, 1993 Trek 970 DB conv, Trek 8900 DB conv

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 758 Post(s)

Likes: 0

Liked 809 Times

in

471 Posts

In my experience, there's really no reason to assume the "cheap Chinese tension meter" is remotely close to accurate. I don't believe one of those meters (the spring in those meters) could measure 140kgf accurately, or even 120kgf.

https://www.bikeforums.net/bicycle-m...on-meters.html

https://www.bikeforums.net/bicycle-m...on-meters.html

Likes For fishboat:

#7

Newbie

It is worth calibrating your tension meter. At least you will know it is accurate, and then over time you will come to rely on it less and less as you get used to what you are aiming for.

For what it's worth, calibrating a tension meter is not difficult and does not require heavy investment.

Also, get yourself a copy of brandts or mussons book and work through it.

For what it's worth, calibrating a tension meter is not difficult and does not require heavy investment.

Also, get yourself a copy of brandts or mussons book and work through it.

#9

Senior Member

Join Date: Jul 2013

Location: Nor-Cal

Posts: 3,767

Bikes: lots

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1958 Post(s)

Liked 2,932 Times

in

1,489 Posts

Wow, an entire dozen? I promise they would have been better if you'd had some way to judge tension. I've built close to 2000 and use one on every wheel I build or true.

Likes For cxwrench:

#10

Newbie

Join Date: Jun 2022

Posts: 10

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

But do remember this.. you cannot teach an old dog new tricks lol.

I will admit w sound and feel even given my Midland hearing I can do a good job without my tension meter. Get your wheel very round while eliminating the poorly tensioned or over tension spokes per each side on the rear. Once you're round you're pretty much done. It's just a matter of adding the subtracting tension per side to get the lateral true right on.

Throw the brost book in the garbage... Where it belongs.

Likes For Jtravels:

#11

Senior Member

Join Date: Jul 2013

Location: Nor-Cal

Posts: 3,767

Bikes: lots

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1958 Post(s)

Liked 2,932 Times

in

1,489 Posts

You can 'true to straightness' and still be wildly off on tension. How do you know other than guessing and then riding the wheel to see if it holds up? Please don't tell me that's how you do it.

#12

Junior Member

Join Date: May 2022

Posts: 13

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

Well, maybe only ten or eleven.. Only a couple professionally one summer, the rest for the pleasure of craft. I've had access to a tensionmeter but it never helped me. Maybe my wheels sucked, maybe not. Except for the ones built for customers, I've ridden every wheel I've built for many, many miles.

#13

Junior Member

Join Date: May 2022

Posts: 13

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

Thousands of robust wheels have been built without a tension meter. Yes, you can build a wheel with wildly inconsistent tension that is straight, and I have built a couple of those (which I ripped apart and rebuilt), but as you're doing that, it's pretty obvious you're getting it wrong.

With patience and some understanding, I've found no need to put a number on the tension in the spokes. It's not a fast way of building wheels, but I'm building for pleasure.

With patience and some understanding, I've found no need to put a number on the tension in the spokes. It's not a fast way of building wheels, but I'm building for pleasure.

#14

Newbie

Join Date: Jun 2022

Posts: 10

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

ASSumptions... One has to find some humor in it.

Your average spoke tightener.. define round? I don't think I've ever seen round from your average run of the mill spoke tightener.

Then define.. wildly inconsistent tension?

Suggest.. making your wheel round once around 1/2 the thickness of your average coin that being a dime. That gives you under .02 in AKA under 1/2 mm. Under one half is (actually more like one mm and above) where the spoke tightener game ends and the wheelbuilder starts. Then one is well past wildly inconsistent tension lol.

Nuff said.

Your average spoke tightener.. define round? I don't think I've ever seen round from your average run of the mill spoke tightener.

Then define.. wildly inconsistent tension?

Suggest.. making your wheel round once around 1/2 the thickness of your average coin that being a dime. That gives you under .02 in AKA under 1/2 mm. Under one half is (actually more like one mm and above) where the spoke tightener game ends and the wheelbuilder starts. Then one is well past wildly inconsistent tension lol.

Nuff said.

Last edited by Jtravels; 06-18-22 at 09:25 PM.

