Gates Carbon Drive timing belt eating bottom brackets?

#1

Full Member

Thread Starter

Gates Carbon Drive timing belt eating bottom brackets?

Amongst all the other various issues I wrestled with our Co-Mo Carrera, one item that has plagued us is a continual consumption of bottom brackets. The stoker bottom bracket develops this incredibly annoying click at a given orientation of the crank set. It will only do this when all 4 of our feet are on the pedals. With any combination of 3 or less feet on the pedals, no click, 4 feet, click. I replace either the entire bottom bracket or just the bearings and the click disappears.... for a few hundred miles, then - click click click.

Crank set is FSA Gossamer tandem cranks with MegaEXO threaded bottom brackets.(Please, no bashing of the crankset, it is what it is and will likely stay on the bike).

I got to thinking about it and thought that maybe the carbon belt could be implicated as I have observed that there is point in the crank rotation where the the belt is very taught and another point where it is noticeably looser. The belts for all intents and purposes do not stretch so any difference in tension would be taken by the bearings and frame flex. A traditional timing chain does not have this characteristic.

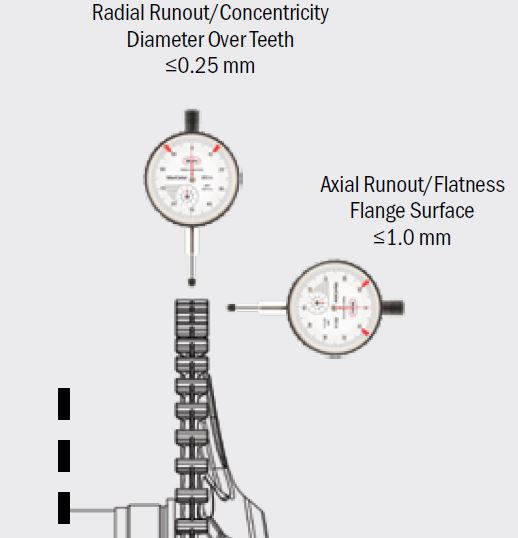

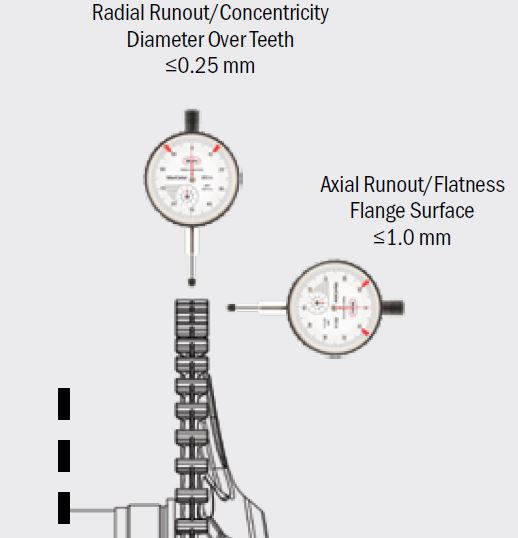

I came across a couple of dial indicators my Dad gave me years ago and thought that maybe I could do some analysis. I found a very detailed tech manual from Gates online and they specify total radial run out (RO) budget of no greater than 0.25mm and axial RO of no greater than 1mm . For those unfamiliar with RO: Radial RO is the distance that circle is out of round, and axial RO is the distance a rotating flat surface is out of planarity:

I removed the belt and took measurements:

Radial

Axial

Results were interesting:

Radial

Front Rear

0.482 0.279

Total 0.762 (Spec is <=0.25)

Axial

Front Rear

0.432 1.778

Total 2.21 (spec is <= 1.00)

(and yes, I realize I am using too many significant digits, and the dial indicators are not aligned perfectly, so the real numbers are different, but the conclusion does not change).

Just considering the radial RO, the length of the path the belt travels varies by up to 1.2mm, or the center to center distance between the bottom brackets would need to change by about 0.6mm per crank revolution just to keep the belt tension constant. This is putting a changing radial force on the bearings

So then I purchased a Krikit tension gauge and measured the belt tension at 12, 3, 6, and 9 o'clock positions. Gates recommends an average tension over 3 positions for a tandem of 45-48 lbs.

Measured: 38 45 45 54 lbs.

By those numbers, the averages vary across about 6 lbs.

I then located the high and low points on both rings and oriented them such that the high section of one ring corresponded with the low section of the other ring. I ended up rotating 1 ring by 2 bolt positions.

Re-installing the belt, I measure: 40 45 45 42 giving a average variation of about 2 lbs.

If you made it this far, congratulations!

So did I fix it? I don't know yet, but my guess is that I have, or at least improved the "time to click click click" characteristic. I believe my findings indicate that the concentricity issue is primarily in the rings and not the cranks, otherwise I would expect the tension differences to remain the same regardless of ring orientation.

