Shredded T-pulley, longevity of the RDs and factors affecting it

#1

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

Shredded T-pulley, longevity of the RDs and factors affecting it

Just had encountered a bizarre situation when after changing a chain and cassette the RD's tension pulley was constantly getting the chain ride on its inner (closer to the frame) edge. At first I would be intuitively going for tuning the gears, but the actual shifting was still crisp. The second suspect became bent derailleur hanger or the cage, but this was not only all fine visually, but again the shifting was all crisp all the way up and down the cassette.

Having a separate set of wheels I momentarily swapped the whole rear wheel i.e. different cassette and quickly changed the chain it was normally used with (perhaps notable to mention this was a change from Shimano-Shimano to SRAM-SRAM and so was also the last chain used before the change). The T-pulley suddenly got much much happier, the chain was mostly nicely in place except for a few large cogs combined with inner chainring.

Baffled by this bizarre set of symptoms I managed to find a way way older RD with compatible T-pulley and only swapped that one, while having discovered there was nothing wrong with free movement of the original one. And there it was, problem solved, the chain was no more riding out of the T-pulley into the RD cage sidewall on low gears. This was a pulley from RD that had had been ridden much much longer miles.

I have to wonder, what could most likely be the culprit, I doubt it's mileage - subjectively comparing with previous experience.

I figured it might be:

1) Riding SRAM chains - they seem to have slightly different shaping of the inside of the outer plates - something I would never pay attention to.

2) Cross chaining - this is something that can be hardly helped when constantly riding in hilly terrain, the chainline seems to be best suited for something like 50-14 or 34-16, anything above 16 on the cassette starts to basically cause the chain to be biting that side of the T-pulley.

3) B screw not optimal - because I swap two different cassettes often, I once set the B-screw to be safe with the larger 32T cassette, the shifting on the roadie cassette is still decent, but of course this changes how far the T-pulley typically finds itself from the crankset in most common riding gears. Perhaps having the distance from the bottom of the chainring to the T-pulley short accelerates T-pulley wear?

4) Long cage GS RD - always before used to ride SS, so can't compare.

5) Materials used for the jockey wheels are not what they used to be? The G-pulley is worn a bit too (more than I would have expected for the mileage), but not shredded thin.

6) Riding much longer distances or with higher cadence than in the past without realising it? I do not feel so.

EDIT: 7) Waxing chains for the whole of 2021 instead of using more traditional lubricants and then having been caught in some heavy rains before getting back few hours later only?

Anything else? How long are the jockey wheels supposed to last anyways? I always thought I rather end up writing off the whole RD (getting worn out in the rivets, corroded, etc.) than reach a point when replacing just jockey wheels becomes a routine.

Having a separate set of wheels I momentarily swapped the whole rear wheel i.e. different cassette and quickly changed the chain it was normally used with (perhaps notable to mention this was a change from Shimano-Shimano to SRAM-SRAM and so was also the last chain used before the change). The T-pulley suddenly got much much happier, the chain was mostly nicely in place except for a few large cogs combined with inner chainring.

Baffled by this bizarre set of symptoms I managed to find a way way older RD with compatible T-pulley and only swapped that one, while having discovered there was nothing wrong with free movement of the original one. And there it was, problem solved, the chain was no more riding out of the T-pulley into the RD cage sidewall on low gears. This was a pulley from RD that had had been ridden much much longer miles.

I have to wonder, what could most likely be the culprit, I doubt it's mileage - subjectively comparing with previous experience.

I figured it might be:

1) Riding SRAM chains - they seem to have slightly different shaping of the inside of the outer plates - something I would never pay attention to.

2) Cross chaining - this is something that can be hardly helped when constantly riding in hilly terrain, the chainline seems to be best suited for something like 50-14 or 34-16, anything above 16 on the cassette starts to basically cause the chain to be biting that side of the T-pulley.

3) B screw not optimal - because I swap two different cassettes often, I once set the B-screw to be safe with the larger 32T cassette, the shifting on the roadie cassette is still decent, but of course this changes how far the T-pulley typically finds itself from the crankset in most common riding gears. Perhaps having the distance from the bottom of the chainring to the T-pulley short accelerates T-pulley wear?

