Rim cracks

#26

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

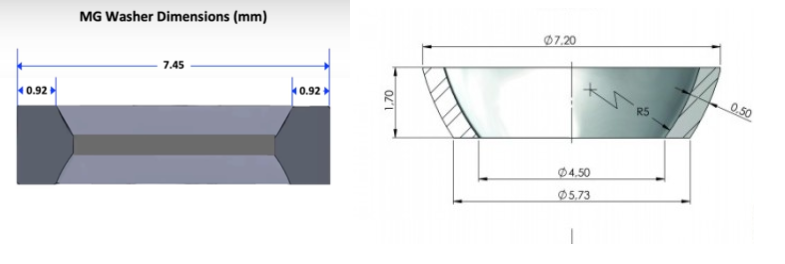

Thanks, that seems like the way to go. I have no experience adding washers. For 0.5 mm thick, but perhaps additional space if the washer is not perfectly flat. Does this have much effect on spoke length calculations?

#27

Senior Member

Join Date: Dec 2019

Posts: 955

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

If the rim should be replaced, I'm not sure what would be much better for this to not happen again. The rim is one of the strongest on the market, but apparently not sufficiently strong for two people and their camping gear, etc. And so my question regarding nipple washers. I should have used washers.

Sockets help and too much spoke tension makes it worse. But a heavily loaded wheel needs quite a lot of tension.

#28

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

The Ryde Andra 35 is a heavy rim with thick walls... in ISO 584 size, it weighs nearly as much as the original steel rims (ISO 590) from my old English 3-speed! And with symmetrical dishing for the Speedhub, there are no extreme spoke tensions. So it should have been extra-kind to the rim, no spokes going slack or exceeding the tension spec under load.

Andy mentioned anodizing, and in poking around on the Ryde website, I learned that their "pre anodized treatment" means that the extrusion is literally anodized before the rim is rolled and machined. I thought the industry had learned not to do that, but perhaps it's why IPassGas had premature (IMO) cracking. I would imagine that he is out of any warranty period by this point, but it would be worth bringing up with the dealer and/or Ryde themselves anyway.

#29

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

You mentioned that the nipples still have a couple of threads left... two 56tpi threads is almost 1mm if my math is right. The ideal spoke would come right to the end of the nipple head. So if you're buying new spokes and planning on 0.5 washers, I'd add 1.5mm to what you had and round to the nearest available spoke.

#30

Blamester

Would a washer make much of a difference?

Its the eylet pulling thru the rim.

The tension on the eylet stays the same.

Maybe a small angle change.

Its the eylet pulling thru the rim.

The tension on the eylet stays the same.

Maybe a small angle change.

#31

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

These rims don't have any eyelets. The hope behind a steel washer is that it would spread out the pulling force of the spoke nipple a bit. (On aluminum rims without eyelets, chamfering the spoke holes helps do this a little.)

Likes For ThermionicScott:

#32

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

Thanks for your digging. Does rolling an anodized rim tend to cause the anodization to separate? I presume this would be of only a cosmetic concern. It still seems that the crack is a sign of an underlying problem, perhaps exaggerated by this anodization process.

#33

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

Since your rims haven't deformed around the spoke drillings, it's possible that the cracks you see are just in the anodized layer and haven't spread yet. I'd be curious how much more riding it would take for them to truly become a problem. Some folks will take a Sharpie and mark the ends of the cracks to check whether they are growing or not.

__________________

RUSA #7498

Originally Posted by noglider

People in this forum are not typical.

Last edited by ThermionicScott; 10-22-21 at 01:06 AM.

#34

Me duelen las nalgas

Join Date: Aug 2015

Location: Texas

Posts: 13,513

Bikes: Centurion Ironman, Trek 5900, Univega Via Carisma, Globe Carmel

Mentioned: 199 Post(s)

Tagged: 0 Thread(s)

Quoted: 4559 Post(s)

Liked 2,802 Times

in

1,800 Posts

Both rear wheels of my 1980s hard anodized lightweight low profile rims cracked a year or so ago, after a few decades of use. The spokes pulled through. I'm not sure I even noticed while riding, other than some minor creaking or ticking sounds. I noticed when I did my usual spot check while airing up the tires. First was an Araya CTL-370, I think the lightest clincher rim of that era. Then the Wolber Super Champion Alpine, a little heavier. Great looking wheels for classic bikes. The front wheels are still okay.

Might have been operator error. Both wheels needed frequent truing. Usually I just tightened spokes with the wheels on the bike, eyeballing them until they were true again. I might have overtightened them, although I pinged and squeezed the spokes all around to roughly check the tension. But other users of the same rims said theirs were prone to cracking the same way after 10-20 years. If I get another set I'll baby them, detensioning and retensioning occasionally, on a proper truing stand with tools to check everything. Or not.

