Latex tube failure - Unlucky or a tube / installation issue?

#1

Senior Member

Thread Starter

Join Date: Jun 2021

Location: Australia

Posts: 821

Bikes: 2002 Trek 5200 (US POSTAL), 2020 Canyon Aeroad SL

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 313 Post(s)

Liked 679 Times

in

327 Posts

Latex tube failure - Unlucky or a tube / installation issue?

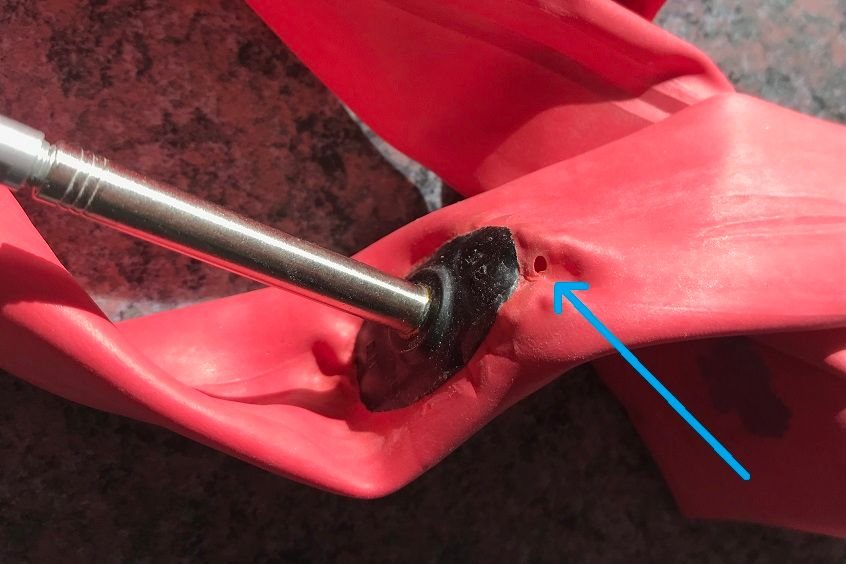

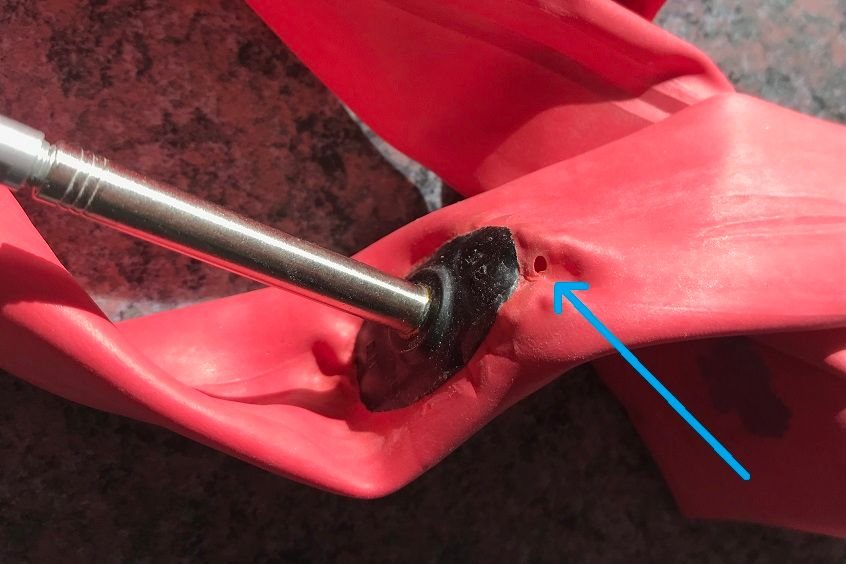

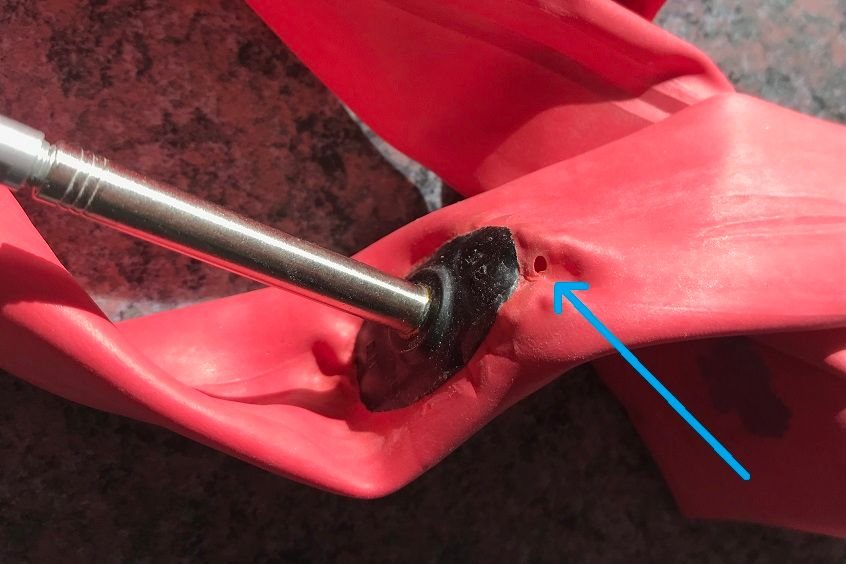

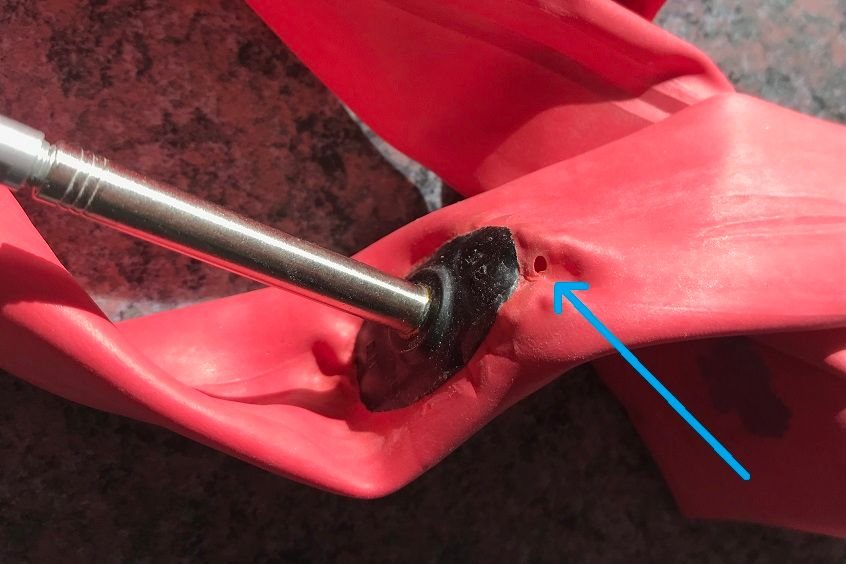

Just back from a ride where I've had another Latex tube failure. This is the third such failure I've had with Latex tubes in around 3000km. I love the ride feel of them and I mainly use them because they "test fast" for rolling resistance. Each tube has failed right around the base of the valve stem.

Same brand of tubes (Challenge) on two different wheels.

One tube failed at home while the bike was stored (went downstairs to find it was flat), next I think was when inflating but I can't remember, then this third one was out on the road while bombing along on the TT bike (the only bike I use Latex on). This tube only lasted 800km. The rims are super smooth tubeless ready style and I inflate to around 80-85psi. Here's what the latest failure looks like, they've all failed in this same area:

Is this an issue with the batch / brand of tubes perhaps?

Maybe the way I'm installing them?