4) Long cage GS RD - always before used to ride SS, so can't compare.

5) Materials used for the jockey wheels are not what they used to be? The G-pulley is worn a bit too (more than I would have expected for the mileage), but not shredded thin.

6) Riding much longer distances or with higher cadence than in the past without realising it? I do not feel so.

EDIT: 7) Waxing chains for the whole of 2021 instead of using more traditional lubricants and then having been caught in some heavy rains before getting back few hours later only?

Anything else? How long are the jockey wheels supposed to last anyways? I always thought I rather end up writing off the whole RD (getting worn out in the rivets, corroded, etc.) than reach a point when replacing just jockey wheels becomes a routine.

Last edited by am8117; 02-19-22 at 08:31 PM.

#2

Expired Member

Join Date: Jun 2007

Location: TN

Posts: 11,509

Mentioned: 37 Post(s)

Tagged: 0 Thread(s)

Quoted: 3657 Post(s)

Liked 5,397 Times

in

2,739 Posts

Just had encountered a bizarre situation when after changing a chain and cassette the RD's tension pulley was constantly getting the chain ride on its inner (closer to the frame) edge. At first I would be intuitively going for tuning the gears, but the actual shifting was still crisp. The second suspect became bent derailleur hanger or the cage, but this was not only all fine visually, but again the shifting was all crisp all the way up and down the cassette.

Having a separate set of wheels I momentarily swapped the whole rear wheel i.e. different cassette and quickly changed the chain it was normally used with (perhaps notable to mention this was a change from Shimano-Shimano to SRAM-SRAM and so was also the last chain used before the change). The T-pulley suddenly got much much happier, the chain was mostly nicely in place except for a few large cogs combined with inner chainring.

Baffled by this bizarre set of symptoms I managed to find a way way older RD with compatible T-pulley and only swapped that one, while having discovered there was nothing wrong with free movement of the original one. And there it was, problem solved, the chain was no more riding out of the T-pulley into the RD cage sidewall on low gears. This was a pulley from RD that had had been ridden much much longer miles.

I have to wonder, what could most likely be the culprit, I doubt it's mileage - subjectively comparing with previous experience. Blah blah blah

I figured it might be:

1) Riding SRAM chains - they seem to have slightly different shaping of the inside of the outer plates - something I would never pay attention to.

2) Cross chaining - this is something that can be hardly helped when constantly riding in hilly terrain, the chainline seems to be best suited for something like 50-14 or 34-16, anything above 16 on the cassette starts to basically cause the chain to be biting that side of the T-pulley.

3) B screw not optimal - because I swap two different cassettes often, I once set the B-screw to be safe with the larger 32T cassette, the shifting on the roadie cassette is still decent, but of course this changes how far the T-pulley typically finds itself from the crankset in most common riding gears. Perhaps having the distance from the bottom of the chainring to the T-pulley short accelerates T-pulley wear?

4) Long cage GS RD - always before used to ride SS, so can't compare.

5) Materials used for the jockey wheels are not what they used to be? The G-pulley is worn a bit too (more than I would have expected for the mileage), but not shredded thin.

6) Riding much longer distances or with higher cadence than in the past without realising it? I do not feel so.

EDIT: 7) Waxing chains for the whole of 2021 instead of using more traditional lubricants and then having been caught in some heavy rains before getting back few hours later only? Blah blah blah

Anything else? How long are the jockey wheels supposed to last anyways? I always thought I rather end up writing off the whole RD (getting worn out in the rivets, corroded, etc.) than reach a point when replacing just jockey wheels becomes a routine.

Having a separate set of wheels I momentarily swapped the whole rear wheel i.e. different cassette and quickly changed the chain it was normally used with (perhaps notable to mention this was a change from Shimano-Shimano to SRAM-SRAM and so was also the last chain used before the change). The T-pulley suddenly got much much happier, the chain was mostly nicely in place except for a few large cogs combined with inner chainring.