I have not considered the axial RO (yet). I believe that the excessive RO on the stoker side is due to the press fit spline of the crank arm onto the crank axle. I don't know if that can be controlled. I may come back and shim the ring with thin washers to bring the axial RO down.

I also realize that having to go to this level of analysis is not what most folks would do, nor should they have to. The manufacturing tolerances of the cranks and most notably, I believe, the rings should be improved so this is not a problem. If your belt has a large range of tension through a rotation, the same results can be achieved by rotating one of the rings one bolt position at a time until the best orientation is found.

I'd be interested in others thoughts and similar experiences.

Crank set is FSA Gossamer tandem cranks with MegaEXO threaded bottom brackets.(Please, no bashing of the crankset, it is what it is and will likely stay on the bike).

I got to thinking about it and thought that maybe the carbon belt could be implicated as I have observed that there is point in the crank rotation where the the belt is very taught and another point where it is noticeably looser. The belts for all intents and purposes do not stretch so any difference in tension would be taken by the bearings and frame flex. A traditional timing chain does not have this characteristic.

I came across a couple of dial indicators my Dad gave me years ago and thought that maybe I could do some analysis. I found a very detailed tech manual from Gates online and they specify total radial run out (RO) budget of no greater than 0.25mm and axial RO of no greater than 1mm . For those unfamiliar with RO: Radial RO is the distance that circle is out of round, and axial RO is the distance a rotating flat surface is out of planarity:

I removed the belt and took measurements:

Radial

Axial

Results were interesting:

Radial

Front Rear

0.482 0.279

Total 0.762 (Spec is <=0.25)

Axial

Front Rear

0.432 1.778

Total 2.21 (spec is <= 1.00)

(and yes, I realize I am using too many significant digits, and the dial indicators are not aligned perfectly, so the real numbers are different, but the conclusion does not change).

Just considering the radial RO, the length of the path the belt travels varies by up to 1.2mm, or the center to center distance between the bottom brackets would need to change by about 0.6mm per crank revolution just to keep the belt tension constant. This is putting a changing radial force on the bearings

So then I purchased a Krikit tension gauge and measured the belt tension at 12, 3, 6, and 9 o'clock positions. Gates recommends an average tension over 3 positions for a tandem of 45-48 lbs.

Measured: 38 45 45 54 lbs.

By those numbers, the averages vary across about 6 lbs.

I then located the high and low points on both rings and oriented them such that the high section of one ring corresponded with the low section of the other ring. I ended up rotating 1 ring by 2 bolt positions.

Re-installing the belt, I measure: 40 45 45 42 giving a average variation of about 2 lbs.

If you made it this far, congratulations!

So did I fix it? I don't know yet, but my guess is that I have, or at least improved the "time to click click click" characteristic. I believe my findings indicate that the concentricity issue is primarily in the rings and not the cranks, otherwise I would expect the tension differences to remain the same regardless of ring orientation.

I have not considered the axial RO (yet). I believe that the excessive RO on the stoker side is due to the press fit spline of the crank arm onto the crank axle. I don't know if that can be controlled. I may come back and shim the ring with thin washers to bring the axial RO down.

I also realize that having to go to this level of analysis is not what most folks would do, nor should they have to. The manufacturing tolerances of the cranks and most notably, I believe, the rings should be improved so this is not a problem. If your belt has a large range of tension through a rotation, the same results can be achieved by rotating one of the rings one bolt position at a time until the best orientation is found.

I'd be interested in others thoughts and similar experiences.

Last edited by Alcanbrad; 07-15-21 at 10:45 AM.

Likes For Alcanbrad:

#2

Bike Doctor

Join Date: May 2015

Location: Southern Ontario

Posts: 141

Bikes: Norco Cape Cod tandem, KHS Tandemania Cross, 1952 Claud Butler ladyback tandem, 1971 & '73 Raleigh Suberbes, 1985 Gazelle Sport Solide, 1985 Rossi professional

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 58 Post(s)

Liked 52 Times

in

24 Posts

I like the thoroughness that you've displayed chipping away at this problem. Sounds like it will be better, if not solved. Sometimes its a stack up of little things. If it was easy, anybody could do it!

Last edited by bazil4696; 07-15-21 at 06:40 AM.

#3

just another gosling

Join Date: Feb 2007

Location: Everett, WA

Posts: 19,527

Bikes: CoMo Speedster 2003, Trek 5200, CAAD 9, Fred 2004

Mentioned: 115 Post(s)

Tagged: 0 Thread(s)

Quoted: 3885 Post(s)

Liked 1,938 Times

in

1,383 Posts

Yes, quite. I had to fiddle with my timing belt rings quite a bit to eliminate the RO. It's a thing. The other very noticeable thing is that the belt imposes off-center stresses on the bearings. Spin your single bike cranks backwards, then your tandem cranks. I measured the increased pedal load at about 3 oz. with the belt. However there's obviously a lot more loading while riding, so I doubt that we lose that much power from the off-center load compared with a chain.

