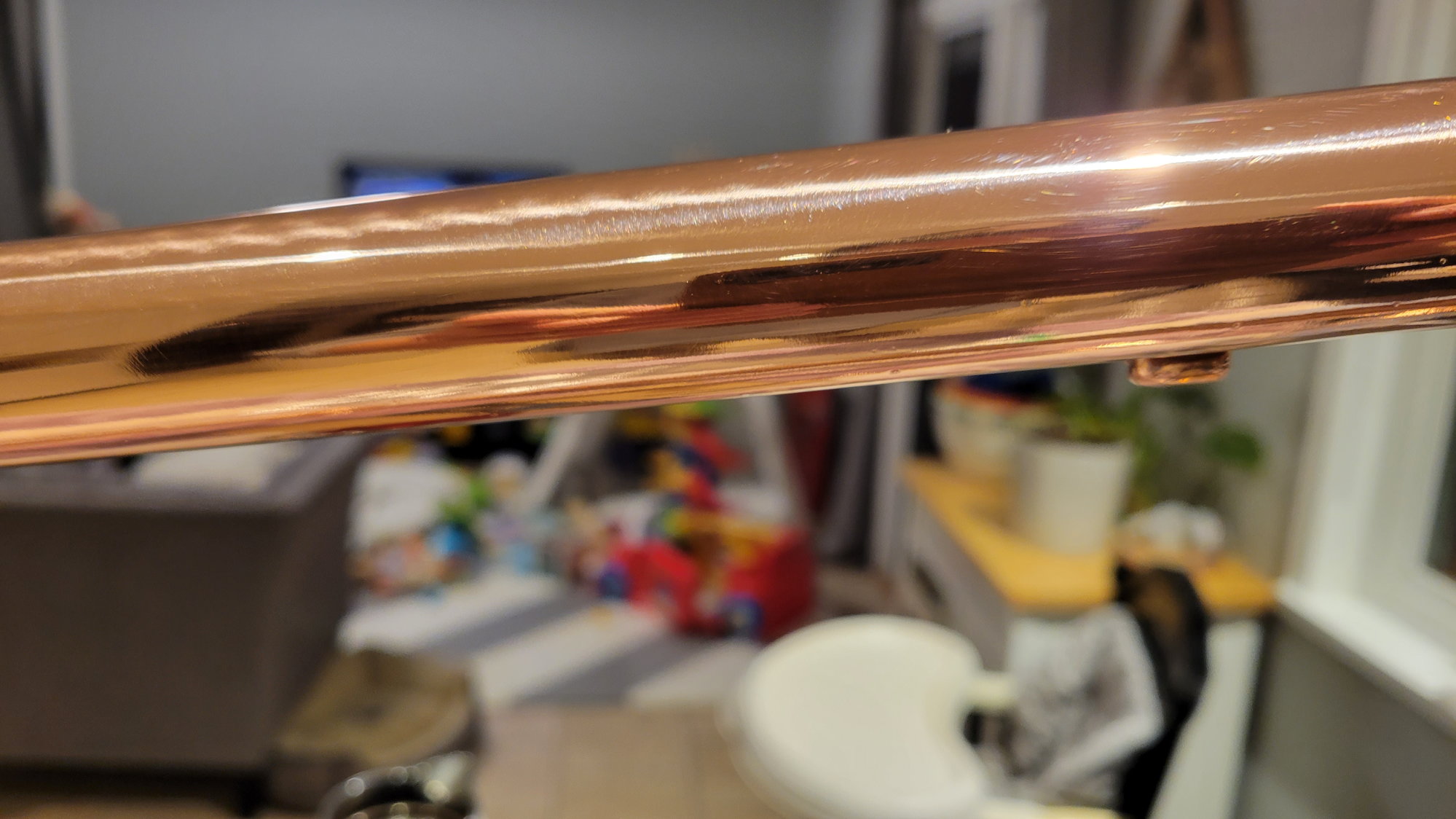

Copper plate and other alternative finishes

#26

Back to being a Clyde....

Join Date: Oct 2004

Location: Santa Clara

Posts: 1,544

Bikes: Giant OCR1(specialized carbon seatpost,Terry Fly sadle, Syntace C2): Leader TT frame, Easton EC70fork, Aerolite bars, nashbar bullhorn, Titan Wheels: Fuji Track Pro(2003)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Ken,

How prevelant are Electroless Nickel platers(do you know of any that do bikes)? Any idea how much a frame/fork would be?

How prevelant are Electroless Nickel platers(do you know of any that do bikes)? Any idea how much a frame/fork would be?

