Spokes

#1

Senior Member

Thread Starter

Join Date: May 2016

Location: Yucatán. México

Posts: 6,230

Bikes: 79 Trek 930 is back on the road, 80 Trek 414, 84 Schwinn Letour Luxe,87 Schwinn Prelude, 92 Schwinn Paramount PDG 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3191 Post(s)

Liked 1,842 Times

in

1,162 Posts

Spokes

A take-off from Mad Honk's for sale thread. I have been led to believe that db spokes are stronger than straight gage due to their ability to stretch without breaking. The opposite is being stated in that thread.. Thought? Experience? Science?

#2

Senior Member

Join Date: Aug 2015

Posts: 3,297

Mentioned: 39 Post(s)

Tagged: 0 Thread(s)

Quoted: 1142 Post(s)

Liked 1,739 Times

in

960 Posts

Now that sounds like a shop joke on the newbie hire.

'Hey these are short, take them over to Bob he's got the spoke stretcher...'

Honesty I don't know, the butted spokes may have more flex but I don't think one wants to stretch spokes.

'Hey these are short, take them over to Bob he's got the spoke stretcher...'

Honesty I don't know, the butted spokes may have more flex but I don't think one wants to stretch spokes.

#3

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,218 Times

in

2,365 Posts

Double-butted spokes do more than save weight. The thick ends make them as strong in the highly-stressed areas as straight-gauge spokes of the same thickness, but the thinner middle sections make the spokes effectively more elastic, allowing them to stretch (temporarily) more than thicker spokes.As a result, when the wheel is subjected to sharp localized stresses, the most heavily-stressed spokes can elongate enough to shift some of the stress to adjoining spokes. This is particularly desirable when the limiting factor is how much stress the rim can withstand without cracking around the spoke holes.

If you want a scientific approach, Pillar Spokes is the only place I’ve seen that has actual test results on the strength of spokes. Below are the strength graphs for various gauges and buttings of spokes made by Pillar.

Straight gauge. The P14 (blue line) is a typical 2.0mm straight gauge spoke. The breaking strength is about 250kgf.

Image 5-11-18 at 1.41 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.41 PM by Stuart Black, on FlickrDouble butted. The 1415 (red line) is a 2.0/1.8/2.0mm. It breaks at around 300kgf or a 20% increase in strength.

Image 5-11-18 at 1.44 PM by Stuart Black, on Flickr

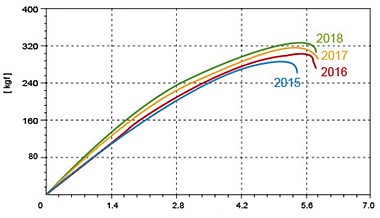

Image 5-11-18 at 1.44 PM by Stuart Black, on FlickrTriple butted: The 2018 is a triple butted spoke that is 2.2/1.9/2.0mm spoke that breaks at about 340kgf or about 40% stronger than the straight gauge spoke.

Image 5-11-18 at 1.43 PM by Stuart Black, on Flickr

Image 5-11-18 at 1.43 PM by Stuart Black, on FlickrThe Ric Hjertberg article says that going to triple butted spokes is the equivalent of adding 10 spokes to the wheel. I might not go that far…I’d say at least 4 spokes so a 32 performs like a 36 and a 36 performs like a 40, etc…but there is definitely an advantage to butting. And an extra advantage to a thicker head.

I’ve been building with triple butted spokes…mostly DT Swiss Alpine III…since around 2000. Spoke breakages is mostly a thing of the past even though I haven’t changed the way I build wheels.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Last edited by cyccommute; 05-25-23 at 08:48 AM.

Likes For cyccommute:

#4

spondylitis.org

Join Date: Mar 2013

Location: Fleetwood, PA, USA

Posts: 1,003

Bikes: '84 Colnago Super; '90 Bridgestone MB-1; '81 Trek 930; '01 Cinelli Supercorsa; '62 Ideor Asso; '87 Tommasini Super Prestige; '13 Lynskey R2300; '84 Serotta Nova Special; '94 Litespeed Catalyst; etc.

