DIY Chuck Harris cycling mirror?

#1

Disraeli Gears

Thread Starter

DIY Chuck Harris cycling mirror?

I've read a bit about Chuck Harris and his well-regarded/beloved cycling mirror, made from "pieces of broken car mirrors" and "recycled spokes". I am interested by the idea of perhaps in fashioning my own, but my desideratum is to have a sun/eyeglasses-mounted one rather than a helmet-mounted, because I often ride without a helmet. While there's a fair amount of internet notice of Mr Harris's persona (a singular fellow), there doesn't seem to be a lot of info about the design and technical details. For instance:

1. Car mirror material: any particular reason for that, as opposed to some other sort of mirror? Did he use the convex passenger-side ("objects in mirror are closer than they appear") for wide angle view, or just a flat mirror. Whichever it is, how does one cut/shape such a mirror? (He used a bike as a grinding machine, apparently -- I'm assuming that a bench grinder could be used also?)

2. How is the spoke fastened to the mirror? Just epoxy, or something more complicated?

3. I've read that the glasses-mount configuration doesn't work very well on frames with wire temples. I imagine that has to do with purchase and developing resistance to rotating around the temple. But that's the type of glasses I wear, so . . . looking for a way around that -- bracing against the eye rim or the temple over the ear, possibly.

4. Seems to me that a spoke is maybe more robust than is necessary; I'd like to try using music or stainless wire of a bit smaller gauge.

If anyone has any experience with Chuck Harris mirrors, and can inform me about the above issues, or about anything I seem to be overlooking, I'd appreciate it. Also, if anyone has a copy of the brochure or instructions pictured below, I'd like to see the full thing.

I realize that Hubbubonline.com, who had some sort of license from Mr Harris, is the source of the mirror below it (helmet-mount type, the only type they seem to sell these days -- though the one shown on the instructions is a glasses-mount type), and that they probably came up with the instructions too. If anyone has a glasses-mount mirror made by Chuck Harris himself, I'd appreciate a photo or two with a ruler shown for scale.

EDIT: Another eBay auction for some of these mirrors shows the entire sheet folded up in the image above:

And, another one of the auctions shows a somewhat different sheet:

I can see that Mr Harris used different types of wire (stainless, copper, aluminum) for different temples, and that there were both "set and forget" and "adjustable head" versions. I'd like to see an example of one of the adjustables made by Harris, and have a hunch that this involved brass tubing, as I have seen on some cycling mirror images I found (such as the Take-A-Look mirror).

1. Car mirror material: any particular reason for that, as opposed to some other sort of mirror? Did he use the convex passenger-side ("objects in mirror are closer than they appear") for wide angle view, or just a flat mirror. Whichever it is, how does one cut/shape such a mirror? (He used a bike as a grinding machine, apparently -- I'm assuming that a bench grinder could be used also?)

2. How is the spoke fastened to the mirror? Just epoxy, or something more complicated?

3. I've read that the glasses-mount configuration doesn't work very well on frames with wire temples. I imagine that has to do with purchase and developing resistance to rotating around the temple. But that's the type of glasses I wear, so . . . looking for a way around that -- bracing against the eye rim or the temple over the ear, possibly.

4. Seems to me that a spoke is maybe more robust than is necessary; I'd like to try using music or stainless wire of a bit smaller gauge.

If anyone has any experience with Chuck Harris mirrors, and can inform me about the above issues, or about anything I seem to be overlooking, I'd appreciate it. Also, if anyone has a copy of the brochure or instructions pictured below, I'd like to see the full thing.

I realize that Hubbubonline.com, who had some sort of license from Mr Harris, is the source of the mirror below it (helmet-mount type, the only type they seem to sell these days -- though the one shown on the instructions is a glasses-mount type), and that they probably came up with the instructions too. If anyone has a glasses-mount mirror made by Chuck Harris himself, I'd appreciate a photo or two with a ruler shown for scale.

EDIT: Another eBay auction for some of these mirrors shows the entire sheet folded up in the image above:

And, another one of the auctions shows a somewhat different sheet:

I can see that Mr Harris used different types of wire (stainless, copper, aluminum) for different temples, and that there were both "set and forget" and "adjustable head" versions. I'd like to see an example of one of the adjustables made by Harris, and have a hunch that this involved brass tubing, as I have seen on some cycling mirror images I found (such as the Take-A-Look mirror).

Last edited by Charles Wahl; 06-29-21 at 06:48 AM.

Likes For Charles Wahl:

#2

Freewheel Medic

Join Date: Oct 2005

Location: An Island on the Coast of GA!

Posts: 12,881

Bikes: Snazzy* Schwinns, Classy Cannondales & a Super Pro Aero Lotus (* Ed.)