#15

AmiableNitrite Member

Join Date: Mar 2009

Location: From California, currently in Utah

Posts: 267

Bikes: '74 Alex Singer -'81 Mercian(sold) - '72 Motobecane GR(sold) - '73 Legnano(sold) - '6? Dawes Galaxy(sold) - '87 Masi GC(sold)

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 5 Post(s)

Liked 4 Times

in

3 Posts

I have a Park tension meter and use it to just confirm what I've trued, based on spoke ring sound.

Likes For VonCarlos:

#16

Newbie

Thread Starter

My cheapo tension meter just uses aluminum posts for the three contact points. With my rusty spokes, there's a range of readings (about 2 markings, ~30 kgf) where friction holds the meter steady. Does the Park tension meter have any sort of friction reduction measures (bearing/plastic bushing)? Would it be a good idea to grease/oil my tension meter?

#17

Full Member

Is the Park tensionmeter a good standard for someone truing a half-dozen wheels a year? What about a wheel stand? I've checked trueness in the frame with a clamped steel pointer aimed at the rim and eyeballing it seemed to be good enough. I have a Starrett dial indicator, but I'm not sure any of the wheels I own could ever be trued that precisely. We're talking early-eighties Belgian Weinmann rims on Maillard and Normandy hubs - not even close to CNC.

I had one set checked and trued by a LBS mechanic, but I have a few other bikes where the whole bike's value is not much more than the cost of an hour labor at the LBS. I might be willing to buy the Park Tool, not to build wheelsets, but to keep my few good wheels true and maybe take a crack at my junk sets.

I had one set checked and trued by a LBS mechanic, but I have a few other bikes where the whole bike's value is not much more than the cost of an hour labor at the LBS. I might be willing to buy the Park Tool, not to build wheelsets, but to keep my few good wheels true and maybe take a crack at my junk sets.

#18

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,464

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 955 Post(s)

Liked 1,619 Times

in

1,039 Posts

I gave up on trying to pay attention to the charts and numbers on my ChiCom tension meter. The reason is that I have no way of calibrating it reliably. My solution to this was to just pay attention to the numbers on the meter for what ever they indicate. I went around to my wheel sets and measured the tension on front and rear wheels. Surprisingly they were very close and in my newer well trued wheels there was little variance between the spokes for each side. Not so with some of my trued but beaten up wheel sets. I expected as much as they are survivors and at least round. For what its worth I'll post my findings but remember I am using a cheap ChiCom uncalibrated spoke tension meter. Your meter might have numbers entirely different. So what I am paying attention to is really finding that oddball spoke that is just to loose or too tight.

...........................................................

700c M13II 700c 622 14ga

Front: 32-34 Average = 33

Rear Drive Side: 32-33 Average = 31

Rear Nondrive Side: 28-30 Average = 29

..........................................................

Rm19 Weinmann 27-1/4 x 28c / 35c ETRTO 630X19 14ga

Front = 31

Rear Drive = 30

Rear Nondrive = 25

..........................................................

CR18 27-1/4 14ga SUNRIMS 14ga

Front = 31-32

Rear Drive = 31

Rear Nodrive = 27

..........................................................

...........................................................

700c M13II 700c 622 14ga

Front: 32-34 Average = 33

Rear Drive Side: 32-33 Average = 31

Rear Nondrive Side: 28-30 Average = 29

..........................................................

Rm19 Weinmann 27-1/4 x 28c / 35c ETRTO 630X19 14ga

Front = 31

Rear Drive = 30

Rear Nondrive = 25

..........................................................

CR18 27-1/4 14ga SUNRIMS 14ga

Front = 31-32

Rear Drive = 31

Rear Nodrive = 27

..........................................................

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

#19

Senior Member

When assembling new or used wheels, I have never had a typical spoke torque. I just tighten them semi snug and start truing. If the wheel is true and the spokes dont have a good ring, I give a quarter turn to all of them and make sure its still true until I have a good tension.

Yep, I never had all the fancy tools when I assembled wheels as a kid and as a testament to getting it right, they stayed true and never broke spokes either. But I'm mechanically inclined. Others may not have that skill as they do this task.

-SP

Yep, I never had all the fancy tools when I assembled wheels as a kid and as a testament to getting it right, they stayed true and never broke spokes either. But I'm mechanically inclined. Others may not have that skill as they do this task.

-SP

#20

Newbie

The park tension meter, like any measuring guage is only any good if it is calibrated, maintained, and used in a consistent manner.