Or perhaps it's sabotage from Big Tubeless?

Any thoughts? 🤔

That said, the rims and tyres are tubeless ready, so perhaps I'm better off converting them to tubeless instead.

Same brand of tubes (Challenge) on two different wheels.

One tube failed at home while the bike was stored (went downstairs to find it was flat), next I think was when inflating but I can't remember, then this third one was out on the road while bombing along on the TT bike (the only bike I use Latex on). This tube only lasted 800km. The rims are super smooth tubeless ready style and I inflate to around 80-85psi. Here's what the latest failure looks like, they've all failed in this same area:

Is this an issue with the batch / brand of tubes perhaps?

Maybe the way I'm installing them?

Or perhaps it's sabotage from Big Tubeless?

Any thoughts? 🤔

That said, the rims and tyres are tubeless ready, so perhaps I'm better off converting them to tubeless instead.

#2

Thread Killer

Join Date: Aug 2008

Location: Ann Arbor, MI

Posts: 12,422

Bikes: 15 Kinesis Racelight 4S, 76 Motebecane Gran Jubilée, 17 Dedacciai Gladiatore2, 12 Breezer Venturi, 09 Dahon Mariner, 12 Mercier Nano, 95 DeKerf Team SL, 19 Tern Rally, 21 Breezer Doppler Cafe+, 19 T-Lab X3, 91 Serotta CII, 23 3T Strada

Mentioned: 30 Post(s)

Tagged: 0 Thread(s)

Quoted: 3124 Post(s)

Liked 1,694 Times

in

1,025 Posts

Looks like abrasion causing the failure.