But I've switched to all higher profile non-anodized rims, Mavic CXP 30, and Reflex SUP UBI. They're stiffer, don't need truing as often, and seem sturdier. If they're any slower due to the weight, my engine isn't strong enough to notice.

The most bulletproof rims I've ridden are inexpensive Alex S500, semi-high profile. Take-offs from a friend's bike. I use 'em on one of my hybrids. Other than redishing the rear wheel to suit my bike, I don't think I've ever needed to true those rims. And that bike is ridden heavily on rough roads and gravel. Not light or fancy but durable.

Might have been operator error. Both wheels needed frequent truing. Usually I just tightened spokes with the wheels on the bike, eyeballing them until they were true again. I might have overtightened them, although I pinged and squeezed the spokes all around to roughly check the tension. But other users of the same rims said theirs were prone to cracking the same way after 10-20 years. If I get another set I'll baby them, detensioning and retensioning occasionally, on a proper truing stand with tools to check everything. Or not.

But I've switched to all higher profile non-anodized rims, Mavic CXP 30, and Reflex SUP UBI. They're stiffer, don't need truing as often, and seem sturdier. If they're any slower due to the weight, my engine isn't strong enough to notice.

The most bulletproof rims I've ridden are inexpensive Alex S500, semi-high profile. Take-offs from a friend's bike. I use 'em on one of my hybrids. Other than redishing the rear wheel to suit my bike, I don't think I've ever needed to true those rims. And that bike is ridden heavily on rough roads and gravel. Not light or fancy but durable.

#35

Senior Member

Join Date: Dec 2019

Posts: 955

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

True that aluminum fatigues and tandems are harder on wheels... but I disagree that 7000 miles was "pretty good". This wheel should have been bulletproof!

The Ryde Andra 35 is a heavy rim with thick walls... in ISO 584 size, it weighs nearly as much as the original steel rims (ISO 590) from my old English 3-speed! And with symmetrical dishing for the Speedhub, there are no extreme spoke tensions. So it should have been extra-kind to the rim, no spokes going slack or exceeding the tension spec under load.

Andy mentioned anodizing, and in poking around on the Ryde website, I learned that their "pre anodized treatment" means that the extrusion is literally anodized before the rim is rolled and machined. I thought the industry had learned not to do that, but perhaps it's why IPassGas had premature (IMO) cracking. I would imagine that he is out of any warranty period by this point, but it would be worth bringing up with the dealer and/or Ryde themselves anyway.

The Ryde Andra 35 is a heavy rim with thick walls... in ISO 584 size, it weighs nearly as much as the original steel rims (ISO 590) from my old English 3-speed! And with symmetrical dishing for the Speedhub, there are no extreme spoke tensions. So it should have been extra-kind to the rim, no spokes going slack or exceeding the tension spec under load.

Andy mentioned anodizing, and in poking around on the Ryde website, I learned that their "pre anodized treatment" means that the extrusion is literally anodized before the rim is rolled and machined. I thought the industry had learned not to do that, but perhaps it's why IPassGas had premature (IMO) cracking. I would imagine that he is out of any warranty period by this point, but it would be worth bringing up with the dealer and/or Ryde themselves anyway.

#36

Junior Member

Ryde makes Andra rims specially drilled for Rohloff-the angle of the spoke hole drilling is optimized for the large hub flange so the spoke path from the rim is less severe. The one photo seems to show quite an angle at the rim. Are these wheels laced 2X as the Rohloff manual requires? Many problems with Rohloff based wheels seem to result from not following the detailed instructions while building.

Likes For Ross200:

#37

Senior Member

Join Date: Jan 2009

Location: San Diego, CA

Posts: 3,670

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 836 Post(s)

Liked 1,061 Times

in

745 Posts

Shoot Ryde an email explaining your situation with photos and see what they say. They may have some advice on building the wheels differently or a remote chance they may replace the rim or may just have some valuable info. Nothing to lose by contacting them.

#38

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

Ryde makes Andra rims specially drilled for Rohloff-the angle of the spoke hole drilling is optimized for the large hub flange so the spoke path from the rim is less severe. The one photo seems to show quite an angle at the rim. Are these wheels laced 2X as the Rohloff manual requires? Many problems with Rohloff based wheels seem to result from not following the detailed instructions while building.

The cracks are very small, but a concern. We might bike towards Alaska next year if Canada leaves the door open

I would like to determine what action to take on a new wheel to stop this problem. I will pressure Ryde for answers, but that is like sending an email into a black hole. I don't consider myself an expert, so it is good to have comments with different perspectives.

I would like to determine what action to take on a new wheel to stop this problem. I will pressure Ryde for answers, but that is like sending an email into a black hole. I don't consider myself an expert, so it is good to have comments with different perspectives.

