Stem digging in the steering tube

#26

Senior Member

Thread Starter

Thanks.

No. My steerer is under built. It is a 6.5kg bike L size, with some weight savings coming from very light frame and fork. The expander is thick and correctly installed and the torque was always 5Nm - max allowed. I can see some pressure signs on it at the level of stem edge, which means that the steerer bents imperceptible under the forces.

That would result in longer reach, which my back and arms can not manage for a 2-3 hrs ride...

No. My steerer is under built. It is a 6.5kg bike L size, with some weight savings coming from very light frame and fork. The expander is thick and correctly installed and the torque was always 5Nm - max allowed. I can see some pressure signs on it at the level of stem edge, which means that the steerer bents imperceptible under the forces.

That would result in longer reach, which my back and arms can not manage for a 2-3 hrs ride...

#27

Method to My Madness

Join Date: Nov 2020

Location: Orange County, California

Posts: 3,638

Bikes: Trek FX 2, Cannondale Synapse, Cannondale CAAD4, Santa Cruz Stigmata GRX

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 1938 Post(s)

Liked 1,460 Times

in

1,011 Posts

Assuming that your current stem rises from back to front, and has certain length L and a certain angle A, which give you both a horizonal distance X and a vertical distance Y to your handlebar. With a new stem, keeping L the same and increasing A (to increase rise), the horizonal distance X decreases while the vertical distance Y increases. This should allow you to install the new stem at a lower spot on the steerer, because that lower spot is also further from you. What length you need depends on the stem angle and how much lower on the steerer you want to go. Use the stem comparison tool posted above to figure out unless you want to do the trigonometry yourself.

Likes For SoSmellyAir:

#28

Senior Member

Thread Starter

Thanks.

#29

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,829

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2336 Post(s)

Liked 2,802 Times

in

1,531 Posts

Mine has a special spacer above and the steerer extends around 2mm above the stem.

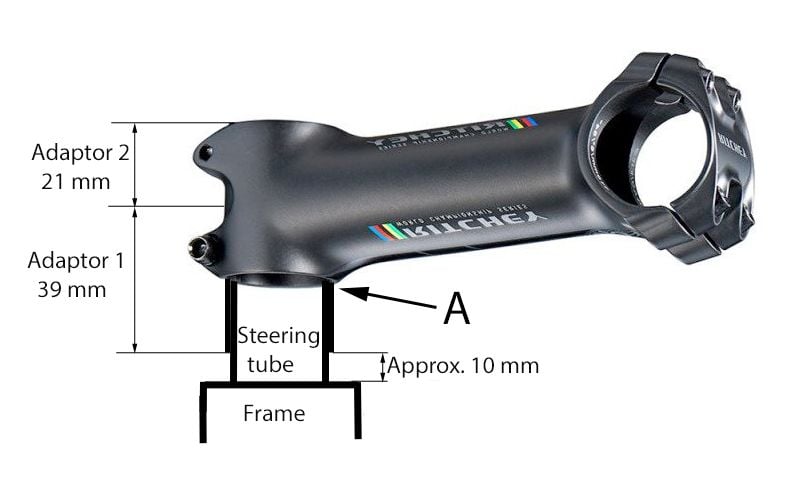

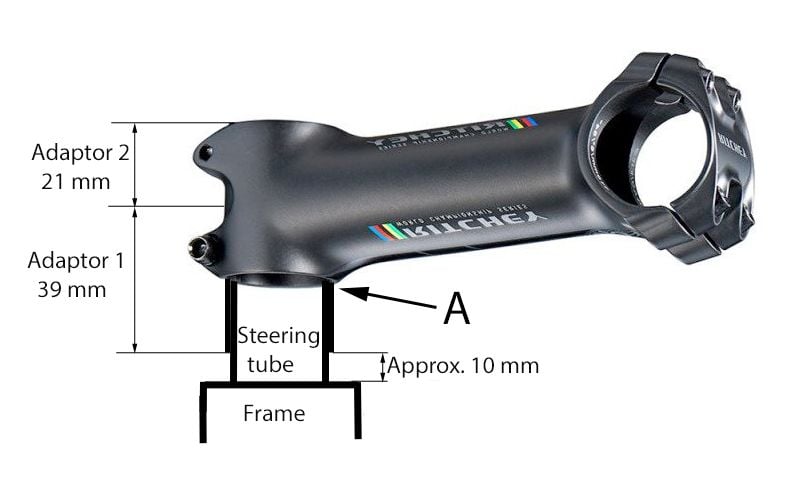

I was thinking about a workaround for my issue, although a little expensive and not very elegant (see the sketch below):