All that said, the first thing you need to do is to replace your rings and belt with the CDX Centertrack version. Gates replaced our old set on warranty after the belt wouldn't stay on after about 3000 miles and the rings were obviously badly worn though the belt seemed fine. The Centertrack version doesn't seem to wear the rings and obviously doesn't have an issue with tracking. The original belt wouldn't stay centered and would track inward until it rubbed on the chainstay, no matter what tension was used.

We have our BB bearings replaced every year, which helps. I have the Centertrack belt set quite loosely, about 1.75" of play. We never get a jump from the belt at that reduced tension. I think the recced tension is idiotic, but then I can't put out more than 700 watts in a sprint. The belt and rings don't seem to wear even at that tension. That's the advantage of Centertrack - the original belts wouldn't stay on unless the tension was set per Getes.

All that said, the first thing you need to do is to replace your rings and belt with the CDX Centertrack version. Gates replaced our old set on warranty after the belt wouldn't stay on after about 3000 miles and the rings were obviously badly worn though the belt seemed fine. The Centertrack version doesn't seem to wear the rings and obviously doesn't have an issue with tracking. The original belt wouldn't stay centered and would track inward until it rubbed on the chainstay, no matter what tension was used.

We have our BB bearings replaced every year, which helps. I have the Centertrack belt set quite loosely, about 1.75" of play. We never get a jump from the belt at that reduced tension. I think the recced tension is idiotic, but then I can't put out more than 700 watts in a sprint. The belt and rings don't seem to wear even at that tension. That's the advantage of Centertrack - the original belts wouldn't stay on unless the tension was set per Getes.

__________________

Results matter

Results matter

#4

Senior Member

Join Date: Nov 2006

Location: Lafayette, Colorado

Posts: 1,047

Bikes: 1998 Co-Motion Co-Pilot, 2015 Calfee Tetra

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 177 Post(s)

Likes: 0

Liked 6 Times

in

5 Posts

His pulleys do look like Centertrack to me (I could be mistaken).

On our old bike we had a similar effect with the timing chain. I recall that rotating the rings with respect to each other helped the problem.

Reducing the tension variability from 6# to 2# is pretty significant. I'm guessing you fixed it.

Interesting that this is the first report of this type of problem. My guess is that this condition is pretty widespread (just nobody else looked this closely).

Keep us posted on the result.

On our old bike we had a similar effect with the timing chain. I recall that rotating the rings with respect to each other helped the problem.

Reducing the tension variability from 6# to 2# is pretty significant. I'm guessing you fixed it.

Interesting that this is the first report of this type of problem. My guess is that this condition is pretty widespread (just nobody else looked this closely).

Keep us posted on the result.

#5

Full Member

I'm interested in this since we have a Speedster which I put a Gates CDX system on about 3000 miles ago. The conversion was quite easy and after doing an 'eyeball' alignment (never thought of using a dial indicator), it has been smooth sailing ever since. I adjusted tension by 'feel' and as such, I'm sure it's a bit lower than recommended. I also used the method discussed by Sheldon Brown (https://www.sheldonbrown.com/synchain.html) to minimise differences in tension from rotational position. Never thought about moving cogs around.

From my previous experience, the stoker's bottom bracket does see a lot more wear since it is being twisted in the frame; pulled forward on the left side and pulled back on the right. It does make sense that it should wear out quicker than the captain's BB. However, we've ridden easily 6000 miles (about 3000+ miles with the chain and sprocket timing chain that came with the bike) since we bought this Speedster and so far the stoker BB remains rock solid. That's about the extent of my knowledge about tandem bottom brackets. So I have a couple of questions:

The OP talks about Axial Alignment. Is this the alignment of the two cogs in the same plane, or the wobble of each cog - each cog not square with its axle?

I'm also wondering about belt tension. It seems to me that even if you put the belt on a little too tight, that tension would never come near the tension of the belt when the captain stands on the pedal. ( I don't really understand how the what's going when the stoker is also standing on the pedals - how does that all equate? Does that force add to, or is it subtracted from the belt tension? Always been confused about how those forces are shared.)

We are about 320lbs team. Not lightweight, but not super heavy either, which I'm sure affects loading on the whole system. So far, despite our weight and mileage, I have not yet had to replace either of the BBs. So is belt tension or alignment causing the OP to replace his rear BB so often? Or perhaps something else: frame flex, choice of bearings, etc?

