Bent and straight forks

#26

ambulatory senior

Join Date: Dec 2016

Location: Peoria Il

Posts: 5,998

Bikes: Austro Daimler modified by Gugie! Raleigh Professional and lots of other bikes.

Mentioned: 76 Post(s)

Tagged: 0 Thread(s)

Quoted: 1954 Post(s)

Liked 3,658 Times

in

1,677 Posts

Bent forks look better to me and I'm sure that changes my impression of how they ride. Honestly I ride upright porteur bars on sport tourers and am told that this makes for a horrible ride but I love it so fork blades probably don't mean anything to me.

#27

Senior Member

Join Date: Dec 2020

Location: Wake Forest, NC

Posts: 5,756

Bikes: 1989 Cinelli Supercorsa

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3492 Post(s)

Liked 2,911 Times

in

1,766 Posts

I vastly prefer curved fork blades, but I wonder why? All the other frame tubes are straight. You would think it would make more aesthetic sense for the fork blades to remain straight too?

#28

Senior Member

Join Date: Dec 2005

Posts: 17,146

Mentioned: 481 Post(s)

Tagged: 0 Thread(s)

Quoted: 3804 Post(s)

Liked 6,642 Times

in

2,602 Posts

Yeah, those straight-blade forks will just never catch on.

Likes For nlerner:

#29

Senior Member

Join Date: Dec 2020

Location: Wake Forest, NC

Posts: 5,756

Bikes: 1989 Cinelli Supercorsa

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3492 Post(s)

Liked 2,911 Times

in

1,766 Posts

Likes For smd4:

#30

Team Beer

Join Date: Apr 2004

Location: Sacramento CA

Posts: 6,339

Bikes: Too Many

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 114 Post(s)

Liked 159 Times

in

104 Posts

My running assumption is that larger tires dull all the nuances in frame materials. All these details can be easily felt on 120psi 23mm tires but I doubt it for 38mm 40 psi tires.

__________________

I'm not one for fawning over bicycles, but I do believe that our bikes communicate with us, and what this bike is saying is, "You're an idiot." BikeSnobNYC

I'm not one for fawning over bicycles, but I do believe that our bikes communicate with us, and what this bike is saying is, "You're an idiot." BikeSnobNYC

#31

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,779

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3583 Post(s)

Liked 3,395 Times

in

1,929 Posts

Jan Heine did a comparison of straight and curved fork blades and decided that curved blades offer slightly better shock absorption than straight blades, but were otherwise quite similar.

Likes For JohnDThompson:

#32

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,469

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1827 Post(s)

Liked 3,367 Times

in

1,573 Posts

An electrical engineer wouldn't understand

I'm obviously extrapolating on real world design results from recognized material properties; strength and rigidity.

Certainly you know CF's advantage is in strength to weight ratio and rigidity - it barely flexes at all, even it it's curved.

I'm obviously extrapolating on real world design results from recognized material properties; strength and rigidity.

Certainly you know CF's advantage is in strength to weight ratio and rigidity - it barely flexes at all, even it it's curved.

The difference between a straight fork and a raked fork is nearly zero. The one significant difference is that the raked fork will be longer, and if all else is identical, it will be more flexible.

Just to be clear, strength of a material is not relevant to stiffness.

Also, to be clear, stiffness of a material is not relevant to strength.

Since we are talking about the differences between straight and raked forks, the discussion assumes the same material, the same cross section, and wall thickness is used.

The cross section, both size and shape, and wall thickness used in the fork blades are the big variables in fork design, since there is very little variation in the fork blade length for a given wheel size.

There is an argument that most flex occurs in the steerer tube, and not in the fork blades themselves. Could be.. I haven't seen any data on it, though.

As for "dampening", that is a measure of the wetness. I'll assume you are referring to damping, which is a measure of the energy loss on each oscillation or vibration cycle. Steel absorbs no significant amount of energy in a cycle. Carbon fiber doesn't absorb much more.. at least based on some tests I ran on a CF vs steel fork, where I tapped them like a tuning fork and measured the vibration with an accelerometer. When we ride bikes and hit a bump, the oscillation stops in a cycle, and the energy gets absorbed mostly in our bodies, and presumably a bit in the tire.

