Forks bent: but which and to what direction?

#1

Junior Member

Thread Starter

Forks bent: but which and to what direction?

Hello!

I bought this Gitane TdF via internet some years ago, took it for a quick spin and dissasembled for tuning and cleaning. Now I was building it as a rainy day bike with fenders. I did not crash it so I believe the fork was bent already when I bought it, I just did not notice that.

The wheel sits way to the right blade, flipping the wheel won't help. I can't see any typical front end collision marks anywhere on frame.

Blade proximal parts look somewhat in line, but when I press right eyelet to the table, left eyelet is still in air. So right blade is bent to the back? Or is left bent to front?? Does this even matter when bending back as the difference is not that big?

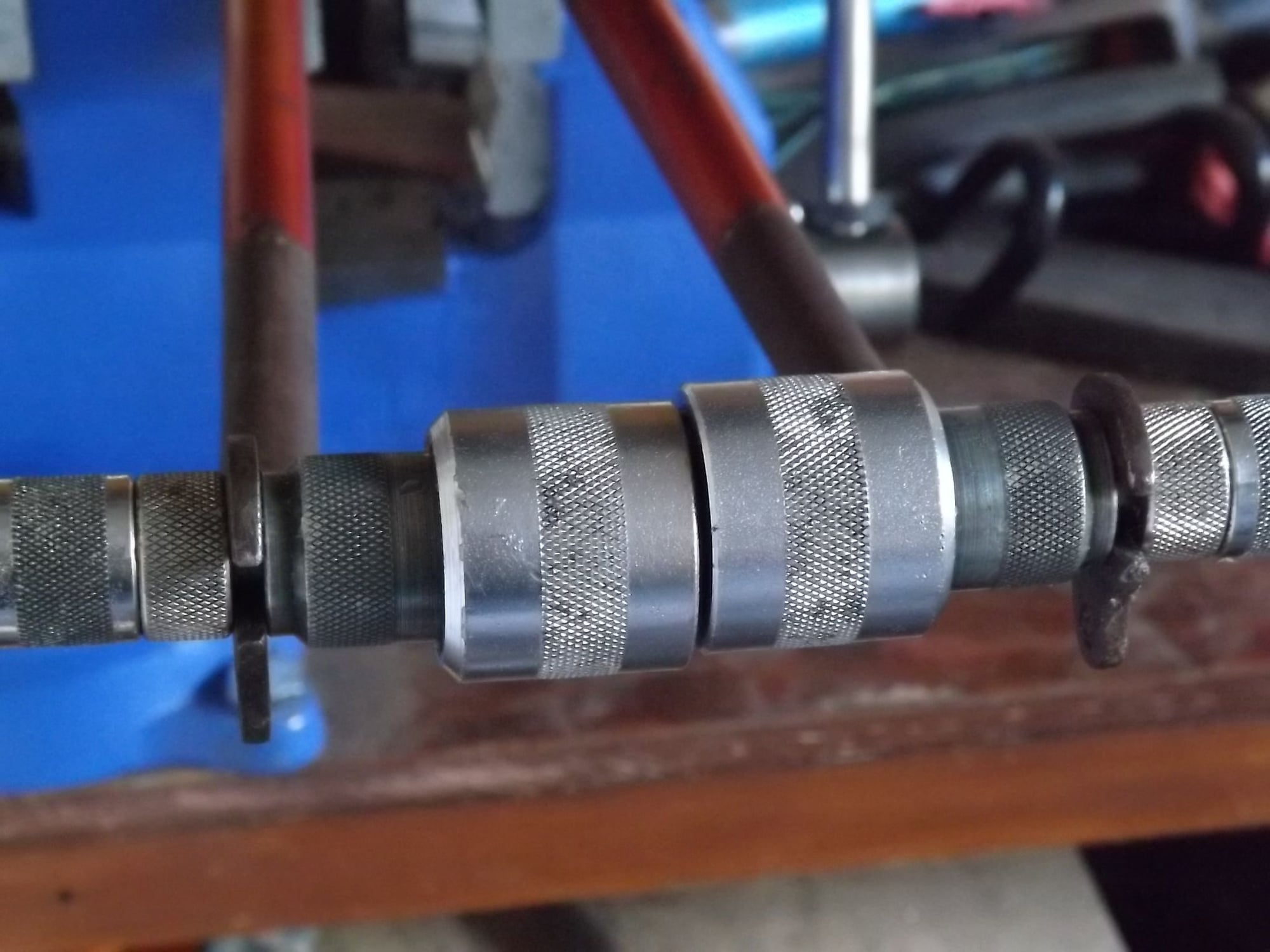

I have just this DIY deluxe fork rig, not much of use checking alignment, but decent for keeping fork in place while bending.