#27

Doortrapper

Join Date: Nov 2005

Location: Syracuse, NY

Posts: 892

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Originally Posted by isotopesope

i'd really like to try gun blueing (sp?) on a steel frame.

Did you see the FGG bike with the over heated steel tubes? I'd expect it to look like that, but not subject to premature fatuige.

#28

\||||||/

Join Date: Mar 2006

Location: pdx

Posts: 1,360

Bikes: highly modified specialized crossroads and GT hybrid (really a [formerly] 12-speed bmx cruiser, made before 'hybrid' took on its current meaning), as yet unmodified redline 925, couple of other projects

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

actually, there are lots of interesting gun finishes - green parkerizing from some US WWII firearms, glock's tennifer and beretta's burnition (sp?)among others... all of them are thin rust-resistant (some HIGHLY rust-resistant) coatings for steel.

a parkerized frame would be badass.

a parkerized frame would be badass.

#29

King of the Hipsters

Join Date: Jan 2005

Location: Bend, Oregon

Posts: 2,128

Bikes: Realm Cycles Custom

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

Over one hundred years ago some European gun makers offered a finish called slow rust browning.

I have tried to find a description of the process on the internet, but the links lead to chemical processes.

Slow rust browning requires a cool, humid room, and vigorously wiping every bit of the steel's surface with a clean, damp, lightly-oiled cloth twice a day, without fail.

One day without wiping and the steel might rust and pit.

The steel will gradually darken, perhaps first going through a straw-colored phase.

It may stop at brown or go on to a dark grey.

Once the color-change stops, the steel will have substantial resistance to rusting and pitting.

One often sees this finish unintentionally created on steel farm tools that get handled daily in cool, humid environments.

The steel turns dark grey or brown, but it doesn't rust where frequently touched by human hands.

This process takes about two weeks of patience and diligence, but it works and, with an occasional rub down with a lightly-oiled cloth, will protect the steel from everything except neglect.

For an environmentally friendly and aesthetically-pleasing oil, consider Camellia oil, made from the plant of the same name.

Camellia oil is a favorite traditional tool treatment among both samurai and woodworkers, used both for preventing corrosion and for easing chisels and knives through their work. Light and odorless, the oil is non-staining and doesn't affect glue-up. Use a light wipe on all your steel tools to keep them clean & shiny.

https://www.tools-for-woodworking.com...ROD&ProdID=756

For that matter, a person could leave a bike frame in its raw metal state and wipe it down once or twice a week with Camellia oil, and just see what happens.

The steel shouldn't rust if regularly and carefully wiped down with Camellia oil.

I have tried to find a description of the process on the internet, but the links lead to chemical processes.

Slow rust browning requires a cool, humid room, and vigorously wiping every bit of the steel's surface with a clean, damp, lightly-oiled cloth twice a day, without fail.

One day without wiping and the steel might rust and pit.

The steel will gradually darken, perhaps first going through a straw-colored phase.

It may stop at brown or go on to a dark grey.

Once the color-change stops, the steel will have substantial resistance to rusting and pitting.

One often sees this finish unintentionally created on steel farm tools that get handled daily in cool, humid environments.

The steel turns dark grey or brown, but it doesn't rust where frequently touched by human hands.

This process takes about two weeks of patience and diligence, but it works and, with an occasional rub down with a lightly-oiled cloth, will protect the steel from everything except neglect.

For an environmentally friendly and aesthetically-pleasing oil, consider Camellia oil, made from the plant of the same name.

Camellia oil is a favorite traditional tool treatment among both samurai and woodworkers, used both for preventing corrosion and for easing chisels and knives through their work. Light and odorless, the oil is non-staining and doesn't affect glue-up. Use a light wipe on all your steel tools to keep them clean & shiny.

https://www.tools-for-woodworking.com...ROD&ProdID=756

For that matter, a person could leave a bike frame in its raw metal state and wipe it down once or twice a week with Camellia oil, and just see what happens.

The steel shouldn't rust if regularly and carefully wiped down with Camellia oil.

#30

seeking simple

Join Date: Nov 2003

Location: South Dakota

Posts: 1,031

Bikes: Yes!

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Originally Posted by wangster

cheaper way to speed up the patina process is to just piss on it... really... it works... long story, but it works. The question is do you really want to piss on your bike?

Heh.