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 121 Post(s)

Liked 97 Times

in

63 Posts

From a wheel-builder's perspective, it's pretty easy to tell the difference. Straight-gauge spokes tend to be spongy, and they also tend to build tension up slowly and somewhat unpredictably. This matters less when spoke counts per wheel are high. DB spokes build up tension a lot more quickly and in linear fashion. Triple-butted spokes are a must-have IMO for the drive-side rear, as they have to take more tension (due to the dish). The biggest disadvantage for DB spokes is in wind-up for the thinner gauges.

#5

Senior Member

Do keep in mind these DB spokes vs. straight gauge spoke discussions are more theoretical than practical in application, meaning in application it makes no difference provided all materials in the wheel are of proper design, ie rim/spoke/hub/build and of good quality. My experience from working in a bike shop as a full-time or part-timer since 1981 is that there is no real world difference between the two types of spokes as long as the builder knows what they are doing and the rims, hubs, spokes and nipples are good quality stuff.

I have personally built dozens of wheels with straight gauge spokes and have zero fatigue failures. My friend Al, builds them as a side biz and he has the same track record as myself. Zero failures.

I have personally built dozens of wheels with straight gauge spokes and have zero fatigue failures. My friend Al, builds them as a side biz and he has the same track record as myself. Zero failures.

#6

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,218 Times

in

2,365 Posts

Do keep in mind these DB spokes vs. straight gauge spoke discussions are more theoretical than practical in application, meaning in application it makes no difference provided all materials in the wheel are of proper design, ie rim/spoke/hub/build and of good quality. My experience from working in a bike shop as a full-time or part-timer since 1981 is that there is no real world difference between the two types of spokes as long as the builder knows what they are doing and the rims, hubs, spokes and nipples are good quality stuff.

I have personally built dozens of wheels with straight gauge spokes and have zero fatigue failures. My friend Al, builds them as a side biz and he has the same track record as myself. Zero failures.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#7

Senior Member

Join Date: Jan 2019

Location: Toledo Ohio

Posts: 1,494

Bikes: 1964 Huffy Sportsman, 1972 Fuji Newest, 1973 Schwinn Super Sport (3), 1982 Trek 412, 1983 Trek 700, 1989 Miyata 1000LT, 1991 Bianchi Boardwalk, plus others

Mentioned: 21 Post(s)

Tagged: 0 Thread(s)

Quoted: 582 Post(s)

Liked 697 Times

in

393 Posts

A real amateur here as I’ve built one wheel and have never bought new spokes. The bikes I’ve acquired have been mostly neglected. My personal 73 Schwinn Super Sport that I bought used in 1975 was neglected by me for 40 years as I didn’t know better. It has double butted spokes, and a replacement bike shop front rim was relaced in about 1982 with db spokes about 1/4” short.

I wonder if some of us have most experience with neglected bikes. Often I bet, spoke tension is never checked, and the results with the general vintage sampling of bikes represents generally maintenance differed bikes. Often probably not many miles on these bikes we acquire, so apples to apples comparisons are not part of the equation. I greatly respect users opinions with bikes going thousands of miles and find the theoretical points quite interesting. I also don’t fret things too much on my smaller fleet, as each bike gets ridden in the 50-200 miles a year range, so proper attention to maintenance is good for me now. DB spokes for sure, if I ever do buy some, especially for the vintage NOS Super Champion 58 rims I just purchased.

I wonder if some of us have most experience with neglected bikes. Often I bet, spoke tension is never checked, and the results with the general vintage sampling of bikes represents generally maintenance differed bikes. Often probably not many miles on these bikes we acquire, so apples to apples comparisons are not part of the equation. I greatly respect users opinions with bikes going thousands of miles and find the theoretical points quite interesting. I also don’t fret things too much on my smaller fleet, as each bike gets ridden in the 50-200 miles a year range, so proper attention to maintenance is good for me now. DB spokes for sure, if I ever do buy some, especially for the vintage NOS Super Champion 58 rims I just purchased.

#8

aka Tom Reingold

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,502

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7348 Post(s)

Liked 2,465 Times

in

1,433 Posts

Yes, it's counterintuitive that a weaker spoke makes a stronger wheel, but the explanations above should clarify it.

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Likes For noglider:

#10

Senior Member

Are these tensile test results?

