First custom steel frame

#1

Member

Thread Starter

Join Date: Sep 2008

Location: Brisbane, Australia

Posts: 23

Bikes: Trek, Merida, Cannondale

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

First custom steel frame

Hi, I'm interested in a steel frame made to my dimensions. I contacted a local frame builder and discussed some of my preferences: essentially I'm looking for a tig welded frame, Reynolds tubing (of some description) and either a steel or carbon fork.

I'm 6'3" tall and weigh ~72kg (160 lbs). Intended use is mainly fast club rides and crit racing. The builder suggested Reynolds 853 tubing would be suitable but wasn't forthcoming about tubing diameters or other info.

Can anyone suggest a good combination for my weight and intended use?

I'm 6'3" tall and weigh ~72kg (160 lbs). Intended use is mainly fast club rides and crit racing. The builder suggested Reynolds 853 tubing would be suitable but wasn't forthcoming about tubing diameters or other info.

Can anyone suggest a good combination for my weight and intended use?

#2

Decrepit Member

IMHO, OS Reynolds 853 (28.6 TT and ST, 31.75 DT) would work well for your application. It is air-hardening, which makes it suitable for TIG welding. At your weight, a frame made from OS 853 would be strong, stiff, and light.

From the Reynolds 853 and 631 Technical Advice:

In August 1995, we introduced the first commercially available "air-hardening" steel. Until now, this alloy has been available for aerospace and automotive use, but the Reynolds engineers found a way of overcoming the obstacles in producing tubing that could be used by frame builders at a reasonable (non-aerospace!) cost.

And in September of 1997, Reynolds introduced our 631 cold-drawn alloy tubing. It has a strength-to-weight ration equal to aluminum, coupled with a high fatigue life. Like the air-hardening 853, 631 increases in strength after frame jointing. And the 631 Ultimate Tensile Stress (UTS) rating is 115,000 to 130,000 psi before jointing. Because 631 is not heat treated, it is a cost-competitive tubeset for a wide market who loves to ride steel.

Our 853 material, when heated above 850 C (as in high-temperature brazing or normal TIG welding), does not lose strength in the welded zone. Instead the joints actually increase in strength at these critical areas, thus permitting designers to use lighter tubes for a given stress, provide a higher safety factor -- or a combination of both. The 853 tubes have a UTS rating of 200,000 psi when delivered to the frame builder, and joint UTS ratings after assembly will be significantly higher. Framebuilders will be happy to know that chainstays and seatstays are now available in Reynolds 853.

Technical Advice

From tests done on 853 by a number of major bicycle companies, the fatigue life on framesets will be appreciably higher than conventional Chrome-Mo frames, suiting competitive riders who want to ride their frames for several seasons before they upgrade. Builders can use 853 for the main triangle and the chainstays and seatstays.

The mechanical properties of Reynolds 853 can be altered to suit particular strength level requirements. Unless particularly specified the mechanical properties will be as follows:

UTS: 81-94 Tsi (180-210 Ksi, 1250-1450 MPa

Elongation: 10% Min

Hardness: 400Hv Min (40HRC Min)

After welding or high temperature brazing, U.T.S. and Hardness properties in the joints can be significantly higher than those quoted above.

Machinability

Reynolds 853 is an inherently hard material and can therefore give problems with machining unless care is taken. Where possible, tungsten carbide-tipped tools should be used, however, high speed steel is acceptable provided plenty of lubricant and a relatively slow feed rate is used. Machining or drilling of tubes in the heat-affected zone after welding or brazing is extremely difficult due to increased strength from the air hardening.

Machining in these areas after welding or brazing is not recommended.

Manipulation

Reynolds 853 is a high strength material having limited manipulation capacity in the as-supplied form. Any ovaling/flattening or cranking operations that involve significant amounts of material deformation should not be undertaken. Reynolds are able to carry out these operations prior to heat treatment if required. Minor manipulation, i.e. setting or bending to fit can be carried out in the as-supplied heat treated condition.

Welding and brazing

Reynolds 853 can be welded or brazed using conventional jointing techniques used for other chrome molybdenum tubing currently available. The only rule of welding or brazing is that the jointing operation must be carried out above 850 C (1560 F) otherwise softening of the joints may occur. Reynolds 853 tubing can be welded or brazed to other chrome molybdenum tubes without any deleterious effects.

Silver soldering or low temperature brazing of Reynolds 853 should NOT be undertaken.

Recommended welding wire: 1% or 2% Cr Rod

Recommended braze metal: Per AWS Classification RBCuZn Type

The above recommendations also apply to the fixing of frame fittings.

Tips on what you MUST do with Reynolds 853:

1. Weld or braze the material at a temperature above 850 C (1560 F).

2. Use tungsten Carbide cutting tools or high speed steel, well lubricated and with a relatively slow feed rate.

3. Allow to cool naturally away from draughts after jointing operations.

Tips on what you MUST NOT do with Reynolds 853:

1. Attempt to machine or drill in the areas of the heat affected zone after welding or brazing as these areas will be extremely hard.

2. Attempt to undertake severe manipulation of tube section in the as-supplied heat treated condition.

3. Do not joint using silver solder or other low temperature braze below 850 C (1560 F).

4. Force cooling with air, oil or water or any other medium from jointing operations.

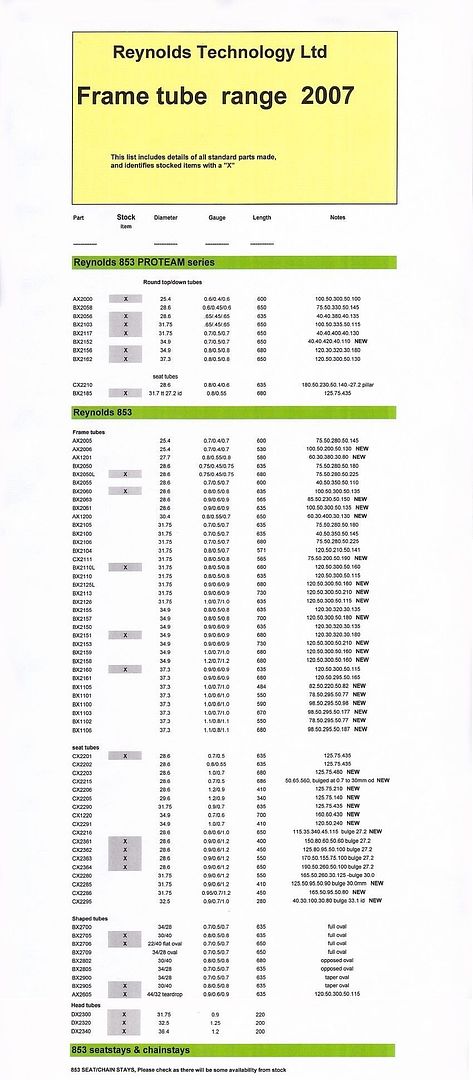

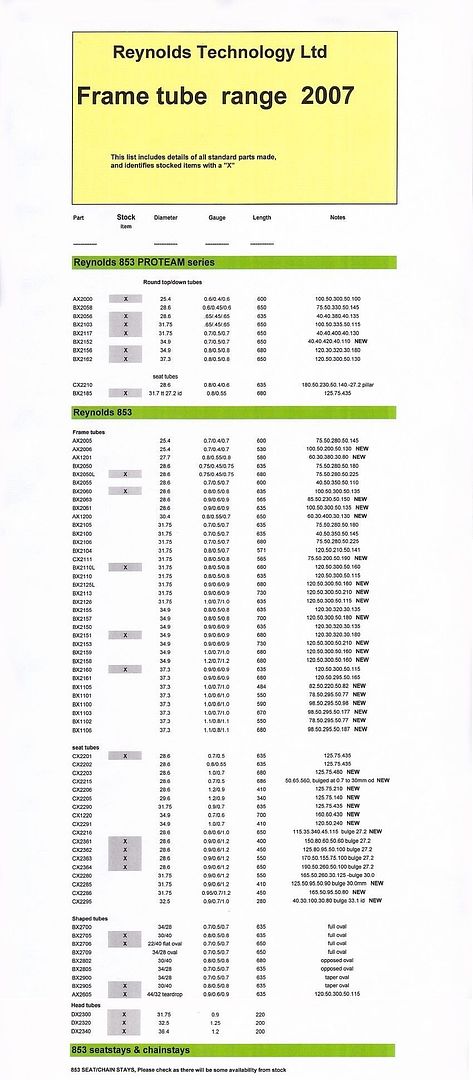

Here is the range of 853 tubing including diameters and butting:

From the Reynolds 853 and 631 Technical Advice:

In August 1995, we introduced the first commercially available "air-hardening" steel. Until now, this alloy has been available for aerospace and automotive use, but the Reynolds engineers found a way of overcoming the obstacles in producing tubing that could be used by frame builders at a reasonable (non-aerospace!) cost.

And in September of 1997, Reynolds introduced our 631 cold-drawn alloy tubing. It has a strength-to-weight ration equal to aluminum, coupled with a high fatigue life. Like the air-hardening 853, 631 increases in strength after frame jointing. And the 631 Ultimate Tensile Stress (UTS) rating is 115,000 to 130,000 psi before jointing. Because 631 is not heat treated, it is a cost-competitive tubeset for a wide market who loves to ride steel.

Our 853 material, when heated above 850 C (as in high-temperature brazing or normal TIG welding), does not lose strength in the welded zone. Instead the joints actually increase in strength at these critical areas, thus permitting designers to use lighter tubes for a given stress, provide a higher safety factor -- or a combination of both. The 853 tubes have a UTS rating of 200,000 psi when delivered to the frame builder, and joint UTS ratings after assembly will be significantly higher. Framebuilders will be happy to know that chainstays and seatstays are now available in Reynolds 853.

Technical Advice

From tests done on 853 by a number of major bicycle companies, the fatigue life on framesets will be appreciably higher than conventional Chrome-Mo frames, suiting competitive riders who want to ride their frames for several seasons before they upgrade. Builders can use 853 for the main triangle and the chainstays and seatstays.

The mechanical properties of Reynolds 853 can be altered to suit particular strength level requirements. Unless particularly specified the mechanical properties will be as follows:

UTS: 81-94 Tsi (180-210 Ksi, 1250-1450 MPa

Elongation: 10% Min

Hardness: 400Hv Min (40HRC Min)

After welding or high temperature brazing, U.T.S. and Hardness properties in the joints can be significantly higher than those quoted above.

Machinability

Reynolds 853 is an inherently hard material and can therefore give problems with machining unless care is taken. Where possible, tungsten carbide-tipped tools should be used, however, high speed steel is acceptable provided plenty of lubricant and a relatively slow feed rate is used. Machining or drilling of tubes in the heat-affected zone after welding or brazing is extremely difficult due to increased strength from the air hardening.

Machining in these areas after welding or brazing is not recommended.

Manipulation

Reynolds 853 is a high strength material having limited manipulation capacity in the as-supplied form. Any ovaling/flattening or cranking operations that involve significant amounts of material deformation should not be undertaken. Reynolds are able to carry out these operations prior to heat treatment if required. Minor manipulation, i.e. setting or bending to fit can be carried out in the as-supplied heat treated condition.

Welding and brazing

Reynolds 853 can be welded or brazed using conventional jointing techniques used for other chrome molybdenum tubing currently available. The only rule of welding or brazing is that the jointing operation must be carried out above 850 C (1560 F) otherwise softening of the joints may occur. Reynolds 853 tubing can be welded or brazed to other chrome molybdenum tubes without any deleterious effects.

Silver soldering or low temperature brazing of Reynolds 853 should NOT be undertaken.

Recommended welding wire: 1% or 2% Cr Rod

Recommended braze metal: Per AWS Classification RBCuZn Type

The above recommendations also apply to the fixing of frame fittings.

Tips on what you MUST do with Reynolds 853:

1. Weld or braze the material at a temperature above 850 C (1560 F).

2. Use tungsten Carbide cutting tools or high speed steel, well lubricated and with a relatively slow feed rate.

3. Allow to cool naturally away from draughts after jointing operations.

Tips on what you MUST NOT do with Reynolds 853:

1. Attempt to machine or drill in the areas of the heat affected zone after welding or brazing as these areas will be extremely hard.

2. Attempt to undertake severe manipulation of tube section in the as-supplied heat treated condition.

3. Do not joint using silver solder or other low temperature braze below 850 C (1560 F).

4. Force cooling with air, oil or water or any other medium from jointing operations.

Here is the range of 853 tubing including diameters and butting:

#3

Member

Thread Starter

Join Date: Sep 2008

Location: Brisbane, Australia

Posts: 23

Bikes: Trek, Merida, Cannondale

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Thanks Scooper. Is there any benefit going with a fatter down tube, say 1-3/8" (34.9mm), and oversized seat stays? I'm concerned that it might feel like a noodle in a sprint, on the other hand, I don't want something that is unyielding on long rides either.

#4

Decrepit Member

Personally, at 160 pounds and at your height (guessing a ~60cm frame size), I don't think you'd find an 853 frame with standard OS tubing sizes too flexy even when sprinting, and bigger tubes might make it uncomfortably stiff on longer rides. This is exactly the kind of question you should be asking your framebuilder after discussing the kind of riding you anticipate and your concerns about frame stiffness while sprinting vs. tradeoffs in comfort on longer rides.

#6

Banned.

Join Date: Jun 2004

Location: Torrance, CA

Posts: 3,061

Bikes: Homebuilt steel

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 2193 Post(s)

Liked 425 Times

in

337 Posts

60 cm is a pretty big frame so you might consider moving one step thicker than standard with the down tube. This will add a little weight but make the frame stiffer in sprints.

I have a couple of frames with 35mm down tubes and it's noticeably stiffer (which I prefer) than a regular OS frame.

I have a couple of frames with 35mm down tubes and it's noticeably stiffer (which I prefer) than a regular OS frame.

#7

Member

Join Date: Jul 2008

Location: Indianapolis, IN

Posts: 37

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

You talked to a local builder. These are decisions your builder needs/should make. If the builder doesn't have an opinion on what tubes should be used for you go see another builder.

Seeking advice on the Internet for certain issues makes good sense. Seeking advice on proper tubing selection for your custom frame is not one of them.

This is, of course, entirely my opinion and yours may differ.

Seeking advice on the Internet for certain issues makes good sense. Seeking advice on proper tubing selection for your custom frame is not one of them.

This is, of course, entirely my opinion and yours may differ.

#8

Banned.

Join Date: Jun 2004

Location: Torrance, CA

Posts: 3,061

Bikes: Homebuilt steel

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 2193 Post(s)

Liked 425 Times

in

337 Posts

You talked to a local builder. These are decisions your builder needs/should make. If the builder doesn't have an opinion on what tubes should be used for you go see another builder.

Seeking advice on the Internet for certain issues makes good sense. Seeking advice on proper tubing selection for your custom frame is not one of them.

This is, of course, entirely my opinion and yours may differ.

Seeking advice on the Internet for certain issues makes good sense. Seeking advice on proper tubing selection for your custom frame is not one of them.

This is, of course, entirely my opinion and yours may differ.

#9

Member

Thread Starter

Join Date: Sep 2008

Location: Brisbane, Australia

Posts: 23

Bikes: Trek, Merida, Cannondale

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I'll have a chat with the builder naturally; I was mainly interested in soliciting other opinions. We did discuss this briefly and he felt that a) since I've never ridden steel before; b) I've mainly ridden stiff alloy Cannondale's to date and; 3) I'm interested in racing, that he would err towards stiffer.

#10

Member

Join Date: Jul 2008

Location: Indianapolis, IN

Posts: 37

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I strongly disagree with this. Everyone should be educated when talking to a builder and if they shy away from questions about tube selection, or suggest options different than what your research shows is appropriate, you should question them and expect answers until all the pieces come together. Don't be a sheep bowing down to the framebuilder god. Knowledge is power.

Builder: "I am going to use XYZ tube for your DT."

Customer: "I have been doing some research on Internet message boards and I think you should use tube ABC instead."

My opinion is that the correct response from the builder is, "Appreciate your due diligence but in your case I believe tube XYZ is a better solution. If you really want to dig your heels in on the tube choice feel free to contact one of the many builders out there that would happily accept your deposit."

Now, if the builder doesn't have an opinion on tubing selection or, even worse, asks the customer for their suggestions on tubing selection, seek another builder.

#11

Banned.

Join Date: Jun 2004

Location: Torrance, CA

Posts: 3,061

Bikes: Homebuilt steel

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 2193 Post(s)

Liked 425 Times

in

337 Posts

Reasonable people can disagree on this and I do wholeheartedly agree with you that customer knowledge is important. My concern is what happens if you the customer's opinion on optimal tubing selection differs from the builder. There are no cut and dry 100% correct answers to these situations.

Builder: "I am going to use XYZ tube for your DT."

Customer: "I have been doing some research on Internet message boards and I think you should use tube ABC instead."

My opinion is that the correct response from the builder is, "Appreciate your due diligence but in your case I believe tube XYZ is a better solution. If you really want to dig your heels in on the tube choice feel free to contact one of the many builders out there that would happily accept your deposit."

Now, if the builder doesn't have an opinion on tubing selection or, even worse, asks the customer for their suggestions on tubing selection, seek another builder.

Builder: "I am going to use XYZ tube for your DT."

Customer: "I have been doing some research on Internet message boards and I think you should use tube ABC instead."

My opinion is that the correct response from the builder is, "Appreciate your due diligence but in your case I believe tube XYZ is a better solution. If you really want to dig your heels in on the tube choice feel free to contact one of the many builders out there that would happily accept your deposit."

