Rack Making

#1

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

Rack Making

I might be wanting to make a couple of light weight rear racks for my new frames (various reasons including "just because"). Who here has done a bunch? I'll likely want to communicate directly as I go along if this pans out. Andy

__________________

AndrewRStewart

AndrewRStewart

#2

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18373 Post(s)

Liked 4,508 Times

in

3,351 Posts

I haven't "done a bunch", but I've acquired some of the Burley supplies.

I just need some time to go through it all, do some customization, and get the bender reassembled. And, figure out how to make some of the missing parts.

I have found an original Burley rack, but I'm missing the Piccolo attachment... if anybody has one.

I just need some time to go through it all, do some customization, and get the bender reassembled. And, figure out how to make some of the missing parts.

I have found an original Burley rack, but I'm missing the Piccolo attachment... if anybody has one.

#3

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,396

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

after seeing how King Cage makes their water bottle cages, I have thought of making custom benders for the most common rack parts. It would be really cool to slap a length of tubing in a bender and just bend without all the fiddly measuring. And I also want fixtures. Because the thing that takes the most time is just fixturing it up. I have definitely come to empathize with the builders that will not build racks unless you buy a frame. Because it's a lot more stressful than building a frame.

good luck with your new enterprise.

good luck with your new enterprise.

#4

Senior Member

I've done several, including bottle cages. All in 300 series stainless.

I agree with @unterhausen, having a fixture or two speeds things along.

I agree with @unterhausen, having a fixture or two speeds things along.

#5

Framebuilder

Join Date: Dec 2007

Posts: 570

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 8 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

https://www.instagram.com/portercycles/?hl=en in addition to some really nice custom lugs, this builder recently made a bending jig that would definitely save some time.

ive done 50 some odd racks, but they all differ in size/shape/configuration so much that a jig for one type of rack wouldn't help much. I do occasionally feel like standardizing my racks....but then that would hardly be custom, right?

Last edited by Live Wire; 10-21-18 at 01:26 PM.

#6

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

So my initial questions are

1- Tube diameter and wall. For a minimal trunk bag on day loops, likely about 5-7lbs. No panniers or such as the bike is my club/sunday light one. Rack weight is a focus so 5/16x.028 or .035 is my first thought.

2- Tube bending and starting points WRT the bender. I remember a vid someone did a bunch of years ago about this topic. Even when I'd worked with electrical conduit I am challenged by planning bends on the tool.

I will forego placing stay top mounts of the frames until I get my head around this. Given the clearances between the brake, stays and small size of the frames rack mounts will be tight if not something funky/special. Andy

1- Tube diameter and wall. For a minimal trunk bag on day loops, likely about 5-7lbs. No panniers or such as the bike is my club/sunday light one. Rack weight is a focus so 5/16x.028 or .035 is my first thought.

2- Tube bending and starting points WRT the bender. I remember a vid someone did a bunch of years ago about this topic. Even when I'd worked with electrical conduit I am challenged by planning bends on the tool.

I will forego placing stay top mounts of the frames until I get my head around this. Given the clearances between the brake, stays and small size of the frames rack mounts will be tight if not something funky/special. Andy

__________________

AndrewRStewart

AndrewRStewart

#7

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,396

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

Andy, depends on material. I like to use stainless, but it's weaker than 4130. I like to use 5/16" .035. Pretty sure that thicker bends nicer.

The bending is a real struggle to maintain symmetry. And usually once you have bent things halfway, that half gets in the way of bending the other half. Usually there is more than one way to orient the bender and one of those orientations is a lot easier to maintain symmetry. Which bender(s) do you have? I like the Ridgid and Parker benders. Swaglock are nice, but the radius is too small for me most of the time. I also use a large bender for large radiuses. If you are bending a 5 inch diameter bend, a 5/8" tube bender will work on smaller tubes. Lots of people just use pulleys for the bigger radii

lots of interesting things at Porter's instagram account. I found him when I was looking for Dave Porter recently. Really nice work

What I was thinking for fixturing was the hard points. For example, the dropouts/stays/rack platform with some adjustability. Randonneur front racks have hard points in a couple of different configurations. I have the table off of a milling machine that I can build up from. I was thinking about mounting the rack platform to that and then adding uprights to simulate the fork or stays.