I have to say is this - I dislike when people provide data for comparison in graphical format but plot that data on different scales. It makes it impossible to compare without mental gymnastics (recalculating and replotting in your head to understand how they actually compare).

If I did it correctly (in my head), the butted spokes are effectively stiffer (steeper slope) and have higher breaking strength. Is that correct?

Is this from hardening associated with the butting process or do they get annealed? Harder (stiffer) is almost always stronger.

Is breaking strength the key parameter for a spoke, or is it yield or fatigue strength?

Failure mode is also an important characteristic in these tests? Did they all fail in the same way, at the same location?

Absent answers to those, I do not want to draw any conclusions.

I say that because I have broken many, many good quality spokes in my riding - butted spokes, usually not at the head or threads. A typical failure would look like a tensile failure in the thinner section near or right after the transition from the thick to thin section. Was it simple tensile failure (loading) or was it a fatigue failure? New York City roads were notoriously bad.

I have some good quality wheels with good rims and double butted spokes that have lasted me 40 years. They are showing their age but have been a blessing. I've never broken even a single spoke but roads out here are relatively smooth.

I have to say is this - I dislike when people provide data for comparison in graphical format but plot that data on different scales. It makes it impossible to compare without mental gymnastics (recalculating and replotting in your head to understand how they actually compare).

If I did it correctly (in my head), the butted spokes are effectively stiffer (steeper slope) and have higher breaking strength. Is that correct?

Is this from hardening associated with the butting process or do they get annealed? Harder (stiffer) is almost always stronger.

Is breaking strength the key parameter for a spoke, or is it yield or fatigue strength?

Failure mode is also an important characteristic in these tests? Did they all fail in the same way, at the same location?

Absent answers to those, I do not want to draw any conclusions.

I say that because I have broken many, many good quality spokes in my riding - butted spokes, usually not at the head or threads. A typical failure would look like a tensile failure in the thinner section near or right after the transition from the thick to thin section. Was it simple tensile failure (loading) or was it a fatigue failure? New York City roads were notoriously bad.

I have some good quality wheels with good rims and double butted spokes that have lasted me 40 years. They are showing their age but have been a blessing. I've never broken even a single spoke but roads out here are relatively smooth.

#11

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,218 Times

in

2,365 Posts

I would say yes.

Not my graphs. I stole them from Pillar as the examples I can find of actual spoke strength testing. And, to make the matter worst, both axes vary from graph to graph. The units on the Y axis are 14 and 16 units depending on the graph. Yea, it’s hard to compare. It’s be nice if they stuck with the same color scheme as well.

The double butted elongate less before breaking. The straight gauge (P14) break at a bit over 5mm of elongation while the double butted (1415) breaks at bit above 4.5mm. The triple butted (2018) seems to break at around 5.6mm.

From what I’ve seen, the butting process is essentially drawing of a straight wire through a die. They don’t get annealed following the drawing that I’ve ever seen.

Fatigue strength is more important in a spoke but it would be more difficult to measure. Tensile strength isn’t directly relatable to fatigue strength but for comparison purposes of wire spokes, it’s probably not a bad estimate. If you compare spokes to spokes and on spokes to bolts, it’s probably a fair comparison.

It’s hard to say. For spokes, failure is almost always at the head. Occasionally, they fail at the spoke nipple but seldom do they fail mid-spoke. I would suspect that the tensile strength measurement may break them mid-spoke but can’t say for sure.

It’s not perfect but I think the data is valid. It fits real world experience and suggestions made by others that butted spokes and butted spokes with heavier heads result in less spoke breakage than straight gauge spokes.

I’ve never broken a spoke mid-shaft nor have I seen spokes in wheels at my co-op broken mid-shaft. I’ve seen a very few broken at the spoke nipple but the vast majority have been broken at the head.

I’ve broken lots of spokes. The triple butted spokes were suggested to me by a local shop owner back in the early 2000 and I’ve never looked back. They are more robust and durable than anything I’ve used previously. That first wheel lasted me 10 years of mountain biking without issue which isn’t something I could have said previously. They probably would have lasted longer but I loaned the bike to an intern who “adjusted” the shifting and shifted into the spokes. I had reached many of the same conclusion with regard to the durability of triple butted spokes as that of the Hjertberg article I linked to before I read his article. His article explained why but I was already aware of the benefits.