Does rim tape terminate in that location?

Are you running low pressure? Tube could be collapsing and folding back onto the valve stem base. Seems unlikely that would be the same failure mode for all three, though…

You could try Schwalbe Aerothan TPU tubes. Pricey, but lighter, more durable, just as supple and just as fast.

Does rim tape terminate in that location?

Are you running low pressure? Tube could be collapsing and folding back onto the valve stem base. Seems unlikely that would be the same failure mode for all three, though…

You could try Schwalbe Aerothan TPU tubes. Pricey, but lighter, more durable, just as supple and just as fast.

Likes For chaadster:

Likes For Branko D:

#4

Senior Member

Join Date: Aug 2019

Location: Québec, Canada

Posts: 2,101

Bikes: SL8 Pro, TCR beater

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 977 Post(s)

Liked 577 Times

in

435 Posts

Just back from a ride where I've had another Latex tube failure. This is the third such failure I've had with Latex tubes in around 3000km. I love the ride feel of them and I mainly use them because they "test fast" for rolling resistance. Each tube has failed right around the base of the valve stem.

Same brand of tubes (Challenge) on two different wheels.

One tube failed at home while the bike was stored (went downstairs to find it was flat), next I think was when inflating but I can't remember, then this third one was out on the road while bombing along on the TT bike (the only bike I use Latex on). This tube only lasted 800km. The rims are super smooth tubeless ready style and I inflate to around 80-85psi. Here's what the latest failure looks like, they've all failed in this same area:

Is this an issue with the batch / brand of tubes perhaps?

Maybe the way I'm installing them?

Or perhaps it's sabotage from Big Tubeless?

Any thoughts? 🤔

That said, the rims and tyres are tubeless ready, so perhaps I'm better off converting them to tubeless instead.

Same brand of tubes (Challenge) on two different wheels.

One tube failed at home while the bike was stored (went downstairs to find it was flat), next I think was when inflating but I can't remember, then this third one was out on the road while bombing along on the TT bike (the only bike I use Latex on). This tube only lasted 800km. The rims are super smooth tubeless ready style and I inflate to around 80-85psi. Here's what the latest failure looks like, they've all failed in this same area:

Is this an issue with the batch / brand of tubes perhaps?

Maybe the way I'm installing them?

Or perhaps it's sabotage from Big Tubeless?

Any thoughts? 🤔

That said, the rims and tyres are tubeless ready, so perhaps I'm better off converting them to tubeless instead.

It looks like something was rubbing on the inside and caused the puncture. It would be a tough place to put a patch, your tube is good for the bin.

#5

Senior Member

Join Date: Oct 2005

Location: SW Ohio

Posts: 3,681

Bikes: Puch Marco Polo, Saint Tropez, Masi Gran Criterium

Mentioned: 25 Post(s)

Tagged: 0 Thread(s)

Quoted: 1163 Post(s)

Liked 441 Times

in

314 Posts

The puncture is awfully close to the valve. This makes me think that the puncture is a combination of a daily inflation error combined with less than perfect rim tape job.

you mention that the rims are tubeless ready. Can I ask what kind of rim tape you are running? It the hole for the valve stem too big or is there something sharp in that vicinity?

Also, as I’m sure you know latex tubes always lose air over night so they have to be topped up before each ride. This means there are many more cycles of attaching and detaching the pump head. If you are in the habit of pushing the valve down into the rim when starting to pump I have found that this creates premature wear on the valve and the round latex rubber vulcanized valve base. This wear eventually creates leaks. Since the valve stem is not threaded you cannot use a knurled nut to hold it up. That is why I came up with my own solution of using an M6 nylon stop collar. You can get these from industrial supply houses and they are about $7.50 each. I think they are worth it. Since I started this system on my Velocity A23 wheels, I have not had any recurrence of failed valve stems with latex tubes.

The split white nylon stop collar is a 6mm internal diameter. It clamps to the valve stem and is held with a stainless metric Allen cap screw that takes a tiny (2.5 or 3mm) metric Allen wrench to keep the valve stem in place when the tube goes soft over night.

Also, the mere act of how you attach & detach your pump head can impact the wear & tear in this critical area. Any pushing down on the valve stem needs to be minimized.

you mention that the rims are tubeless ready. Can I ask what kind of rim tape you are running? It the hole for the valve stem too big or is there something sharp in that vicinity?