Baffled by this bizarre set of symptoms I managed to find a way way older RD with compatible T-pulley and only swapped that one, while having discovered there was nothing wrong with free movement of the original one. And there it was, problem solved, the chain was no more riding out of the T-pulley into the RD cage sidewall on low gears. This was a pulley from RD that had had been ridden much much longer miles.

I have to wonder, what could most likely be the culprit, I doubt it's mileage - subjectively comparing with previous experience. Blah blah blah

I figured it might be:

1) Riding SRAM chains - they seem to have slightly different shaping of the inside of the outer plates - something I would never pay attention to.

2) Cross chaining - this is something that can be hardly helped when constantly riding in hilly terrain, the chainline seems to be best suited for something like 50-14 or 34-16, anything above 16 on the cassette starts to basically cause the chain to be biting that side of the T-pulley.

3) B screw not optimal - because I swap two different cassettes often, I once set the B-screw to be safe with the larger 32T cassette, the shifting on the roadie cassette is still decent, but of course this changes how far the T-pulley typically finds itself from the crankset in most common riding gears. Perhaps having the distance from the bottom of the chainring to the T-pulley short accelerates T-pulley wear?

4) Long cage GS RD - always before used to ride SS, so can't compare.

5) Materials used for the jockey wheels are not what they used to be? The G-pulley is worn a bit too (more than I would have expected for the mileage), but not shredded thin.

6) Riding much longer distances or with higher cadence than in the past without realising it? I do not feel so.

EDIT: 7) Waxing chains for the whole of 2021 instead of using more traditional lubricants and then having been caught in some heavy rains before getting back few hours later only? Blah blah blah

Anything else? How long are the jockey wheels supposed to last anyways? I always thought I rather end up writing off the whole RD (getting worn out in the rivets, corroded, etc.) than reach a point when replacing just jockey wheels becomes a routine.

#3

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

Also, not everything is Sora 😆

But thanks anyways Ö

#4

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18354 Post(s)

Liked 4,502 Times

in

3,346 Posts

Has anybody told you that a picture is worth 5000 words?

You didn't say what brand, speed, etc.

There is some flexibility with speeds and derailleurs, but a super narrow chain might tend to jump a much wider cog.

Not all Jockey pulleys are made equally. Some of the cheaper ones have no bushings, and are just plastic riding on metal. Most mid range pulleys have steel bushings. And, Ultegra and better ones have gone to ceramic bushings. Many aluminum replacement ones use sealed roller bearings.

So, a jockey wheel without bushings might wear quickly.

I like to service my jockey wheels whenever I replace the chain. I used to grease them, but the grease caused too much drag and accelerated wear. I've now gone to a heavy oil.

You didn't say what brand, speed, etc.

There is some flexibility with speeds and derailleurs, but a super narrow chain might tend to jump a much wider cog.

Not all Jockey pulleys are made equally. Some of the cheaper ones have no bushings, and are just plastic riding on metal. Most mid range pulleys have steel bushings. And, Ultegra and better ones have gone to ceramic bushings. Many aluminum replacement ones use sealed roller bearings.

So, a jockey wheel without bushings might wear quickly.

I like to service my jockey wheels whenever I replace the chain. I used to grease them, but the grease caused too much drag and accelerated wear. I've now gone to a heavy oil.

#5

Expired Member

Join Date: Jun 2007

Location: TN

Posts: 11,509

Mentioned: 37 Post(s)

Tagged: 0 Thread(s)

Quoted: 3657 Post(s)