#39

Senior Member

Join Date: Nov 2010

Location: Minnesota

Posts: 857

Bikes: Cannondale '92 T600 '95 H600 '01 RT1000

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 92 Post(s)

Liked 109 Times

in

82 Posts

Is there any wisdom in removing the anodizing around the cracks and seeing if the cracks also exist in the aluminum? If the rim is fine, I'd say you're good to go, plus by removing the crack in the anodizing, the crack won't propagate into the aluminum over time and miles.

#40

Junior Member

Did you contact Ryde USA or Ryde NL? In my experience, Ryde USA isn't up to speed on all of Ryde offerings.

From the Ryde.nl website- "ANDRA SERIES

The Andra rims can be ordered in many different wheel sizes and with the drilling angle for the spoke holes optimized for the hub and application. All Andra rims are built to withstand and carry more load than regular rims and can ideally be used for not only regular e-bikes, but also transport bikes with or without motor support." That looks to me like different drilling angles are on someone's radar.

Are all of the cracks on only one side of the nipple and in the same relation to the angle of the spoke? From your pictures, I would believe even the Polyax nipples are not making proper contact with the spoke bed causing localized stress on only one side of the spoke hole. The nipples might be pushing down on one side of the hole and prying up on the other at that angle. 7000 miles of loaded tandem touring is very good service life if this is indeed the case.

If you do disassemble the wheel, you might put some marking ink on a nipple and actually see what kind of contact is being made with the rim.

Sapim makes three different profile nipple washers to match different spoke bed shapes which might help distribute the stresses around the hole. Your pictures suggest the nipples might be too short as is, but you will definitely need longer with the addition of washers. But if the nipple is unable to fit properly because of the angle and diameter of the spoke hole, they might exacerbate the situation.

From the Ryde.nl website- "ANDRA SERIES

The Andra rims can be ordered in many different wheel sizes and with the drilling angle for the spoke holes optimized for the hub and application. All Andra rims are built to withstand and carry more load than regular rims and can ideally be used for not only regular e-bikes, but also transport bikes with or without motor support." That looks to me like different drilling angles are on someone's radar.

Are all of the cracks on only one side of the nipple and in the same relation to the angle of the spoke? From your pictures, I would believe even the Polyax nipples are not making proper contact with the spoke bed causing localized stress on only one side of the spoke hole. The nipples might be pushing down on one side of the hole and prying up on the other at that angle. 7000 miles of loaded tandem touring is very good service life if this is indeed the case.

If you do disassemble the wheel, you might put some marking ink on a nipple and actually see what kind of contact is being made with the rim.

Sapim makes three different profile nipple washers to match different spoke bed shapes which might help distribute the stresses around the hole. Your pictures suggest the nipples might be too short as is, but you will definitely need longer with the addition of washers. But if the nipple is unable to fit properly because of the angle and diameter of the spoke hole, they might exacerbate the situation.

#41

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

Did you contact Ryde USA or Ryde NL? In my experience, Ryde USA isn't up to speed on all of Ryde offerings.

From the Ryde.nl website- "ANDRA SERIES

The Andra rims can be ordered in many different wheel sizes and with the drilling angle for the spoke holes optimized for the hub and application. All Andra rims are built to withstand and carry more load than regular rims and can ideally be used for not only regular e-bikes, but also transport bikes with or without motor support." That looks to me like different drilling angles are on someone's radar.

Are all of the cracks on only one side of the nipple and in the same relation to the angle of the spoke? From your pictures, I would believe even the Polyax nipples are not making proper contact with the spoke bed causing localized stress on only one side of the spoke hole. The nipples might be pushing down on one side of the hole and prying up on the other at that angle. 7000 miles of loaded tandem touring is very good service life if this is indeed the case.

If you do disassemble the wheel, you might put some marking ink on a nipple and actually see what kind of contact is being made with the rim.

Sapim makes three different profile nipple washers to match different spoke bed shapes which might help distribute the stresses around the hole. Your pictures suggest the nipples might be too short as is, but you will definitely need longer with the addition of washers. But if the nipple is unable to fit properly because of the angle and diameter of the spoke hole, they might exacerbate the situation.

From the Ryde.nl website- "ANDRA SERIES

The Andra rims can be ordered in many different wheel sizes and with the drilling angle for the spoke holes optimized for the hub and application. All Andra rims are built to withstand and carry more load than regular rims and can ideally be used for not only regular e-bikes, but also transport bikes with or without motor support." That looks to me like different drilling angles are on someone's radar.