Mentioned: 140 Post(s)

Tagged: 0 Thread(s)

Quoted: 1452 Post(s)

Liked 2,185 Times

in

961 Posts

I can't help with any of your specific questions nor with any scans of the literature. But I'll share my two cents:

I've used both helmet and eyeglass mounted mirrors and prefer the eyeglass ones. I find them to be more stabilized, with the helmet moving independent of my head just enough to make rearview seeing a bit more challenging with helmet mounted mirrors.

However, the problem I've run into with the spectacle mounted version is that eventually the wire or the plastic fingers extending from the main support arm (on the mirror), which secure the mirrors to my glasses, eventually break. While I primarily wear a pair of wrap-around prescription sports glasses (plastic blades for arms) for riding (I have a tearing issue from the wind), my everyday spectacles have wire or thin metal arms, I've broken the mirror arms on those types of frames as well.

My final work around (after breaking a good half dozen mirror arms), was to sew a leather sleeve around the main support arm on the mirror and the blade arm on my prescription glasses. If you are interested, I'd be glad to post a picture.

I've used both helmet and eyeglass mounted mirrors and prefer the eyeglass ones. I find them to be more stabilized, with the helmet moving independent of my head just enough to make rearview seeing a bit more challenging with helmet mounted mirrors.

However, the problem I've run into with the spectacle mounted version is that eventually the wire or the plastic fingers extending from the main support arm (on the mirror), which secure the mirrors to my glasses, eventually break. While I primarily wear a pair of wrap-around prescription sports glasses (plastic blades for arms) for riding (I have a tearing issue from the wind), my everyday spectacles have wire or thin metal arms, I've broken the mirror arms on those types of frames as well.

My final work around (after breaking a good half dozen mirror arms), was to sew a leather sleeve around the main support arm on the mirror and the blade arm on my prescription glasses. If you are interested, I'd be glad to post a picture.

__________________

Bob

Enjoying the GA coast all year long!

Thanks for visiting my website: www.freewheelspa.com

Bob

Enjoying the GA coast all year long!

Thanks for visiting my website: www.freewheelspa.com

Likes For pastorbobnlnh:

Likes For Charles Wahl:

#4

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,467

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1826 Post(s)

Liked 3,367 Times

in

1,573 Posts

I've read a bit about Chuck Harris and his well-regarded/beloved cycling mirror, made from "pieces of broken car mirrors" and "recycled spokes". I am interested by the idea of perhaps in fashioning my own, but my desideratum is to have a sun/eyeglasses-mounted one rather than a helmet-mounted, because I often ride without a helmet. While there's a fair amount of internet notice of Mr Harris's persona (a singular fellow), there doesn't seem to be a lot of info about the design and technical details. For instance:

1. Car mirror material: any particular reason for that, as opposed to some other sort of mirror? Did he use the convex passenger-side ("objects in mirror are closer than they appear") for wide angle view, or just a flat mirror. Whichever it is, how does one cut/shape such a mirror? (He used a bike as a grinding machine, apparently -- I'm assuming that a bench grinder could be used also?)

1. Car mirror material: any particular reason for that, as opposed to some other sort of mirror? Did he use the convex passenger-side ("objects in mirror are closer than they appear") for wide angle view, or just a flat mirror. Whichever it is, how does one cut/shape such a mirror? (He used a bike as a grinding machine, apparently -- I'm assuming that a bench grinder could be used also?)

Mike Hauptman of Rockford, IL (and formerly(?) active on the I-Bob group) used to make mirrors of the same style, but used plastic mirrors purchased from hobby shops (Micheals, Hobby Lobby, etc). This seems like an easier and more reliable method. Acting on his advice, I did go looking for mirrors of this type, but only found glass ones.

a couple of shots of one mirror with tarnishing...

photos....

3. I've read that the glasses-mount configuration doesn't work very well on frames with wire temples. I imagine that has to do with purchase and developing resistance to rotating around the temple. But that's the type of glasses I wear, so . . . looking for a way around that -- bracing against the eye rim or the temple over the ear, possibly.

If anyone has any experience with Chuck Harris mirrors, and can inform me about the above issues, or about anything I seem to be overlooking, I'd appreciate it. Also, if anyone has a copy of the brochure or instructions pictured below, I'd like to see the full thing.

and for fun, a shot of Chuck adjusting a mirror for a customer....

I realize that Hubbubonline.com, who had some sort of license from Mr Harris, is the source of the mirror below it (helmet-mount type, the only type they seem to sell these days -- though the one shown on the instructions is a glasses-mount type), and that they probably came up with the instructions too. If anyone has a glasses-mount mirror made by Chuck Harris himself, I'd appreciate a photo or two with a ruler shown for scale.