By the way, I don’t look at the failure of something as bad. I’ve learned a lot over my years of bicycling and my science career through failure. I’ve always felt I learn a lot more from failure than from constant success. Success is good but failure tells you where the limits are.

I have to say is this - I dislike when people provide data for comparison in graphical format but plot that data on different scales. It makes it impossible to compare without mental gymnastics (recalculating and replotting in your head to understand how they actually compare).

If I did it correctly (in my head), the butted spokes are effectively stiffer (steeper slope) and have higher breaking strength. Is that correct?

Is this from hardening associated with the butting process or do they get annealed? Harder (stiffer) is almost always stronger.

Is breaking strength the key parameter for a spoke, or is it yield or fatigue strength?

Failure mode is also an important characteristic in these tests? Did they all fail in the same way, at the same location?

Absent answers to those, I do not want to draw any conclusions.

I say that because I have broken many, many good quality spokes in my riding - butted spokes, usually not at the head or threads. A typical failure would look like a tensile failure in the thinner section near or right after the transition from the thick to thin section. Was it simple tensile failure (loading) or was it a fatigue failure? New York City roads were notoriously bad.

I have some good quality wheels with good rims and double butted spokes that have lasted me 40 years. They are showing their age but have been a blessing. I've never broken even a single spoke but roads out here are relatively smooth.

By the way, I don’t look at the failure of something as bad. I’ve learned a lot over my years of bicycling and my science career through failure. I’ve always felt I learn a lot more from failure than from constant success. Success is good but failure tells you where the limits are.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#12

Senior Member

I have a set of hubs and rims in the garage waiting for the wheels to fail. The ferrules show corrosion, so it is just a matter of time.

What brand is the triple butted spoke to which you refer?

What brand is the triple butted spoke to which you refer?

#13

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,218 Times

in

2,365 Posts

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#14

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,904

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,928 Times

in

2,553 Posts

Spoke strength in tension is not really a factor in a wheel. Yes, butted spokes are weaker in pure tension. But spokes rarely fail in tension and when they do, it is usually from defects or damage. Spokes fail far more often from fatigue and the "neck" at the hub flange and less often through the threads (usually from poor alignment with the rim nipple seat). Butted spokes absorb road shock and simply stretch, sparing those high stress locations from the biggest loads. (Easier on both rims - less likely to crack at the spoke holes and hub flanges also.)

All the wheels I have ridden for very long distances have had double butted spokes. Most of the wheels I've owned that have cracked nipple seats on the rim have had 14g (2.0) straight spokes. I will use 14g straight for right rear if I am going 14-15 double butted for the rest. Yes, triple butted or 13-14 would be better but these seem to work and I build few wheels that heavy. The vast majority of my wheels are 14-16, 15-17 and the like (2.0-1.6, 1.8-1.5) and 14-15 right rear (2.0-1.8).

My wheels almost always go until the rims fail; impact or crash damage or brake wear. For the latter I often rebuild with same spokes and new rim if I can match ERDs.

All the wheels I have ridden for very long distances have had double butted spokes. Most of the wheels I've owned that have cracked nipple seats on the rim have had 14g (2.0) straight spokes. I will use 14g straight for right rear if I am going 14-15 double butted for the rest. Yes, triple butted or 13-14 would be better but these seem to work and I build few wheels that heavy. The vast majority of my wheels are 14-16, 15-17 and the like (2.0-1.6, 1.8-1.5) and 14-15 right rear (2.0-1.8).

My wheels almost always go until the rims fail; impact or crash damage or brake wear. For the latter I often rebuild with same spokes and new rim if I can match ERDs.

Likes For 79pmooney:

#15

Senior Member

Spoke strength in tension is not really a factor in a wheel. Yes, butted spokes are weaker in pure tension. But spokes rarely fail in tension and when they do, it is usually from defects or damage. Spokes fail far more often from fatigue and the "neck" at the hub flange and less often through the threads (usually from poor alignment with the rim nipple seat). Butted spokes absorb road shock and simply stretch, sparing those high stress locations from the biggest loads. (Easier on both rims - less likely to crack at the spoke holes and hub flanges also.)