Now, with my equipment, is there a better aligning method than "I'll bend this there and hope it helps. If not, I'll bend some more or in other place"?

AFAIK, there are no LBS capable of doing this nearby. I think I can find a framebuilder, but this would include shipping the fork.

I bought this Gitane TdF via internet some years ago, took it for a quick spin and dissasembled for tuning and cleaning. Now I was building it as a rainy day bike with fenders. I did not crash it so I believe the fork was bent already when I bought it, I just did not notice that.

The wheel sits way to the right blade, flipping the wheel won't help. I can't see any typical front end collision marks anywhere on frame.

Blade proximal parts look somewhat in line, but when I press right eyelet to the table, left eyelet is still in air. So right blade is bent to the back? Or is left bent to front?? Does this even matter when bending back as the difference is not that big?

I have just this DIY deluxe fork rig, not much of use checking alignment, but decent for keeping fork in place while bending.

Now, with my equipment, is there a better aligning method than "I'll bend this there and hope it helps. If not, I'll bend some more or in other place"?

AFAIK, there are no LBS capable of doing this nearby. I think I can find a framebuilder, but this would include shipping the fork.

#2

Senior Member

Join Date: Mar 2019

Posts: 1,606

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 581 Post(s)

Liked 921 Times

in

518 Posts

One parameter for which you can make a quick 'alignment tool' is the dropout alignment and parallelism - if you can find two longish bolt about the diameter of the axle, and 4 nuts to go with them, you fasten one bolt to each dropout such that the nuts are properly flat against the dropout face and the bolts are close to meeting in the middle. THis will give you an idea of how close to parallel and aligned the dropouts are.

#3

Senior Member

Join Date: May 2008

Location: Fredericksburg, Va

Posts: 9,579

Bikes: '65 Frejus TDF, '73 Bottecchia Giro d'Italia, '83 Colnago Superissimo, '84 Trek 610, '84 Trek 760, '88 Pinarello Veneto, '88 De Rosa Pro, '89 Pinarello Montello, '94 Burley Duet, 97 Specialized RockHopper, 2010 Langster, Tern Link D8

Mentioned: 73 Post(s)

Tagged: 0 Thread(s)

Quoted: 1607 Post(s)

Liked 2,216 Times

in

1,103 Posts

@Jantaras - In preparation for bending a fork, I would research what the offset should be. Most are around 40 on up with track forks sometimes around 38. The Trek 760 is 38 unlike most others.

Then you can measue which blade has the right offset. @Doug Fattic among other frame builders on the forum may offer really good advice/direction.

Then you can measue which blade has the right offset. @Doug Fattic among other frame builders on the forum may offer really good advice/direction.

__________________

Bikes don't stand alone. They are two tired.

Bikes don't stand alone. They are two tired.

#4

www.theheadbadge.com

Join Date: Sep 2005

Location: Southern Florida

Posts: 28,513

Bikes: https://www.theheadbadge.com

Mentioned: 124 Post(s)

Tagged: 0 Thread(s)

Quoted: 2422 Post(s)

Liked 4,391 Times

in

2,092 Posts

Using the fork brace you built, take measurements from the bench up to the bottom of each blade at different points.

Do the same across an imaginary line down the center of the steerer tube, out to each blade.

There's a remote possibility one dropout was brazed in lower than the other from factory, but that's the LAST place you look after eliminating all other possibilities. I highly doubt anyone would have put up with it when new if it were built like that either.

Highly suggest you get a Park fork jig just so you have the ability to move a fixed reference point up and down the fork.

-Kurt

Do the same across an imaginary line down the center of the steerer tube, out to each blade.

There's a remote possibility one dropout was brazed in lower than the other from factory, but that's the LAST place you look after eliminating all other possibilities. I highly doubt anyone would have put up with it when new if it were built like that either.

Highly suggest you get a Park fork jig just so you have the ability to move a fixed reference point up and down the fork.

-Kurt

#5

Cat 6

Join Date: Dec 2007

Location: Mountain Brook, AL

Posts: 7,482

Mentioned: 27 Post(s)

Tagged: 0 Thread(s)

Quoted: 500 Post(s)

Liked 183 Times

in

118 Posts

If you go the framebuilder route: I had a fork that was similar wonky, but worse. Sent it off to Dave @ SW Frameworks in Dallas. Very reasonable price and came back perfect.