Also, as I’m sure you know latex tubes always lose air over night so they have to be topped up before each ride. This means there are many more cycles of attaching and detaching the pump head. If you are in the habit of pushing the valve down into the rim when starting to pump I have found that this creates premature wear on the valve and the round latex rubber vulcanized valve base. This wear eventually creates leaks. Since the valve stem is not threaded you cannot use a knurled nut to hold it up. That is why I came up with my own solution of using an M6 nylon stop collar. You can get these from industrial supply houses and they are about $7.50 each. I think they are worth it. Since I started this system on my Velocity A23 wheels, I have not had any recurrence of failed valve stems with latex tubes.

The split white nylon stop collar is a 6mm internal diameter. It clamps to the valve stem and is held with a stainless metric Allen cap screw that takes a tiny (2.5 or 3mm) metric Allen wrench to keep the valve stem in place when the tube goes soft over night.

Also, the mere act of how you attach & detach your pump head can impact the wear & tear in this critical area. Any pushing down on the valve stem needs to be minimized.

Likes For masi61:

#6

Thread Killer

Join Date: Aug 2008

Location: Ann Arbor, MI

Posts: 12,422

Bikes: 15 Kinesis Racelight 4S, 76 Motebecane Gran Jubilée, 17 Dedacciai Gladiatore2, 12 Breezer Venturi, 09 Dahon Mariner, 12 Mercier Nano, 95 DeKerf Team SL, 19 Tern Rally, 21 Breezer Doppler Cafe+, 19 T-Lab X3, 91 Serotta CII, 23 3T Strada

Mentioned: 30 Post(s)

Tagged: 0 Thread(s)

Quoted: 3124 Post(s)

Liked 1,694 Times

in

1,025 Posts

At least BRR acknowledges their test results are not absolute, so when they found .3w variance between a latex tube and a TPU tube, it was an average across 3 different tire brands, so we— well, perhaps unless you’re a paid Pro Member who apparently has access to complete results— don’t know if TPU was faster in one of the tires (or at what pressure). We also know that BRR perform 3 Crr tests for tires, indicating test results have margin of error, but we don’t know what that potential error is, so it stands to reason it could be tenths of a watt.

So yeah, if tenths of a watt are significant, your point is taken, but I don’t think there’s anything in that, not with what I currently know. I’m also training and working on a scale literally an order of magnitude greater, so tenths of a watt are not even perceptible. I mean, what if instead of maintaining speed as is done in the tests, I wanted to convert the .2w savings at a given test speed to increased power output by .2w, how much faster would I go? I think that answer is a big, fat zero.

#7

Senior Member

Join Date: Sep 2017

Posts: 7,827

Mentioned: 37 Post(s)

Tagged: 0 Thread(s)

Quoted: 6927 Post(s)

Liked 10,930 Times

in

4,667 Posts

When they claim that latex tubes are 'faster,' are they factoring in the time spent on the roadside fixing flats?

Likes For Koyote:

#8

Should Be More Popular

Join Date: Dec 2007

Location: Malvern, PA (20 miles West of Philly)

Posts: 43,025

Bikes: 1986 Alpine (steel road bike), 2009 Ti Habenero, 2013 Specialized Roubaix

Mentioned: 560 Post(s)

Tagged: 2 Thread(s)

Quoted: 22570 Post(s)

Liked 8,918 Times

in

4,152 Posts

OP, did you check the inside of the rim at the failure point to verify if there is a rough spot or irregularity?? I agree it looks like it's either wear from inflation and/or related to friction/wear from the inside at site of failure.

Let us know about inside of wheels question??

Let us know about inside of wheels question??

#9

Mother Nature's Son

Join Date: Mar 2016

Location: Sussex County, Delaware

Posts: 3,107

Bikes: 2014 Orbea Avant MD30, 2004 Airborne Zeppelin TI, 2003 Lemond Poprad, 2001 Lemond Tourmalet, 2014? Soma Smoothie

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 852 Post(s)

Liked 1,433 Times

in

815 Posts

FYI, I have patched latex in that same location; Rema patches worked well, glueless not so.

Likes For delbiker1:

#10

Senior Member

Join Date: Feb 2018

Posts: 786

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 338 Post(s)

Liked 408 Times

in

252 Posts

At least BRR acknowledges their test results are not absolute, so when they found .3w variance between a latex tube and a TPU tube, it was an average across 3 different tire brands, so we— well, perhaps unless you’re a paid Pro Member who apparently has access to complete results— don’t know if TPU was faster in one of the tires (or at what pressure). We also know that BRR perform 3 Crr tests for tires, indicating test results have margin of error, but we don’t know what that potential error is, so it stands to reason it could be tenths of a watt.

Went to tubeless in the end.