Change the actual 28.6 to 31.8 mm stem and use two adapters like This, in such a way that they meet in the middle of stem clamping area. The first adaptor will go down around 20 mm below the edge of the stem. It should protect the steerer from stem edge and distribute the forces somehow similar with the situation of a longer stack stem and around 10mm spacer.

Would this be a solution to my issue? Would it create other issue? Should I use higher torque than recommended 5Nm for steerer clamping, since I use adaptors?

Thanks.

I was thinking about a workaround for my issue, although a little expensive and not very elegant (see the sketch below):

Change the actual 28.6 to 31.8 mm stem and use two adapters like This, in such a way that they meet in the middle of stem clamping area. The first adaptor will go down around 20 mm below the edge of the stem. It should protect the steerer from stem edge and distribute the forces somehow similar with the situation of a longer stack stem and around 10mm spacer.

Would this be a solution to my issue? Would it create other issue? Should I use higher torque than recommended 5Nm for steerer clamping, since I use adaptors?

Thanks.

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

#30

Mother Nature's Son

Join Date: Mar 2016

Location: Sussex County, Delaware

Posts: 3,107

Bikes: 2014 Orbea Avant MD30, 2004 Airborne Zeppelin TI, 2003 Lemond Poprad, 2001 Lemond Tourmalet, 2014? Soma Smoothie

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 852 Post(s)

Liked 1,433 Times

in

815 Posts

I wish you well.

#31

Senior Member

Thread Starter

Thanks

.

Last edited by Redbullet; 10-17-22 at 03:09 PM.

#32

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,929

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6163 Post(s)

Liked 4,779 Times

in

3,297 Posts

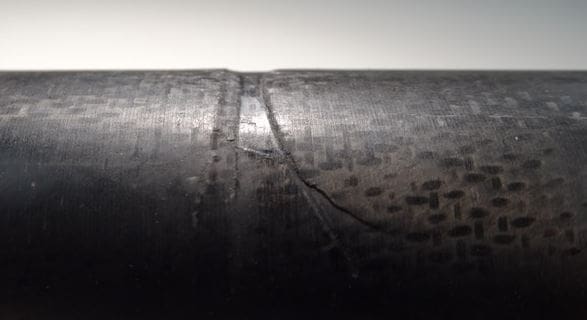

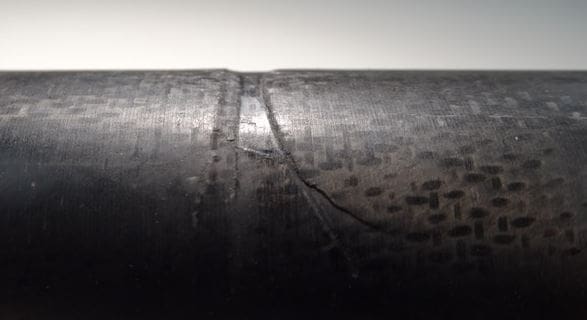

What's this that looks like a crack? Maybe you should go to a bike shop and get some one's opinion that can examine it closer than any of us can.

Likes For Iride01:

#33

Senior Member

Thread Starter

Thanks

#34

Senior Member

Join Date: Apr 2007

Posts: 6,760

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1109 Post(s)

Liked 1,200 Times

in

760 Posts

I should disassemble the system I am not sure that I can take such a quality picture to show a dent of 0.1 mm, but "rm-rf" posted a link above with the general issue. My issue is very similar with the one in picture below, with the main difference that the dent is much smaller at this moment. It only appears at the contact with bottom edge of the stem.

Thanks

.