I don't really see the need for racks to be fully custom. Mostly tire clearance needs to change.

The bending is a real struggle to maintain symmetry. And usually once you have bent things halfway, that half gets in the way of bending the other half. Usually there is more than one way to orient the bender and one of those orientations is a lot easier to maintain symmetry. Which bender(s) do you have? I like the Ridgid and Parker benders. Swaglock are nice, but the radius is too small for me most of the time. I also use a large bender for large radiuses. If you are bending a 5 inch diameter bend, a 5/8" tube bender will work on smaller tubes. Lots of people just use pulleys for the bigger radii

lots of interesting things at Porter's instagram account. I found him when I was looking for Dave Porter recently. Really nice work

What I was thinking for fixturing was the hard points. For example, the dropouts/stays/rack platform with some adjustability. Randonneur front racks have hard points in a couple of different configurations. I have the table off of a milling machine that I can build up from. I was thinking about mounting the rack platform to that and then adding uprights to simulate the fork or stays.

I don't really see the need for racks to be fully custom. Mostly tire clearance needs to change.

Last edited by unterhausen; 10-21-18 at 07:13 PM.

#8

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

Steel, 4130, powder coated after (unfortunately...) I have an Eastwood 12345 (?) bender. A simple multi sized device with a sliding shoe. I was thinking of making two halves of the rack top, LH and RH joined with a splice at the front and rear ends to simplify the bending issues. (The only other bender I've used also has the multi stepped form for differing tube diameters but only a tube end stop and no sliding shoe.)

Fixturing will be on the frames as these will be one offs.

The big deal is that I'll be having two foot surgeries this fall/winter so I have a lot of down time but will be quite limited in mobility for a few weeks, twice. The frames have had all their brazing completed as of today. Just a bunch of finish filing/sanding, cutting/chase/facings and alignment checks before they can be painted. So all this will slow down, way down. Andy

Fixturing will be on the frames as these will be one offs.

The big deal is that I'll be having two foot surgeries this fall/winter so I have a lot of down time but will be quite limited in mobility for a few weeks, twice. The frames have had all their brazing completed as of today. Just a bunch of finish filing/sanding, cutting/chase/facings and alignment checks before they can be painted. So all this will slow down, way down. Andy

__________________

AndrewRStewart

AndrewRStewart

#9

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,845

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2338 Post(s)

Liked 2,822 Times

in

1,541 Posts

Andrew I am pretty sure @gugie has done a few, not sure he folllows Framebuilders, but I would touch base with him

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

#10

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,635

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4678 Post(s)

Liked 5,795 Times

in

2,281 Posts

Hi Andrew,

I typically work in stainless, but have done several CrMo ones as well. Stainless needs silver filler, and isn't a strong, so I use internal pins and such to add mechanical strength.

You can see my work here.

I use typically use 1/4" for handlebar bag type racks, 5/16" for low riders. Believe it or not, my go-to bender is an $8 tool from Harbor Freight. For large diameter bends I've made some wooden "pullies" using a large hole saw and a 45 degree router bit. I make two halves and glue them together.

The great thing about making a custom rack is that it exactly fits your bike. The deck can be made perfectly horizontal. No adjustable bits to loosen.

PM me and I'll send you my email address if you're interested in discussing further.

I typically work in stainless, but have done several CrMo ones as well. Stainless needs silver filler, and isn't a strong, so I use internal pins and such to add mechanical strength.

You can see my work here.

I use typically use 1/4" for handlebar bag type racks, 5/16" for low riders. Believe it or not, my go-to bender is an $8 tool from Harbor Freight. For large diameter bends I've made some wooden "pullies" using a large hole saw and a 45 degree router bit. I make two halves and glue them together.

The great thing about making a custom rack is that it exactly fits your bike. The deck can be made perfectly horizontal. No adjustable bits to loosen.