From my previous experience, the stoker's bottom bracket does see a lot more wear since it is being twisted in the frame; pulled forward on the left side and pulled back on the right. It does make sense that it should wear out quicker than the captain's BB. However, we've ridden easily 6000 miles (about 3000+ miles with the chain and sprocket timing chain that came with the bike) since we bought this Speedster and so far the stoker BB remains rock solid. That's about the extent of my knowledge about tandem bottom brackets. So I have a couple of questions:

The OP talks about Axial Alignment. Is this the alignment of the two cogs in the same plane, or the wobble of each cog - each cog not square with its axle?

I'm also wondering about belt tension. It seems to me that even if you put the belt on a little too tight, that tension would never come near the tension of the belt when the captain stands on the pedal. ( I don't really understand how the what's going when the stoker is also standing on the pedals - how does that all equate? Does that force add to, or is it subtracted from the belt tension? Always been confused about how those forces are shared.)

We are about 320lbs team. Not lightweight, but not super heavy either, which I'm sure affects loading on the whole system. So far, despite our weight and mileage, I have not yet had to replace either of the BBs. So is belt tension or alignment causing the OP to replace his rear BB so often? Or perhaps something else: frame flex, choice of bearings, etc?

#6

Full Member

I have used the method of strumming the belt and measuring the tone frequency at various rotation angles to find where the belt may be tightest, then simply loosened the ring bolts and retightened to get the tension fairly even over the full 360 degrees. I shoot for roughly 40 hertz, plus or minus. All very crude compared to your analysis. But I have yet to replace a BB since switching to the belt, although I did have to replace one when we had a timing chain.

I agree with others that the Gates recommended tension is way higher than necessary.

Are you sure the two rings are perfectly aligned, and neither is bent causing some of the axial runout you are measuring?

I agree with others that the Gates recommended tension is way higher than necessary.

Are you sure the two rings are perfectly aligned, and neither is bent causing some of the axial runout you are measuring?

#7

Full Member

Thread Starter

Oldacura and Carbonfiberboy, I do have already have the centertrack.

It's the later. The plane of the belt ring is not perpendicular to the crank axle.

So this is a good question. The forces applied by the pressure on the pedals can be very high and causes the same wear/damage the over tensioned belt causes. My take on it here is that while the pedalling forces can be huge, on average those forces only occur for a smll percentage of the time whereas with the over tensioned belt (due to excessive run out) the damaging forces are applied for every rotation of the crank regardless of rider power input into the system so the wear/damage happens much faster.

We are about 320lbs team. Not lightweight, but not super heavy either, which I'm sure affects loading on the whole system. So far, despite our weight and mileage, I have not yet had to replace either of the BBs. So is belt tension or alignment causing the OP to replace his rear BB so often? Or perhaps something else: frame flex, choice of bearings, etc?

My belief is that it is excessive belt tension applied unevenly due to large radial runout. This is similar to the problems many have had with press fit bearing in poorly aligned bottom bracket bearing seats in carbon fiber frames. The excessive and repetitive forces trash the bearing faster than if the bearing rolls with uniform forces.

I'm also wondering about belt tension. It seems to me that even if you put the belt on a little too tight, that tension would never come near the tension of the belt when the captain stands on the pedal. ( I don't really understand how the what's going when the stoker is also standing on the pedals - how does that all equate? Does that force add to, or is it subtracted from the belt tension? Always been confused about how those forces are shared.)

We are about 320lbs team. Not lightweight, but not super heavy either, which I'm sure affects loading on the whole system. So far, despite our weight and mileage, I have not yet had to replace either of the BBs. So is belt tension or alignment causing the OP to replace his rear BB so often? Or perhaps something else: frame flex, choice of bearings, etc?

Likes For Alcanbrad:

#8

Full Member

Thread Starter

I have used the method of strumming the belt and measuring the tone frequency at various rotation angles to find where the belt may be tightest, then simply loosened the ring bolts and retightened to get the tension fairly even over the full 360 degrees. I shoot for roughly 40 hertz, plus or minus. All very crude compared to your analysis. But I have yet to replace a BB since switching to the belt, although I did have to replace one when we had a timing chain.

I agree with others that the Gates recommended tension is way higher than necessary.

Are you sure the two rings are perfectly aligned, and neither is bent causing some of the axial runout you are measuring?

I agree with others that the Gates recommended tension is way higher than necessary.

Are you sure the two rings are perfectly aligned, and neither is bent causing some of the axial runout you are measuring?

I am confident that the rings are flat and true. I laid both of them on the cast iron surface of my table saw which is pretty flat. Both rings where true and flat. I used the dial indicator and indicated the axial alignment of the crank spider arm surfaces of the crank that is way out of alignment and the surfaces are out consistent with what I measure on the ring when it was installed. This tells me that the primary condition is that the crank/spider is not perpendicular to the crank axle. I think that this is a deficiency of the timing crank design where the timing side crank is bolted to the splined end of the crank axle. I don't know how to control the perpendicularity of this interface without a machined flat surface on the axel to hold the crank arm against. This does not exist so it is what it is.