#6

Full Member

Join Date: Apr 2019

Location: Denver Metro, CO

Posts: 392

Bikes: 1972 Fuji The Finest | 1990 Bianchi Giro | 1999 LeMond Buenos Aires

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 151 Post(s)

Liked 303 Times

in

134 Posts

I might have missed it, but did you post your location? Might be a nearby frame builder or tinkerer extraordinaire nearby that forum members know.

Second the thoughts of drawing a centerline from your current jig/ setup (either by measuring down from the steerer OD with a square and extending those lines, or maybe a plumb bob?) and then measuring offsets to the fork legs in several spots, both horizontally and vertically. If it’s off a lot should be measurable.

Dropout alignment check is a good idea too. The long bolt and/or all-thread with some washers and nuts is cheap and easy check. It’s aligned pretty well if you can spin a nut from one bolt onto the other. 9mm front axle means that 5/16” is a pretty decent fit, or 11/32” if you find it. My Bianchi had enough of a sideways bias that the dropouts were aligned but not the fork itself, a local frame builder checked and fixed it when he also fixed the frame alignment for me.

Second the thoughts of drawing a centerline from your current jig/ setup (either by measuring down from the steerer OD with a square and extending those lines, or maybe a plumb bob?) and then measuring offsets to the fork legs in several spots, both horizontally and vertically. If it’s off a lot should be measurable.

Dropout alignment check is a good idea too. The long bolt and/or all-thread with some washers and nuts is cheap and easy check. It’s aligned pretty well if you can spin a nut from one bolt onto the other. 9mm front axle means that 5/16” is a pretty decent fit, or 11/32” if you find it. My Bianchi had enough of a sideways bias that the dropouts were aligned but not the fork itself, a local frame builder checked and fixed it when he also fixed the frame alignment for me.

#7

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,984

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26406 Post(s)

Liked 10,374 Times

in

7,203 Posts

.

...I would be hard pressed to properly realign that without a fork jig. Park made one, and VAR made one. You don't se them around much inn bike shops any more because they all stopped doing this for issues of liability. I could point you to at least three different people with a fork jig here in Sacramento, but you probably need to do some looking around where you live, for a local one. People on this forum have made their own, based on this same design. But that's a lot of work for one fork. Here is what it looks like in use.

...I would be hard pressed to properly realign that without a fork jig. Park made one, and VAR made one. You don't se them around much inn bike shops any more because they all stopped doing this for issues of liability. I could point you to at least three different people with a fork jig here in Sacramento, but you probably need to do some looking around where you live, for a local one. People on this forum have made their own, based on this same design. But that's a lot of work for one fork. Here is what it looks like in use.

#8

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,476

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 963 Post(s)

Liked 1,628 Times

in

1,044 Posts

Having seen what can result with fork failure when ridding I would send this fork to a frame builder. I am a DIY guy, so if doing it myself, I would first strip all the paint off of the fork and inspect it inside and out with magnification before doing anything else.

I really like that long sweep...

I really like that long sweep...

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

#9

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,634

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4678 Post(s)

Liked 5,795 Times

in

2,281 Posts

PM sent.

The problem is almost certainly that the distance from dropout (axle) to fork crown (A-C distance) is slightly mismatched. The solution is to match them. My method is to add a touch more fork offset on one side, which shortens the A-C on one side, and "pulls" the wheel back up to center. After tha I touch up the dropout parallelism as others have stated.

I've done this for many forum members with good success. It takes some very specialized tools, and I made my own fork reraking tool which only touches the fork blade, so no extra stress is applied to brazed points (fork crown and dropouts).

The problem is almost certainly that the distance from dropout (axle) to fork crown (A-C distance) is slightly mismatched. The solution is to match them. My method is to add a touch more fork offset on one side, which shortens the A-C on one side, and "pulls" the wheel back up to center. After tha I touch up the dropout parallelism as others have stated.

I've done this for many forum members with good success. It takes some very specialized tools, and I made my own fork reraking tool which only touches the fork blade, so no extra stress is applied to brazed points (fork crown and dropouts).

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

Likes For gugie:

#10

Junior Member

Thread Starter

As always, thank you all for responses!

I forgot to mention, I live in Finland, I should state it in account's description...