PM me and I'll send you my email address if you're interested in discussing further.

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

#11

Senior Member

Join Date: Jul 2008

Location: 25 miles northwest of Boston

Posts: 29,549

Bikes: Bottecchia Sprint, GT Timberline 29r, Marin Muirwoods 29er, Trek FX Alpha 7.0

Mentioned: 112 Post(s)

Tagged: 0 Thread(s)

Quoted: 5224 Post(s)

Liked 3,581 Times

in

2,342 Posts

lots of talk about bending but do you guys also do some welding? sorry if I missed that

#12

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,396

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

the bending is the hard part. Brazing things together is simple.

#13

Banned

changing places

Bruce Gordon recently retired and sold everything.. from Petaluma shop,

I Bought a set of his touring racks in the 80's

He Was Still in Eugene , then, I was in SFO..

Then, he brazed them together.. at some joints he made reinforcing pieces,

a 'pringled' washer..

a simple but effective "lug"..

later, I think, (From afar, I'd moved back to Oregon, again )

he hired a skilled Tig Welder for the newer rack production runs..

....

I Bought a set of his touring racks in the 80's

He Was Still in Eugene , then, I was in SFO..

Then, he brazed them together.. at some joints he made reinforcing pieces,

a 'pringled' washer..

a simple but effective "lug"..

later, I think, (From afar, I'd moved back to Oregon, again )

he hired a skilled Tig Welder for the newer rack production runs..

....

Last edited by fietsbob; 10-27-18 at 01:28 PM.

#14

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

I'll be brazing because that's what I do. I ordered a rigging pulley as a possible bending form. I'll post photos of the various bends in a week or so when I get around to playing in the shop. Andy

__________________

AndrewRStewart

AndrewRStewart

#15

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

Here's another update or discovery point. I received a rigging pulley made for 5/16" rope and tried to use it as a bending form. Here's a shot with the 3 different forms I have for 5/16" tubing and the resulting curves made. Top is a common cheap multi tube diameter form (about 3/4" radius) with it's fixed tubing hook. A very tight curve and it has some flattening to the tube's cross section. Next it the Eastwood bender (slightly less then a 3/4" radius) with it's tube hook and following shoe. Less cross sectional flattening and a bit larger a radius. Lowest is the pulley (about a 1 1/4" radius), held in a vice with the jaw being the tube hook. Smoothest and largest curve with no section flattening.

A very interesting exercise as the simple multi stepped tool and the fancier Eastwood (with it's pressure shoe) are of almost the exact same form radius but the Eastwood produced a little bit larger tube curve (with less flattening). I was most curious about the bare pulley and it's results seem predictable. All three curves have some inconsistencies in their curves along the entire 90* bent. Not much but there to see if you look. I suspect that my inexperience and "quick" use is at fault to a large degree.

I hold the resulting curves up against my drawing (based on the rack top bag's size and fit) and then against the existing racks I have in the house (Tubus and Blackburn) and I make a judgement as to what looks nicest. I have to admit that the most basic form, the multi stepped cheap one, seems to fit the design and look I want. So my next step is to practice some bends on more tubing and track the start and end dimensions of the curves to better deal with the rack's specs. Andy

__________________

AndrewRStewart

AndrewRStewart

#16

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,396

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

I have given up on my 1/4" swagelok bender because it flattens tubes too much. I really don't like it. I feel like my racks aren't suffering too much because of that.

I was watching a Hirose video the other day, and he uses cylinders to do most of his bending. As you can imagine, his tubes come out pretty well flattened most of the time. I suppose I should re-think my objections.

I have always thought that pulleys were best for large radius bends, but that's because I have benders for the smaller radius bends. Your bend came out looking pretty good.

I was watching a Hirose video the other day, and he uses cylinders to do most of his bending. As you can imagine, his tubes come out pretty well flattened most of the time. I suppose I should re-think my objections.

I have always thought that pulleys were best for large radius bends, but that's because I have benders for the smaller radius bends. Your bend came out looking pretty good.

