Should I drill and tap my stem for a bell?

#1

working on my sandal tan

Thread Starter

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

Should I drill and tap my stem for a bell?

All the cool kids in my cycling clubs have bells (which probably tells you something about the clubs I ride with.) But due to my handlebar bag and non-aero brake cables, any place I can mount one of my clamp-on bells puts the striker in an awkward place.

I've always admired the way some constructeurs mounted bells to the stem, and that would certainly get it out of the way. But I don't want to create a stress riser in my stem and crash and die as a result. Any recommendations pro/con?

Any recommendations pro/con?

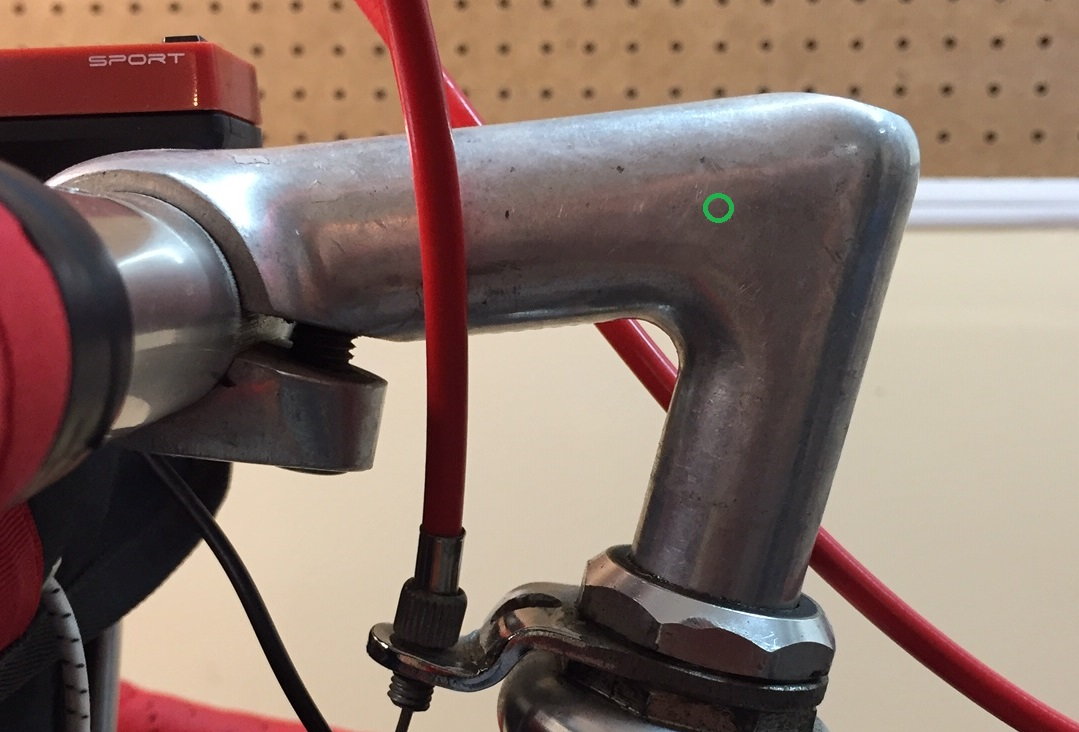

Thanks. Stem is one of these guys:

I've always admired the way some constructeurs mounted bells to the stem, and that would certainly get it out of the way. But I don't want to create a stress riser in my stem and crash and die as a result.

Any recommendations pro/con?

Any recommendations pro/con?Thanks. Stem is one of these guys:

__________________

RUSA #7498

Originally Posted by noglider

People in this forum are not typical.

Last edited by ThermionicScott; 09-04-21 at 02:31 PM.

#2

Senior Member

Join Date: Dec 2005

Posts: 17,146

Mentioned: 481 Post(s)

Tagged: 0 Thread(s)

Quoted: 3803 Post(s)

Liked 6,639 Times

in

2,602 Posts

I have several clamp on Crane bells on stems. You don’t have a ton of real estate there but likely enough.

Likes For nlerner:

#3

Senior Member

Join Date: Jun 2008

Location: Louisville, KY

Posts: 13,443

Mentioned: 33 Post(s)

Tagged: 0 Thread(s)

Quoted: 4224 Post(s)

Liked 2,944 Times

in

1,803 Posts

Yeah, why not just clamp on a Crane bell?