The first thing I thought of was fork end alignment, I checked them and they were not aligned, it was a month or so ago, so the memory is hazy now. I think they were not paralel and one was more posterior than the other. I got them aligned, not perfectly, but to a much beteer shape. Did did not help, though.

Well, forks are too difficult for me still. Could it be that one blade was shorter and I bent it trying to align forkends? Again, if one blade is shorter, should't the fork end alignment tool "bolts" (not sure what is the proper name) be on different levels?

I forgot to mention, I live in Finland, I should state it in account's description...

The first thing I thought of was fork end alignment, I checked them and they were not aligned, it was a month or so ago, so the memory is hazy now. I think they were not paralel and one was more posterior than the other. I got them aligned, not perfectly, but to a much beteer shape. Did did not help, though.

Well, forks are too difficult for me still. Could it be that one blade was shorter and I bent it trying to align forkends? Again, if one blade is shorter, should't the fork end alignment tool "bolts" (not sure what is the proper name) be on different levels?

#11

framebuilder

Steel forks are frequently somewhat out of alignment. There are 4 primary factors to check. 1st, is the rake (curve) on both blades the same. And does the current amount of rake match the original design? 2nd, are the dropouts equidistant from the steerer's centerline? 3rd, are the dropouts parallel to each other? And 4th, are the fork blades the same length so the wheel centers? If any one of those factors are not correct, it will influence the others. For example if the dropouts are over to one side (#2), then the wheel will not center. The problem is not that one fork blade is longer than the other (although both may be a problem).

I'm a framebuilder with all the right tools so I haven't given much thought to how one can check a fork without them. I would think check #2 and #3 would require proper equipment (like you already have for #3). On a recent subject thread on Questions about a Schwinn Super Sport I posted pictures of bringing a damaged fork back to spec.

I'm a framebuilder with all the right tools so I haven't given much thought to how one can check a fork without them. I would think check #2 and #3 would require proper equipment (like you already have for #3). On a recent subject thread on Questions about a Schwinn Super Sport I posted pictures of bringing a damaged fork back to spec.

#12

Full Member

Join Date: Jul 2015

Location: Chicago

Posts: 309

Bikes: nothing to brag about

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 130 Post(s)

Liked 206 Times

in

116 Posts

This looks a bit like how my 1970 Raleigh International came, straight from the factory. The two legs of the fork were of different lengths, then bent differently so that the dropouts were in the same place so that the wheel appeared centered. There was nothing subtle about it! The bike never rode right and when I gave the frame to a friend for his son to convert to a fixee I suggested that they buy a new fork. I attributed the problem to the spectacularly poor manufacturing standards that seemed to prevail in many industries in the 70s.

#13

Junior Member

Thread Starter

Thanks for inputs!

It is quite clear that it is a job for a more experienced person than I am. I contacted a shop/buider about 500 miles from me (same country, though) and he said he/they have the equipment and skills to align steel forks. Will be visiting local post office soon. Thanks for help!

It is quite clear that it is a job for a more experienced person than I am. I contacted a shop/buider about 500 miles from me (same country, though) and he said he/they have the equipment and skills to align steel forks. Will be visiting local post office soon. Thanks for help!

#14

Junior Member

Thread Starter

Update

So an update. After 2 months at the (somewhat) local workshop I got the fork back. He was not in a hurry with my fork, I called several times...

The package also had a note that fork is softened because of damage and he does not recommend using it.

After trying to install it I noticed that end spacing is waaay off, insted of usual 100 mm it is 87 mm (it was 100 mm before I sent the fork). Also forkends are not paralell (visually), my end alignment tools won't even fit in between. The original blade misalignment is corrected, it seems.

After calling the shop it looks like he forgot to check the fork end alignment and spacing. He should be quite experienced with older bikes (at least was back in the day), but yeah, the finished alignment doesn't look good and reliable... Also, he said, the damage/blade bend makes somewhat diffucult to get all spacings right...

Looks like forkends were fixed in the 100mm rig during straightening process and after releasing rebounded to 87mm and no one cared to check.

In any case, he thinks that because of the damage the fork is softened significantly, way softer that intact forks of that age. He tried to explain but that was a bit too difficult for my understand. Somekind of a bent, that formed during damage (if I understood correctly, some kind of "shoulder"), that after straightening still prone to bending (or becomes softer).

Well, maybe it is time for a new fork...

Is this common for a fork to become softer after some kind of misalignment/bend damage and alignment? I always thought the steel is quite tolerant to bendings ( at least for a one or two). I can't find any marks of a collision on the frame.