Calibrating is easy. Rig up a spoke to a luggage scales and a fixed point using a bolt you can tighten up. Tighten the bolt until you get to say 90kg. Take a reading and compare it to the chart and adjust the screw on the meter accordingly.

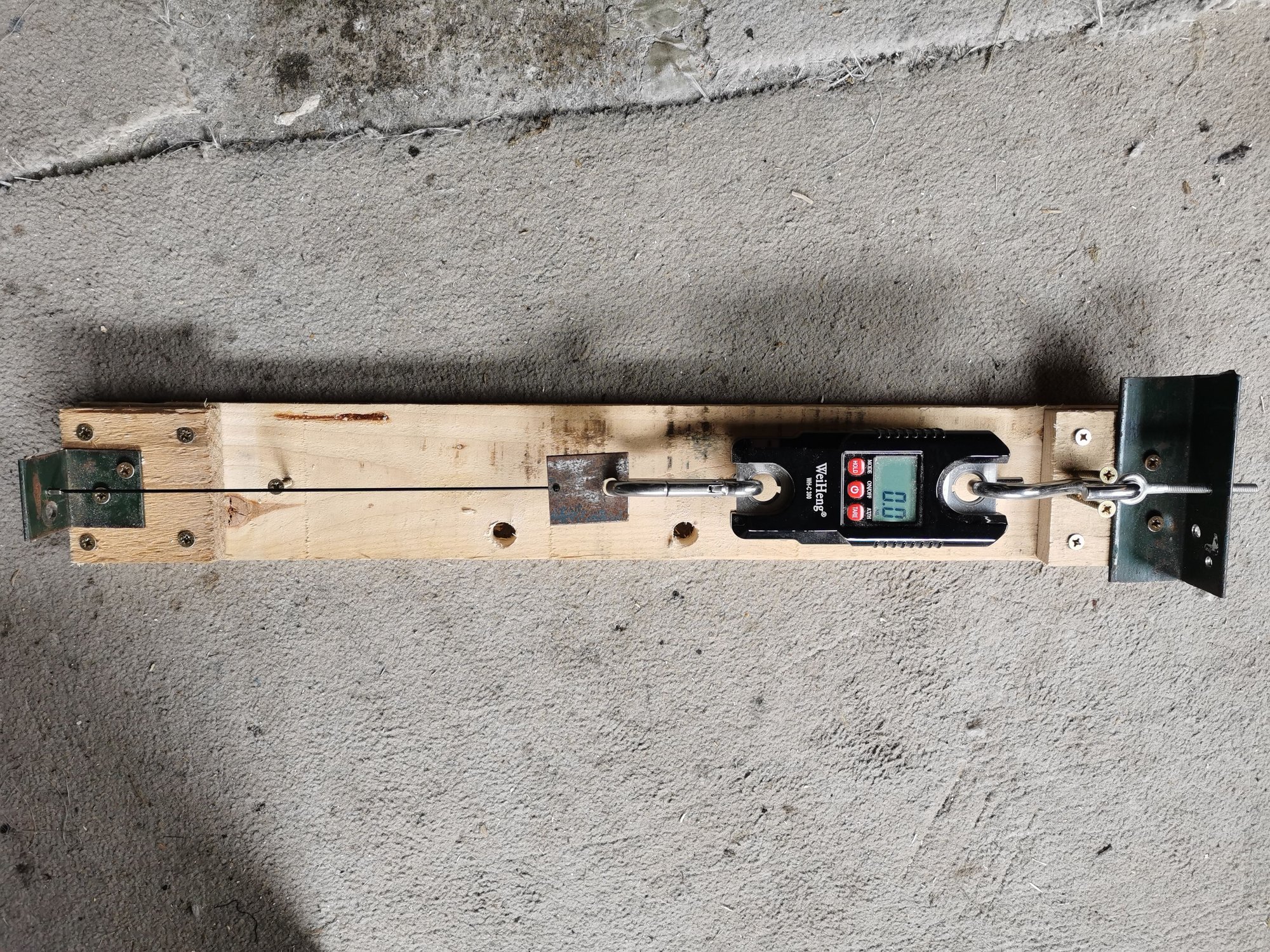

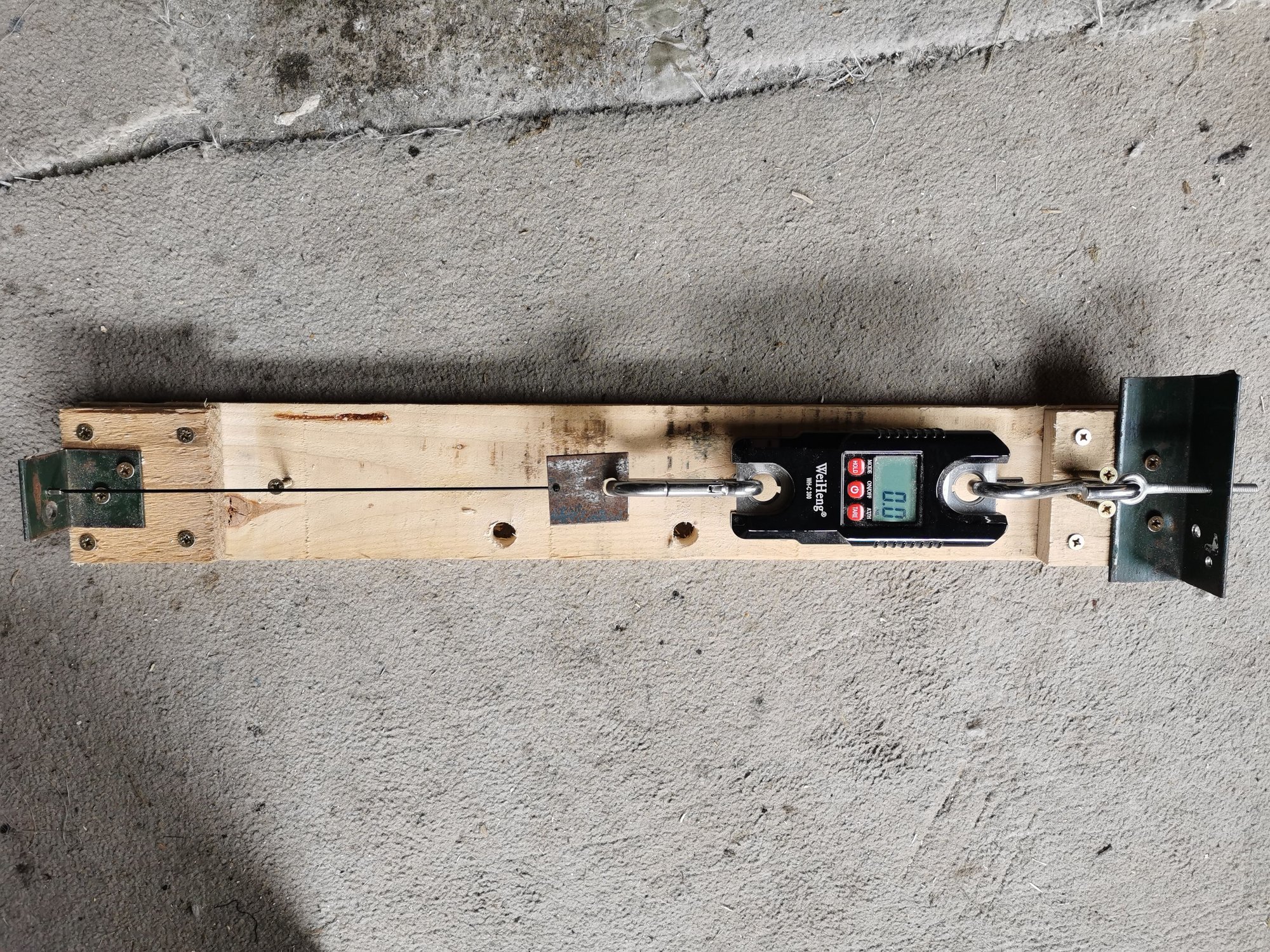

Here's a pic of my rig:

I'll calibrate my tensionmeter every couple of months or so because that's how often all my measuring devices in work need to be done.

As for the stand, I got by with a wooden one made to Roger Musson's design which is in his book. Cost me some labour. I bought a Park one because I treated myself. A stand is super nice because you can take the wheel into the house in the evening and work from a sofa if you want.

As for wheels and dial indicators - I have got a wheelset from a 90s cheap mountain bike as true as my good set on my modern Ridley roadbike. Same for my kids cheap bikes. Their wheels are so cheap they don't even file the weld beads off inside the rims an they still true up lovely. The dial indicators just put a number on it, but that is still satisfying.