Likes For himespau:

#4

Me duelen las nalgas

Join Date: Aug 2015

Location: Texas

Posts: 13,513

Bikes: Centurion Ironman, Trek 5900, Univega Via Carisma, Globe Carmel

Mentioned: 199 Post(s)

Tagged: 0 Thread(s)

Quoted: 4559 Post(s)

Liked 2,802 Times

in

1,800 Posts

The original riser stem on my '93 Univega was drilled with a stepped hole that served as the cable hanger/stop for the front cantilever brake. Didn't seem to do any harm.

Likes For canklecat:

#5

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,630

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4677 Post(s)

Liked 5,790 Times

in

2,279 Posts

I wouldn't drill an aluminum stem, too much unknown risk.

Try like Neal's setup, I think you'll have enough room.

Try like Neal's setup, I think you'll have enough room.

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

Likes For gugie:

#6

Senior Member

Join Date: Jun 2008

Location: Louisville, KY

Posts: 13,443

Mentioned: 33 Post(s)

Tagged: 0 Thread(s)

Quoted: 4224 Post(s)

Liked 2,944 Times

in

1,803 Posts

Velo Orange also sells a quill stem that's drilled and tapped for a bell if you want to go that route. I think it's one of the few stems that they actually have in stock with the parts shortages.

#7

Senior Member

Join Date: Sep 2017

Location: Eastern Shore, MD

Posts: 2,106

Bikes: Road ready: 1993 Koga Miyata City Liner Touring Hybrid, 1989 Centurion Sport DLX, "I Blame GP" Bridgestone CB-1. Projects: Yea, I got a problem....

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 753 Post(s)

Liked 735 Times

in

421 Posts

I was going to say the same thing, but while I would assume that drilling and tapping a small hole on the side of a stem would be "fine" Im pretty sure the structual effects are different from drilling a stem for a cable hanger.

#8

Senior Member

I have done it with no ill effects. It’s a pretty small hole. And it’s round. I believe those two things are in one’s favor. But I am one data point. Fwiw.

Likes For due ruote:

#9

Senior Member

Join Date: Sep 2005

Location: Oakland, CA

Posts: 3,265

Bikes: '82 Univega Competizione, '72 Motobecane Grand Record, '83 Mercian KOM Touring, '85 Univega Alpina Uno, '76 Eisentraut Limited

Mentioned: 57 Post(s)

Tagged: 0 Thread(s)

Quoted: 1088 Post(s)

Liked 1,205 Times

in

701 Posts

If the main objective is to have a bell and avoid dying, then I have had very good luck with this cheap Zefal bell. I love these — very small, very loud, pretty chime. If you’re after a brass bell, then I agree with others that the extra expense of a clamp bell is worth the peace of mind in not drilling your stem.

EDIT: Apparently, it's called the "Piing" -- yes, with a double "i".

EDIT: Apparently, it's called the "Piing" -- yes, with a double "i".

Last edited by noobinsf; 09-04-21 at 05:30 PM.

#10

señor miembro

Join Date: Dec 2018

Location: Pac NW

Posts: 6,601

Bikes: '70s - '80s Campagnolo

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 3869 Post(s)

Liked 6,454 Times

in

3,192 Posts

What about using a headband? I know it would be a little loud, but maybe you can wear earbuds.

#11

working on my sandal tan

Thread Starter

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

Thanks for the sanity check, guys. If there had been more "sure, there's plenty of meat in those stems, go for it" responses I might have, but I would probably always be a bit nervous about it.

Time to shop for a different bell...

Time to shop for a different bell...

#12

Senior Member

Join Date: Apr 2007

Location: Ottawa, Canada

Posts: 777

Bikes: Raleigh Classic 15, 84; Miyata 912, 85; Miyata Ridge Runner SE, 85; Miyata 610, 86; Miyata 100M, 86; Miyata Valley Runner, 88; Miyata Triple Cross, 89; GT Karakoram, 90; Miyata Elevation 300, 91; Marinoni Touring, 95; Long Haul Trucker, 2013

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 159 Post(s)

Liked 133 Times

in

80 Posts

I'm having trouble understanding how you could have room for a bell but not a clamp.