Fatigue testing is not so difficult to do once you understand the real world application and construct the test to simulate that, even if it is cyclic (pun) tensile loading. Fatigue testing is done all the time.

#16

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,218 Times

in

2,365 Posts

Spoke strength in tension is not really a factor in a wheel. Yes, butted spokes are weaker in pure tension. But spokes rarely fail in tension and when they do, it is usually from defects or damage. Spokes fail far more often from fatigue and the "neck" at the hub flange and less often through the threads (usually from poor alignment with the rim nipple seat). Butted spokes absorb road shock and simply stretch, sparing those high stress locations from the biggest loads. (Easier on both rims - less likely to crack at the spoke holes and hub flanges also.)

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#17

Full Member

Have you never read the hundreds of posts on rec.bike.tech by Jobst Brandt, declaring again and again that a bicycle wheel under load stands on the lower spokes, between the hub and contact patch?

When challenged sufficiently to give up, he would occasionally fall back to "I guess you just don't understand prestressed structures."

#18

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,904

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,928 Times

in

2,553 Posts

I can’t agree. The only force on a spoke is tension. There is no other force acting on the spoke at all. In fact, if you try to compress a wire spoke, it will simple collapse. Fatigue of the spoke head is related to the cycle of tension decreasing and increasing as the spoke moves past the contact patch as the wheel rolls down the road.

#19

Senior Member

I can’t agree. The only force on a spoke is tension. There is no other force acting on the spoke at all. In fact, if you try to compress a wire spoke, it will simple collapse. Fatigue of the spoke head is related to the cycle of tension decreasing and increasing as the spoke moves past the contact patch as the wheel rolls down the road.

If it were a simple tensile strength issue, the spokes would fail as soon as you sat on the seat or hit your first bump.

Rather, it is that initial pre-load overlaid with the successive stress reduction/relaxation and re-application of the load as the wheel rotates that causes eventual fatigue life failure (look up S-N curves).

Last edited by Bad Lag; 05-27-23 at 10:26 PM.

#20

Senior Member

F=Ma. Does the rate of loading come into play? When you pick up the grocery bag slowly, no problem. Yank on it and the groceries rip out the bottom. All spokes I have broken have been straight gauge. 1 butted spoke lost in 10 years. Being over 200 pounds I am surprised I have not broken more.

Also, I am sure that some hub drillings might affect general wear at the head.

Also, I am sure that some hub drillings might affect general wear at the head.

#21

Master Parts Rearranger

Join Date: Mar 2015

Location: Portlandia's Kuiper Belt, OR

Posts: 4,403

Bikes: 1982 Trek 720 - 1985 Trek 620 - 1984 Trek 620 - 1980 Trek 510 - Other luminaries past and present

Mentioned: 221 Post(s)

Tagged: 0 Thread(s)

Quoted: 1556 Post(s)

Liked 2,024 Times

in

989 Posts

Very interesting, all of this. I've built with double butted spokes (2.0-1.8-2.0 and 2.0-1.5-2.0) and the resulting wheelsets have been fine. Nothing to gush over other than the considerable weight savings over straight gauge spokes, IMO. I am in the middle of building a set with Ultegra 6500 hubs, polished H Plus Son TB14 rims, and DT Swiss Champion straight gauge spokes. 2,045g for the wheelset. Not light! Sure, the TB14s are a hair over 500g--no Open Pros that's for sure--but a lot closer to 200g could be shaved in switching to butted spokes alone.

I've built TB14s to both 7400 Dura-Ace hubs and Superbe Pro hubs, both times using the fancier butted spoke profiles (1.5 butting for the front and NDS rear, 1.8 butting for the DS rear). Both times the resulting ride was less than desirable over Seattle streets unless the tire size was 35mm or bigger. Given that (broken record here) straight gauge 36-spoke wheels on my Cannondale SR don't kill me, and neither does the 6400-to-Matrix-Iso-C-II wheel build (straight gauge again) on my OS Paramount, I am hopeful and certainly a somewhat confident that a straight gauge spoke setup on these TB14s will yield a more cohesive and pleasant reaction to street irregularities. So I'll take "less stiff" if it means everybody in the wheelset ecosystem gets along better. The wheelset will certainly dazzle with all it's anodized and polished pieces, which is a big reason I built it up.