Thanks

.

Last edited by Camilo; 05-01-22 at 02:31 PM.

#35

Senior Member

Thread Starter

Ok, I disassembled for pictures.

- 3 pictures (taken from right, front and left).

The arrow above shows the mark of stem bottom edge when I had 35mm spacers. The arrow below shows the new scratch after I removed one spacer of 5mm. Steerer diameter front - back in the section marked with a red point (between the arrow above and the circular mark of the stem), is with 0.1-0.13 mm smaller than the diameter left-right measured in the same section. It is smaller with roughly the same amount than the diameter measured in other sections.

- 1 picture of the compression plug: the top edge stays around 0.5-1 mm below steerer edge. The bottom edge of the ACTIVE part stays around 3-5 mm below the region of stem edge.

Thanks.

- 3 pictures (taken from right, front and left).

The arrow above shows the mark of stem bottom edge when I had 35mm spacers. The arrow below shows the new scratch after I removed one spacer of 5mm. Steerer diameter front - back in the section marked with a red point (between the arrow above and the circular mark of the stem), is with 0.1-0.13 mm smaller than the diameter left-right measured in the same section. It is smaller with roughly the same amount than the diameter measured in other sections.

- 1 picture of the compression plug: the top edge stays around 0.5-1 mm below steerer edge. The bottom edge of the ACTIVE part stays around 3-5 mm below the region of stem edge.

Thanks.

Last edited by Redbullet; 10-17-22 at 03:10 PM.

#36

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,929

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6163 Post(s)

Liked 4,779 Times

in

3,297 Posts

Is the clamp on the stem rough around the edges and around the hole where the actual stem meets the clamp part of it? That's about all I can think of to explain the curved marks. Some almost a complete circle. My Specialized and Easton stems are pretty smooth and rounded edges in those areas of the clamp. They haven't made marks like that on my steerer tube.

Even so, I still say take it and let someone experienced see it in person.

Even so, I still say take it and let someone experienced see it in person.

Likes For Iride01:

#37

Senior Member

Thread Starter

Is the clamp on the stem rough around the edges and around the hole where the actual stem meets the clamp part of it? That's about all I can think of to explain the curved marks. Some almost a complete circle. My Specialized and Easton stems are pretty smooth and rounded edges in those areas of the clamp. They haven't made marks like that on my steerer tube.

Even so, I still say take it and let someone experienced see it in person.

Even so, I still say take it and let someone experienced see it in person.

#38

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,929

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6163 Post(s)

Liked 4,779 Times

in

3,297 Posts

You had 65 mm of spacers under that stem? Geesh! You really need to get a different model bike with a higher frame stack, IMO.

Now that you've gotten the pictures for us, let us know what the guy at the bike shop says after they look at it in person.

There is still too much here to digest and is probably yet unknown to us to render a decision. Other than currently, I'd say don't ride it and that you might want another fork that has a steerer in better shape. Though I'd definitely yield to the opinion of someone that can see it in person.

Others might disagree and that's okay.

Now that you've gotten the pictures for us, let us know what the guy at the bike shop says after they look at it in person.

There is still too much here to digest and is probably yet unknown to us to render a decision. Other than currently, I'd say don't ride it and that you might want another fork that has a steerer in better shape. Though I'd definitely yield to the opinion of someone that can see it in person.

Others might disagree and that's okay.

Likes For Iride01:

#39

Senior Member

Thread Starter

No, I said I had 35mm and got this issue within around 3 years - some 25000+ km. Then I reduced to 30mm and I got some new scratches within around 1 year - some 5000-10000 km, but it looks to me that the new scratches will transform in a new similar issue and I want to avoid it.

65 was 6.5 and it was kg - the rated weight of the bike.

I don't really think I can get a valuable advice from the bike shop. I bought the bike over the internet directly from the producer, well known in the "second tier" level. Just changing to a new fork is not a solution, as it will probably evolve in the same way...

65 was 6.5 and it was kg - the rated weight of the bike.

I don't really think I can get a valuable advice from the bike shop. I bought the bike over the internet directly from the producer, well known in the "second tier" level. Just changing to a new fork is not a solution, as it will probably evolve in the same way...

Last edited by Redbullet; 05-02-22 at 02:33 PM.

#40

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,829

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2336 Post(s)

Liked 2,802 Times

in

1,531 Posts

picture help..... it seems like the whole for the stem making marks on the steerer ( ovale/circle) this is past my hands on experience, but it almost looks like the steerer expanded into the stem.

So only thing i can add are a couple of questions, that I don't think I saw details on

1) was torque wrench used and torque at spec for the installation of the compression plug?

2) was torque wrench used and torque at spec for the stem pinch bolts?

So only thing i can add are a couple of questions, that I don't think I saw details on

1) was torque wrench used and torque at spec for the installation of the compression plug?

2) was torque wrench used and torque at spec for the stem pinch bolts?

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Likes For squirtdad:

#41

Senior Member

Join Date: Apr 2007

Posts: 6,760

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1109 Post(s)

Liked 1,200 Times

in

760 Posts

The picture helps.

You know, 30 and 35mm of spacers is not unusual. Yeah, maybe for racers. but a lot of (most?) cyclists use 30-35, even 40 (which is the maximum I've seen spec'd for a CF steer tube). I really don't think the spacer height is the problem, especially since it happened again with 30. I would bet good money that if a fork manufacturer spec's 35mm, it's well within engineered safety, probably significantly below. I'd look for another cause.

You know, 30 and 35mm of spacers is not unusual. Yeah, maybe for racers. but a lot of (most?) cyclists use 30-35, even 40 (which is the maximum I've seen spec'd for a CF steer tube). I really don't think the spacer height is the problem, especially since it happened again with 30. I would bet good money that if a fork manufacturer spec's 35mm, it's well within engineered safety, probably significantly below. I'd look for another cause.

#42

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,048

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4191 Post(s)

Liked 3,834 Times

in

2,293 Posts

picture help..... it seems like the whole for the stem making marks on the steerer ( ovale/circle) this is past my hands on experience, but it almost looks like the steerer expanded into the stem.

So only thing i can add are a couple of questions, that I don't think I saw details on

1) was torque wrench used and torque at spec for the installation of the compression plug?

2) was torque wrench used and torque at spec for the stem pinch bolts?

So only thing i can add are a couple of questions, that I don't think I saw details on

1) was torque wrench used and torque at spec for the installation of the compression plug?

2) was torque wrench used and torque at spec for the stem pinch bolts?

This, as I tried to say before. The photos sure look like the steerer is being compressed by the stem. Were it only a rocking action the lower marks would be far deeper than the upper ones. To also pull up on the bars with similar force as they see when you ride over a bump is asking a lot from a human body.

I forget how old the bike is, this is one reason why forks are becoming a component and no longer considered a frame WRT warranties by many brands.

I have some conflict with this situation. The proactive will either monitor the steerer often (with all the effort to see it as frequently as your risk management says is acceptable) or replace the fork. Others will do as they wish, and pay those "costs" if they don't sell the bike first. There are a few applications of carbon construction which I don't agree with and steerers are one. Andy

__________________

AndrewRStewart

AndrewRStewart

#43

Senior Member

Thread Starter

Lower marks are deeper: the difference of 0.1-0.13 mm in diameter exists only at the level of the red point, generated during previous period of using 35mm of spacers, 3-4 years / 25000 km. Upper marks are scratches, there is no decrease in diameter. Lowest marks are also scratches for the moment and were generated within 1-1.5 years / approx 10000 km with 30mm spacers. Torque was always 5Nm, for plug and for stem. The plug was the first tightened and the stem was the second.

Since normal maintenance or costs and hassle of sending the bike abroad to producer for a new fork would not eliminate the reason of the issue, I want to make a change. I am tented to proceed with changing of the stem from 28.5 to 31.8 mm clamping and use aluminum shim adapters that go down 1-2 cm below the stem edge. That would distribute clamping forces to a much larger area of the steerer, see the sketch at the 22nd post in this thread.

But I am wondering whether the stem might easily slip at 5Nm torque in this setup, since I shall have 2 surfaces of friction instead of one: one between the stem and adapters and another between the adapters and the steerer. I also wonder whether some other issues (unidentified by me) might be generated by this change...

Last edited by Redbullet; 10-17-22 at 03:10 PM.

#44

Senior Member

Join Date: Apr 2007

Posts: 6,760

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1109 Post(s)

Liked 1,200 Times

in

760 Posts

...I am tented to proceed with changing of the stem from 28.5 to 31.8 mm clamping and use aluminum shim adapters that go down 1-2 cm below the stem edge. That would distribute clamping forces to a much larger area of the steerer, see the sketch at the 22nd post in this thread.

But I am wondering whether the stem might easily slip at 5Nm torque in this setup, since I shall have 2 surfaces of friction instead of one: one between the stem and adapters and another between the adapters and the steerer. I also wonder whether some other issues (unidentified by me) might be generated by this change...

But I am wondering whether the stem might easily slip at 5Nm torque in this setup, since I shall have 2 surfaces of friction instead of one: one between the stem and adapters and another between the adapters and the steerer. I also wonder whether some other issues (unidentified by me) might be generated by this change...

Now, if you were talking about shimming up a small diameter handlebar to a larger diameter stem clamp (which I have done), the chance of slippage would be greater and more dangerous. This is because, especially in the drops, but also on the hoods, you are forcing the bars downward just because of your body weight, exacerbated when you go over a bump. This can slip, for sure, and if it does, could be catastrophic. But again, using gritty assembly paste eliminates this, and you can test ahead of time by forcefully pushing down on the drops or the hoods.

Last edited by Camilo; 05-03-22 at 11:32 PM.

#45

don't try this at home.

Join Date: Jan 2006

Location: N. KY

Posts: 5,931

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 972 Post(s)

Liked 509 Times

in

349 Posts

Your steerer photos look okay to me. The carbon doesn't look damaged. But it's hard to see in photos compared to in person.

I think your nice lightweight steerer is way more reflective than my standard carbon steerer, that shiny surface makes it look worse than it is?

I don't use the full 5 nm torque on my stem. It holds fine at a range of around 3.5 nm to 4 or so. I have a 20mm of spacers below, and 5mm above the stem.

I think your nice lightweight steerer is way more reflective than my standard carbon steerer, that shiny surface makes it look worse than it is?

I don't use the full 5 nm torque on my stem. It holds fine at a range of around 3.5 nm to 4 or so. I have a 20mm of spacers below, and 5mm above the stem.

Last edited by rm -rf; 05-03-22 at 03:28 PM.

Likes For rm -rf:

#46

Go Ride!

Join Date: May 2019

Location: Minnesota—55346

Posts: 268

Bikes: Klein Quantum Pro, Klein Attitude, Azuki SS, Merckx AXM, Klein Quantum Race, Klein Quantum

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 109 Post(s)

Liked 154 Times

in

87 Posts

I am tented to proceed with changing of the stem from 28.5 to 31.8 mm clamping and use aluminum shim adapters that go down 1-2 cm below the stem edge. That would distribute clamping forces to a much larger area of the steerer, see the sketch at the 22nd post in this thread.

But I am wondering whether the stem might easily slip at 5Nm torque in this setup, since I shall have 2 surfaces of friction instead of one: one between the stem and adapters and another between the adapters and the steerer. I also wonder whether some other issues (unidentified by me) might be generated by this change...

But I am wondering whether the stem might easily slip at 5Nm torque in this setup, since I shall have 2 surfaces of friction instead of one: one between the stem and adapters and another between the adapters and the steerer. I also wonder whether some other issues (unidentified by me) might be generated by this change...

#47

Senior Member

Thread Starter

I am balancing between a new fork and preserving the actual… But what about the mark at the contact with headset? Wall thickness here was reduced with 0.1-0.15mm.

If this does not mean critical reduction in resistance, I could cover the area with a thin layer of epoxy. Not to increase resistance, but only to protect against further reduction of wall thickness…

Last edited by Redbullet; 10-17-22 at 03:02 PM.

#48

Go Ride!