Are all of the cracks on only one side of the nipple and in the same relation to the angle of the spoke? From your pictures, I would believe even the Polyax nipples are not making proper contact with the spoke bed causing localized stress on only one side of the spoke hole. The nipples might be pushing down on one side of the hole and prying up on the other at that angle. 7000 miles of loaded tandem touring is very good service life if this is indeed the case.

If you do disassemble the wheel, you might put some marking ink on a nipple and actually see what kind of contact is being made with the rim.

Sapim makes three different profile nipple washers to match different spoke bed shapes which might help distribute the stresses around the hole. Your pictures suggest the nipples might be too short as is, but you will definitely need longer with the addition of washers. But if the nipple is unable to fit properly because of the angle and diameter of the spoke hole, they might exacerbate the situation.

The 4 cracks are on the side of the highest stress point (the side on the obtuse spoke angle). I was thinking the Sapim HM nipple washer would be best, with a conic profile. However, I think the HM will just mimic the nipple surface contact and so NOT spread the pressure point at the rim hole. Sapim's literature is unclear on this point saying "HM Washers decrease friction of nipple", which does not equate to increased strength. IMO 7000 miles is not good. I am contacting Ryde, but in the meantime I will not change anything to learn if the cracks grow significantly in time. 105kgf is appropriate for these rims rated for 140kgf and also what rohloff suggests. Anything less for a loaded tandem would not be good.

#42

Senior Member

Join Date: Jan 2009

Location: San Diego, CA

Posts: 3,670

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 836 Post(s)

Liked 1,061 Times

in

745 Posts

You could put a small amount of penetrating fluid on the possible cracks and put some baby powder in the inside of the rim where the suspect cracks are. The powder will make any penetrant more visible. Maybe a little difficult to get the powder through the double wall of the rim but a cotton swap could be used to apply it. This won't necessarily reveal every crack but if the penetrant does seep through you'll at least know for sure that it's a goner.

#43

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

You could put a small amount of penetrating fluid on the possible cracks and put some baby powder in the inside of the rim where the suspect cracks are. The powder will make any penetrant more visible. Maybe a little difficult to get the powder through the double wall of the rim but a cotton swap could be used to apply it. This won't necessarily reveal every crack but if the penetrant does seep through you'll at least know for sure that it's a goner.

Likes For IPassGas:

#44

Junior Member

I wouldn't take a chance...replace the rims & consider 40 hole rims...not sure you can even find 40 hole hubs anymore, but it's a consideration with all that weight & milage

#45

Senior Member

Ryde Andra 40? Fully rated to 180kg.

Carrying load is plain hard on rims. On a single bike the rider is usually fully sprung weight. What is in the panniers is unsprung weight. And it bounces. Stoker on a tandem is usually at least partly unsprung weight.

Good suggestions above. Use washers. Try hard to get closer to even tension than +/- 15%. Use bigger tires if they will fit. I would not easily discard a 36 hole Rohloff, tandems are hard on front wheels too so use a 40 hole in front. And if cracks continue to appear you just qualified for steel rims. At possibly less than perfect those are still very strong rims no matter how you look at it.

Carrying load is plain hard on rims. On a single bike the rider is usually fully sprung weight. What is in the panniers is unsprung weight. And it bounces. Stoker on a tandem is usually at least partly unsprung weight.

Good suggestions above. Use washers. Try hard to get closer to even tension than +/- 15%. Use bigger tires if they will fit. I would not easily discard a 36 hole Rohloff, tandems are hard on front wheels too so use a 40 hole in front. And if cracks continue to appear you just qualified for steel rims. At possibly less than perfect those are still very strong rims no matter how you look at it.

#46

Junior Member

Bill Mould offers some interesting(in a science guy/engineer way) thoughts on rim cracking at the spoke holes in this video. Some thought provoking responses in the comments also.

#47

Over the hill

Join Date: Mar 2006

Location: Los Angeles, CA

Posts: 24,376

Bikes: Giant Defy, Giant Revolt

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 998 Post(s)

Liked 1,206 Times

in

692 Posts

If the rim should be replaced, I'm not sure what would be much better for this to not happen again. The rim is one of the strongest on the market, but apparently not sufficiently strong for two people and their camping gear, etc. And so my question regarding nipple washers. I should have used washers.

As someone who experienced the joy of flying over the handlebars when a rim failed and caught the fork (no cracks prior), I wouldn't ride one more mile on a cracked rim if I could avoid it.

__________________

It's like riding a bicycle

It's like riding a bicycle

#48

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

Bill Mould offers some interesting(in a science guy/engineer way) thoughts on rim cracking at the spoke holes in this video. Some thought provoking responses in the comments also.https://www.youtube.com/watch?v=qKeeHDuoFq8

#49

Senior Member

The hard anodizing used in some rims will contribute to cracking. It is harder than the Al. and more prone to cracking and taking the crack through the al.