I've built TB14s to both 7400 Dura-Ace hubs and Superbe Pro hubs, both times using the fancier butted spoke profiles (1.5 butting for the front and NDS rear, 1.8 butting for the DS rear). Both times the resulting ride was less than desirable over Seattle streets unless the tire size was 35mm or bigger. Given that (broken record here) straight gauge 36-spoke wheels on my Cannondale SR don't kill me, and neither does the 6400-to-Matrix-Iso-C-II wheel build (straight gauge again) on my OS Paramount, I am hopeful and certainly a somewhat confident that a straight gauge spoke setup on these TB14s will yield a more cohesive and pleasant reaction to street irregularities. So I'll take "less stiff" if it means everybody in the wheelset ecosystem gets along better. The wheelset will certainly dazzle with all it's anodized and polished pieces, which is a big reason I built it up.

#22

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,218 Times

in

2,365 Posts

This is what I was thinking, too. That's why I asked about the nature of the testing and test data.

Fatigue testing is not so difficult to do once you understand the real world application and construct the test to simulate that, even if it is cyclic (pun) tensile loading. Fatigue testing is done all the time.

Fatigue testing is not so difficult to do once you understand the real world application and construct the test to simulate that, even if it is cyclic (pun) tensile loading. Fatigue testing is done all the time.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#23

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,218 Times

in

2,365 Posts

Ooh, you sweet summer child.

Have you never read the hundreds of posts on rec.bike.tech by Jobst Brandt, declaring again and again that a bicycle wheel under load stands on the lower spokes, between the hub and contact patch?

When challenged sufficiently to give up, he would occasionally fall back to "I guess you just don't understand prestressed structures."

Have you never read the hundreds of posts on rec.bike.tech by Jobst Brandt, declaring again and again that a bicycle wheel under load stands on the lower spokes, between the hub and contact patch?

When challenged sufficiently to give up, he would occasionally fall back to "I guess you just don't understand prestressed structures."

As to the wheel “standing” on the spokes, I guess he didn’t understand tensegrity structures. For example the Lego tensegrity structure illustrates how tension alone holds up the upper part of the structure. The black chain is the carrying the load while the gray chains only serve to stabilize the structure below.

Now let’s look at how the wire spoke works using a simplified wheel of 2 spokes, a hub, and a bit of rim. This picture models the wheel “standing” on the spokes.

But turn the picture upside down and the hub is now hanging from the rim.

Now isolate the hub like it would be in a frame and the rim slides down the spoke. There is no attachment between the spoke and the rim so the rim is free to move on the spoke.

If we hold up the rim section, you can, again, that the rim is free to move on the spokes. If we were to put the spokes in contact with the ground, the spoke would collapse under the slightest weight placed on it.

Taking this illustration further, we can use a real wheel. I removed spokes from half of the wheel. You can see that the hub is hanging from the spokes. If I were braver, I’d put this is a frame and have some confidence that I could get on the bike and the bike wheel would not collapse (as long as it doesn’t rotate). In that case there would be tension on the spokes from the weight of the bicycle and rider. The structure wouldn’t be sound but it would hold under static load.

Spin the wheel 90° and it’s easy to see that the wheel can’t “stand” on the spokes because there is nothing to stand on. Put weight on the structure and it will collapse like a house of cards.

This close up even shows how the spokes are now in contact with the ground and would bend under slight weight. I’m not brave…nor dumb…enough to try to put a load on the wheel with the spoke at the bottom of the wheel.

This clearly shows that the wheel doesn’t “stand” on anything but rather hangs from the rim.

The only force may be tension but what breaks spokes is not force but stress. The stress at both the bend and the head includes shear. Tension and shear add up but not simply. (Sophomore engineering, Morh's Circle where they weed out those who aren't up to it.) The two stresses love to hang out at stress risers. The straight portion of the spoke is in pretty close to pure tension and the after Mohr's Circle total stress is virtually the very easy to calculate average tension across the spoke section.

Mechanical Stress is a measure of internal resistance exhibited by a body or material when an external force is applied to it.