Join Date: May 2019

Location: Minnesota—55346

Posts: 268

Bikes: Klein Quantum Pro, Klein Attitude, Azuki SS, Merckx AXM, Klein Quantum Race, Klein Quantum

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 109 Post(s)

Liked 154 Times

in

87 Posts

Good concern to have—IF (per your drawings above and earlier posts) that wear mark is under your stem’s clamp area (so ABOVE your headset bearings) then your stem contact area is big enough that a narrow depression like that is manageable—there are stems out there with much lower stack heights (and thus contact area) than the one you have and they still manage just fine. But if (as I’m reading your latest post above) the wear mark is IN the headset area, that’s a whole different issue as your headset bearing (race) would be what wore that groove and will no longer be tight to your fork—you’d have a gap (‘slop’) in your top bearing area. No epoxy will help there as it would wear out faster than the carbon before it. That’s a much more difficult issue to solve for—the most direct solution would be to go with a different fork. Since your preferred set up is putting so much torsion on this, maybe opt for an aluminum steerer in the replacement fork?

Last edited by Sonofamechanic; 05-07-22 at 06:02 AM.

#49

Senior Member

Thread Starter

.

.The part in the photo below is the one that grove in the fork at that level - I understand it is named "headset bearing (race)". In my case id does not stay tight, it has a very small play if you put it anywhere along the steerer (even at 28.6 mm diameter, not only in affected area). I can't see how it can be tightened to the fork, especially that it has a cut as shown by the arrow, which prevents it to be really tightened. So: is it normal that the headset bearing (race) to rotate free around the fork?

Thanks

Last edited by Redbullet; 10-17-22 at 03:11 PM.

#50

Go Ride!

Join Date: May 2019

Location: Minnesota—55346

Posts: 268

Bikes: Klein Quantum Pro, Klein Attitude, Azuki SS, Merckx AXM, Klein Quantum Race, Klein Quantum

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 109 Post(s)

Liked 154 Times

in

87 Posts

Sorry for insisting, it looks that I just start to learn some things about the forks and headsets  .

.

The part in the photo below is the one that grove in the fork at that level - I understand it is named "headset bearing (race)". In my case id does not stay tight, it has a very small play if you put it anywhere along the steerer (even at 28.6 mm diameter, not only in affected area). I can't see how it can be tightened to the fork, especially that it has a cut as shown by the arrow, which prevents it to be really tightened. So: is it normal that the headset bearing (race) to rotate free around the fork?

Thanks

.

.The part in the photo below is the one that grove in the fork at that level - I understand it is named "headset bearing (race)". In my case id does not stay tight, it has a very small play if you put it anywhere along the steerer (even at 28.6 mm diameter, not only in affected area). I can't see how it can be tightened to the fork, especially that it has a cut as shown by the arrow, which prevents it to be really tightened. So: is it normal that the headset bearing (race) to rotate free around the fork?

Thanks

1) what you have there is not the bearing race but is the collar that needs to be pressed down from the top firmly between the bearing and the steerer tube to ‘fill in’ any gap between them—if you don’t/didn’t do this then that would leave it loose to slide around and completely explains the groove that you have! No problem—that’s an easy fix… 2) the ‘cut’ as you call it is there so that as you push the collar down it can wedge in tight and constrict (get smaller) around the steerer tube. So as you push it down you will see that ‘cut’/gap get narrower. 3) So!…put your fork back on and tap that collar down into place (you can see how it slides in and tightens up) and then put on your stem (if you put spacers in first, make sure they are narrow/thin enough to ONLY touch that collar and not the bearing—you want those spacers to push that collar down into place ( to “seat” the collar). 4) Before you tighten the stem bolts, install and tighten your steerer (expander) bolt—that will ‘pull’ the stem (and spacers) down and push the collar tightly into place. THEN you tighten the bolts on the stem.

>>given the fork steerer wear, etc, your smartest move is to take this to your local bike mechanic to show you how to do what I’ve outlined above (once you see it done it will make sense). He/She may say you need a new fork—maybe you do, maybe you don’t—but have them show you how to do it regardless of that. IF that was loose that would explain most of your issues!