Compression plug for oval carbon steerer

#1

Junior Member

Thread Starter

Compression plug for oval carbon steerer

I've picked up a fork from a Trek Madone 9-series to install in my Cube frame, but it's missing its expander/compression plug. And one idiosyncracy of this fork (along with others!) is its non-round steerer tube. I could buy an official one (designed for this fork) from Trek that they're flogging at nearly 50 dollars, but that would be obscene; I paid half that for the fork. Pissflaps to you Trek (even though I bought your fork). If we find a cheaper solution, I will be giving the difference to charity.

So could any of you folks with more knowledge of material stresses than I tell me whether a traditional round compression plug will put inappropriate stresses on the oval carbon steerer? I'd get a long one, if that'll help.

So could any of you folks with more knowledge of material stresses than I tell me whether a traditional round compression plug will put inappropriate stresses on the oval carbon steerer? I'd get a long one, if that'll help.

Last edited by Jonneh; 02-09-20 at 10:14 AM.

#2

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,784

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3587 Post(s)

Liked 3,400 Times

in

1,934 Posts

I wouldn't use a round compression plug in a non-round steer tube; it would concentrate stresses in a manner the steer tube was not designed to handle.

You've already bought into the proprietary Trek technology, and as they say, "in for a dime, in for a dollar."

You've already bought into the proprietary Trek technology, and as they say, "in for a dime, in for a dollar."

#4

Junior Member

Thread Starter

Fine by me if it'll serve the purpose.

A lot depends on whether the function of the compression plug is just to get a grip while the headset bearings are preloaded, or whether it's to resist compressive forces from the stem's grip on the steerer. There was a debate on here some time back that covered that topic. No consensus, as I remember, although the trend was towards thinking that it performs both functions (rather than just the former). A star-fangled nut doesn't do much for the latter function, but maybe the compression-resistance is a carbon-specific need. An epoxied plug would serve the first purpose, but perhaps not the second?

Another option is a plug with a double semi-cylinder design. The inside of the steerer has a stadium shape, so this could work if the lobes of the plug pushed into the two semi-cylindrical parts.

A lot depends on whether the function of the compression plug is just to get a grip while the headset bearings are preloaded, or whether it's to resist compressive forces from the stem's grip on the steerer. There was a debate on here some time back that covered that topic. No consensus, as I remember, although the trend was towards thinking that it performs both functions (rather than just the former). A star-fangled nut doesn't do much for the latter function, but maybe the compression-resistance is a carbon-specific need. An epoxied plug would serve the first purpose, but perhaps not the second?

Another option is a plug with a double semi-cylinder design. The inside of the steerer has a stadium shape, so this could work if the lobes of the plug pushed into the two semi-cylindrical parts.

Last edited by Jonneh; 02-09-20 at 11:41 AM.

#5

Senior Member

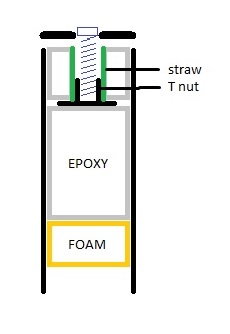

I never use a compression plug anymore. I stuff some foam rubber or core foam into the steering tube, to the appropriate depth, like the bottom of the stem clamp, place a 6mm tee nut or a 1" star nut into the tube and epoxy in place. 1" start nuts will slip right in to 1-1/8" round steering tubes, with just a little filing on the tip of the stars. A 6mm bolt with the threads covered by a plastic drinking straw of heat shrink tubing keeps the epoxy out of the threads.

The tee nut is lighter, but much harder to align. My last plug weighed only 22 grams, with the help of some core foam to reduce the amount of epoxy needed.

No spacer is needed on top of the stem and the steering tube is crush proof.

The tee nut is lighter, but much harder to align. My last plug weighed only 22 grams, with the help of some core foam to reduce the amount of epoxy needed.

No spacer is needed on top of the stem and the steering tube is crush proof.

#6

Junior Member

Thread Starter

Thanks to your homemade modifications, or just as it is? In the latter case I could just use a standard compression plug while preloading the bearings, then clamp on the stem and remove the plug. I'd need an arrangement such as yours for the top cap, but the standard compression ring surely won't do any damage during the bearing compression, oval steerer or otherwise. Else having clamped the stem I could just loosen the plug until it's tight enough to stay put but not to plausibly inflict any damage. I don't get your weight gains, but I'm not too fussed about that.

#8

Junior Member

Thread Starter

#9

Full Member

I think this should be pinned to all future "what I should never do to my carbon frame and fork" threads. There's some crazy advice on here. OP needs to pony up and get the right part for his bike.

#10

Senior Member

Join Date: Jan 2009

Location: San Diego, CA

Posts: 3,669

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 836 Post(s)

Liked 1,061 Times

in

745 Posts

This FSA plug has 4 separate pieces that can conform to the oval shape a little better. Can't say for sure the it has a small enough outside diameter to fit inside but there the grinding option. Contact TREK to find out if the plug needs to provide strength against crushing from the stem clamp first as this may not work. https://www.jensonusa.com/FSA-Compre...SABEgJbRPD_BwE or https://www.performancebike.com/prob...iABEgKdSfD_BwE

#11

Senior Member

Join Date: Jan 2011

Posts: 2,977

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 1638 Post(s)

Liked 741 Times

in

495 Posts

This FSA plug has 4 separate pieces that can conform to the oval shape a little better. Can't say for sure the it has a small enough outside diameter to fit inside but there the grinding option. Contact TREK to find out if the plug needs to provide strength against crushing from the stem clamp first as this may not work. https://www.jensonusa.com/FSA-Compre...SABEgJbRPD_BwE or https://www.performancebike.com/prob...iABEgKdSfD_BwE

__________________

nine mile skid on a ten mile ride

nine mile skid on a ten mile ride

#12

Junior Member

Thread Starter

I take this (albeit in other words) to be a conclusion about a required function of the plug being to resist crushing forces then?

Last edited by Jonneh; 02-10-20 at 03:03 AM.

#13

With a mighty wind

Join Date: May 2015

Posts: 2,588

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 1086 Post(s)

Liked 859 Times

in

488 Posts

I've used subpar plugs before. You know, basically enough to snug up the headset. I've even tightened a headset with a long piece of all thread and washers.

It sure seems that with carbon, it will eventually get loose without the constant preload of a good and grippy inner plug. It was a big surprise considering I had steel and aluminum steerers with no plug that were fine.

I am unfamiliar with the fork. Do you need a proprietary stem or headset?

It sure seems that with carbon, it will eventually get loose without the constant preload of a good and grippy inner plug. It was a big surprise considering I had steel and aluminum steerers with no plug that were fine.

I am unfamiliar with the fork. Do you need a proprietary stem or headset?

#14

Junior Member

Thread Starter

The original stem on the 9-series Madone is a fancy Bontrager one, but its clamp is just a standard (round) 28.6 mm one.

#15

Senior Member

Yes, compression plugs are intended to provide support, so the stem clamping pressure doesn't crack the steering tube. It's also why a 5mm spacer is recommended on top of the stem, with the steerer cut 3-4mm above the top of the stem. Taking the compression plug out, after the headset bearings are preloaded isn't real smart. Compression plugs can also be over tightened.

I avoid all of that by filling the top 40mm of the steerer with epoxy. The weight of the epoxy is about the same as a typical compression plug and provides much better support. I use JB Weld epoxy. Don't use 5 minute or quick epoxy.

I avoid all of that by filling the top 40mm of the steerer with epoxy. The weight of the epoxy is about the same as a typical compression plug and provides much better support. I use JB Weld epoxy. Don't use 5 minute or quick epoxy.

#16

Junior Member

Thread Starter

Do you have any data that vouches for epoxy in such a role, or it it based on personal experience?

#17

Senior Member

I see, sounds good. I took it for granted that the epoxy wouldn't serve a structural funcion, and was rather there just to hold the tee nut (and therefore just for bearing preloading purposes), but if it also resists compression that's another matter.