#17

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

Since I posted my shot and comments I've though about things more. I suspect that the reason the cheap multi step bender curve came out as tighter then the Eastwood bender's did (both having pretty much the same radius) is that without a pressure shoe/follower component the cheap bender allowed the tube to lift off the bender's "floor" at the apex of the curve, and thus the tube got more tightly radiused at that point. As I said I will play a bit more and report back.

One thing I will say about hand made stuff in general, and frames in particular, is that most all others don't know what the builder had in mind. I don't know how many times I've shown a completed frame to a friend and gotten stellar comments when all I see are the "sort of rights but not quites" Andy

One thing I will say about hand made stuff in general, and frames in particular, is that most all others don't know what the builder had in mind. I don't know how many times I've shown a completed frame to a friend and gotten stellar comments when all I see are the "sort of rights but not quites" Andy

__________________

AndrewRStewart

AndrewRStewart

#18

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

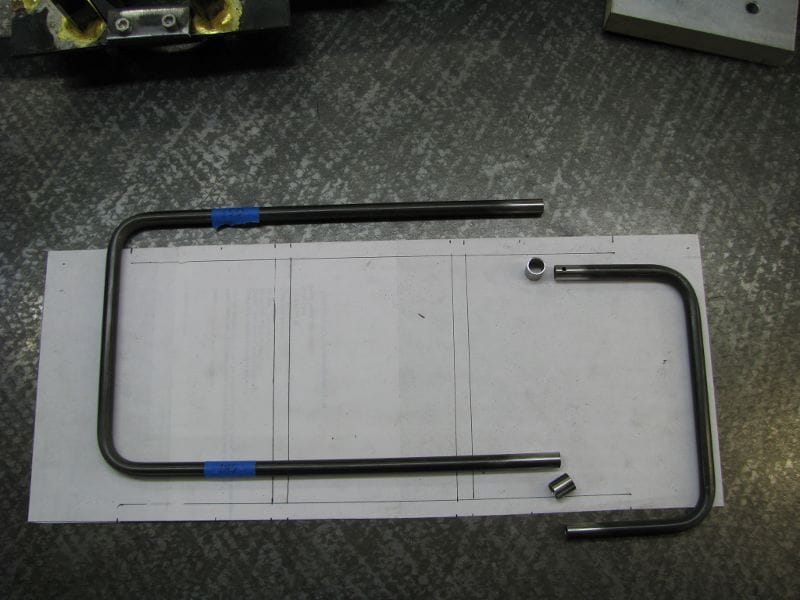

Bending the top frame. The hole was an aborted effort at splicing the two parts together. I decided to just use a over sleeve. The bending has some spring back so a bit of trial and error is needed to get 90* corners. See the last photo for more description.

The two parts of the top frame. I decided to make two "halves" to minimize the calculating and actually doing of multiple bends in one tube length. The paper shows the rough shape/size the top frame needs to handle the rack top bag. The ends and corners are left out because when I drew up this plan I wasn't sure which bender I would use, thus which corner radius to draw.