Now, if the builder doesn't have an opinion on tubing selection or, even worse, asks the customer for their suggestions on tubing selection, seek another builder.

A much better approach would be for the builder to take a little time and explain some of the different mechanical properties of the materials in question and explain how the stiffness is affected by wall thickness, etc. Explain to the customer why your tubing choice is better in a way they can understand and then you can win the customer over to your way of thinking. Telling the customer to go elsewhere if they question you is a great way to go out of business.

Last edited by Nessism; 02-16-10 at 05:20 PM.

#12

Member

Join Date: Jul 2008

Location: Indianapolis, IN

Posts: 37

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

As Carl Strong has been known to say, "some customers need to be fired".

Like I said, reasonable people are free to disagree on this and I respect your opinion as I hope you respect mine. Pick the business model that works best for you and run with it.

Buy the builder, buy the expertise, buy the experience, buy the journey. Don't buy the tubes.

Like I said, reasonable people are free to disagree on this and I respect your opinion as I hope you respect mine. Pick the business model that works best for you and run with it.

Buy the builder, buy the expertise, buy the experience, buy the journey. Don't buy the tubes.

#13

Banned.

Join Date: Jun 2004

Location: Torrance, CA

Posts: 3,061

Bikes: Homebuilt steel

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 2193 Post(s)

Liked 425 Times

in

337 Posts

As Carl Strong has been known to say, "some customers need to be fired".

Like I said, reasonable people are free to disagree on this and I respect your opinion as I hope you respect mine. Pick the business model that works best for you and run with it.

Buy the builder, buy the expertise, buy the experience, buy the journey. Don't buy the tubes.

Like I said, reasonable people are free to disagree on this and I respect your opinion as I hope you respect mine. Pick the business model that works best for you and run with it.

Buy the builder, buy the expertise, buy the experience, buy the journey. Don't buy the tubes.

#14

Member

Join Date: Jul 2008

Location: Indianapolis, IN

Posts: 37

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Those are perfectly valid questions to ask. Asking questions are welcomed. My question is what happens when, after discussions with your builder, there remains disagreement on tube choice? Who should win out?

If we were talking about paint choice instead of tube choice we wouldn't be having this discussion. Some decisions are in the lap of the builder and others are in the lap of the customer.

If we were talking about paint choice instead of tube choice we wouldn't be having this discussion. Some decisions are in the lap of the builder and others are in the lap of the customer.

#15

Banned

Join Date: Aug 2005

Posts: 5,115

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 2 Times

in

1 Post

I sorta agree with both sides of the "let's just talk this out until everyone is on the same page" thing. Evidence suggests that unless you are metalurgist level you can't really "understand" these issues. Even at that level there are areas of practice that can bend the rules quite successfully. "There are more things in heaven and earth... Than are dreamt of in your philosophy".

I think the Tigability thing is largely just marketing, since when did making stuff really hard for higher strength become a huge objective in these kinds of structure? 100 years of practice is all in the opposite direction. What it really shows (as far as I can tell) is that even when you go in the opposite direction of sense, the process is well strong enough to deal with it, given the parameters of these joints. That has always been the case, but due to the huge investment in lug theory this industry just keeps digging hoping to reconcile two contradictory points that often crop up in the same product line, or product. 853 is mostly superior due to the higher strength of the tube outside the weld zone, which allows lighter structures to be built, when well designed, however joined.

If one really wants to get into it one would have to look at the structure in the casting like weld face/reenforcement, in the fusion zone where the base metal and filler mixed, in adjacent base metal that was super heated, in adjacent metal that was not heated above the trans temp... Just for starters.

I think the Tigability thing is largely just marketing, since when did making stuff really hard for higher strength become a huge objective in these kinds of structure? 100 years of practice is all in the opposite direction. What it really shows (as far as I can tell) is that even when you go in the opposite direction of sense, the process is well strong enough to deal with it, given the parameters of these joints. That has always been the case, but due to the huge investment in lug theory this industry just keeps digging hoping to reconcile two contradictory points that often crop up in the same product line, or product. 853 is mostly superior due to the higher strength of the tube outside the weld zone, which allows lighter structures to be built, when well designed, however joined.

If one really wants to get into it one would have to look at the structure in the casting like weld face/reenforcement, in the fusion zone where the base metal and filler mixed, in adjacent base metal that was super heated, in adjacent metal that was not heated above the trans temp... Just for starters.