The package also had a note that fork is softened because of damage and he does not recommend using it.

After trying to install it I noticed that end spacing is waaay off, insted of usual 100 mm it is 87 mm (it was 100 mm before I sent the fork). Also forkends are not paralell (visually), my end alignment tools won't even fit in between. The original blade misalignment is corrected, it seems.

After calling the shop it looks like he forgot to check the fork end alignment and spacing. He should be quite experienced with older bikes (at least was back in the day), but yeah, the finished alignment doesn't look good and reliable... Also, he said, the damage/blade bend makes somewhat diffucult to get all spacings right...

Looks like forkends were fixed in the 100mm rig during straightening process and after releasing rebounded to 87mm and no one cared to check.

In any case, he thinks that because of the damage the fork is softened significantly, way softer that intact forks of that age. He tried to explain but that was a bit too difficult for my understand. Somekind of a bent, that formed during damage (if I understood correctly, some kind of "shoulder"), that after straightening still prone to bending (or becomes softer).

Well, maybe it is time for a new fork...

Is this common for a fork to become softer after some kind of misalignment/bend damage and alignment? I always thought the steel is quite tolerant to bendings ( at least for a one or two). I can't find any marks of a collision on the frame.

#15

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

So an update. After 2 months at the (somewhat) local workshop I got the fork back. He was not in a hurry with my fork, I called several times...

The package also had a note that fork is softened because of damage and he does not recommend using it.

After trying to install it I noticed that end spacing is waaay off, insted of usual 100 mm it is 87 mm (it was 100 mm before I sent the fork). Also forkends are not paralell (visually), my end alignment tools won't even fit in between. The original blade misalignment is corrected, it seems.

After calling the shop it looks like he forgot to check the fork end alignment and spacing. He should be quite experienced with older bikes (at least was back in the day), but yeah, the finished alignment doesn't look good and reliable... Also, he said, the damage/blade bend makes somewhat diffucult to get all spacings right...

Looks like forkends were fixed in the 100mm rig during straightening process and after releasing rebounded to 87mm and no one cared to check.

In any case, he thinks that because of the damage the fork is softened significantly, way softer that intact forks of that age. He tried to explain but that was a bit too difficult for my understand. Somekind of a bent, that formed during damage (if I understood correctly, some kind of "shoulder"), that after straightening still prone to bending (or becomes softer).

Well, maybe it is time for a new fork...

Is this common for a fork to become softer after some kind of misalignment/bend damage and alignment? I always thought the steel is quite tolerant to bendings ( at least for a one or two). I can't find any marks of a collision on the frame.

The package also had a note that fork is softened because of damage and he does not recommend using it.

After trying to install it I noticed that end spacing is waaay off, insted of usual 100 mm it is 87 mm (it was 100 mm before I sent the fork). Also forkends are not paralell (visually), my end alignment tools won't even fit in between. The original blade misalignment is corrected, it seems.

After calling the shop it looks like he forgot to check the fork end alignment and spacing. He should be quite experienced with older bikes (at least was back in the day), but yeah, the finished alignment doesn't look good and reliable... Also, he said, the damage/blade bend makes somewhat diffucult to get all spacings right...

Looks like forkends were fixed in the 100mm rig during straightening process and after releasing rebounded to 87mm and no one cared to check.

In any case, he thinks that because of the damage the fork is softened significantly, way softer that intact forks of that age. He tried to explain but that was a bit too difficult for my understand. Somekind of a bent, that formed during damage (if I understood correctly, some kind of "shoulder"), that after straightening still prone to bending (or becomes softer).

Well, maybe it is time for a new fork...

Is this common for a fork to become softer after some kind of misalignment/bend damage and alignment? I always thought the steel is quite tolerant to bendings ( at least for a one or two). I can't find any marks of a collision on the frame.

Hard to know what all is going on there, but steel hardens with each bending cycle, unless cycled too many times at which point cracks develop.

The structure however may itself "soften" after deformation, due to the metal no longer following a straight enough path for the stresses to contribute fully to the structure's rigidity and strength. Any ripple in the metal would be an example of this.

With the rim being off-center at the crown, the next thing I usually do is test-ride the bike to see which direction that the steering pulls toward.

If the steering pulls to the right, then the tire's contact patch needs to move toward the right. This test thus informs whether the off-center wheel more likely needs to be corrected by bending the fork legs laterally or by filing one dropout deeper. These are opposites, since correcting the wheel centering under the crown needs to also correct the steering pull to one side and not make it worse.