Likes For John Nolan:

#13

Senior Member

Join Date: Nov 2013

Location: Near Pottstown, PA: 30 miles NW of Philadelphia

Posts: 2,185

Bikes: 2 Trek Mtn, Cannondale R600 road, 6 vintage road bikes

Mentioned: 83 Post(s)

Tagged: 0 Thread(s)

Quoted: 472 Post(s)

Liked 1,028 Times

in

404 Posts

I've come to like the old all steel Reich "ice cream truck" bells and now have two. Most people can hear them fine and many respond with a smile and a wave. Let's just say that they can't hear me call out a warning very well any more. Both of my bells use their original clamps and they easily fit on the vertical portion of stems on the 4 bikes I use them on. I zip tied a length of inner tube rubber to ID of each clamp to prevent rotation and protect the stem. Each clamp uses a cap screw n allen key to sung the clamp and it only takes a minute or two to install. Just part of the prep for any ride. Bell, tool bag, water bottle, tire pressures. Nice bright chrome on each too.

I see see no reason to drill a hole in a stem.

I see see no reason to drill a hole in a stem.

Last edited by Prowler; 09-05-21 at 08:42 AM.

Likes For Prowler:

#14

Senior Member

Join Date: May 2008

Location: Fredericksburg, Va

Posts: 9,579

Bikes: '65 Frejus TDF, '73 Bottecchia Giro d'Italia, '83 Colnago Superissimo, '84 Trek 610, '84 Trek 760, '88 Pinarello Veneto, '88 De Rosa Pro, '89 Pinarello Montello, '94 Burley Duet, 97 Specialized RockHopper, 2010 Langster, Tern Link D8

Mentioned: 73 Post(s)

Tagged: 0 Thread(s)

Quoted: 1607 Post(s)

Liked 2,213 Times

in

1,103 Posts

Want to be noticed? works on cars occasionally.

Amazon.com : Hornit dB140 Bike Horn with Remote Trigger for Cycling (dB140) : Bike Horns : Sports & Outdoors

Other wise I find the full size Crane to be loud and friendly enough as a worning.

Amazon.com : Hornit dB140 Bike Horn with Remote Trigger for Cycling (dB140) : Bike Horns : Sports & Outdoors

Other wise I find the full size Crane to be loud and friendly enough as a worning.

__________________

Bikes don't stand alone. They are two tired.

Bikes don't stand alone. They are two tired.

#15

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,047

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3011 Post(s)

Liked 3,786 Times

in

1,405 Posts

You do know if you drill a hole then fill said hole with a screw, you have pretty much removed any potential stress riser.

Would a unfilled 3mm hole cause for concern? Only if you drilled it into a crabon stem. I believe it would assplode while drilling said hole. I read that on the internet.

Would a unfilled 3mm hole cause for concern? Only if you drilled it into a crabon stem. I believe it would assplode while drilling said hole. I read that on the internet.

Likes For iab:

#16

Senior Member

Join Date: Jun 2008

Location: Louisville, KY

Posts: 13,443

Mentioned: 33 Post(s)

Tagged: 0 Thread(s)

Quoted: 4224 Post(s)

Liked 2,944 Times

in

1,803 Posts

Likes For himespau:

#17

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,047

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3011 Post(s)

Liked 3,786 Times

in

1,405 Posts

Also, without knowing your intended location for the hole, the severity of any potential stress riser cannot be known and will continue rampant speculation in this thread. So by all means, don't tell us.

#19

Senior Member

Join Date: Oct 2010

Posts: 8,515

Mentioned: 69 Post(s)

Tagged: 0 Thread(s)

Quoted: 3241 Post(s)

Liked 2,512 Times

in

1,510 Posts

You can't mount it with a thick rubber band thing like most front/tail lights use?

#20

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

I've drilled and tapped 5 stems for bells: Cinelli 1A, two Technomics, a Technomic Deluxe, and an SR Custom. That's all my bikes. I don't think it's a problem. A lot of them are also drilled for the brake cable as well.

@ThermionicScott That one you posted in your original post looks like an SR Custom. Those are forged, and especially beefy based on my experience. And like I said, I drilled one, both for a cable stop and a bell.

The original René Herse stem on my tandem is aluminum with a drilled and tapped hole for a bell also.

I talked to a couple machinists and none of them thought it would fail. I did this last year. Here are a few.

@ThermionicScott That one you posted in your original post looks like an SR Custom. Those are forged, and especially beefy based on my experience. And like I said, I drilled one, both for a cable stop and a bell.

The original René Herse stem on my tandem is aluminum with a drilled and tapped hole for a bell also.

I talked to a couple machinists and none of them thought it would fail. I did this last year. Here are a few.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Last edited by scarlson; 09-05-21 at 08:45 AM.

Likes For scarlson:

#21

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,181

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1562 Post(s)

Liked 1,285 Times

in

856 Posts

Reasoning is all wrong, as is trusting a machinist in this case.