Last edited by Alcanbrad; 07-16-21 at 09:08 AM.

#9

Full Member

I have never had luck with the strumming method. I would get 40 hz, then 25, then 80, then 40 again, then nothing,... Maybe I don't know how to strum a belt? (you must also understand that I am as far from being musically inclined as one can be and still fog a mirror).

.

.

#10

Full Member

Based on some of the discussion here it seems like, in general there is some amount of difficulty in getting the tension of the timing belt or chain consistent throughout a full crank rotation. It seems that many of us that use belts (and maybe chains, too) have discovered that it's okay to run them at a little lower tension to avoid the problem of them being over tensioned at certain angles and that there appears to be no ill affect in doing it that way.

I used the Gates app and strumming the belt, but as I approached the correct frequency I noticed the timing cranks got harder to turn and nearly didn't spin at all when I gave them a good push. Lowering the tension a bit, but not enough to have the belt come off the cogs, allowed the cranks to spin a lot longer.

If it is the varying belt tension that's eating up bottom brackets, maybe just run them a little looser? I don't know. I would bet that the bearing in this Comotion are original from 2006. In any case, we've probably put another 6-8,000 miles on it (at least 3000 since we put the belt on) and they seem to still be good. Maybe I should pull out my dial indicator and check if I'm on the ball or not.

I used the Gates app and strumming the belt, but as I approached the correct frequency I noticed the timing cranks got harder to turn and nearly didn't spin at all when I gave them a good push. Lowering the tension a bit, but not enough to have the belt come off the cogs, allowed the cranks to spin a lot longer.

If it is the varying belt tension that's eating up bottom brackets, maybe just run them a little looser? I don't know. I would bet that the bearing in this Comotion are original from 2006. In any case, we've probably put another 6-8,000 miles on it (at least 3000 since we put the belt on) and they seem to still be good. Maybe I should pull out my dial indicator and check if I'm on the ball or not.

#11

Senior Member

Join Date: May 2005

Location: SFBay

Posts: 2,334

Bikes: n, I would like n+1

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 127 Post(s)

Likes: 0

Liked 133 Times

in

108 Posts

Congratulations on a solid analysis. You're ahead of many of the manufacturing engineers I've worked with over the years, who I've had to remind to put an indicator on and measure things. The runout you need to minimize is radial at the back of the stoker's crank relative to the front of the captain's crank at any given (in sync) rotation. It isn't clear to me if you have minimized the absolute runout in each crank, or minimized one relative to the other, although it's likely an improvement in any case. Zero absolute runout on each crank would of course also equal zero relative runout.

There's also some very slight adjustment available by moving the rings around using the clearance to the bolts and crank arm. This is about all you have on single applications due to timing of the rings (and an anti drop pin for the crank arm). I don't know if the gates belts actually ride on the ID, or if a pitch diameter should be used (in which case it's indicator over a drill bit of the right diameter). I'd expect the two to be very close, but then again I'd also expect the Gates parts to meet their own runout spec. Given that it changes with chain ring (pulley?) rotation, I'd agree that it's likely in the pulley, not the crank, unless you have a lot of slop in the bolts and centering features.

For those curious, the use of indicators makes wheel truing easier and faster as well.

Correct on the stoker's BB seeing higher loads.

Axial alignment ≠ axial runout. Runout (what was referenced in this case) will be wobble as the crank rotates. I would expect a separate chain line specification. That one really should be angle, although for a given belt size an offset will be close enough to the same thing.

Pretending that the stoker is in sync with the captain, their inputs don't alter what the belt sees. It will twist the BB region a bit, but doesn't really change the loads on the stoker timing ring otherwise.

There's also some very slight adjustment available by moving the rings around using the clearance to the bolts and crank arm. This is about all you have on single applications due to timing of the rings (and an anti drop pin for the crank arm). I don't know if the gates belts actually ride on the ID, or if a pitch diameter should be used (in which case it's indicator over a drill bit of the right diameter). I'd expect the two to be very close, but then again I'd also expect the Gates parts to meet their own runout spec. Given that it changes with chain ring (pulley?) rotation, I'd agree that it's likely in the pulley, not the crank, unless you have a lot of slop in the bolts and centering features.

For those curious, the use of indicators makes wheel truing easier and faster as well.

I'm interested in this since we have a Speedster which I put a Gates CDX system on about 3000 miles ago. The conversion was quite easy and after doing an 'eyeball' alignment (never thought of using a dial indicator), it has been smooth sailing ever since. I adjusted tension by 'feel' and as such, I'm sure it's a bit lower than recommended. I also used the method discussed by Sheldon Brown (https://www.sheldonbrown.com/synchain.html) to minimise differences in tension from rotational position. Never thought about moving cogs around.