Likes For Branko D:

#11

Thread Killer

Join Date: Aug 2008

Location: Ann Arbor, MI

Posts: 12,422

Bikes: 15 Kinesis Racelight 4S, 76 Motebecane Gran Jubilée, 17 Dedacciai Gladiatore2, 12 Breezer Venturi, 09 Dahon Mariner, 12 Mercier Nano, 95 DeKerf Team SL, 19 Tern Rally, 21 Breezer Doppler Cafe+, 19 T-Lab X3, 91 Serotta CII, 23 3T Strada

Mentioned: 30 Post(s)

Tagged: 0 Thread(s)

Quoted: 3124 Post(s)

Liked 1,694 Times

in

1,025 Posts

Looking at BRR (I'm a paid member because I like the work they do), the Schwalbe TPU tests closer to Conti race 28 light butyl tube than to, say, Vittoria latex, both at 80 and 100 psi (25c GP5000 S tire). The best were Vredestein latex, but in practice I have had them self destruct with regularity, which I wasn't able to solve.

Went to tubeless in the end.

Went to tubeless in the end.

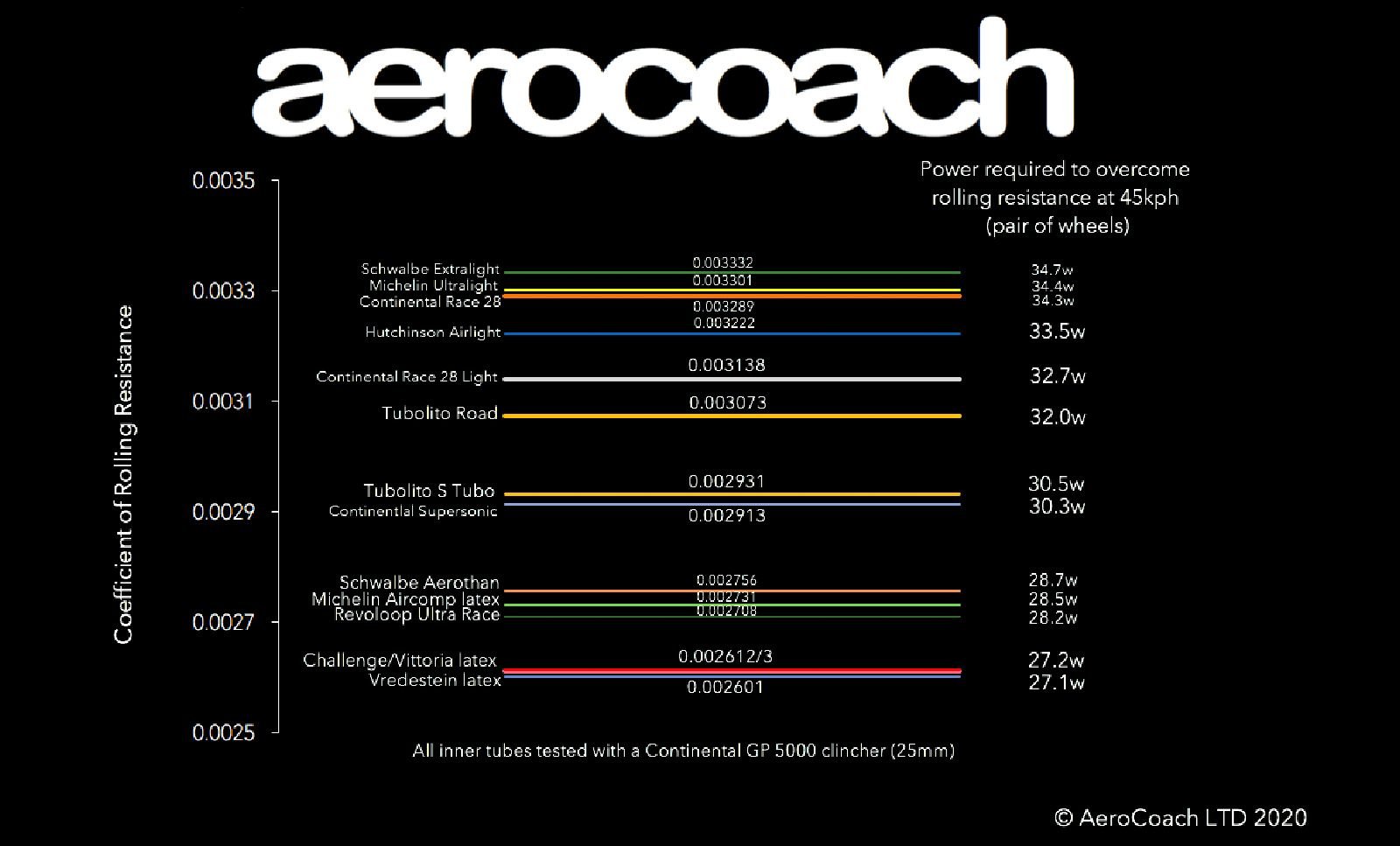

Further, Aerocoach found a full 4w penalty (per pair) for running the same Conti Race Lights BRR tested compared to Aerothan, so pick who you believe, I guess, or just call it “just as fast.” At least Aerocoach is testing in only one tire, so they remove that part of the noise from BRR’s results :

#12

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,931

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6163 Post(s)

Liked 4,781 Times

in

3,299 Posts

All your previous failures were in the same area around the valve stem boot?