I've corrected perhaps half of my vintage bikes using only the above choice of methods, being sure never to remove metal that shouldn't be removed.

I of course use common sense and a visual inspection of the fork to guide my choices as well, but usually the other parameters are fine.

Checking the straightness of the steerer is a good idea in cases such as yours, but of course I say this having not seen your bike or fork.

Defective forks do turn up, especially on less-expensive bikes, where one fork leg positions it's dropout further from the crown than the other, and only so much metal can be safely removed to correct such cases. The same is true of the frame's rear triangle and I've had to take a file to a rear dropout more than once, though always on a lower-level bike.

From your description, I don't have any faith at all in the knowledge or ability of the guy who worked on your fork.

Last edited by dddd; 09-22-21 at 02:05 AM.

#16

verktyg

Join Date: Jul 2006

Location: SF Bay Area

Posts: 4,030

Bikes: Current favorites: 1988 Peugeot Birraritz, 1984 Gitane Super Corsa, 1980s DeRosa, 1981 Bianchi Campione Del Mondo, 1992 Paramount OS, 1988 Colnago Technos, 1985 RalieghUSA SBDU Team Pro

Mentioned: 207 Post(s)

Tagged: 0 Thread(s)

Quoted: 1036 Post(s)

Liked 1,238 Times

in

654 Posts

BS !!!! Standby, Novella TdF 102

Evidenced based reality. History lesson, no guessin'

Excuse me for the diversion but for starters, you have a VERY nice European version Gitane Tour de France probably a 1968 model, but late 67 to early 69.

I'm suggesting those years because Gitane started using that style of DuPont Mylar foil decals in 1968 and continued until 1974.

They only used the Mylar foil on the head tubes of their better quality models and only for maybe a year - 1968-69? It had to be a major PITA to install and then place the Gitane logo stickers over top of it. In addition, it was easily damaged!

Why is it most likely a European version Tour de France? Well first off the OP is in Finland....

Besides that from the 1960's until 1976 on, European TdFs were made with only the 3 main tubes Reynolds 531. The fork blades on those European bikes had 1/2 chrome plated "socks". The rear triangles were painted.

3 TUBES RENFORCES

At least up through the 1966 catalog and price list, the forks and rear triangles on the European TdFs were listed as being made of Durifort tubing. It a short jump to assume that the forks and stays on the 1968 TdFs were made of the same Durifort tubing.

Durifort Forks and Rear Stays sticker on a 1963 Gitane. The stickers were very fragile so not many survived.

Durifort forks and stays with butted 3 main tubes of Reynolds 531 was the standard fare for many mid range to better quality French bikes up into the early 70's. Zeus and other European makers used that formula too.

The wall thickness of Durifort forks and stays was very close to that of the Reynolds 531 tubes used on most production frames of that era so there wasn't much if any noticeable difference in the ride and handling between those 2 brands of tubing.

The after brazing strength of Durifort was a little over 1/2 the after brazing strength of Reynolds 531 but it was far less susceptible to damage caused by overheating during brazing.

**** NOW THE BS REPELLENT....

Bending or deforming most types of steels past the point where they don't return to their original dimension, also called "taking a set" as in "Cold Setting" increases the hardness in the area where the deformation takes place. It's referred to as "work hardening" which also increases the strength of the steel in that area.

"The package also had a note that fork is softened because of damage and he does not recommend using it"

(Please reread above lines in reference to the hammersmith who supposedly worked on your fork)

I've personally realigned (cold set) Durifort forks and stays on Gitanes, Zeus bikes and frames that I built. They're very "soft" and bend easily on the first attempt. With each subsequent bend they become stiffer thus stronger from work hardening. Unless the fork blade or blades were bent to the point where a crack forms because the strength of the steel has been exceeded, there is NO WAY that the blade or blades have softened unless they've been reheated!

Back on TdF topic, Mel Pinto started importing the US version TdFs in February 1969. They were made with "all Reynolds 531 tubing" (or at least 9 tubes were). The 3 main tubes plus the forks blades and rear stays were Reynolds 531.

Gitane frames from that era made with Reynolds 531 forks and stays had "fishtails" cut into the ends of the tubes. All other types of tubing were domed. Easy way to tell the difference.