From my previous experience, the stoker's bottom bracket does see a lot more wear since it is being twisted in the frame; pulled forward on the left side and pulled back on the right. It does make sense that it should wear out quicker than the captain's BB. However, we've ridden easily 6000 miles (about 3000+ miles with the chain and sprocket timing chain that came with the bike) since we bought this Speedster and so far the stoker BB remains rock solid. That's about the extent of my knowledge about tandem bottom brackets. So I have a couple of questions:

The OP talks about Axial Alignment. Is this the alignment of the two cogs in the same plane, or the wobble of each cog - each cog not square with its axle?

I'm also wondering about belt tension. It seems to me that even if you put the belt on a little too tight, that tension would never come near the tension of the belt when the captain stands on the pedal. ( I don't really understand how the what's going when the stoker is also standing on the pedals - how does that all equate? Does that force add to, or is it subtracted from the belt tension? Always been confused about how those forces are shared.)

We are about 320lbs team. Not lightweight, but not super heavy either, which I'm sure affects loading on the whole system. So far, despite our weight and mileage, I have not yet had to replace either of the BBs. So is belt tension or alignment causing the OP to replace his rear BB so often? Or perhaps something else: frame flex, choice of bearings, etc?

From my previous experience, the stoker's bottom bracket does see a lot more wear since it is being twisted in the frame; pulled forward on the left side and pulled back on the right. It does make sense that it should wear out quicker than the captain's BB. However, we've ridden easily 6000 miles (about 3000+ miles with the chain and sprocket timing chain that came with the bike) since we bought this Speedster and so far the stoker BB remains rock solid. That's about the extent of my knowledge about tandem bottom brackets. So I have a couple of questions:

The OP talks about Axial Alignment. Is this the alignment of the two cogs in the same plane, or the wobble of each cog - each cog not square with its axle?

I'm also wondering about belt tension. It seems to me that even if you put the belt on a little too tight, that tension would never come near the tension of the belt when the captain stands on the pedal. ( I don't really understand how the what's going when the stoker is also standing on the pedals - how does that all equate? Does that force add to, or is it subtracted from the belt tension? Always been confused about how those forces are shared.)

We are about 320lbs team. Not lightweight, but not super heavy either, which I'm sure affects loading on the whole system. So far, despite our weight and mileage, I have not yet had to replace either of the BBs. So is belt tension or alignment causing the OP to replace his rear BB so often? Or perhaps something else: frame flex, choice of bearings, etc?

Axial alignment ≠ axial runout. Runout (what was referenced in this case) will be wobble as the crank rotates. I would expect a separate chain line specification. That one really should be angle, although for a given belt size an offset will be close enough to the same thing.

Pretending that the stoker is in sync with the captain, their inputs don't alter what the belt sees. It will twist the BB region a bit, but doesn't really change the loads on the stoker timing ring otherwise.

Likes For jccaclimber:

#12

Senior Member

Join Date: Nov 2006

Location: Lafayette, Colorado

Posts: 1,047

Bikes: 1998 Co-Motion Co-Pilot, 2015 Calfee Tetra

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 177 Post(s)

Likes: 0

Liked 6 Times

in

5 Posts

I have used the method of strumming the belt and measuring the tone frequency at various rotation angles to find where the belt may be tightest, then simply loosened the ring bolts and retightened to get the tension fairly even over the full 360 degrees. I shoot for roughly 40 hertz, plus or minus. All very crude compared to your analysis. But I have yet to replace a BB since switching to the belt, although I did have to replace one when we had a timing chain.

I agree with others that the Gates recommended tension is way higher than necessary.

Are you sure the two rings are perfectly aligned, and neither is bent causing some of the axial runout you are measuring?

I agree with others that the Gates recommended tension is way higher than necessary.

Are you sure the two rings are perfectly aligned, and neither is bent causing some of the axial runout you are measuring?

#13

Full Member

Yes, Iím using the Gates app on an iPhone. The app recommends 60-65 Hz which I find unnecessarily high. 40 Hz is low enough that I donít notice appreciable drag when spinning the cranks backwards. Itís something I set once and forget. I find the Gates belt to be completely trouble free.

#14

Senior Member

Join Date: Nov 2006

Location: Lafayette, Colorado

Posts: 1,047

Bikes: 1998 Co-Motion Co-Pilot, 2015 Calfee Tetra

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 177 Post(s)

Likes: 0

Liked 6 Times

in

5 Posts

We probably only have 3000 miles on our bike but I have never done anything with the belt. We also have a pair of Faraday Porteur E-Bikes that have Shimano Alfine rear hubs and a Gates Carbon belt drive. These have been completely maintenance free as well.