If a stem wasn't tested with the drilled hole by the manufacturer, then I would not have a drilled hole in my stem.

The OP's pictured stem is a melt-forged or "pressure cast" part imo, looks very strong but I wouldn't drill it either way.

A big (very big) factor in terms of metal parts breakage vs. not breakage will always be the operating conditions including 1) the duration of service i.e. the # of load cycles and 2) the level of tension stress in any aluminum clamping portion where such tension is constant and could lead to creep-yield failure.

The bar width and especially the size and strength of the rider, and riding style, ALL play huge into the cycles-to-failure metrics.

Drilled holes and/or countersinks are notorious for creating failure-inducing stress risers (some of Modolo's stems are one fine example).

If a stem wasn't tested with the drilled hole by the manufacturer, then I would not have a drilled hole in my stem.

The OP's pictured stem is a melt-forged or "pressure cast" part imo, looks very strong but I wouldn't drill it either way.

A big (very big) factor in terms of metal parts breakage vs. not breakage will always be the operating conditions including 1) the duration of service i.e. the # of load cycles and 2) the level of tension stress in any aluminum clamping portion where such tension is constant and could lead to creep-yield failure.

The bar width and especially the size and strength of the rider, and riding style, ALL play huge into the cycles-to-failure metrics.

Drilled holes and/or countersinks are notorious for creating failure-inducing stress risers (some of Modolo's stems are one fine example).

Likes For dddd:

#22

Senior Member

That VO stem is steel not aluminum. Steel is a VERY different material than aluminum.

I have had the joyful experience of having my aluminum stem snap off while riding. I will NEVER forget it.

If it were me, I would NOT drill a hole in an aluminum stem, certainly not to add a bell.

A bell is a warning device but it is no substitute for slowing down and giving pedestrians a wide berth.

Do that and you don't really need a bell - the bell becomes an affectation.

Fail to do that and the bell becomes a dangerous distraction that keeps you from reaching for your brakes.

I have had the joyful experience of having my aluminum stem snap off while riding. I will NEVER forget it.

If it were me, I would NOT drill a hole in an aluminum stem, certainly not to add a bell.

A bell is a warning device but it is no substitute for slowing down and giving pedestrians a wide berth.

Do that and you don't really need a bell - the bell becomes an affectation.

Fail to do that and the bell becomes a dangerous distraction that keeps you from reaching for your brakes.

Likes For Bad Lag:

#23

working on my sandal tan

Thread Starter

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

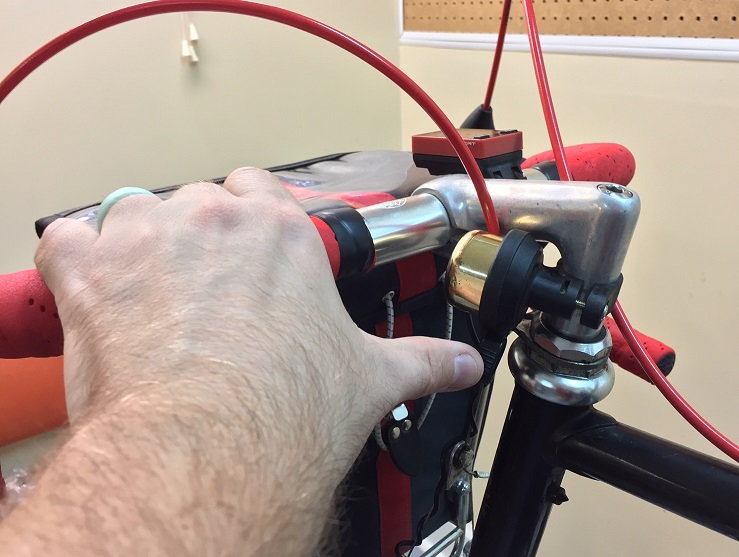

The green circle is the spot I had in mind. It would be ahead of the hollow section for the stem bolt at minimum. Thinking about it some more, routing the front brake cable over the stem could free up more real estate on the extension if I were to go that route:

P.S. noobinsf 's picture got me thinking: there's no reason but aesthetics not to mount the bell at an angle to everything else. I'll try rotating my PDW bell way forward and see how I like it:

__________________

RUSA #7498

Originally Posted by noglider

People in this forum are not typical.

Last edited by ThermionicScott; 09-05-21 at 10:51 AM.

#24

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,891

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4790 Post(s)

Liked 3,917 Times

in

2,548 Posts

Reasoning is all wrong, as is trusting a machinist in this case.