Steve in Peoria

Likes For steelbikeguy:

#33

Senior Member

Join Date: Apr 2007

Posts: 6,760

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1109 Post(s)

Liked 1,200 Times

in

760 Posts

IIRC, it was Colnago's marketing department that promoted straight-blade forks in the late 80s to early-90s. I suspect it was done mostly to eliminate a manufacturing step (raking the fork blades) and thereby sightly reduce the cost of production, more than anything else. ....

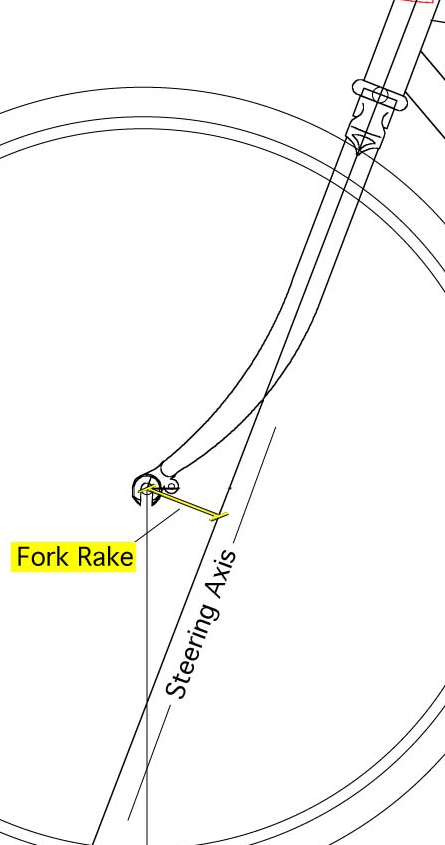

Straight leg fork rake:

Curved fork rake:

Last edited by Camilo; 07-01-22 at 12:40 AM.

Likes For Camilo:

#34

Senior Member

#35

Senior Member

It would be much simpler to fabricate a graphite fiber fork that is straight, even though it tapers, than one that is curved.

You can design the layup* to provide the stiffness (springiness) you want and strength you need. Creating that layup* will be less sensitive to workmanship issues if the shape is simpler.

* Layup - fiber type, fiber direction, number of plies, etc.

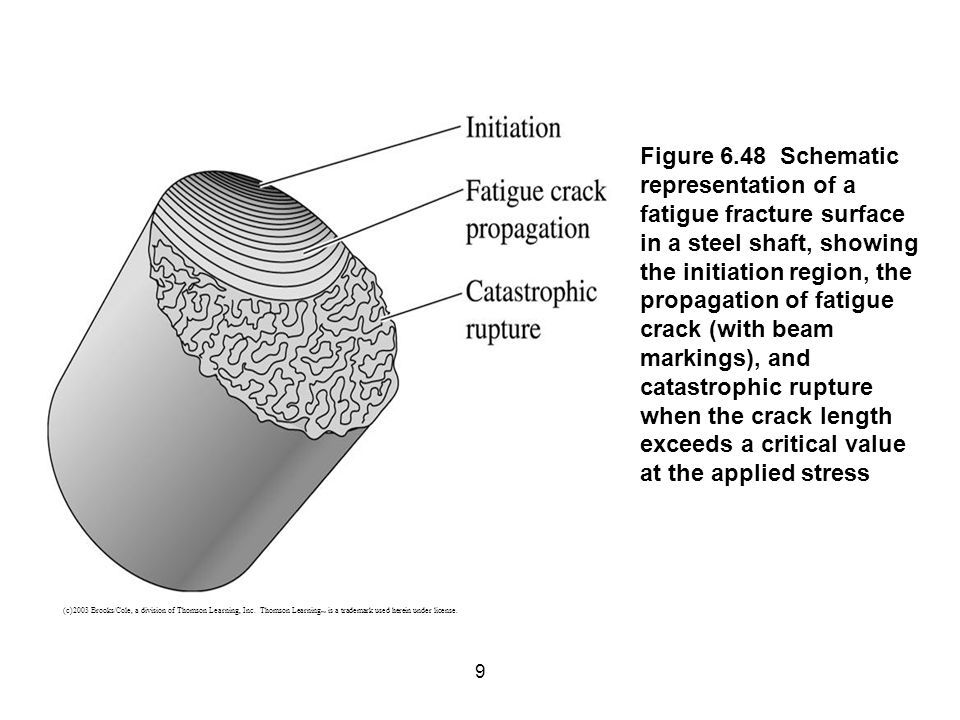

P.S. - I hate straight forks but cannot claim any performance issues. I do not like the catastrophic failure modes of graphite fiber composites, especially in highly stressed applications like the bars and fork.

You can design the layup* to provide the stiffness (springiness) you want and strength you need. Creating that layup* will be less sensitive to workmanship issues if the shape is simpler.

* Layup - fiber type, fiber direction, number of plies, etc.

P.S. - I hate straight forks but cannot claim any performance issues. I do not like the catastrophic failure modes of graphite fiber composites, especially in highly stressed applications like the bars and fork.

#36

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,469

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1827 Post(s)

Liked 3,367 Times

in

1,573 Posts

No injuries, but I didn't appreciate the 5 mile walk home.

another BF C&V member has shown me a photo of a chromed steel fork where one of the blades broke at the crown. No explanation of why it happened. Perhaps poor cleaning after the chroming process? I'm not sure what lesson to draw from this. Maybe get a painted fork instead of chromed?

Steve in Peoria

Likes For steelbikeguy:

#37

Senior Member

Good point, aluminum is also subject to sudden failure. There's a reason they were called, The Death Fork". I once had a "Death Stem", too.

I once had an aluminum stem snap clean off with no prior warning. I was in traffic, accelerating hard, then SNAP!!!,... all of a sudden, I had no way to steer the bike while alongside cars going 40-50 mph.

I once had an aluminum stem snap clean off with no prior warning. I was in traffic, accelerating hard, then SNAP!!!,... all of a sudden, I had no way to steer the bike while alongside cars going 40-50 mph.

Last edited by Bad Lag; 07-04-22 at 11:08 AM.

#38

Senior Member

Join Date: Jan 2013

Posts: 2,675

Bikes: too many sparkly Italians, some sweet Americans and a couple interesting Japanese

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 567 Post(s)

Liked 563 Times

in

405 Posts

A frequent poster here who I have not seen in a long while did some pretty detailed testing changing out steel and carbon forks which on the same bike gave me the idea. Being a retired engineer tinkerer I swapped out my Colnago Master fork for a Tommasini Air Fork, same wheels, stem, etc. I am sensitive due to arthritis in my hands, wrists, one knee and back and have to ride a recumbent trike on bad days. I could not detect any difference in the forks. This reinforces my contention that good frame/fork materials, each with a different physical properties, Gilco, Columbus EL, etc., can be made as compliant or ridged as a competent builder wants.

Likes For easyupbug:

#39

Senior Member

You guys got it all wrong. Straight blade forks, with a nice taper down to a pencil point at the axle, is far superior aesthetically, and because we all love to ogle our (and others') bikes, a straight bladed fork will win every time. My favorites include but are not limited to: Nishiki mountain of the late 80's, Raleigh mountain of the early 90's, the Bontrager composite fork and the Tange Switchblade, a licensed copy of the Bontrager. How they ride, for me, is irrelevant. First and foremost, the bicycle must be beautiful. Performance is secondary. Hopefully my light hearted cheekiness will come through the screen as I can give no other opinion than my own, and because its the internet it must be the correct opinion above all others, no?

#40

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,630

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4677 Post(s)

Liked 5,790 Times

in

2,279 Posts

I appreciate the vote of confidence, but as an electrical engineer, I'll defer to those who have actual knowledge of the data.