#15

Newbie

Consider mounting your Gates sprockets on the inside of the spider thus shortening the lever arm against the bottom brackets which will also reduce the frame bowing tendency. The newer Gossamer cranks, produced in recent years in combination with the CDX model, typically allow the sprockets to mount on the inside while still maintaining enough chainstay clearance. As others have mentioned and alluded to, one can center the sprockets a bit on the spider (same with timing chains) by taking them loose and retightening after finding the greatest tension point, which helps greatly in striving for more uniform tension. That said, you may consider running the tension slightly on the low end. Gates provides a range of tension for single bike applications of their belt systems with further instructions to increase tension should slippage take place. Transposing that single bike instruction to the timing belt might also help. Lastly and as a final check of needed tension, push forcefully down on the left pedal while having someone view the lower part of the belt and or strum it for tension. If it goes slack, there is not enough tension. One can do this on a trainer with the brakes applied or being on the bike and leaning against a wall. The needed belt tension would vary greatly depending on rider weight, power out put, frame flex, length of the crank spindle (referring to non FSA systems since they may be different), and whether the sprockets are mounted on the inside or outside of the spider. Personally, mine ends up being a little loose, over time, and since it has never slipped, I leave it alone. YMMV

#16

Junior Member

BB Chamgeout

Thanks for the detailed analysis on your gates belt drive and the attention to detail.

We also have the Gates center track drive belt and started hearing creaks in the bb area. I popped the captains bb out yesterday and the non drive side bearing is bad. I will go into the stokers tonight to check its condition.

After reading all your posts, I may not go back to the OEMís tension guidelines and stay with a little less tension. Our Co-Motion is about 10 years old, and on the original bbís, and this is our third year on the belt drive. So, it is time to change them and like a previous post may do them yearly.

One last question for Co-Motion owners, are the front and rear bbís the same? Thanks in advance.

We also have the Gates center track drive belt and started hearing creaks in the bb area. I popped the captains bb out yesterday and the non drive side bearing is bad. I will go into the stokers tonight to check its condition.

After reading all your posts, I may not go back to the OEMís tension guidelines and stay with a little less tension. Our Co-Motion is about 10 years old, and on the original bbís, and this is our third year on the belt drive. So, it is time to change them and like a previous post may do them yearly.

One last question for Co-Motion owners, are the front and rear bbís the same? Thanks in advance.

#17

Newbie

The FSA bottom brackets are the same, front and rear, Gossamer or SL-K light, on the newer version of the crank, most readily identified by having black cups which utilizes a yellow gold aluminum spacer between the cups. The older version had bronzy Ti colored cups. Those were actually different as the rear used a heavy duty internal spacer aluminum sleeve to insure the spacing between the bottom bracket cups was as it should be without relying on the frame being exact given paint and facing variances. The front had only a plastic sleeve. And the new version bottom brackets also fit the older tandem integrated FSA crank models.

#18

Full Member

As an old industrial maintenance man.

I have a lot experience with gates belts and bearings. The problem is the belt is tight and is loading the bearing. Do you see it with one of the bottom bracket more than the other?

There could be a small miss Alinement of the the two BBís causing this issue. This can increase over over time as the pressure from the belt will increase the Alinement issue. If properly aligned the bearings and belt will last for years.

I have a lot experience with gates belts and bearings. The problem is the belt is tight and is loading the bearing. Do you see it with one of the bottom bracket more than the other?

There could be a small miss Alinement of the the two BBís causing this issue. This can increase over over time as the pressure from the belt will increase the Alinement issue. If properly aligned the bearings and belt will last for years.

#19

Senior Member

I put a Gates belt on our Santana Arriva last year and now you guys have me all stressed out! All this tech-speak hurts my tiny English-major brain...

#20

pan y agua

Join Date: Aug 2005

Location: Jacksonville

Posts: 31,299

Bikes: Willier Zero 7; Merlin Extralight; Calfee Dragonfly tandem, Calfee Adventure tandem; Cervelo P2; Motebecane Ti Fly 29er; Motebecanne Phantom Cross; Schwinn Paramount Track bike

Mentioned: 17 Post(s)

Tagged: 0 Thread(s)

Quoted: 1443 Post(s)

Liked 712 Times

in

366 Posts

Philly,

IMHO, you don’t need to stress this. I appreciate the analysis here, and I think I even kind of follow it. My takeaway based on reading the thread, and now close to a decade of using gates belts on 3 different bikes is that you can run them way looser than Gate’s spec, which on a practical level reduces the the problem identified by the OP.

IMHO, you don’t need to stress this. I appreciate the analysis here, and I think I even kind of follow it. My takeaway based on reading the thread, and now close to a decade of using gates belts on 3 different bikes is that you can run them way looser than Gate’s spec, which on a practical level reduces the the problem identified by the OP.