As for my local LBS and wheel truing - a few sets have come my way and they were laughably rubbish. Total abscence of basics.

Calibrating is easy. Rig up a spoke to a luggage scales and a fixed point using a bolt you can tighten up. Tighten the bolt until you get to say 90kg. Take a reading and compare it to the chart and adjust the screw on the meter accordingly.

Here's a pic of my rig:

I'll calibrate my tensionmeter every couple of months or so because that's how often all my measuring devices in work need to be done.

As for the stand, I got by with a wooden one made to Roger Musson's design which is in his book. Cost me some labour. I bought a Park one because I treated myself. A stand is super nice because you can take the wheel into the house in the evening and work from a sofa if you want.

As for wheels and dial indicators - I have got a wheelset from a 90s cheap mountain bike as true as my good set on my modern Ridley roadbike. Same for my kids cheap bikes. Their wheels are so cheap they don't even file the weld beads off inside the rims an they still true up lovely. The dial indicators just put a number on it, but that is still satisfying.

As for my local LBS and wheel truing - a few sets have come my way and they were laughably rubbish. Total abscence of basics.

Is the Park tensionmeter a good standard for someone truing a half-dozen wheels a year? What about a wheel stand? I've checked trueness in the frame with a clamped steel pointer aimed at the rim and eyeballing it seemed to be good enough. I have a Starrett dial indicator, but I'm not sure any of the wheels I own could ever be trued that precisely. We're talking early-eighties Belgian Weinmann rims on Maillard and Normandy hubs - not even close to CNC.

I had one set checked and trued by a LBS mechanic, but I have a few other bikes where the whole bike's value is not much more than the cost of an hour labor at the LBS. I might be willing to buy the Park Tool, not to build wheelsets, but to keep my few good wheels true and maybe take a crack at my junk sets.

I had one set checked and trued by a LBS mechanic, but I have a few other bikes where the whole bike's value is not much more than the cost of an hour labor at the LBS. I might be willing to buy the Park Tool, not to build wheelsets, but to keep my few good wheels true and maybe take a crack at my junk sets.

Likes For Tawraste666:

#21

Newbie

Join Date: Jun 2022

Posts: 10

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Just wrapped up my first adventure into wheel truing. I first tried to do it by ear, got no where, and bought a cheap Chinese tension meter. If the included conversion table is accurate, I ended up ~140kgf on the drive side, and ~80kgf on the non-drive side (rear wheel). Does that look right? I know the drive side should be higher, but 75% difference? Also, my other bike (which is identical, but spokes are untouched) measured ~90kgf on the drive side, and ~56kgf on the non-drive side. How much of the difference is because I freshly tightened the spokes on bike#1, whereas bike#2's spokes stretched over the years? Should I lower the tension on bike#1 to match bike#2? How low can I go before I risk the nipples loosening themselves?

(They're basic single wall rims. Weimann ZAC1900.)

(They're basic single wall rims. Weimann ZAC1900.)

For sure 140 is way too high for a single wall rim. I seem to remember when I was practicing starting out that I tensioned a steel single wall rim 27-in to above 150 kg force. It was extremely round... and so very tight. LOL. Happens... You ain't the lone ranger. Lol again.

Any comments to what you learned so far?

#22

Newbie

Thread Starter

So Mr 140/80.. how did you solve that problem?

For sure 140 is way too high for a single wall rim. I seem to remember when I was practicing starting out that I tensioned a steel single wall rim 27-in to above 150 kg force. It was extremely round... and so very tight. LOL. Happens... You ain't the lone ranger. Lol again.

Any comments to what you learned so far?

For sure 140 is way too high for a single wall rim. I seem to remember when I was practicing starting out that I tensioned a steel single wall rim 27-in to above 150 kg force. It was extremely round... and so very tight. LOL. Happens... You ain't the lone ranger. Lol again.

Any comments to what you learned so far?

#23

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,660

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5766 Post(s)

Liked 2,537 Times

in

1,404 Posts

The tension differences aren't controlled by you, or anything you can do. They're about basic geometry and can be predicted with some simple math. The difference will always be proportional to the difference in drive and off side center to flange distance.