The European TdFs from the mid 60's until 1974 had either proprietary Huret rear dropouts or proprietary Simplex rear dropouts to match the brand of derailleurs supplied with the bikes. They used as many as 6 different types of Simplex rear dropouts during the 1970's bike boom depending on availability. I'm not going to get into the can of worms concerning Campy dropouts. I've hijacked this thread enough.

After trying to install it I noticed that end spacing is waaay off, instead of usual 100 mm it is 87 mm (it was 100 mm before I sent the fork). Also forkends are not paralell (visually), my end alignment tools won't even fit in between. The original blade misalignment is corrected, it seems

As Doug Fattic mentioned, fork blades back in the day frequently came misaligned from the factory... More than frequently on entry level bikes made of gaspipe tubing. We had a large rubber mallet at our shop.....

S

referring again to the hammersmith, some folks shouldn't be let near any tools more complicated than a ROCK!

Paleo stone hammer...

One of the first things that I do with every bike or frame that I bring into MY workshop is check the fork ends and rear dropouts plus the frame alignment.

I have the same set up as 3alarmer in my home shop. If I see that a fork needs more realigning than I can do with my tools, I take to Ed Litton and he does the job on his fork jigs.

After calling the shop it looks like he forgot to check the fork end alignment and spacing. He should be quite experienced with older bikes (at least was back in the day), but yeah, the finished alignment doesn't look good and reliable... Also, he said, the damage/blade bend makes somewhat diffucult to get all spacings right...

Looks like forkends were fixed in the 100mm rig during straightening process and after releasing rebounded to 87mm and no one cared to check.

Looks like forkends were fixed in the 100mm rig during straightening process and after releasing rebounded to 87mm and no one cared to check.

In any case, he thinks that because of the damage the fork is softened significantly, way softer that intact forks of that age. He tried to explain but that was a bit too difficult for my understand. Some kind of a bent, that formed during damage (if I understood correctly, some kind of "shoulder"), that after straightening still prone to bending (or becomes softer).

Well, maybe it is time for a new fork...

Well, maybe it is time for a new fork...

Sinun englantisi on erittäin hyvää. Valitettavasti tiedän hieman ruotsia, mutta en puhu suomea

onnea

verktyg

__________________

Don't believe everything you think! History is written by those who weren't there....

Chas. ;-)

Don't believe everything you think! History is written by those who weren't there....

Chas. ;-)

Last edited by verktyg; 09-22-21 at 05:20 AM.

Likes For verktyg:

#17

Junior Member

Thread Starter

Thanks for replies, dddd and verktyg! Thank you for your time and encouragement to seek another person who could fix the fork. Forks, handlebars and cranks are the parts I discard a bit more easily than other parts. So the recommendation not to use the fork was worrying. Now I fel more confident the fork should be fixed.

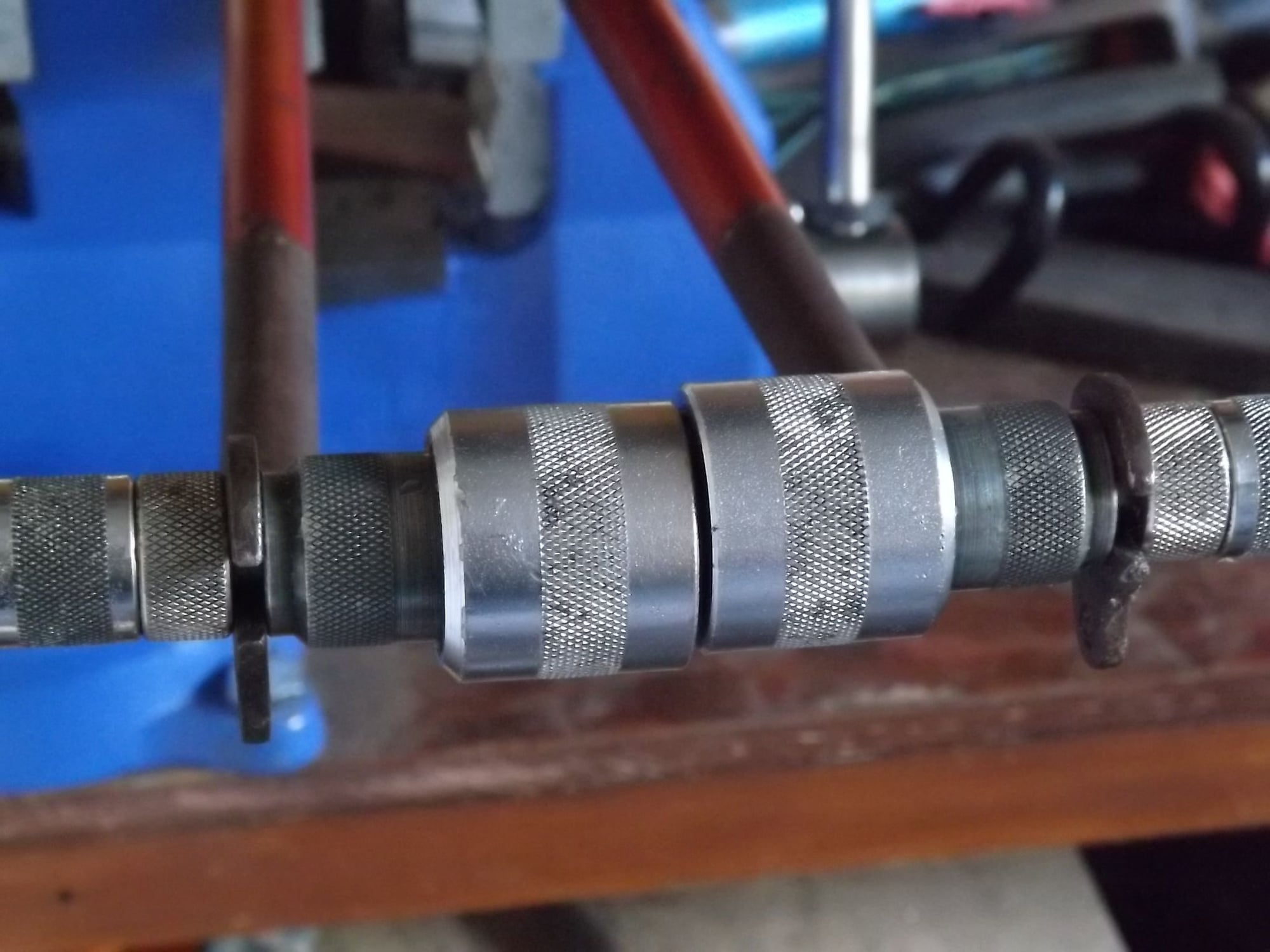

dddd > thanks for tips! Never thought about filing one side of fork end. In any case, I believe the original problem (one fork blade more posterior or anterior that the other) is fixed (image). The problem the spacing is way off and forkends not paralel. I have the tools for forkends, but can't check is there other alignment problems now.

I knew about steel hardening with each bending cycle, so could't understand fork now beeing too soft. I could undestand if there would be ripple, crack or something major. The steerer looks straight, at least to my eyes, can't see or feel any ripples or dings in steel surface.

verktyg > Thanks for information! When I bought it, it was said it is from 80's, I myself thought it is from 1976 plus minus a year or so. Never thought ir could be older than 1970. Nice to know that other tubes are probably Durifort, I assumed some hi-ten steel. And yes, the fork was probably already spaced 96mm, not 100, I did not measure it then.

dddd > thanks for tips! Never thought about filing one side of fork end. In any case, I believe the original problem (one fork blade more posterior or anterior that the other) is fixed (image). The problem the spacing is way off and forkends not paralel. I have the tools for forkends, but can't check is there other alignment problems now.

I knew about steel hardening with each bending cycle, so could't understand fork now beeing too soft. I could undestand if there would be ripple, crack or something major. The steerer looks straight, at least to my eyes, can't see or feel any ripples or dings in steel surface.

verktyg > Thanks for information! When I bought it, it was said it is from 80's, I myself thought it is from 1976 plus minus a year or so. Never thought ir could be older than 1970. Nice to know that other tubes are probably Durifort, I assumed some hi-ten steel. And yes, the fork was probably already spaced 96mm, not 100, I did not measure it then.

#18

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

It shouldn't be a huge trauma to the metal to re-space to 96mm, but bending tubing should be done very carefully to prevent possibility of buckling, where the leg narrows and starts bending easier with increased movement (I therefore use some sort of stopper to limit the distance that the leg can bend with each effort, usually a block of wood on the ground as I push down on the lower end of the fork leg with my foot, and with the bike held down with my other foot in a strategic location, and with one hand controlling the handlebar from turning and the other perhaps grasping another part of the frame. It's like a gymnastic floor exercise, real effort involved, and several iterative repetitions with each effort following re-measuring the dropout spacing as a reference of yielding movement).