Likes For longhitv:

#32

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,902

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4802 Post(s)

Liked 3,922 Times

in

2,551 Posts

If you nickle plate your frame and it is quality steel, make sure the plater knows to heat treat it properly afterwards. I had a new Columbus SL fork nickle plated and bead blasted. 3 years later both blades developed cracks totaling a full circumference at the edge of the fork crown. (Builder did not know yet the importance of the heat treat. Plater knew but never said (maybe because he feared mentioning the additional $60 would cost him the job).

Builder learned when he took my fork to a forensic engineer at the local university. We all learned. But, man, that was close! Fate that day meant I didn't blast around my favorite downhill corner, braking very hard coming into it.

Builder learned when he took my fork to a forensic engineer at the local university. We all learned. But, man, that was close! Fate that day meant I didn't blast around my favorite downhill corner, braking very hard coming into it.

Likes For 79pmooney:

#33

Quixote

Join Date: Jun 2019

Location: New York

Posts: 164

Bikes: Bianchi Pista Concept 05, Level 2014

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 44 Post(s)

Liked 78 Times

in

60 Posts

I used to have a nickel plated Reynolds Wishbone - long long time ago - it was a very attractive durable finish and a fun bike.

#34

Senior Member

Join Date: Nov 2010

Posts: 3,504

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 586 Post(s)

Liked 612 Times

in

447 Posts

If you nickle plate your frame and it is quality steel, make sure the plater knows to heat treat it properly afterwards. I had a new Columbus SL fork nickle plated and bead blasted. 3 years later both blades developed cracks totaling a full circumference at the edge of the fork crown. (Builder did not know yet the importance of the heat treat. Plater knew but never said (maybe because he feared mentioning the additional $60 would cost him the job).

Builder learned when he took my fork to a forensic engineer at the local university. We all learned. But, man, that was close! Fate that day meant I didn't blast around my favorite downhill corner, braking very hard coming into it.

Builder learned when he took my fork to a forensic engineer at the local university. We all learned. But, man, that was close! Fate that day meant I didn't blast around my favorite downhill corner, braking very hard coming into it.

Another thing to be aware of is there are portions of the frame where you don't want plating, such as inside the bottom bracket. Protect the threads. You can always have them chased afterwards, but why if your don't need to? Also, on forks, make sure they mask off the entire steerer. I had a fork chromed and while it turned out fabulous, there was a ring of chrome at the bottom of the steerer tube that prevented the bottom of the headset from seating. Had to have it ground off. Chrome is remarkably hard and difficult to remove when you want to.

#35

Senior Member

I've seen chrome, copper, powder-coated, rattlecan painted, plain steel with a clear coat and a few others. The nickel coated bike described above sounds interesting for sure.

However, the one bike finish I have never seen is a genuine blued finish on steel. I am sure it is possible to do with the right equipment but I think a deeply blued steel bike with chromed lugs (would they be even possible?) would look spectacular. I'm not talking about a DIY but have it professionally done. And when I say deeply blued I mean vintage Colt or Smith & Wesson revolver deep blue.

--

However, the one bike finish I have never seen is a genuine blued finish on steel. I am sure it is possible to do with the right equipment but I think a deeply blued steel bike with chromed lugs (would they be even possible?) would look spectacular. I'm not talking about a DIY but have it professionally done. And when I say deeply blued I mean vintage Colt or Smith & Wesson revolver deep blue.

--

Last edited by drlogik; 02-21-23 at 05:54 PM.

#36

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,902

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4802 Post(s)

Liked 3,922 Times

in

2,551 Posts

Might be good to give details on what "heat treatment" looks like. That way if someone does visit a plating company they will know exactly what to tell them.

Another thing to be aware of is there are portions of the frame where you don't want plating, such as inside the bottom bracket. Protect the threads. You can always have them chased afterwards, but why if your don't need to? Also, on forks, make sure they mask off the entire steerer. I had a fork chromed and while it turned out fabulous, there was a ring of chrome at the bottom of the steerer tube that prevented the bottom of the headset from seating. Had to have it ground off. Chrome is remarkably hard and difficult to remove when you want to.

Another thing to be aware of is there are portions of the frame where you don't want plating, such as inside the bottom bracket. Protect the threads. You can always have them chased afterwards, but why if your don't need to? Also, on forks, make sure they mask off the entire steerer. I had a fork chromed and while it turned out fabulous, there was a ring of chrome at the bottom of the steerer tube that prevented the bottom of the headset from seating. Had to have it ground off. Chrome is remarkably hard and difficult to remove when you want to.

I didn't have to sweat the other details. Threads, etc. Fork went back to the builder for fork and headset and onto frame before I saw it.

Likes For 79pmooney: