1980's Frame Misalignment

#1

Senior Member

Thread Starter

Join Date: Jun 2018

Location: The Urban Shores Of Michigami

Posts: 1,749

Bikes: ........................................ .....Holdsworth "Special"..... .......Falcon "Special".......... .........Miyata 912........... ........................................

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 702 Post(s)

Liked 672 Times

in

420 Posts

1980's Frame Misalignment

Most of the bikes I've owned and worked on were 1970's era Raleigh's and all have had misaligned frames. This is the second bike I've worked on from the 1980's and both have misaligned frames. First was a ROSS Signature, this one is a SCHWINN Traveler.

How common is this?

The first photo is of the non-drive side, second is drive side, the gap is 7mm. The dropouts are parallel and are perfectly spaced for a 126mm hub.

How common is this?

The first photo is of the non-drive side, second is drive side, the gap is 7mm. The dropouts are parallel and are perfectly spaced for a 126mm hub.

#2

Senior Member

Join Date: Mar 2012

Location: Niagara Region, Canada

Posts: 1,455

Bikes: 1970s Alex Singer, 1960s Peugeot PX 10, 1960s Bertin C37, 1973 Carre Bertin C 37, 1972 Carlton Kermesse, 1981 Peugeot PX 14 Super Competition

Mentioned: 65 Post(s)

Tagged: 0 Thread(s)

Quoted: 345 Post(s)

Liked 266 Times

in

157 Posts

branko 76-

Misalignment of older steel bikes is pretty common in my experience. Wear and tear, getting crashed or dropped, all sorts of things happen over 40 years. I routinely have my bike purchases checked by a nearby frame builder and then aligned. It makes a great difference in the ride and tracking even when I previously considered the bike to be fine.

Misalignment of older steel bikes is pretty common in my experience. Wear and tear, getting crashed or dropped, all sorts of things happen over 40 years. I routinely have my bike purchases checked by a nearby frame builder and then aligned. It makes a great difference in the ride and tracking even when I previously considered the bike to be fine.

#3

Senior Member

Thread Starter

Join Date: Jun 2018

Location: The Urban Shores Of Michigami

Posts: 1,749

Bikes: ........................................ .....Holdsworth "Special"..... .......Falcon "Special".......... .........Miyata 912........... ........................................

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 702 Post(s)

Liked 672 Times

in

420 Posts

branko 76-

Misalignment of older steel bikes is pretty common in my experience. Wear and tear, getting crashed or dropped, all sorts of things happen over 40 years. I routinely have my bike purchases checked by a nearby frame builder and then aligned. It makes a great difference in the ride and tracking even when I previously considered the bike to be fine.

Misalignment of older steel bikes is pretty common in my experience. Wear and tear, getting crashed or dropped, all sorts of things happen over 40 years. I routinely have my bike purchases checked by a nearby frame builder and then aligned. It makes a great difference in the ride and tracking even when I previously considered the bike to be fine.

#4

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,984

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26400 Post(s)

Liked 10,373 Times

in

7,202 Posts

.

...of the stuff I have redone for my own use, probably 70% of them need some sort of either minor or major realignment. As stated above, it's pretty common.

I routinely check the dropout spacing and alignment, frame alignment, fork alignment, and derailleur hanger alignment as part of the process on every bike I work on.

If a bike gets used, **** happens. And some of them were not well aligned when sold new, anyway.

...of the stuff I have redone for my own use, probably 70% of them need some sort of either minor or major realignment. As stated above, it's pretty common.

I routinely check the dropout spacing and alignment, frame alignment, fork alignment, and derailleur hanger alignment as part of the process on every bike I work on.

If a bike gets used, **** happens. And some of them were not well aligned when sold new, anyway.

__________________

#5

Senior Member

Join Date: Jan 2013

Posts: 2,678

Bikes: too many sparkly Italians, some sweet Americans and a couple interesting Japanese

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 569 Post(s)

Liked 580 Times

in

408 Posts

It is worth the trouble. My worst was 7 years ago an utterly unridable 80's custom from a local builder. Hung upside down by strings looped through the rims the fork would cant off 30º. A lugged Reynolds 753 which you can find Reynolds engineers documents saying 753 can not be cold set. I tried to cold set the fork first and as soon as i mount and moved it would snap back to the original position. Fortunately an old time framebuilder in town with Marchetti frame table and Lange fork table got it perfect. I enjoy it to this day.

#6

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,471

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 960 Post(s)

Liked 1,626 Times

in

1,044 Posts

branko 76-

Misalignment of older steel bikes is pretty common in my experience. Wear and tear, getting crashed or dropped, all sorts of things happen over 40 years. I routinely have my bike purchases checked by a nearby frame builder and then aligned. It makes a great difference in the ride and tracking even when I previously considered the bike to be fine.

Misalignment of older steel bikes is pretty common in my experience. Wear and tear, getting crashed or dropped, all sorts of things happen over 40 years. I routinely have my bike purchases checked by a nearby frame builder and then aligned. It makes a great difference in the ride and tracking even when I previously considered the bike to be fine.

As to the OP: Yes, pretty common. A further question would be what methods can we use as a DIY alignment check.

Our guys at Sheldon have a few things posted

https://sheldonbrown.com/frame-spacing.html

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)Last edited by zandoval; 08-13-22 at 10:37 AM.

Likes For zandoval:

#7

Senior Member

Join Date: Apr 2007

Location: Thunder Bay, Ontario, Canada - burrrrr!

Posts: 11,674

Bikes: 1958 Rabeneick 120D, 1968 Legnano Gran Premio, 196? Torpado Professional, 2000 Marinoni Piuma

Mentioned: 210 Post(s)

Tagged: 0 Thread(s)

Quoted: 1372 Post(s)

Likes: 0

Liked 1,751 Times

in

938 Posts

Yup, tweaked frame alignment is not at all uncommon. I always check frame and fork alignment and correct as required. And, in many cases, correction is required. I use the string method to check stays alignment but I no longer have a fork gauge. Stupid me sold mine a long time ago:-(

__________________

"98% of the bikes I buy are projects".

"98% of the bikes I buy are projects".

#8

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,986

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,567 Times

in

1,072 Posts

The string should come off the dropout at a point that matters, namely where the wheel will sit, the inner face of the "land" for the axle. This shows the string coming off a part of the dropout that's not involved with holding the axle, and it's different between the right and left (that knot can throw off the string's centerline).

Even if you do it right, you might want to measure and compensate for the curve in the seat tube from brazing on the front derailer attachment. All tubes have some runout of course, nothing is perfectly straight, but the F. der. BO puts a pretty decent curve in the tube, more than any runout I have measured in an unbrazed tube.

So the string method is not the ultimate alignment, but it's decent as a shade-tree mechanic technique for those without more rigorous methods, or even for a pro framebuilder in too much of a hurry for a complete alignment, say for a frame that isn't valuable enough to warrant the complete tear-down and rebuild. Just run that string in the right place, and try to see how bent your seattube is!

Note this string method (done right) is equivalent to the Park ***-1 tool shown in the OP; they measure the same thing. So the ***-1 (or -2) is also, in my opinion, not a "be-all and end-all" pro alignment tool, but it is very fast and easy to use. I have one and use it, but I keep its limitations in mind.

EDIT: the asterisks were put there by the censor. They replace the name of the Park Frame Alignment Gauge.

I, for one, welcome our new robot overlords!

Mark B

Last edited by bulgie; 08-13-22 at 04:19 PM. Reason: Censor bleeped the name of the Park tool!

#9

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,986

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,567 Times

in

1,072 Posts

<snip> you can find Reynolds engineers documents saying 753 can not be cold set. I tried to cold set the fork first and as soon as i mount and moved it would snap back to the original position. Fortunately an old time framebuilder in town with Marchetti frame table and Lange fork table got it perfect. I enjoy it to this day.

That's not a problem with the forks though, which are no thinner than 531. They're just 531 blades that got heat-treated to make them stronger, a very dubious advantage since 531 forks are strong enough. (I'm mad at Reynolds for "chickening out" and not making the blades lighter, a missed opportunity.)

The 753 steerer is also the same gauge as 531 for most of its length, but where the 531 steerer gets a butt at the bottom, the 753 doesn't, so the lower part of the steerer is lighter than 531. This a 753 fork is just a little bit lighter than a 531 fork, but it's really very little, like an ounce? Sorrry, I once knew the weight difference but I forget now, someone here will know.

Even if the blades were infinitely strong, you can still bend the crown, so yeah those forks definitely can be cold-set. You just need a longer lever, and a stout vise! Or a 100+ lb alignment fixture like the one I made recently from vintage cast iron industrial parts,

That's a work-in-progress shot. It's now finished and bolted down to a very heavy steel table that's bolted into the concrete floor. Main difference from this pic is the handwheel is spaced upward an inch so you don't pinch your fingers against the crown. Unfortunately it only does 1" forks (I'm a committed C&V retrogrouch).

Mark B

Last edited by bulgie; 08-14-22 at 11:52 PM.

Likes For bulgie:

#10

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,828 Times

in

1,995 Posts

Braze on front derailleur mounts are definitely a way to bow a seat tube.

Likes For easyupbug:

#12

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,782

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3587 Post(s)

Liked 3,398 Times

in

1,932 Posts

Yeah it's "common knowledge" that 753 can't be cold-set, but what they really should have said is it's difficult to cold set. If it springs back without taking a set, it just means you didn't push hard enough. Any steel, no matter how strong, can be bent, unless it's too brittle and snaps. But the problem with 753 isn't brittleness, it's just very thinwall (in the frame tubes, not the fork), making it likely to buckle or kink, a.k.a. beercan failure mode.

And that's why I don't recommend cold-setting 753 frames.

Likes For JohnDThompson:

#13

framebuilder

I'll start by answering the OP's question about how often are classic era bike frames out of alignment. As a builder/painter since the mid 70's, I've done hundreds (thousands probably) of alignments. The answer is most frames are somewhat out of alignment and some seriously out. I've visited many framebuilding places (especially in the UK) in the 70's and most were pretty casual about it with rudimentary tools. Furthermore, the $100/150 retail cost of a painted frame in Europe required those builders to make them quickly. The exception I've found were 80's Japanese frames that always seemed to be spot on. American builders raised the price and standard although not everyone does it perfectly. Where I learned to build at Ellis Briggs in Yorkshire, they had a very nice cast iron fixture/alignment table combination. I took back with me from Manchester much of Johnny Berry's Equipment including his 3' X 4' cast iron table. I've gotten others since but that one is still my main table for alignment. I was very fortunate to get it (and the knowledge of how to use it).

The problem with DIY alignment is figuring out what is the problem. I'm not a fan of Sheldon's string method. So you measure the distance of the string to the seat tube on both sids and there is a discrepancy. What's off? One might think that the rear dropouts are left or right of the center of the frame but how do you know? Maybe the down tube is leaning over to one side or maybe it's the seat tube leaning but not the head tube. Or the other way around. Or both. Or the front triangle is really 90 degrees from the threads of the bottom bracket shell and the dropouts are really off center. So the string method is only telling you something isn't right but it can't tell you where to fix what is wrong. There is a way to DIY if one wants to make a straight edge with an adjustable screw but that is beyond the scope of my post.

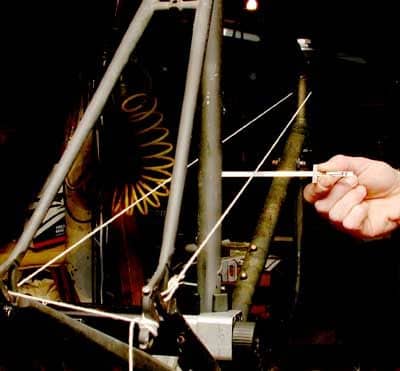

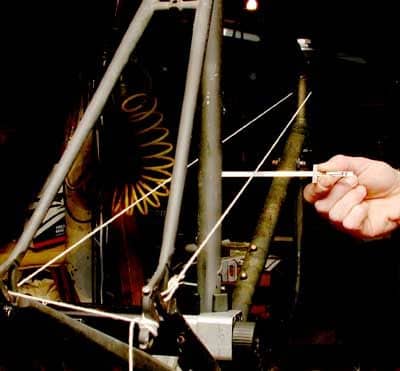

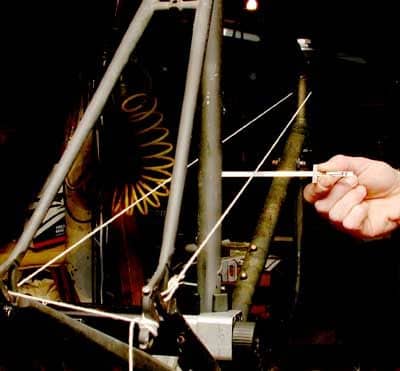

Just for your amusement, I'll show a couple of pictures of frames and accessories on my Johnny Berry alignment table. The 1st picture shows a carved lug frame I was making for my nephew. The other picture shows 3 kinds of straight edges with adjustable screws.

some of the accessories to check frame alignment on a cast iron table

a gaggle of straight edges that can be used in checking alignment

The problem with DIY alignment is figuring out what is the problem. I'm not a fan of Sheldon's string method. So you measure the distance of the string to the seat tube on both sids and there is a discrepancy. What's off? One might think that the rear dropouts are left or right of the center of the frame but how do you know? Maybe the down tube is leaning over to one side or maybe it's the seat tube leaning but not the head tube. Or the other way around. Or both. Or the front triangle is really 90 degrees from the threads of the bottom bracket shell and the dropouts are really off center. So the string method is only telling you something isn't right but it can't tell you where to fix what is wrong. There is a way to DIY if one wants to make a straight edge with an adjustable screw but that is beyond the scope of my post.

Just for your amusement, I'll show a couple of pictures of frames and accessories on my Johnny Berry alignment table. The 1st picture shows a carved lug frame I was making for my nephew. The other picture shows 3 kinds of straight edges with adjustable screws.

some of the accessories to check frame alignment on a cast iron table

a gaggle of straight edges that can be used in checking alignment

#14

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,986

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,567 Times

in

1,072 Posts

When I was with Trek, we decided to test cold-setting a 753 frame on a crashed team frame that was headed for the scrap barrel anyway. Put it on the alignment table and had at it with the Big Levers of Alignment, and just as you say, it kept springing back, and we kept increasing the force. Finally, it gave, by crumpling at the shift lever bosses.

And that's why I don't recommend cold-setting 753 frames.

And that's why I don't recommend cold-setting 753 frames.

Mark B

#15

Junior Member

For me just getting proper derailleur alignment has been a great thing. And I don't even have proper tools to do it. I just use two large "C" clamps.

As to the OP: Yes, pretty common. A further question would be what methods can we use as a DIY alignment check.

Our guys at Sheldon have a few things posted

https://sheldonbrown.com/frame-spacing.html

As to the OP: Yes, pretty common. A further question would be what methods can we use as a DIY alignment check.

Our guys at Sheldon have a few things posted

https://sheldonbrown.com/frame-spacing.html

Bought a vintage frame set, being shipped to me now, and I wanted to do an alignment check on it.

Likes For reroll:

#16

Junior Member

Alarming that ShelBroCo would show a picture of doing it wrong. (I am admittedly too picky by half, but why not do it right? It's not any harder.)

The string should come off the dropout at a point that matters, namely where the wheel will sit, the inner face of the "land" for the axle. This shows the string coming off a part of the dropout that's not involved with holding the axle, and it's different between the right and left (that knot can throw off the string's centerline).

Even if you do it right, you might want to measure and compensate for the curve in the seat tube from brazing on the front derailer attachment. All tubes have some runout of course, nothing is perfectly straight, but the F. der. BO puts a pretty decent curve in the tube, more than any runout I have measured in an unbrazed tube.

So the string method is not the ultimate alignment, but it's decent as a shade-tree mechanic technique for those without more rigorous methods, or even for a pro framebuilder in too much of a hurry for a complete alignment, say for a frame that isn't valuable enough to warrant the complete tear-down and rebuild. Just run that string in the right place, and try to see how bent your seattube is!

Note this string method (done right) is equivalent to the Park ***-1 tool shown in the OP; they measure the same thing. So the ***-1 (or -2) is also, in my opinion, not a "be-all and end-all" pro alignment tool, but it is very fast and easy to use. I have one and use it, but I keep its limitations in mind.

EDIT: the asterisks were put there by the censor. They replace the name of the Park Frame Alignment Gauge.

I, for one, welcome our new robot overlords!

Mark B

The string should come off the dropout at a point that matters, namely where the wheel will sit, the inner face of the "land" for the axle. This shows the string coming off a part of the dropout that's not involved with holding the axle, and it's different between the right and left (that knot can throw off the string's centerline).

Even if you do it right, you might want to measure and compensate for the curve in the seat tube from brazing on the front derailer attachment. All tubes have some runout of course, nothing is perfectly straight, but the F. der. BO puts a pretty decent curve in the tube, more than any runout I have measured in an unbrazed tube.

So the string method is not the ultimate alignment, but it's decent as a shade-tree mechanic technique for those without more rigorous methods, or even for a pro framebuilder in too much of a hurry for a complete alignment, say for a frame that isn't valuable enough to warrant the complete tear-down and rebuild. Just run that string in the right place, and try to see how bent your seattube is!

Note this string method (done right) is equivalent to the Park ***-1 tool shown in the OP; they measure the same thing. So the ***-1 (or -2) is also, in my opinion, not a "be-all and end-all" pro alignment tool, but it is very fast and easy to use. I have one and use it, but I keep its limitations in mind.

EDIT: the asterisks were put there by the censor. They replace the name of the Park Frame Alignment Gauge.

I, for one, welcome our new robot overlords!

Mark B

#17

Senior Member

Join Date: Jan 2013

Posts: 2,678

Bikes: too many sparkly Italians, some sweet Americans and a couple interesting Japanese

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 569 Post(s)

Liked 580 Times

in

408 Posts

The above 753 Andy saved hung afterward by strings run through the rims hung straight as an arrow and it fails Sheldon's string test badly but I can ride it around the block w/o touching the handlebars, it is a delight. Andy also painted it for me, he is a gilt to C&V in Southern Arizona and I recall him saying basically what you did above.

#18

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,782

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3587 Post(s)

Liked 3,398 Times

in

1,932 Posts

Right, I think you're agreeing with what I wrote. But do you agree that 753 forks should be alignable? (Is that a word?) Can't say as I recall ever having tried it, but I have aligned Prestige forks (maybe a thousand times, but weaker than 753) and a fair number of 853, which ISTR is even stronger than 753.

Likes For JohnDThompson:

#19

Junior Member

The problem with DIY alignment is figuring out what is the problem. I'm not a fan of Sheldon's string method. So you measure the distance of the string to the seat tube on both sids and there is a discrepancy. What's off? One might think that the rear dropouts are left or right of the center of the frame but how do you know? Maybe the down tube is leaning over to one side or maybe it's the seat tube leaning but not the head tube. Or the other way around. Or both. Or the front triangle is really 90 degrees from the threads of the bottom bracket shell and the dropouts are really off center. So the string method is only telling you something isn't right but it can't tell you where to fix what is wrong. There is a way to DIY if one wants to make a straight edge with an adjustable screw but that is beyond the scope of my post.

some of the accessories to check frame alignment on a cast iron table

a gaggle of straight edges that can be used in checking alignment

#20

Senior Member

Join Date: Apr 2005

Location: Ann Arbor, MI

Posts: 16,874

Bikes: 1980 Masi, 1984 Mondonico, 1984 Trek 610, 1980 Woodrup Giro, 2005 Mondonico Futura Leggera ELOS, 1967 PX10E, 1971 Peugeot UO-8

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1856 Post(s)

Liked 664 Times

in

506 Posts

Yeah it's "common knowledge" that 753 can't be cold-set, but what they really should have said is it's difficult to cold set. If it springs back without taking a set, it just means you didn't push hard enough. Any steel, no matter how strong, can be bent, unless it's too brittle and snaps. But the problem with 753 isn't brittleness, it's just very thinwall (in the frame tubes, not the fork), making it likely to buckle or kink, a.k.a. beercan failure mode.

That's not a problem with the forks though, which are no thinner than 531. They're just 531 blades that got heat-treated to make them stronger, a very dubious advantage since 531 forks are strong enough. (I'm mad at Reynolds for "chickening out" and not making the blades lighter, a missed opportunity.)

The 753 steerer is also the same gauge as 531 for most of its lenght, but where the 531 steerer gets a butt at the bottom, the 753 doesn't, so the lower part of the steerer is lighter than 531. This a 753 fork is just a little bit lighter than a 531 fork, but it's really very little, like an ounce? Sorrry, I once knew the weight difference but I forget now, someone here will know.

Even if the blades were infinitely strong, you can still bend the crown, so yeah those forks definitely can be cold-set. You just need a longer lever, and a stout vise! Or a 100+ lb alignment fixture like the one I made recently from vintage cast iron industrial parts,

That's a work-in-progress shot. It's now finished and bolted down to a very heavy steel table that's bolted into the concrete floor. Main difference from this pic is the handwheel is spaced upward an inch so you don't pinch your fingers against the crown. Unfortunately it only does 1" forks (I'm a committed C&V retrogrouch).

Mark B

That's not a problem with the forks though, which are no thinner than 531. They're just 531 blades that got heat-treated to make them stronger, a very dubious advantage since 531 forks are strong enough. (I'm mad at Reynolds for "chickening out" and not making the blades lighter, a missed opportunity.)

The 753 steerer is also the same gauge as 531 for most of its lenght, but where the 531 steerer gets a butt at the bottom, the 753 doesn't, so the lower part of the steerer is lighter than 531. This a 753 fork is just a little bit lighter than a 531 fork, but it's really very little, like an ounce? Sorrry, I once knew the weight difference but I forget now, someone here will know.

Even if the blades were infinitely strong, you can still bend the crown, so yeah those forks definitely can be cold-set. You just need a longer lever, and a stout vise! Or a 100+ lb alignment fixture like the one I made recently from vintage cast iron industrial parts,

That's a work-in-progress shot. It's now finished and bolted down to a very heavy steel table that's bolted into the concrete floor. Main difference from this pic is the handwheel is spaced upward an inch so you don't pinch your fingers against the crown. Unfortunately it only does 1" forks (I'm a committed C&V retrogrouch).

Mark B