However, I do support the use of data and experiments and tests, as opposed to opinions based on limited experience with a piece of equipment.

One of my projects that is still waiting for time and attention is to be able to measure fork flex while riding. Until that happens, the next best thing is for someone with a good workshop to hang weights off of a range of forks and measure how much they deflect. Gugie? Bulgie? Anyone want to volunteer?

Steve in Peoria

However, I do support the use of data and experiments and tests, as opposed to opinions based on limited experience with a piece of equipment.

One of my projects that is still waiting for time and attention is to be able to measure fork flex while riding. Until that happens, the next best thing is for someone with a good workshop to hang weights off of a range of forks and measure how much they deflect. Gugie? Bulgie? Anyone want to volunteer?

Steve in Peoria

Back to subject, thinking about curved vs straight forks, if all else is equal, and the distance between the fork crown base and dropout center are the same, the curved fork will flex a bit more. Why? The fork blades are longer, for the simple reason that most know that the shortest distance between two points is a straight line - a curved one will be longer. Longer spring will flex more than a shorter one. I'm thinking if curving the blade will make the curved section flexier, but can't think offhand of any first principals that would says so. FEA and dynamic analysis would give an answer.

I prefer a fork with thin blades, especially when riding on gravel roads, and especially those with washboard on them. An interesting phenomena occurs on washboard roads. Counter-intuitively, if you speed up you'll "float" more on the tops, and minimize the vibration through the bike to your body. This probably has to do with resonance frequency. A few years ago when @scozim put together his Tour of the Palouse I rode for several miles on a pure washboard road. Keeping my speed up minimized the vibration transmitted to my body. I bought a Ritchey Breakaway with some beefy unicrown forkblades. Riding it on washboard was rougher than I felt on my skinnier fork bladed bikes.

As purchased. Note that some research tells me the fork was originally carbon fiber, this fork is after market.

I built a fork with the same geometry, but with much skinnier blades. Riding on the same washboard roads just a few weeks apart I noticed a significant difference - less vibration when riding at speed.

Fork I made to replace the unicrown fork.

So, my best guess is that there is curved blades flex a bit more than straight due to longer blade length. Anecdotal evidence supplied by others suggests that it isn't significant. I perused the link to the Colnago marketing collateral, which had zero data in it.

I'll continue to curve my fork blades for this reason:

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

Likes For gugie:

#41

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,630

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4677 Post(s)

Liked 5,790 Times

in

2,279 Posts

it's a bit off-topic, but it's not just CF forks that can suddenly snap. I've had a recumbent fork where the aluminum fork blade broke. This was not unheard of for this fork, and the general hypothesis was that the attachment of the little loop that the disk brake cable fastened to might have affected the heat treatment of the fork blade.

I've done a small amount of failure analysis over the years. Here's a good picture and explanation of what to look for in a stress fracture:

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

#42

spondylitis.org

Join Date: Mar 2013

Location: Fleetwood, PA, USA

Posts: 1,003

Bikes: '84 Colnago Super; '90 Bridgestone MB-1; '81 Trek 930; '01 Cinelli Supercorsa; '62 Ideor Asso; '87 Tommasini Super Prestige; '13 Lynskey R2300; '84 Serotta Nova Special; '94 Litespeed Catalyst; etc.

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 121 Post(s)

Liked 97 Times

in

63 Posts

Straight blade forks blew up during the mountain bike era. From about 1987 to about 1994, the mountain bike industry (which cared little for tradition) dominated design trends, and some of that domination bled over into road bikes. Colnago was not immune, and neither were other road bike manufacturers who were trying to re-invigorate the waning interest in their products.

In spite of the MTB hype of the era, I'm not sure straight vs. curved design made that big of a difference. Metallurgy and tube diameter/thickness were likely the big determinants in terms of ride quality in road bikes - until carbon fiber forks hit the market.