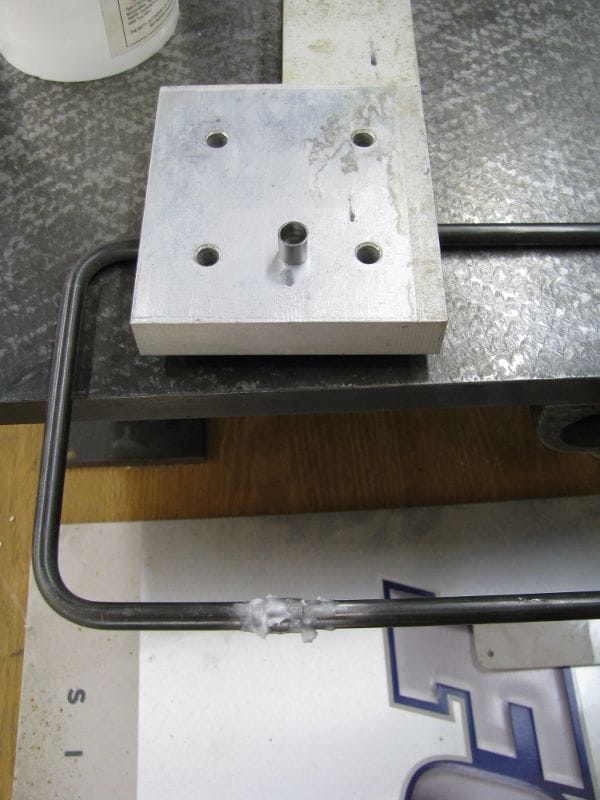

Here we see the joining of the two halves with a silvered sleeve. I used 3/8" x .035 drilled out to clear the 5/16" frame. I placed a wrap of masking tape 150mm from the end of the longer piece and with a 10mm long sleeve placed the edge of the sleeve 145mm from the tape, to center the sleeve on the frame butt joint. The AL plate holds down the two pieces and ensures their flatness WRT each other. The back round is a large piece of scrap AL sign to deflect the flame from my bench top.

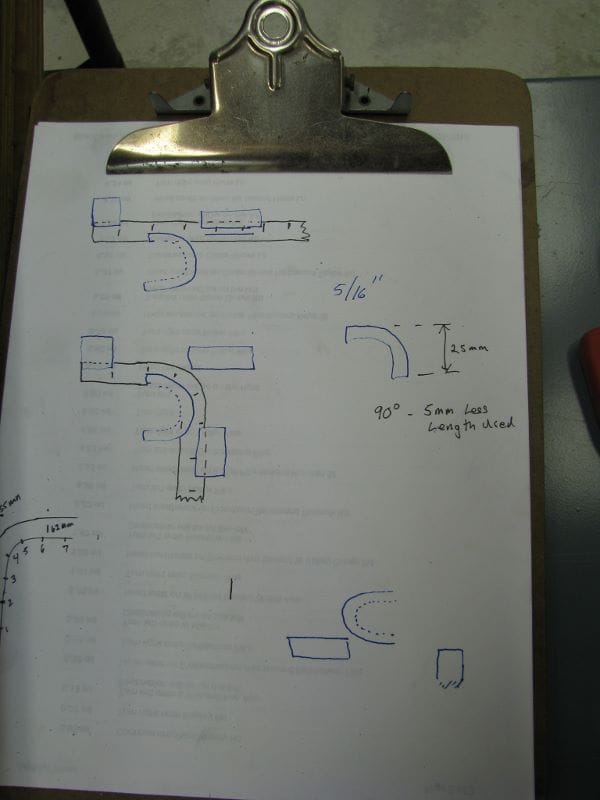

This shot should have been the first... It shows my learning how to locate the beginning of the curve bending with the tool I have and the 5/16" x .035 wall tubing. For a 90* bend the beginning of the bent sits about 25mm in from the resulting bent tube's outer edge.

My next steps are to determine where WRT the wheel and the seat I want the top frame to be. The bag (Jandd Rac Bag 2) needs to clear the rider's butt. I want the rack to sit lower to the top of the tire then commercially made racks do. I have cut/ground 4 drop out eyelet plates for the struts to attach to and now need more tubing. To be continued after the holiday. Andy