Yes, however, the idea is that they do not fail in use because of excessive tensile loading but due to fatigue from repetitive cyclic tensile loading.

If it were a simple tensile strength issue, the spokes would fail as soon as you sat on the seat or hit your first bump.

Rather, it is that initial pre-load overlaid with the successive stress reduction/relaxation and re-application of the load as the wheel rotates that causes eventual fatigue life failure (look up S-N curves).

If it were a simple tensile strength issue, the spokes would fail as soon as you sat on the seat or hit your first bump.

Rather, it is that initial pre-load overlaid with the successive stress reduction/relaxation and re-application of the load as the wheel rotates that causes eventual fatigue life failure (look up S-N curves).

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#24

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,218 Times

in

2,365 Posts

Very interesting, all of this. I've built with double butted spokes (2.0-1.8-2.0 and 2.0-1.5-2.0) and the resulting wheelsets have been fine. Nothing to gush over other than the considerable weight savings over straight gauge spokes, IMO. I am in the middle of building a set with Ultegra 6500 hubs, polished H Plus Son TB14 rims, and DT Swiss Champion straight gauge spokes. 2,045g for the wheelset. Not light! Sure, the TB14s are a hair over 500g--no Open Pros that's for sure--but a lot closer to 200g could be shaved in switching to butted spokes alone.

I've built TB14s to both 7400 Dura-Ace hubs and Superbe Pro hubs, both times using the fancier butted spoke profiles (1.5 butting for the front and NDS rear, 1.8 butting for the DS rear). Both times the resulting ride was less than desirable over Seattle streets unless the tire size was 35mm or bigger. Given that (broken record here) straight gauge 36-spoke wheels on my Cannondale SR don't kill me, and neither does the 6400-to-Matrix-Iso-C-II wheel build (straight gauge again) on my OS Paramount, I am hopeful and certainly a somewhat confident that a straight gauge spoke setup on these TB14s will yield a more cohesive and pleasant reaction to street irregularities. So I'll take "less stiff" if it means everybody in the wheelset ecosystem gets along better. The wheelset will certainly dazzle with all it's anodized and polished pieces, which is a big reason I built it up.

I've built TB14s to both 7400 Dura-Ace hubs and Superbe Pro hubs, both times using the fancier butted spoke profiles (1.5 butting for the front and NDS rear, 1.8 butting for the DS rear). Both times the resulting ride was less than desirable over Seattle streets unless the tire size was 35mm or bigger. Given that (broken record here) straight gauge 36-spoke wheels on my Cannondale SR don't kill me, and neither does the 6400-to-Matrix-Iso-C-II wheel build (straight gauge again) on my OS Paramount, I am hopeful and certainly a somewhat confident that a straight gauge spoke setup on these TB14s will yield a more cohesive and pleasant reaction to street irregularities. So I'll take "less stiff" if it means everybody in the wheelset ecosystem gets along better. The wheelset will certainly dazzle with all it's anodized and polished pieces, which is a big reason I built it up.

Consider what “kills” a wheel. If you crack a rim due to spoke tension, the wheel isn’t “done”. It’s somewhat trivial to replace a rim if you have one with the same ERD. Reduce tension on the spokes and swap them over to the new rim. I’ve done it a number of times when I can find the same model rim or one with a similar enough ERD. But break a single spoke and the wheel is somewhat suspect. Break another spoke and the wheel is more than “somewhat” suspect. Break a third spoke and you should seriously consider rebuilding the wheel. Break more than 3 spokes and you are just wasting your time trying to keep up with the cascade of spoke failure that you are going to be dealing with shortly.

And if you just go by the posts here in the Bike Forums, rim failure is relatively uncommon. Spoke failure, on the other hand, is a far more common topic, especially in the touring and Clydesdale forums where the loads carried are higher and the stress on the wheels are greater.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#25

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,904

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,928 Times

in

2,553 Posts

cyccommute - stress. J-bend spokes. Tension. At the J-bend, the load on the spoke is in large part shear from the hub flange to the spoke which is at near right angle to the flange there. It would be fun to see a 3-d stress view of the last 3mm of a spoke. All sorts of stuff going on there.