I can see that Mr Harris used different types of wire (stainless, copper, aluminum) for different temples, and that there were both "set and forget" and "adjustable head" versions. I'd like to see an example of one of the adjustables made by Harris, and have a hunch that this involved brass tubing, as I have seen on some cycling mirror images I found (such as the Take-A-Look mirror).

Steve in Peoria

Likes For steelbikeguy:

#5

Senior Member

Join Date: Sep 2015

Location: Massachusetts

Posts: 763

Bikes: S-Works Stumpjumper HT Disc, Fuji Absolute, Kona Jake the Snake, '85 Cannondale SR900

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 219 Post(s)

Liked 217 Times

in

142 Posts

I just want to contribute that I initially read the thread title as "DIY Chuck NORRIS cycling mirror!"

#6

Senior Member

#7

Disraeli Gears

Thread Starter

Thanks Steve!

I'm not up on mirror technology, but wouldn't it be easy enough to cut a mirror down and seal the edges with, say, silicone or varnish, or epoxy?

Can one, indeed, grind the edges of a tempered mirror and not have it shatter? As an architect, I'm used to the idea that you have to fabricate any glass panes (cut to size, polish, drill any holes; admittedly for much larger pieces) before tempering, or it simply breaks.

Note that the b/w sheet you've posted has, after "HEAD TOO LOOSE ON WIRE?" the following: "The threads and the internal steel coil are tapered". Sounds pretty high-tech, {EDIT} and not simply like a threaded spoke end and a nipple. If a nipple, then for DIY purposes one might use a (brass) nipple with the head cut off (or filed off). I suppose one could "taper" the threads in a nipple by squeezing the end of it a bit in a vise.

What is the size that you prefer?

Do you think that the mirrors are flat, or convex?

And: what is that tool that Chuck Harris is brandishing in the photo of him adjusting? Huge needle-nose plier?

I think he used car mirrors because they were tempered and wouldn't just shatter into dangerous shards upon impact. I'm not sure that I want to know how he learned that lesson. The risk of cutting a car mirror into pieces is that the seal along the edge is compromised.

Can one, indeed, grind the edges of a tempered mirror and not have it shatter? As an architect, I'm used to the idea that you have to fabricate any glass panes (cut to size, polish, drill any holes; admittedly for much larger pieces) before tempering, or it simply breaks.

Do you think that the mirrors are flat, or convex?

And: what is that tool that Chuck Harris is brandishing in the photo of him adjusting? Huge needle-nose plier?

Last edited by Charles Wahl; 06-29-21 at 10:31 AM.

#8

multimodal commuter

Join Date: Nov 2006

Location: NJ, NYC, LI

Posts: 19,808

Bikes: 1940s Fothergill, 1959 Allegro Special, 1963? Claud Butler Olympic Sprint, Lambert 'Clubman', 1974 Fuji "the Ace", 1976 Holdsworth 650b conversion rando bike, 1983 Trek 720 tourer, 1984 Counterpoint Opus II, 1993 Basso Gap, 2010 Downtube 8h, and...

Mentioned: 584 Post(s)

Tagged: 0 Thread(s)

Quoted: 1908 Post(s)

Liked 574 Times

in

339 Posts

I don't have any experience with the Chuck Harris mirror. I had an excellent mirror of this type that I got in 1980 or so; the mirror was a lucite disc with a groove machined into the edge, and the end of the wire was bent into a circle just a little smaller than that, so the wire held the lucite mirror snugly and firmly (until it didn't; the mirror fell out a few years ago. Cheap **** didn't even last 40 years! If I were making myself a new mirror, I'd try to replicate that one.

I don't bother making them for myself, though. These are better than what I could make: https://www.ebay.com/itm/33404809845...UAAOSwOvJe2fB9

They don't last for ever. I got three of them a while ago, and am still on my second one.

I don't bother making them for myself, though. These are better than what I could make: https://www.ebay.com/itm/33404809845...UAAOSwOvJe2fB9

They don't last for ever. I got three of them a while ago, and am still on my second one.

__________________

www.rhmsaddles.com.

www.rhmsaddles.com.