__________________

AndrewRStewart

AndrewRStewart

#19

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

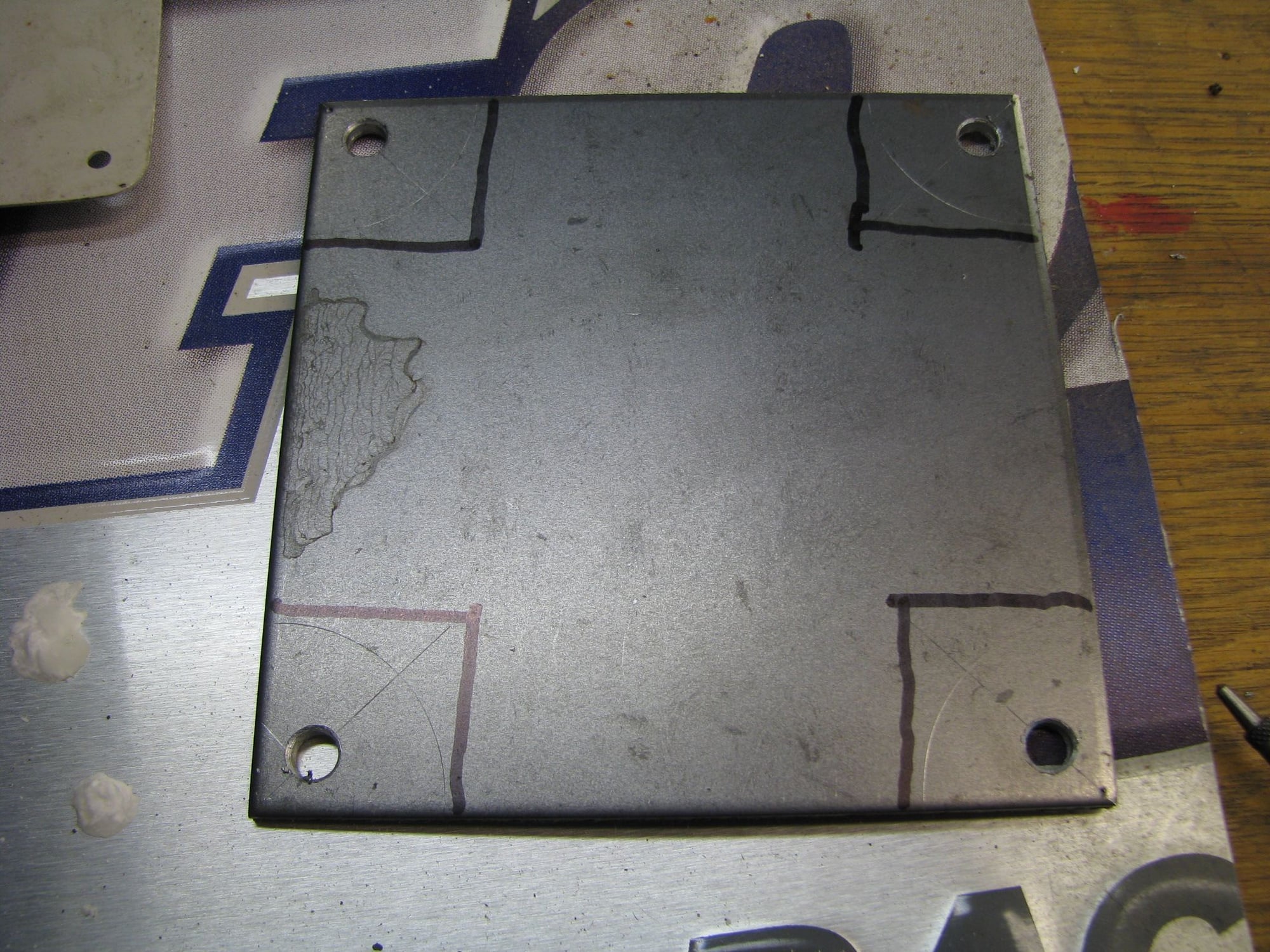

The 3/16" plate I am cutting the strut tabs out of. I've had this plate for a few decades...

The jigging to set up the top and struts. The black thing is a handle bar bag rack for behind the seat post (I no longer use) that I made years ago. The Al block is one of my small diameter tube clamps, happens to have the two tube sizes on either end. The wire keeps the top level. The second Al block laying on the top is just a dead weight. This stuff, how to set up the bits is fun, after I get that light bulb over my head.