Liked 5,397 Times

in

2,739 Posts

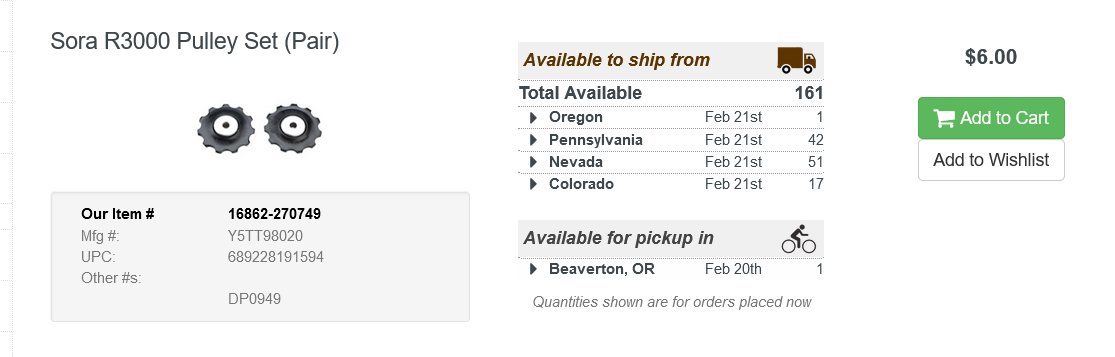

That was all I could find. Probably would work fine on Claris or any of the A groups. Worth a try for $6.

#6

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

Has anybody told you that a picture is worth 5000 words?

You didn't say what brand, speed, etc.

There is some flexibility with speeds and derailleurs, but a super narrow chain might tend to jump a much wider cog.

Not all Jockey pulleys are made equally. Some of the cheaper ones have no bushings, and are just plastic riding on metal. Most mid range pulleys have steel bushings. And, Ultegra and better ones have gone to ceramic bushings. Many aluminum replacement ones use sealed roller bearings.

So, a jockey wheel without bushings might wear quickly.

I like to service my jockey wheels whenever I replace the chain. I used to grease them, but the grease caused too much drag and accelerated wear. I've now gone to a heavy oil.

You didn't say what brand, speed, etc.

There is some flexibility with speeds and derailleurs, but a super narrow chain might tend to jump a much wider cog.

Not all Jockey pulleys are made equally. Some of the cheaper ones have no bushings, and are just plastic riding on metal. Most mid range pulleys have steel bushings. And, Ultegra and better ones have gone to ceramic bushings. Many aluminum replacement ones use sealed roller bearings.

So, a jockey wheel without bushings might wear quickly.

I like to service my jockey wheels whenever I replace the chain. I used to grease them, but the grease caused too much drag and accelerated wear. I've now gone to a heavy oil.

Whatís a normal wear for jockeys?

#7

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

Some might wonder why so much interest in worn pulleys when it can by just swapped for 5 bucks but if itís a symptom of something else going on because itís abnormal wear itís a valid question which the above has not provided much answer.

#8

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

I took some pictures when at there but they came out pretty bad the black absorbing all the light with both flash on and off. Iíll try later but basically itís not visibly spike like as per normal wear it actually looks rather alright from a profile but narrowed dramatically from the inside, the jockeys all moving very freely, itís the bushings kind, nothing special but I donít remember this kind of stuff happening on 2005 stuff even.

Whatís a normal wear for jockeys?

Whatís a normal wear for jockeys?

#9

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18354 Post(s)

Liked 4,502 Times

in

3,346 Posts

Good ones really should last a very long time. Perhaps 10K, 20K, or more miles.

I did blow up a couple. One, I think was the plastic bushing type and just hogged out the center hole (as well as grinding off all the teeth). It went pretty nasty, on the back of my homemade cargo bike.

Another got spiky teeth from too much rolling resistance (greasing rather than oiling).

But others have gone many miles for years or decades with no discernible wear.

I think I did push my chain off of one. I fixed it as soon as it was discovered. Although, that may have been the upper pulley dropping the chain.

I fixed it as soon as it was discovered. Although, that may have been the upper pulley dropping the chain.

The Jockeys are both very simple and moderately complex. I'll try to make a diagram shortly.

If installed right, it should turn almost frictionless, have one or 2mm of lateral float, and last a very long time.

I did blow up a couple. One, I think was the plastic bushing type and just hogged out the center hole (as well as grinding off all the teeth). It went pretty nasty, on the back of my homemade cargo bike.

Another got spiky teeth from too much rolling resistance (greasing rather than oiling).

But others have gone many miles for years or decades with no discernible wear.

I think I did push my chain off of one.

I fixed it as soon as it was discovered. Although, that may have been the upper pulley dropping the chain.