Are you certain the air chuck on your pump isn't pulling on the stem too much when you take it off? I let mine get so bad that I was pulling stems out of butyl tubes. For about 4 bucks I got a new chuck with hose that I put on my pump. Chuck was much better and different design and actually easier to use.

Are you certain the air chuck on your pump isn't pulling on the stem too much when you take it off? I let mine get so bad that I was pulling stems out of butyl tubes. For about 4 bucks I got a new chuck with hose that I put on my pump. Chuck was much better and different design and actually easier to use.

Likes For Iride01:

#13

Senior Member

Thread Starter

Join Date: Jun 2021

Location: Australia

Posts: 821

Bikes: 2002 Trek 5200 (US POSTAL), 2020 Canyon Aeroad SL

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 313 Post(s)

Liked 679 Times

in

327 Posts

OP, did you check the inside of the rim at the failure point to verify if there is a rough spot or irregularity?? I agree it looks like it's either wear from inflation and/or related to friction/wear from the inside at site of failure.

Let us know about inside of wheels question??

Let us know about inside of wheels question??

The first wheel was running some pretty good rim tape all the way around including over the valve hole, the newer rims are internally sealed and smooth so I don't use rim tape. I'll try and snap off a photo today when I check on the rim.

I have a feeling you're spot on with it being the frequent inflate/deflate cycles of Latex tubes combined with maybe being not gentle enough with my inflation technique (and no valve nut) that's causing a stress point.

#14

Senior Member

Thread Starter

Join Date: Jun 2021

Location: Australia

Posts: 821

Bikes: 2002 Trek 5200 (US POSTAL), 2020 Canyon Aeroad SL

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 313 Post(s)

Liked 679 Times

in

327 Posts

I love the testing and data that Aerocoach put out there. I find it super interesting.

If I'm totally honest a 4W difference at 45km/hr (thin Butyl vs Latex) isn't going to make a difference to me, certainly not going to get me on any podiums, but I'm an aero / rr nerd so I chase these small gains. 😂

I have a pair of TL valve stems that came with the wheels, plus sealant that I use in my MTB. Might have to give it a go at some point. Haven't ventured into (road) tubeless yet!

If I'm totally honest a 4W difference at 45km/hr (thin Butyl vs Latex) isn't going to make a difference to me, certainly not going to get me on any podiums, but I'm an aero / rr nerd so I chase these small gains. 😂

I have a pair of TL valve stems that came with the wheels, plus sealant that I use in my MTB. Might have to give it a go at some point. Haven't ventured into (road) tubeless yet!

Last edited by tempocyclist; 10-03-22 at 03:13 PM.

#15

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,879

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4783 Post(s)

Liked 3,901 Times

in

2,538 Posts

Not a watt counter here but I love both the feel of the roll and better overall flex/adhesion I see cornering on latex tubes. That said, I don't do latex in clinchers. Too fussy and lack of attention could be costly (in $$s or flatting at an inopportune time).

I'm back to tubulars which are crafted around that latex tube by people who know what they are doing. Not much I can do to screw things up. And man, do I love the ride! No constructive advice for you non-tubular riders trying latex except, after the steep and expensive learning curve, they are wonderful. (When I was trying them, Cycle Oregon with its many thousands of feet of descending roads I'd never seen was a month or two away. Quickly became obvious I wasn't going to get to the trust-my-life-on-these point before CO arrived. Now this last one on tubulars, those descents were a blast!)

I'm back to tubulars which are crafted around that latex tube by people who know what they are doing. Not much I can do to screw things up. And man, do I love the ride! No constructive advice for you non-tubular riders trying latex except, after the steep and expensive learning curve, they are wonderful. (When I was trying them, Cycle Oregon with its many thousands of feet of descending roads I'd never seen was a month or two away. Quickly became obvious I wasn't going to get to the trust-my-life-on-these point before CO arrived. Now this last one on tubulars, those descents were a blast!)