Do you have any data that vouches for epoxy in such a role, or it it based on personal experience?

Do you have any data that vouches for epoxy in such a role, or it it based on personal experience?

The question about this oval tube is what the maximum diameter is - 1-1/8" of something larger? Getting threads centered in the long direction might be a bit tricky.

#19

Junior Member

Thread Starter

I'm a mechanical engineer. JB Weld epoxy has a tensile strength of over 5000 psi and great bond strength. I first made this type of modification over 10 years ago. I just sold the frame with that mod this week. It works perfectly. I also built up two new Colnago frames recently and made the same mod to them. I've even used this product to extend the length of a steering tube by up to 15mm. https://www.jbweld.com/product/j-b-w...fessional-size

The question about this oval tube is what the maximum diameter is - 1-1/8" of something larger? Getting threads centered in the long direction might be a bit tricky.

The question about this oval tube is what the maximum diameter is - 1-1/8" of something larger? Getting threads centered in the long direction might be a bit tricky.

The maximum external diameter is 1-1/8". Because of the ovality and thick walls, the minimum internal diameter is a fair bit less. I can measure it later.

Just to check that I understand your setup, is it something like this?

#20

Junior Member

Thread Starter

Regarding long-axis alignment of the T nut, that could probably be got right by setting the epoxy in two stages: first, by filling the space above the foam until it's just high enough to contact the base of the T nut (calculated beforehand), and setting the T nut in place by having it screwed into the headset top-cap bolt to the appropriate extent, with the top-cap bolt and cap set up as normal (that is, with the stem in place and headtube angled so as to get a level set). Once the epoxy is set, the bolt is removed, a straw inserted over the outside of the T nut, and the steerer filled to the top with epoxy.

#21

Senior Member

I used a piece of 1 inch copper tubing with the end sharpened to cut foam rubber. You could also use a 1" copper tube coupling that's a little larger. The bottom has to be sealed, so the epoxy doesn't leak out.

The inside of the steerer should be cleaned with acetone and lightly sanded, with something around 120 grit, then cleaned again with acetone.

To extend a steerer, a 1" no-stop copper tube coupling that as a 1-1/8" inside diameter is slipped over the steering tube and the epoxy extends up to 15mm above the top of the steering tube. The coupling has to be very lightly greased, so the epoxy does not adhere to it. I want more the half of the stem clamping area to be the original steering tube.

Last edited by DaveSSS; 02-17-20 at 11:10 AM.

#22

Junior Member

Thread Starter

Excellent. That all sounds very clear.

I make it about 20 mls that'll be required for a 50 mm section of 11 mm radius (without discounting the T nut and straw volume). Allowing 1.5 g/cm3 for the density of epoxy, a 2x28 g pack should easily do it, for a grand total of 7 euros. So that's 40 dollars of Trek's money that's heading to charity. Any nominations?

I make it about 20 mls that'll be required for a 50 mm section of 11 mm radius (without discounting the T nut and straw volume). Allowing 1.5 g/cm3 for the density of epoxy, a 2x28 g pack should easily do it, for a grand total of 7 euros. So that's 40 dollars of Trek's money that's heading to charity. Any nominations?

#23

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

...To extend a steerer, a 1" no-stop copper tube coupling that as a 1-1/8" inside diameter is slipped over the steering tube and the epoxy extends up to 15mm above the top of the steering tube. The coupling has to be very lightly greased, so the epoxy does not adhere to it. I want more the half of the stem clamping area to be the original steering tube.

Then there is the consideration of the strength of the extension, and of how firmly fixed it is to the steerer.

Also the manner in which the extension transmits stresses to the steerer, as it is only attached to the inside of the steerer, and so exerts forces that might tend to open the end of the steerer. This is the part that I feel is no bueno.

I don't think that the stem clamp should be expected to help support such a joining, as the stress distribution is complicated where the end of the steerer likely could see extreme stress concentration due to it being primarily UD fiber orientation. Also, the inside of stem clamps often feature a huge hole centered on the stem's horizontal extension.