I fixed it as soon as it was discovered. Although, that may have been the upper pulley dropping the chain.The Jockeys are both very simple and moderately complex. I'll try to make a diagram shortly.

Plastic (or aluminum wheel).

Steel or ceramic outer bushing permanently attached to this wheel. This bushing should be the width of the jockey wheel.

Steel or ceramic inner bushing. This is typically 1 or 2mm wider than the outer bushing. The extra width of the inner bushing helps prevent lateral binding, and gives a little lateral float to the pulleys.

Two dust covers. Better pulleys (Ultegra) may also have some kind of O-Ring under the dust covers to prevent contamination. The inner hole is sized for the bolt, so the dust covers lock tight against the inner bushing.

Bolt, cage, etc. All holding it in place. Because everything is locked against the inner bushing, the bolt can be tightened.

Steel or ceramic outer bushing permanently attached to this wheel. This bushing should be the width of the jockey wheel.

Steel or ceramic inner bushing. This is typically 1 or 2mm wider than the outer bushing. The extra width of the inner bushing helps prevent lateral binding, and gives a little lateral float to the pulleys.

Two dust covers. Better pulleys (Ultegra) may also have some kind of O-Ring under the dust covers to prevent contamination. The inner hole is sized for the bolt, so the dust covers lock tight against the inner bushing.

Bolt, cage, etc. All holding it in place. Because everything is locked against the inner bushing, the bolt can be tightened.

If installed right, it should turn almost frictionless, have one or 2mm of lateral float, and last a very long time.

#10

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,954

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6179 Post(s)

Liked 4,796 Times

in

3,308 Posts

Were there any shifting issues? Or are you just looking for something to make more perfect than it needs to be?

#11

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

Good ones really should last a very long time. Perhaps 10K, 20K, or more miles.

I did blow up a couple. One, I think was the plastic bushing type and just hogged out the center hole (as well as grinding off all the teeth). It went pretty nasty, on the back of my homemade cargo bike.

Another got spiky teeth from too much rolling resistance (greasing rather than oiling).

But others have gone many miles for years or decades with no discernible wear.

I think I did push my chain off of one. I fixed it as soon as it was discovered. Although, that may have been the upper pulley dropping the chain.

I fixed it as soon as it was discovered. Although, that may have been the upper pulley dropping the chain.

The Jockeys are both very simple and moderately complex. I'll try to make a diagram shortly.

If installed right, it should turn almost frictionless, have one or 2mm of lateral float, and last a very long time.

I did blow up a couple. One, I think was the plastic bushing type and just hogged out the center hole (as well as grinding off all the teeth). It went pretty nasty, on the back of my homemade cargo bike.

Another got spiky teeth from too much rolling resistance (greasing rather than oiling).

But others have gone many miles for years or decades with no discernible wear.

I think I did push my chain off of one.

I fixed it as soon as it was discovered. Although, that may have been the upper pulley dropping the chain.

I fixed it as soon as it was discovered. Although, that may have been the upper pulley dropping the chain.The Jockeys are both very simple and moderately complex. I'll try to make a diagram shortly.

Plastic (or aluminum wheel).

Steel or ceramic outer bushing permanently attached to this wheel. This bushing should be the width of the jockey wheel.

Steel or ceramic inner bushing. This is typically 1 or 2mm wider than the outer bushing. The extra width of the inner bushing helps prevent lateral binding, and gives a little lateral float to the pulleys.

Two dust covers. Better pulleys (Ultegra) may also have some kind of O-Ring under the dust covers to prevent contamination. The inner hole is sized for the bolt, so the dust covers lock tight against the inner bushing.

Bolt, cage, etc. All holding it in place. Because everything is locked against the inner bushing, the bolt can be tightened.

Steel or ceramic outer bushing permanently attached to this wheel. This bushing should be the width of the jockey wheel.

Steel or ceramic inner bushing. This is typically 1 or 2mm wider than the outer bushing. The extra width of the inner bushing helps prevent lateral binding, and gives a little lateral float to the pulleys.

Two dust covers. Better pulleys (Ultegra) may also have some kind of O-Ring under the dust covers to prevent contamination. The inner hole is sized for the bolt, so the dust covers lock tight against the inner bushing.