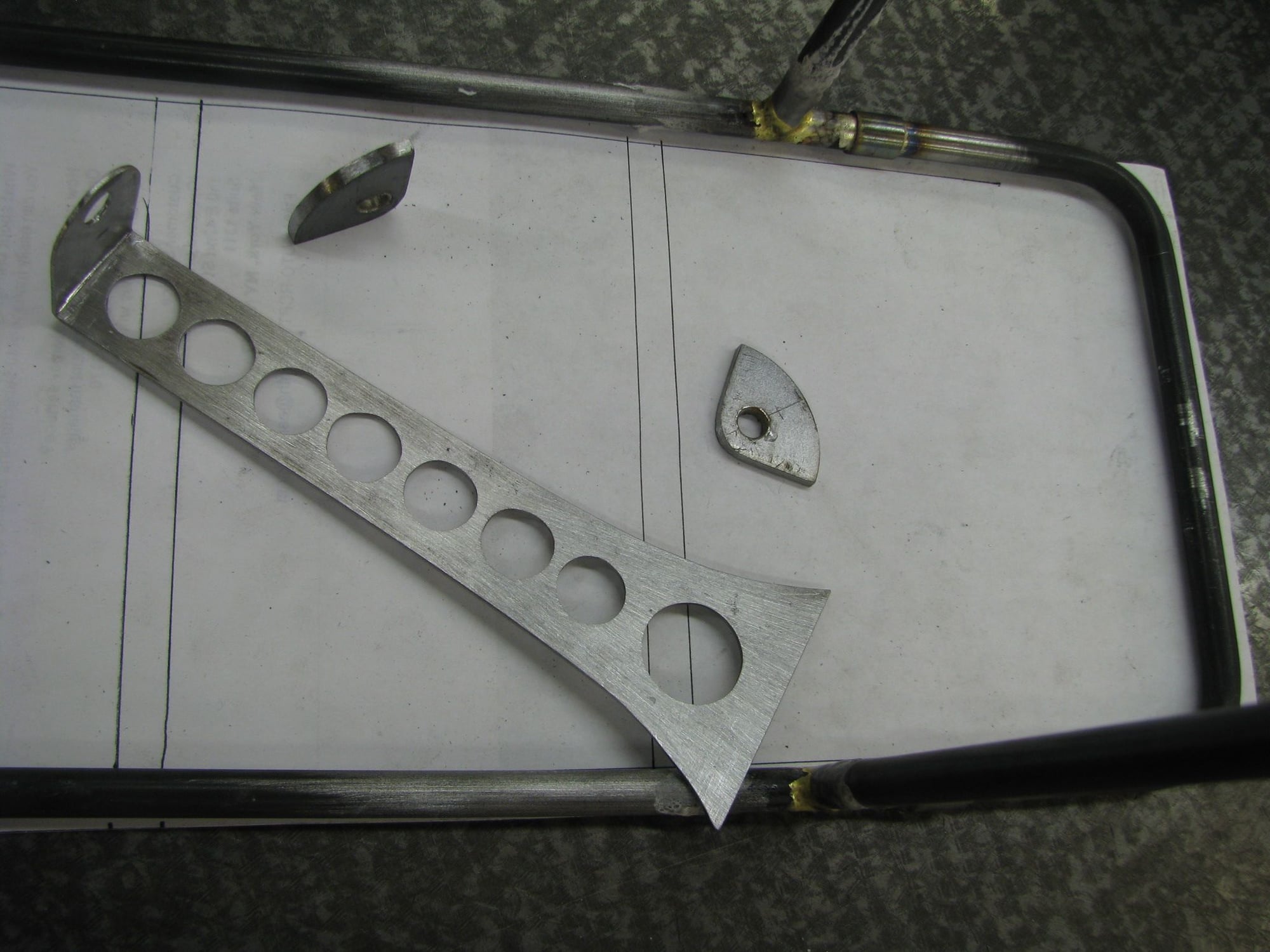

Another decades old stock seeing use. These are the tongues that run from the top to the rear brake mounting bolt. .049" thick. Cut from the raw plate with a fiber disk on my die grinder. The template is Elmers glued on the plate as the guide. I'll grinder off the extra, then belt sand the edges smooth and end up clamping the two together to drill the "lightening" holes.

First set of struts braze on the top. The second rack's tabs for a close up of them. The tongue finished too.