If a stem wasn't tested with the drilled hole by the manufacturer, then I would not have a drilled hole in my stem.

The OP's pictured stem is a melt-forged or "pressure cast" part imo, looks very strong but I wouldn't drill it either way.

A big (very big) factor in terms of metal parts breakage vs. not breakage will always be the operating conditions including 1) the duration of service i.e. the # of load cycles and 2) the level of tension stress in any aluminum clamping portion where such tension is constant and could lead to creep-yield failure.

The bar width and especially the size and strength of the rider, and riding style, ALL play huge into the cycles-to-failure metrics.

Drilled holes and/or countersinks are notorious for creating failure-inducing stress risers (some of Modolo's stems are one fine example).

If a stem wasn't tested with the drilled hole by the manufacturer, then I would not have a drilled hole in my stem.

The OP's pictured stem is a melt-forged or "pressure cast" part imo, looks very strong but I wouldn't drill it either way.

A big (very big) factor in terms of metal parts breakage vs. not breakage will always be the operating conditions including 1) the duration of service i.e. the # of load cycles and 2) the level of tension stress in any aluminum clamping portion where such tension is constant and could lead to creep-yield failure.

The bar width and especially the size and strength of the rider, and riding style, ALL play huge into the cycles-to-failure metrics.

Drilled holes and/or countersinks are notorious for creating failure-inducing stress risers (some of Modolo's stems are one fine example).

Another thought - if you drill a stem for bell, you probably should retire it earlier. But ... if it works out, that might become your favorite; perhaps even being copied on to other bikes. (Stems like yours often get retired because the handlebar clamp bolt area gets tired - but a failure there and your handlebar is still on the bike, just rotated and loose. Think about what your stem will have left if it does break at the bell drilling.)

(I've been riding a long time. I've seen at least 5 failures on the "sacred" path. One was of ordinary steel and not a big deal at all. (Fork blade; midway. Complete failure. I rode the bike home.) Another was a fork failure that near cost me my life and did cost me dearly. And an old HB that bent 30 degrees at the re-enforcing sleeve that I rode to a train station for a ride home. Recently, a suspected crack at the stem on a nice aluminum HB. (I was going to the velodrome to watch the races. Going home had a downhill with a stop at the bottom. I put the word in to the MC/announcer that I had a bike issue and needed a ride home. One of the competitors was grateful to be of assistance.) And the huge scare. The bike of my logo. Third season, second Cycle Oregon coming up. I was doing weekly 2000' climbing rides to the highest Portland westside hill for training. Both for my legs and heart and to get really good at flipping the rear wheel and unscrewing cogs. (Fix gear) This day, I got to the high point, then could not get the chain to behave on the tiny (13 tooth) downhill cog, It kept going tight, then slack. So I backed off the chain tension and just loafed slowly down all the descents. On the flat coming home the bike started bucking when I hit the front brake! Both fork blades were well on to failure at the fork crown! Got home, pulled the wheel, gave the forkblades a gentle spread and one bent out 8"! Shook me to the core. I DIDN'T blast around my favorite corner and collapse it at 30 mph+ simply because the bike had a mechanical! (Lesson - get your metallurgy right! We - myself, the builder and the plater - had combined to use a minimal crown with no scallops, really nice high grade Columbus forks and nickle plating that did not get the required post plating heat treatment. Perfect scenario for stress cracks. This despite absolutely beautiful workmanship. I got to see what human eyes never see; the inside of the forkcrown socket fit and braze.)

And the fun thought - there are "good" bikes that look after us. My old Peugeot UO-8 that was 20 miles from home but two miles from a train station when that HB bent. (And my riding partner's unlocked kitchen door with a train schedule on it was halfway between.) Other end of the train line - one flat mile from home. Jessica J, my logo bike, that chose to misbehave on a ride. (I was using a 13 tooth cog and my regular lockring, not the special 12 tooth tooth one I had. Well, Miche lockrings are a touch larger than standard and the chain rode on it, not the cog teeth, occasionally falling into the spanner slots! Thank you, Miche and Jessica!)

Likes For 79pmooney:

#25

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,891

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4790 Post(s)

Liked 3,917 Times

in

2,548 Posts

A heresy here. Have you considered aero brake levers to clean up the brake cables? (I wanted aero levers in 1977 when I was doing my long rides as a bike racer. I wanted my palms exactly where the cables came out. When I saw aero in the '80s, I was onboard immediately.)