Likes For kunsunoke:

#43

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,469

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1827 Post(s)

Liked 3,367 Times

in

1,573 Posts

Of course, the results would only apply to that particular fork, so it's not the end of the story. If it was a "typical" fork, the results would surely inspire some discussion, though.

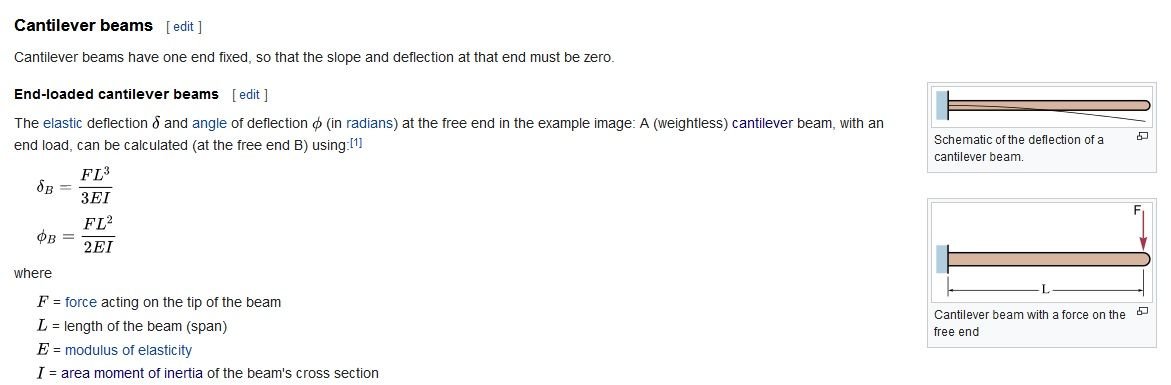

Back to subject, thinking about curved vs straight forks, if all else is equal, and the distance between the fork crown base and dropout center are the same, the curved fork will flex a bit more. Why? The fork blades are longer, for the simple reason that most know that the shortest distance between two points is a straight line - a curved one will be longer. Longer spring will flex more than a shorter one. I'm thinking if curving the blade will make the curved section flexier, but can't think offhand of any first principals that would says so. FEA and dynamic analysis would give an answer.

https://en.wikipedia.org/wiki/Deflection_(engineering)

It's interesting that the deflection varies as the cube of the beam length, so a small increase in length produces a much larger change in deflection.

Of course, with a curved fork, the distance from the head tube to hub axle is the same as for a straight fork, so maybe the ratio of the tube length to the cross section ("area moment of inertia") increases, and that's what makes it more flexible?? I suppose this is similar to the idea for using a coiled spring instead of a short straight piece of metal.

Going further out on the tangent, since a longer beam is more flexible, and since it is theorized that much of the fork flex is actually flexing of the steerer tube, would a tall frame with a long steerer tube have more fork flex than a small frame using the same tube set??

Or does this cross into the territory of the framebuilder sub-forum?

Steve in Peoria

#44

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,469

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1827 Post(s)

Liked 3,367 Times

in

1,573 Posts

Since the break occured right where the upper weld holdng the cable retainer attached, even without looking at the fractured material I'd say that pretty damning circumstantial evience of the cause. Weakened the material, possibly created a stress riser with some of the original material removed?

I've done a small amount of failure analysis over the years. Here's a good picture and explanation of what to look for in a stress fracture:

[image deleted in the interest of not taking up too much space]

I've done a small amount of failure analysis over the years. Here's a good picture and explanation of what to look for in a stress fracture:

[image deleted in the interest of not taking up too much space]

It does look like the failure started at the rear of the blade, where that cable loop was tacked on. The front end shows the rough and ragged failure of the last bit of metal yielding when I hit the pothole that marked the death of the fork.

To their credit, the manufacturer did replace the fork. The replacement was a steel fork that was quite a bit heavier, but I didn't complain. An argument could be made that they knew they had a dangerous fork and should have replaced all of these forks that were being used by unsuspecting customers.