Now I wait for more tubing to be delivered from https://stockcarsteel.com/ to finish rack #1 and start #2 . Andy

__________________

AndrewRStewart

AndrewRStewart

#20

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,396

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

That's going to be a unique looking rack, nice job.

I like that fixturing, does it have another purpose in addition to rack building?

Nice bike stand too. I have a park arm coming out of the back of my frame fixture stand.

I like that fixturing, does it have another purpose in addition to rack building?

Nice bike stand too. I have a park arm coming out of the back of my frame fixture stand.

#21

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

The black fixture thing is a support rack for a handle bar bag to mount behind the post, think of the Eclipse SPT as the inspiration. (And jigging that up was a real brain twister at the time). When I had my retail shop I had 3 PRS-2s and a couple of bench mount single arm clamps too. I kept 2 of the double arm units, really smart choice.

It takes time to think and design in one's mind the many times while seeing others' stuff along the way to come to the point where you think you can do what you want. At least for me it does. My first full rack was over ten years ago and brazed directly to the frame That was at what I consider to be the beginning of the current rack making craze. There were no pre made tabs or even tubing offered by the few material suppliers. Dillsburg was still running so I sourced skinny tubing from Charles. Over the years I've paid more then passing attention to the evolving rack making "business" gathering bits and ideas.

The decision to make these two racks was made in only a couple of days about two weeks ago. I had almost finished the two new frames and was at the stage of "where do I attach the rack bosses on the seat stays"? I was not happy with the height of the commercially available racks (I will use 700cx28 tires and no fenders on these frames). So I decided that if I had a complaint I needed to make them myself. The design is completely driven by the rack top bags I use and the light weight that I will carry (on a Sunday club ride). Andy

It takes time to think and design in one's mind the many times while seeing others' stuff along the way to come to the point where you think you can do what you want. At least for me it does. My first full rack was over ten years ago and brazed directly to the frame That was at what I consider to be the beginning of the current rack making craze. There were no pre made tabs or even tubing offered by the few material suppliers. Dillsburg was still running so I sourced skinny tubing from Charles. Over the years I've paid more then passing attention to the evolving rack making "business" gathering bits and ideas.

The decision to make these two racks was made in only a couple of days about two weeks ago. I had almost finished the two new frames and was at the stage of "where do I attach the rack bosses on the seat stays"? I was not happy with the height of the commercially available racks (I will use 700cx28 tires and no fenders on these frames). So I decided that if I had a complaint I needed to make them myself. The design is completely driven by the rack top bags I use and the light weight that I will carry (on a Sunday club ride). Andy

__________________

AndrewRStewart

AndrewRStewart

#22

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

So here's a tangent- Eric asked about the black "SPTish" rack that I use for a rack fixture base. I mentioned it was a project to jig it up years ago when I made it. I found the photos of making it and thought that this one was most interesting. There's lots of parts all carefully arranged (with measuring and squares used) to get all the bag support's parts in place for tacking. What's more is that I made two with differing reaches and angles for two bikes (using the same bags). Andy

__________________

AndrewRStewart

AndrewRStewart

#23

Senior Member

Thread Starter

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

Spent a lot of time at the bench this week. Decided to forego photos to get stuff done

So here's the results. Racks weigh about 500gm, not quote as light as I had hoped for but I did add a spine to the top to better support the bag base. I figure this added about 30gm. Both are in the true sense hand built with unequal angles and lengths. But if I ride fast enough no one will notice. I learned a bunch and would do some things different the next time. Now I have to spend a few hours sanding before I drop these off at the powder coater. Andy

So here's the results. Racks weigh about 500gm, not quote as light as I had hoped for but I did add a spine to the top to better support the bag base. I figure this added about 30gm. Both are in the true sense hand built with unequal angles and lengths. But if I ride fast enough no one will notice. I learned a bunch and would do some things different the next time. Now I have to spend a few hours sanding before I drop these off at the powder coater. Andy

__________________

AndrewRStewart

AndrewRStewart