So if the left CTF is twice the right, the right tension will be double the left. If your hubs are a more typical 60:40 ratio, that's what the spoke tensions must be if the wheel is properly dished to center.

This is the classic dilemma of modern rear wheels. If, like me, you strive for tension ranges between 80 and 120kgf, it's IMPOSSIBLE to meat both goals if the hub CTF ratio is greater than 3:2. Even where it's possible you'll be squeezed into a narrow band of working tensions. IMO the solution lies in using thinner spokes on the left, so the preferred working elongation occurs at lower tension. You end up with (for example) right side 14/16g spokes at 115kgf, and left 15/17 spokes at 60kgf or so, or even left.

If you are forced to make a compromise, I believe it's better to slight exceed right side limits rather than have the left much less than target.

So if the left CTF is twice the right, the right tension will be double the left. If your hubs are a more typical 60:40 ratio, that's what the spoke tensions must be if the wheel is properly dished to center.

This is the classic dilemma of modern rear wheels. If, like me, you strive for tension ranges between 80 and 120kgf, it's IMPOSSIBLE to meat both goals if the hub CTF ratio is greater than 3:2. Even where it's possible you'll be squeezed into a narrow band of working tensions. IMO the solution lies in using thinner spokes on the left, so the preferred working elongation occurs at lower tension. You end up with (for example) right side 14/16g spokes at 115kgf, and left 15/17 spokes at 60kgf or so, or even left.

If you are forced to make a compromise, I believe it's better to slight exceed right side limits rather than have the left much less than target.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#24

Newbie

Thread Starter

The tension differences aren't controlled by you, or anything you can do. They're about basic geometry and can be predicted with some simple math. The difference will always be proportional to the difference in drive and off side center to flange distance.

So if the left CTF is twice the right, the right tension will be double the left. If your hubs are a more typical 60:40 ratio, that's what the spoke tensions must be if the wheel is properly dished to center.

This is the classic dilemma of modern rear wheels. If, like me, you strive for tension ranges between 80 and 120kgf, it's IMPOSSIBLE to meat both goals if the hub CTF ratio is greater than 3:2. Even where it's possible you'll be squeezed into a narrow band of working tensions. IMO the solution lies in using thinner spokes on the left, so the preferred working elongation occurs at lower tension. You end up with (for example) right side 14/16g spokes at 115kgf, and left 15/17 spokes at 60kgf or so, or even left.

If you are forced to make a compromise, I believe it's better to slight exceed right side limits rather than have the left much less than target.

So if the left CTF is twice the right, the right tension will be double the left. If your hubs are a more typical 60:40 ratio, that's what the spoke tensions must be if the wheel is properly dished to center.

This is the classic dilemma of modern rear wheels. If, like me, you strive for tension ranges between 80 and 120kgf, it's IMPOSSIBLE to meat both goals if the hub CTF ratio is greater than 3:2. Even where it's possible you'll be squeezed into a narrow band of working tensions. IMO the solution lies in using thinner spokes on the left, so the preferred working elongation occurs at lower tension. You end up with (for example) right side 14/16g spokes at 115kgf, and left 15/17 spokes at 60kgf or so, or even left.

If you are forced to make a compromise, I believe it's better to slight exceed right side limits rather than have the left much less than target.

Last edited by gululok; 10-12-22 at 10:18 PM.

#25

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,660

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5766 Post(s)

Liked 2,537 Times

in

1,404 Posts

There's also the percent elongation of the spoke which is critical to the spoke. You want the spoke to be stretched far enough that it won't go slack when the rim moves in or to it's side, yet not so stretched that it's approaching it's own elastic limits.

The two are related as described by Young's Modulus, which is expressed as stress over strain. To visualize it, imagine you're bungee jumping. If you use a bungee that's thinner, you'll get lower before it finally bottoms out. OTOH, too thick and you'll get more Gs and a short ride.The goal is to use the right thickness of bungee to get a great long ride to the bottom without crashing. The choice is driven by your weight; gorillas get thicker bungees than ballerinas.

Likewise, thinner spokes will elongate to their working range at lower tensions, allowing them to be tight enough to do the job on the left side while at low enough tension to maintain the dish.

Assuming you have 100mm flange separation offset 35:65 the ideal would to have the cross section area of the spokes that same 35:65 ratio. That way, they'll all be "stretched" equally.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Last edited by FBinNY; 10-12-22 at 11:05 PM.