Steve in Peoria

#45

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,630

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4677 Post(s)

Liked 5,790 Times

in

2,279 Posts

It's interesting that the deflection varies as the cube of the beam length, so a small increase in length produces a much larger change in deflection.

Of course, with a curved fork, the distance from the head tube to hub axle is the same as for a straight fork, so maybe the ratio of the tube length to the cross section ("area moment of inertia") increases, and that's what makes it more flexible?? I suppose this is similar to the idea for using a coiled spring instead of a short straight piece of metal.

Of course, with a curved fork, the distance from the head tube to hub axle is the same as for a straight fork, so maybe the ratio of the tube length to the cross section ("area moment of inertia") increases, and that's what makes it more flexible?? I suppose this is similar to the idea for using a coiled spring instead of a short straight piece of metal.

Framebuilders know that forkblades come longer than needed. If you want a stiff fork, you can trim from the tapered end, leaving more of the blade in a larger diameter. Conversely, a less stiff fork (which I prefer) you remove material from the tapered end. Framebuilder Supply here in Portland has a nice explanation of this.

I distinctly remember looking down at my front hub while powering through that washboard back at the Tour of the Palouse. It was almost scarey watching how much the fork blades were flexing.

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

Likes For gugie:

#46

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,469

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1827 Post(s)

Liked 3,367 Times

in

1,573 Posts

As I stated earlier, two forks, one straight, and all else being equal, if the fork crown to dropout measurement is the same, if you straightened out the curved fork the blades are longer. So the material distance of the fork blade is longer than the straight one, similar to a coiled spring. The curved fork will flex more. I'm not sure if it makes that much of a difference, but plug it into your formula and see how much.

I am saying that the formula only accounts for straight beams.

That better not be true! Think of what that would do to the bearing contact in your headset, not to mention the havoc it might play with your head tube. A steerer tube is at least 1" diameter, steel fork blades are significantly smaller, especially down in the taper area. Check wikipedia for tubing flex equations, diameter has an effect, tubing wall thickness as well. Simple explanation: I can bend 1/4" tubing with my bare hands quite easily. No way I can bend and deform a 1" thinwall top tube without power assistance.

It seems to me that the steerer tube's large diameter should make it the stiffest element of the fork, even considering that there are two fork blades and just one steerer.

The key detail is probably the fact that the deflection is inversely proportional to the area moment of inertia, with the symbol I. The link to the definition of this shows that it is proportional to the fourth power of the radius.

Of course, now that I measure some of my fork blades, they are about 1" from front to rear, so maybe it's not unlikely that a pair of fork blades might be stiffer than the steerer tube?? Wall thickness would have to be considered too, and I have no idea what those values might be.

Steve in Peoria

#47

Banned.

Join Date: Jan 2022

Posts: 1,070

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 359 Post(s)

Liked 582 Times

in

336 Posts

This is a family forum. Enough with the math porn!

More like it. No way I could tell, sober or normal.

"News you can use" category.

I think my forks identify as "somewhat flexible."

Being a retired engineer tinkerer I swapped out my Colnago Master fork for a Tommasini Air Fork, same wheels, stem, etc. I am sensitive due to arthritis in my hands, wrists, one knee and back and have to ride a recumbent trike on bad days. I could not detect any difference in the forks.

I think my forks identify as "somewhat flexible."

Last edited by bamboobike4; 07-05-22 at 07:42 AM.

#48

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,469

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1827 Post(s)

Liked 3,367 Times

in

1,573 Posts

admittedly, just throwing out the equations isn't a great way to learn this stuff, but a little exposure to it might be useful.

I will say that having a background in everyday technology, such as bikes, where you've wondered "why does this work" or "how do you make a fork stiffer or more flexible" does make it easier to get through engineering classes or a physics class. Seeing a lesson on the stiffness of cantilevered beams and realizing that this is the answer to that question that has been gnawing at your brain for years really does help you pay attention!