#9

Disraeli Gears

Thread Starter

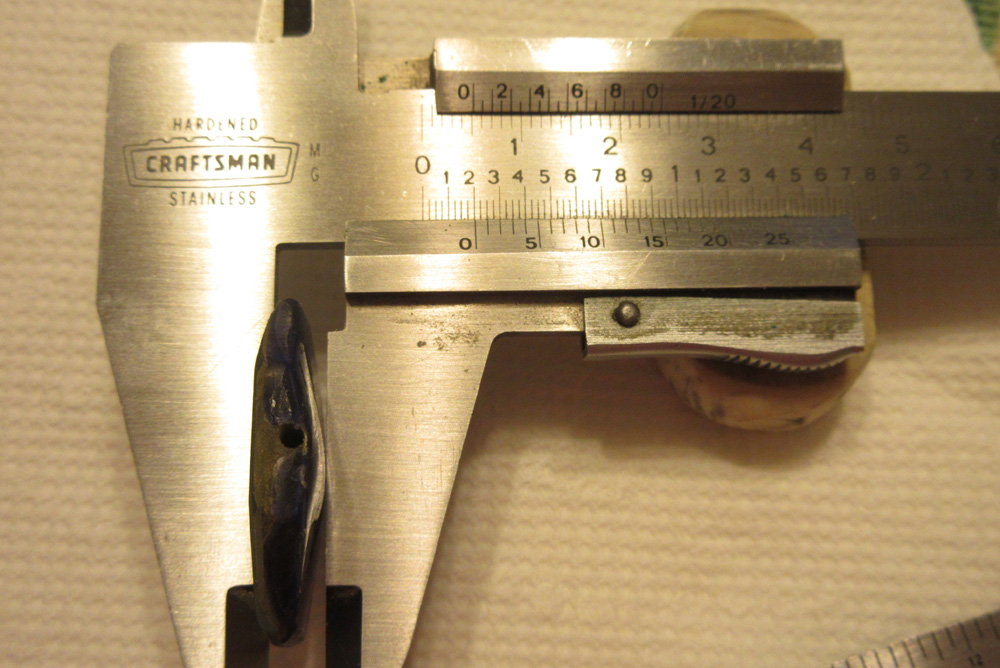

rhm: Do those eBay mirrors have stainless tubes, and a friction fit such that they can adjust in all 3 axes? How do you find the size of the mirror? Could you measure the mirror for me? Do you helmet mount or glasses mount?

Also, for what you're describing on the 1980s mirror: the wire wrapped around most of the circumference of the lucite disk? Like a circlip?

Also, for what you're describing on the 1980s mirror: the wire wrapped around most of the circumference of the lucite disk? Like a circlip?

Last edited by Charles Wahl; 06-29-21 at 01:02 PM.

#10

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,467

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1826 Post(s)

Liked 3,367 Times

in

1,573 Posts

Thanks Steve!

I'm not up on mirror technology, but wouldn't it be easy enough to cut a mirror down and seal the edges with, say, silicone or varnish, or epoxy?

Can one, indeed, grind the edges of a tempered mirror and not have it shatter? As an architect, I'm used to the idea that you have to fabricate any glass panes (cut to size, polish, drill any holes; admittedly for much larger pieces) before tempering, or it simply breaks.

I'm not up on mirror technology, but wouldn't it be easy enough to cut a mirror down and seal the edges with, say, silicone or varnish, or epoxy?

Can one, indeed, grind the edges of a tempered mirror and not have it shatter? As an architect, I'm used to the idea that you have to fabricate any glass panes (cut to size, polish, drill any holes; admittedly for much larger pieces) before tempering, or it simply breaks.

As far as sealing the edges... any time that you are trying to get stuff to stick to something, there are processes for preparing the surface that must be followed. This is a lot easier to do in a factory and with automation than with a garage operation. I've got one mirror that has held up just fine, and three that have considerable tarnishing.

Note that the b/w sheet you've posted has, after "HEAD TOO LOOSE ON WIRE?" the following: "The threads and the internal steel coil are tapered". Sounds pretty high-tech, {EDIT} and not simply like a threaded spoke end and a nipple. If a nipple, then for DIY purposes one might use a (brass) nipple with the head cut off (or filed off). I suppose one could "taper" the threads in a nipple by squeezing the end of it a bit in a vise.

Mostly, this produces a angular range of vision that works for me... enough to see, but not blocking too much of my vision to the front.

The angular range of vision is also affected by how far the mirror is from your eye. This is partly controlled by the need for the mirror to be to the left of one's head, so that puts it a couple of inches to the left of the eye. If the mirror is close to the eye and 2 inches to the left, you have to look quite far to the side to see it, and possibly outside of the range covered by one's glasses. For this reason, the mirror is typically also placed a few inches forward of the eyes.

Put this all together, and a 1.25" wide mirror is what works for me.

The mirrors are flat. No need for a wide field of vision per se, since the user can turn his head to the left and right to scan a larger area. Mostly, you want to see traffic on the road behind you, and a flat mirror does this quite well.

Chuck is holding a large pair of needle nose pliers, or maybe a pair of lineman's pliers? This was used to bend the spoke as he helped the customer get everything adjusted. I think this is a hurdle for a lot of folks who buy a mirror from a retailer and have to figure out how to adjust it themselves. From what I can tell, Chuck adjusted it laterally, to get it just beyond the width of the head, and then adjusted it in pitch so the customer would see the tops of their ear, and then adjust it in yaw (via the spoke threads) so that the head was just barely protruding into view. He was pretty quick.

Steve in Peoria