Likes For 79pmooney:

#16

Senior Member

Join Date: Jun 2002

Location: San Jose, CA

Posts: 3,672

Bikes: Too many bikes, too little time to ride

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 425 Post(s)

Liked 452 Times

in

311 Posts

While latex tubes can be finicky, OP's failures seem consistent enough to point to a rim or rim tape issue, or a pumping behavior issue, and not a tube quality issue.

I've patched latex tubes with success, so perhaps that's a solution. I've also had inexplicable failures as well, following very careful install practices. The most interesting failure I've noted is the latex creeping out of cuts or porous sidewalls and popping. I've now gone to TPU on my fast bikes, and regular butyl on my other bikes.

I've patched latex tubes with success, so perhaps that's a solution. I've also had inexplicable failures as well, following very careful install practices. The most interesting failure I've noted is the latex creeping out of cuts or porous sidewalls and popping. I've now gone to TPU on my fast bikes, and regular butyl on my other bikes.

Likes For tFUnK:

#17

Senior Member

Thread Starter

Join Date: Jun 2021

Location: Australia

Posts: 821

Bikes: 2002 Trek 5200 (US POSTAL), 2020 Canyon Aeroad SL

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 313 Post(s)

Liked 679 Times

in

327 Posts

Rim internals:

I've come to the conclusion it's most likely a pumping up issue on my behalf. Still, I've ordered a different brand (Vittoria) as a replacement just in case.

If I still get a failure, I'm going tubeless! 🤣

If I still get a failure, I'm going tubeless! 🤣

#18

Senior Member

Join Date: Jun 2005

Location: Kentucky

Posts: 2,597

Bikes: 06 Lemond Reno, 98 GT Timberline mtn.bike

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 426 Post(s)

Liked 694 Times

in

433 Posts

Have you considered cutting a piece of butyl tube to fit over the stem and extend to cover the area getting the puncture?

Likes For freeranger:

#19

Senior Member

Join Date: Dec 2020

Location: Los Angeles

Posts: 916

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 445 Post(s)

Liked 1,036 Times

in

440 Posts

Latex tubes are most weakest around the valve tube. I would handle the tubes with care when mounting tires. I'm now using TPU tubes and mine come with a small rubber o-ring that mounts on the valve from inside the rim hole. I'm guessing it's to minimizes valve tears and keep water out.

Likes For jonathanf2:

#20

Me duelen las nalgas

Join Date: Aug 2015

Location: Texas

Posts: 13,516

Bikes: Centurion Ironman, Trek 5900, Univega Via Carisma, Globe Carmel

Mentioned: 199 Post(s)

Tagged: 0 Thread(s)

Quoted: 4559 Post(s)

Liked 2,802 Times

in

1,800 Posts

Yeah, after a year, my Vittoria or Silca (made by Vittoria) latex tubes failed in the same place, at the base of the valve stem. I'm going to blame my own installation shortcuts. I was anxious to get them installed and ignored Silca's recommendations. Instead of using a rim tape, like the kind used for tubeless, I used a heavy duty Schwalbe plastic rim strip. While this provided enough support, the cut-out for the valve stem probably abraded the tube over the course of a year and a few thousand miles.

I have a pair of unused latex tubes from a year or so ago. Before installing I'll use the recommended method, per the Silca video on their website. I'm betting the trick of cutting a minimal hole to accommodate the valve stem should offer enough support with less abrasion than the Schwalbe plastic rim strip.

The ride was pretty sweet. I've been using butyl tubes the past few months and really miss the feel of latex over our coarse chipseal roads.

If I wasn't still limited to 700x25 tires, max, for my older road bikes with narrow chainstays, I'd go tubeless. But I'm not sure tubeless is practical with 700x23 and 700x25 tires.

I have a pair of unused latex tubes from a year or so ago. Before installing I'll use the recommended method, per the Silca video on their website. I'm betting the trick of cutting a minimal hole to accommodate the valve stem should offer enough support with less abrasion than the Schwalbe plastic rim strip.

The ride was pretty sweet. I've been using butyl tubes the past few months and really miss the feel of latex over our coarse chipseal roads.

If I wasn't still limited to 700x25 tires, max, for my older road bikes with narrow chainstays, I'd go tubeless. But I'm not sure tubeless is practical with 700x23 and 700x25 tires.

Likes For canklecat:

#21

Me duelen las nalgas

Join Date: Aug 2015

Location: Texas

Posts: 13,516

Bikes: Centurion Ironman, Trek 5900, Univega Via Carisma, Globe Carmel

Mentioned: 199 Post(s)

Tagged: 0 Thread(s)

Quoted: 4559 Post(s)

Liked 2,802 Times

in

1,800 Posts

The puncture is awfully close to the valve. This makes me think that the puncture is a combination of a daily inflation error combined with less than perfect rim tape job.

you mention that the rims are tubeless ready. Can I ask what kind of rim tape you are running? It the hole for the valve stem too big or is there something sharp in that vicinity?