Steve in Peoria

I will say that having a background in everyday technology, such as bikes, where you've wondered "why does this work" or "how do you make a fork stiffer or more flexible" does make it easier to get through engineering classes or a physics class. Seeing a lesson on the stiffness of cantilevered beams and realizing that this is the answer to that question that has been gnawing at your brain for years really does help you pay attention!

Steve in Peoria

Likes For steelbikeguy:

#49

Senior Member

Not sure if you're being facetious or not. The following is the opinion of an Gen-X engineer, not intended to offend, to be taken or left as necessary.

Straight blade forks blew up during the mountain bike era. From about 1987 to about 1994, the mountain bike industry (which cared little for tradition) dominated design trends, and some of that domination bled over into road bikes. Colnago was not immune, and neither were other road bike manufacturers who were trying to re-invigorate the waning interest in their products.

In spite of the MTB hype of the era, I'm not sure straight vs. curved design made that big of a difference. Metallurgy and tube diameter/thickness were likely the big determinants in terms of ride quality in road bikes - until carbon fiber forks hit the market.

Straight blade forks blew up during the mountain bike era. From about 1987 to about 1994, the mountain bike industry (which cared little for tradition) dominated design trends, and some of that domination bled over into road bikes. Colnago was not immune, and neither were other road bike manufacturers who were trying to re-invigorate the waning interest in their products.

In spite of the MTB hype of the era, I'm not sure straight vs. curved design made that big of a difference. Metallurgy and tube diameter/thickness were likely the big determinants in terms of ride quality in road bikes - until carbon fiber forks hit the market.

#50

Senior Member

Join Date: Apr 2014

Location: Back in Lincoln Sq, Chicago...🙄

Posts: 1,609

Bikes: '84 Miyata 610 ‘91 Cannondale ST600,'83 Trek 720 ‘84 Trek 520, 620, ‘91 Miyata 1000LT, '79 Trek 514, '78 Trek 706, '73 Raleigh Int. frame.

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 684 Post(s)

Liked 370 Times

in

219 Posts

As I stated earlier, two forks, one straight, and all else being equal, if the fork crown to dropout measurement is the same, if you straightened out the curved fork the blades are longer. So the material distance of the fork blade is longer than the straight one, similar to a coiled spring. The curved fork will flex more. I'm not sure if it makes that much of a difference, but plug it into your formula and see how much.

That better not be true! Think of what that would do to the bearing contact in your headset, not to mention the havoc it might play with your head tube. A steerer tube is at least 1" diameter, steel fork blades are significantly smaller, especially down in the taper area. Check wikipedia for tubing flex equations, diameter has an effect, tubing wall thickness as well. Simple explanation: I can bend 1/4" tubing with my bare hands quite easily. No way I can bend and deform a 1" thinwall top tube without power assistance.

Framebuilders know that forkblades come longer than needed. If you want a stiff fork, you can trim from the tapered end, leaving more of the blade in a larger diameter. Conversely, a less stiff fork (which I prefer) you remove material from the tapered end. Framebuilder Supply here in Portland has a nice explanation of this.

I distinctly remember looking down at my front hub while powering through that washboard back at the Tour of the Palouse. It was almost scarey watching how much the fork blades were flexing.

That better not be true! Think of what that would do to the bearing contact in your headset, not to mention the havoc it might play with your head tube. A steerer tube is at least 1" diameter, steel fork blades are significantly smaller, especially down in the taper area. Check wikipedia for tubing flex equations, diameter has an effect, tubing wall thickness as well. Simple explanation: I can bend 1/4" tubing with my bare hands quite easily. No way I can bend and deform a 1" thinwall top tube without power assistance.

Framebuilders know that forkblades come longer than needed. If you want a stiff fork, you can trim from the tapered end, leaving more of the blade in a larger diameter. Conversely, a less stiff fork (which I prefer) you remove material from the tapered end. Framebuilder Supply here in Portland has a nice explanation of this.

I distinctly remember looking down at my front hub while powering through that washboard back at the Tour of the Palouse. It was almost scarey watching how much the fork blades were flexing.