__________________

You could fall off a cliff and die.

You could get lost and die.

You could hit a tree and die.

OR YOU COULD STAY HOME AND FALL OFF THE COUCH AND DIE.

You could fall off a cliff and die.

You could get lost and die.

You could hit a tree and die.

OR YOU COULD STAY HOME AND FALL OFF THE COUCH AND DIE.

Likes For merlinextraligh:

#21

Senior Member

Join Date: Feb 2005

Location: SW Florida

Posts: 1,672

Bikes: '06 Bianchi Pista; '57 Maclean; '10 Scott CR1 Pro; 2005 Trek 2000 Tandem; '09 Comotion Macchiato Tandem; 199? Novara Road; '17 Circe Helios e-tandem:1994 Trek 2300

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 147 Post(s)

Liked 92 Times

in

60 Posts

We have the original Gates drive on our 2009 CoMo Macchiato, bought used in 2011 with few miles on it. We have ridden about 30,000 miles and have had to make no adjustments.

Likes For Artmo:

#22

Ferengii

Join Date: Oct 2014

Location: Loveland, CO

Posts: 46

Bikes: Co-Motion tandem; Bilenky tandem; Trek Domane SL6

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Liked 18 Times

in

14 Posts

We’ve also run the belts looser than the Gates spec for fear of damaging the bottom brackets. So far, we have 28,000 miles on our 2016 Co-motion Equator (now the Speedster with Rohloff) with no apparent issues. I also worked on adjusting the chain rings to minimize the tension differences as the pedals were rotated, which may have helped.

#23

Junior Member

Changing Bottom Brackets - Co-Motiom

Learned something new over the weekend while doing maintenance on the tandem. The BBís are opposite bearings on opposite sides.

The stokers BB has been squeaking and will be changing them out. Bought two new SRAM BBís and started changing them out and realized the Captain's BB bearings are opposite to the Stokers. The drive side is opposite, threaded cups have two sizes bearings that are meant for left or right. They wonít swap unless you change the bearings.

On my BB bearings, both drive side bearings are bad. They still rotated, but rough. I will now be looking for the SRAM BB that fits the Captainí BB. If anyone has a BB they use on their Co-Motionís, specifically the Capetianís I would appreciate your input.

Dave

The stokers BB has been squeaking and will be changing them out. Bought two new SRAM BBís and started changing them out and realized the Captain's BB bearings are opposite to the Stokers. The drive side is opposite, threaded cups have two sizes bearings that are meant for left or right. They wonít swap unless you change the bearings.

On my BB bearings, both drive side bearings are bad. They still rotated, but rough. I will now be looking for the SRAM BB that fits the Captainí BB. If anyone has a BB they use on their Co-Motionís, specifically the Capetianís I would appreciate your input.

Dave

#24

Full Member

Thread Starter

After all the comments and trying with the belt tension looser, I believe that in addition to having excessive runout, I have been running the belt way too tight which is likely my problem (I never could get a consistent tone out of the belt strumming method). To set the looser tension I choose the limit to be just a bit tighter than the belt being able to climb out of the center track when slowly turning the crank and pushing the belt sideways just ahead of where the belt met the ring. If the belt climbed out of the center track and started to ride on top of the ring, I backed off and adjusted the eccentric just a bit tighter. Riding it over the weekend it performed well, but I still need to replace the BB (or bearings) as these are ruined. I believe the belt tension measures in the low 30lb range and the difference due to runout is fairly small.

I'd be curious of how others determine "loose" as "loose enough" or "too loose".

I'd be curious of how others determine "loose" as "loose enough" or "too loose".

#25

Full Member

Thread Starter

Learned something new over the weekend while doing maintenance on the tandem. The BBís are opposite bearings on opposite sides.

The stokers BB has been squeaking and will be changing them out. Bought two new SRAM BBís and started changing them out and realized the Captain's BB bearings are opposite to the Stokers. The drive side is opposite, threaded cups have two sizes bearings that are meant for left or right. They wonít swap unless you change the bearings.

On my BB bearings, both drive side bearings are bad. They still rotated, but rough. I will now be looking for the SRAM BB that fits the Captainí BB. If anyone has a BB they use on their Co-Motionís, specifically the Capetianís I would appreciate your input.

Dave

The stokers BB has been squeaking and will be changing them out. Bought two new SRAM BBís and started changing them out and realized the Captain's BB bearings are opposite to the Stokers. The drive side is opposite, threaded cups have two sizes bearings that are meant for left or right. They wonít swap unless you change the bearings.

On my BB bearings, both drive side bearings are bad. They still rotated, but rough. I will now be looking for the SRAM BB that fits the Captainí BB. If anyone has a BB they use on their Co-Motionís, specifically the Capetianís I would appreciate your input.

Dave