Bolt, cage, etc. All holding it in place. Because everything is locked against the inner bushing, the bolt can be tightened.

If installed right, it should turn almost frictionless, have one or 2mm of lateral float, and last a very long time.

Another thing I realised in some of the configurations I was using the long cage derailleur which officially has minimum max sprocket size at 28T whereas I used it with road cassettes ending at 25 as well for almost entire 2021. I do not think it should matter as shifting worked all well. Anyhow I will get a new RD R3000 this time SS, the prices are low and see what happens with those jockey wheels. I will keep the GS one for when I really need it. See what happens within another year. Maybe it was the lube, maybe I let the waxed chains go dry, maybe too much muddy rides, I just found it intriguing the T-pulley got worn but not the G-pulley, at least it's not comparable wear at all.

And yes this was R3000, but on that particular frame I had a 4500 one since 2008 for ages and remember changing the jockey wheels exactly once even that was not urgent in any way. I don't know if pulleys are different between those lineups but they looked they same at least 4500, 4600 and 3500- all the same back then.

On a separate note, do you happen to know why some T-pulleys appear with directional mark on them? I understand I should put them on only in one direction but the teeth actually look symmetrical still.

#12

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

There were no shifting issues, just with the chain effectively rubbing against the cage already I did not quite feel the need to wait for the perfect scenario of having it bite into the cage plate, break off the hanger and have the whole RD tossed into the wheel spokes. Also, it was noisy, as in ... metal on metal noisy so unless deaf one would notice something's amiss before the aforementioned happens.

#13

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,954

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6179 Post(s)

Liked 4,796 Times

in

3,308 Posts

There were no shifting issues, just with the chain effectively rubbing against the cage already I did not quite feel the need to wait for the perfect scenario of having it bite into the cage plate, break off the hanger and have the whole RD tossed into the wheel spokes. Also, it was noisy, as in ... metal on metal noisy so unless deaf one would notice something's amiss before the aforementioned happens.

Likes For Iride01:

#14

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

I mention this in para 3, but even from the first sentence it's clear the chain doesn't sit on the T-pulley and there's no clearance on any derailleur I have seen for the chain to go elsewhere than into the cage.

I do not mind people telling me here that I am wrong, but telling me not to be worrying about something im asking about however without giving any reasoning is just rude.

I do appreciate all well meant answers I get.

Also, Iride I do appreciate all the engagement from you in the other thread, I know it was well meant, but i don't know what I did that now I am "just looking" and as "usual" worth someone's time just to tell me essentially not to post.

I do not mind people telling me here that I am wrong, but telling me not to be worrying about something im asking about however without giving any reasoning is just rude.

I do appreciate all well meant answers I get.

Also, Iride I do appreciate all the engagement from you in the other thread, I know it was well meant, but i don't know what I did that now I am "just looking" and as "usual" worth someone's time just to tell me essentially not to post.

Last edited by am8117; 02-20-22 at 05:31 PM.

#15

Full Member

Thread Starter

Join Date: Jan 2020

Posts: 265

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 125 Post(s)

Liked 29 Times

in

24 Posts

So this was the best I could get to actually make it somewhat visible, the last one is G-pulley for reference, as in they were being worn together, but only the T-pulley got this narrow shape and mostly from the inner side only.

Not sure if that would help anything though.

Not sure if that would help anything though.

#16

Senior Member

Not all Jockey pulleys are made equally. Some of the cheaper ones have no bushings, and are just plastic riding on metal. Most mid range pulleys have steel bushings. And, Ultegra and better ones have gone to ceramic bushings. Many aluminum replacement ones use sealed roller bearings.

So, a jockey wheel without bushings might wear quickly.

I like to service my jockey wheels whenever I replace the chain. I used to grease them, but the grease caused too much drag and accelerated wear. I've now gone to a heavy oil.

So, a jockey wheel without bushings might wear quickly.

I like to service my jockey wheels whenever I replace the chain. I used to grease them, but the grease caused too much drag and accelerated wear. I've now gone to a heavy oil.