Most of us first became familiar with the way that a threadless setup is gripped by the stem back when metal steer tubes were the norm, so it may still seem familiar and ok to see the end of the steerer cut to where it sits below the top of the stem clamp.

But I think that with a carbon steerer that there should actually always be the equivalent of at least one spacer atop the stem to accomodate 1) the flange on any expanding plug and 2) any drop-down step of the top cap below it's seating edge at the perimeter.

For this reason, I think that the standard for top caps should today be that they all incorporate a spacer of at least a few millimeters, and that the cut end of the steerer should not fall below the top end of the stem clamp. Just my opinion here.

#24

Senior Member

What you apparently don't understand is the fact that with my method, the extension is always less than half of the length of the stem clamping area and the extension is made of solid epoxy with a high tensile strength and a hole in the middle that's no more than 7mm in diameter instead of 23.6mm. The copper tube coupling is made to very accurate tolerances, so there will be no significant mismatch in the diameters. At worst, a tiny bit of sanding with a strip of fine sandpaper might be required. I would lower the threaded insert, so it was close to the bottom of the stem clamping area.

A spacer on top of the stem is used to keep idiots from cracking a thin walled carbon tube by over tightening the top stem clamp bolt. With a steering tube top that's nearly solid high strength epoxy, you'd strip the threads on the stem, long before the top of the steering tube was damaged.

I first did this to a bike 10 years ago, rode it thousands of miles and never had a problem with it. Both of my new Colnagos have epoxied in place threads instead of a compression plug and no spacer on top of the steerer. It works just fine.

Maybe I'll make a sample from a scrap piece of steering tube to show.

Here's a picture of one of my steering tubes, with the tee nut epoxied in place, with the threads in the center of the stem clamping area. The epoxy stops 2-3mm from the top of the steerer and I've added a countersink for additional clearance for the recessed top cap bolt.

A spacer on top of the stem is used to keep idiots from cracking a thin walled carbon tube by over tightening the top stem clamp bolt. With a steering tube top that's nearly solid high strength epoxy, you'd strip the threads on the stem, long before the top of the steering tube was damaged.

I first did this to a bike 10 years ago, rode it thousands of miles and never had a problem with it. Both of my new Colnagos have epoxied in place threads instead of a compression plug and no spacer on top of the steerer. It works just fine.

Maybe I'll make a sample from a scrap piece of steering tube to show.

Here's a picture of one of my steering tubes, with the tee nut epoxied in place, with the threads in the center of the stem clamping area. The epoxy stops 2-3mm from the top of the steerer and I've added a countersink for additional clearance for the recessed top cap bolt.

Last edited by DaveSSS; 02-20-20 at 11:50 AM.

#25

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

The extension does sound strong with the high-strength epoxy. I can't say what tolerances are required for an OD that particular lightweight stems are expected to clamp reliably onto, but I would expect that their design and testing is done on a steerer of consistent OD and straightness.

And if the OD of the epoxy extension were just a bit larger than the steerer, might the stem end up primarily gripping only the epoxy?

OK, I get that it's strong, but OD must be quite straight and consistent for best clamping and for realizing the tested strength of the stem.

Most stems grip a full 40mm of steerer length, and I know that there a lot of owners who would be happy to be able to add an extra spacer's height to their cut-off steerer.

Lastly I will add that craftsmanship counts, safe use of epoxy for structure relies on a good product of known strength and freshness.

And if the OD of the epoxy extension were just a bit larger than the steerer, might the stem end up primarily gripping only the epoxy?

OK, I get that it's strong, but OD must be quite straight and consistent for best clamping and for realizing the tested strength of the stem.

Most stems grip a full 40mm of steerer length, and I know that there a lot of owners who would be happy to be able to add an extra spacer's height to their cut-off steerer.

Lastly I will add that craftsmanship counts, safe use of epoxy for structure relies on a good product of known strength and freshness.