Also, as I’m sure you know latex tubes always lose air over night so they have to be topped up before each ride. This means there are many more cycles of attaching and detaching the pump head. If you are in the habit of pushing the valve down into the rim when starting to pump I have found that this creates premature wear on the valve and the round latex rubber vulcanized valve base. This wear eventually creates leaks. Since the valve stem is not threaded you cannot use a knurled nut to hold it up. That is why I came up with my own solution of using an M6 nylon stop collar. You can get these from industrial supply houses and they are about $7.50 each. I think they are worth it. Since I started this system on my Velocity A23 wheels, I have not had any recurrence of failed valve stems with latex tubes.

The split white nylon stop collar is a 6mm internal diameter. It clamps to the valve stem and is held with a stainless metric Allen cap screw that takes a tiny (2.5 or 3mm) metric Allen wrench to keep the valve stem in place when the tube goes soft over night.

Also, the mere act of how you attach & detach your pump head can impact the wear & tear in this critical area. Any pushing down on the valve stem needs to be minimized.

you mention that the rims are tubeless ready. Can I ask what kind of rim tape you are running? It the hole for the valve stem too big or is there something sharp in that vicinity?

Also, as I’m sure you know latex tubes always lose air over night so they have to be topped up before each ride. This means there are many more cycles of attaching and detaching the pump head. If you are in the habit of pushing the valve down into the rim when starting to pump I have found that this creates premature wear on the valve and the round latex rubber vulcanized valve base. This wear eventually creates leaks. Since the valve stem is not threaded you cannot use a knurled nut to hold it up. That is why I came up with my own solution of using an M6 nylon stop collar. You can get these from industrial supply houses and they are about $7.50 each. I think they are worth it. Since I started this system on my Velocity A23 wheels, I have not had any recurrence of failed valve stems with latex tubes.

The split white nylon stop collar is a 6mm internal diameter. It clamps to the valve stem and is held with a stainless metric Allen cap screw that takes a tiny (2.5 or 3mm) metric Allen wrench to keep the valve stem in place when the tube goes soft over night.

Also, the mere act of how you attach & detach your pump head can impact the wear & tear in this critical area. Any pushing down on the valve stem needs to be minimized.

My frame pumps have threaded chucks but I'm too lazy to use those for daily top-ups with latex. I should replace the floor pump chuck with a threaded type.

Likes For canklecat:

#22

Thread Killer

Join Date: Aug 2008

Location: Ann Arbor, MI

Posts: 12,422

Bikes: 15 Kinesis Racelight 4S, 76 Motebecane Gran Jubilée, 17 Dedacciai Gladiatore2, 12 Breezer Venturi, 09 Dahon Mariner, 12 Mercier Nano, 95 DeKerf Team SL, 19 Tern Rally, 21 Breezer Doppler Cafe+, 19 T-Lab X3, 91 Serotta CII, 23 3T Strada

Mentioned: 30 Post(s)

Tagged: 0 Thread(s)

Quoted: 3124 Post(s)

Liked 1,694 Times

in

1,025 Posts

I dunno if it’s sealing under high pressure you’re concerned about, but even the old stuff worked pretty well and the new stuff is even better. I’ve run 19.4mm IW rims from the beginning and weigh 245lbs, so I run pressures like 95/105psi for 23s, about 5psi less for 25s.

Rather than tire size, I think the big challenge to tubeless is getting the right tire/rim combo.

Likes For chaadster:

#23

I eat carbide.

Join Date: Jan 2006

Location: Elgin, IL

Posts: 21,627

Bikes: Lots. Van Dessel and Squid Dealer

Mentioned: 25 Post(s)

Tagged: 0 Thread(s)

Quoted: 1325 Post(s)

Liked 1,306 Times

in

560 Posts

Flex issue. That's one of the most susceptible points to wearing out if you really have poor technique when pumping up your tire. Also if you're running super low pressures it can cause that all to flex every revolution.

Regardless I have seen batches of tubes that are butlyl fail right there. No rhyme or reason leading to a direct cause.

If I were you I'd patch those and put them back into use.

Regardless I have seen batches of tubes that are butlyl fail right there. No rhyme or reason leading to a direct cause.

If I were you I'd patch those and put them back into use.

__________________

PSIMET Wheels, PSIMET Racing, PSIMET Neutral Race Support, and 11 Jackson Coffee

Podcast - YouTube Channel

Video about PSIMET Wheels

Podcast - YouTube Channel

Video about PSIMET Wheels