Spoke length calculations (wheel building)

#1

Senior Member

Thread Starter

Join Date: Nov 2017

Posts: 122

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 79 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Spoke length calculations (wheel building)

So I'm planning to replace the hubs in my front and rear wheels. I'm replacing them with hubs that have cartridge bearings as well as disc rotor mounts. This is for my Trek 7200 and I realize it's a low-mid range bike, but I'm doing this because I like to "learn" and I'm pretty mechanical.

Anyway the Hubs are Novatec D881SB (front) and D812SB (rear). The Rims are Matrix 750. Based on my research I'm getting the following numbers for the wheel.

Matrix 750 ERD = 544.3mm

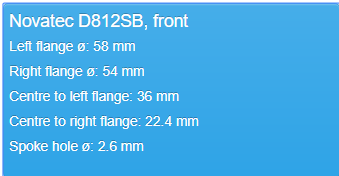

I used a caliper and measured the wheel hubs and compared them with what I'm seeing online and I'm getting fairly close to this, so I figure this is most accurate (mfg data). This is for the Front.

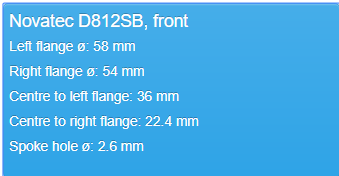

This is for the rear.

Anyway when the calculations come out the spokes for the front are coming out in fractions. 262.8 on the left and 265.4 on the right. Are you supposed to round up? So 263 v.s. 262.8? Also rond down on 265.4 to just 265?

Also, in terms of spoke type are there any considerations I should take. This is going to be for a 3 cross pattern. I'm planning to get black color spokes. These wheels will also have a brake rotor and yes my frame has the appropriate mounts for the caliper. Do these require special considerations in terms of the cross pattern (4 instead of 3)? Also since I'm building these wheels, what are some good spoke types/brands. It seems most of the spokes I'm seeing on ebay are generally stainless with brass nipples.

Thanks

Anyway the Hubs are Novatec D881SB (front) and D812SB (rear). The Rims are Matrix 750. Based on my research I'm getting the following numbers for the wheel.

Matrix 750 ERD = 544.3mm

I used a caliper and measured the wheel hubs and compared them with what I'm seeing online and I'm getting fairly close to this, so I figure this is most accurate (mfg data). This is for the Front.

This is for the rear.

Anyway when the calculations come out the spokes for the front are coming out in fractions. 262.8 on the left and 265.4 on the right. Are you supposed to round up? So 263 v.s. 262.8? Also rond down on 265.4 to just 265?

Also, in terms of spoke type are there any considerations I should take. This is going to be for a 3 cross pattern. I'm planning to get black color spokes. These wheels will also have a brake rotor and yes my frame has the appropriate mounts for the caliper. Do these require special considerations in terms of the cross pattern (4 instead of 3)? Also since I'm building these wheels, what are some good spoke types/brands. It seems most of the spokes I'm seeing on ebay are generally stainless with brass nipples.

Thanks

#2

Made in Taiwan

Join Date: Sep 2008

Location: Vancouver

Posts: 205

Bikes: Camerotti ti roadbike, Old Sears Free Spirit Tange Hi-Ten Single Speed built from a 12 speed, 1997 Cannondale CAD3 r500 with Shimano 6400 groupset

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 35 Post(s)

Liked 11 Times

in

9 Posts

1)When building wheels, I have always rounded up and that was the way that I was taught. The only times that I have rounded down was when the calculations gave me numbers that were 0.2 mm off and I had the "shorter" spokes readily available. Depending on where you source your spokes, you might need to go with 262 and 266, since most bulk spokes only come in 2 mm increments.

2)There are shops (both online and local), that can measure, cut and thread whatever length spokes that you need.

3) 4 cross is not going to give you a much stronger wheel then a 3 cross, it is stronger, but not by much. The strength of the wheel, ultimately comes down to quality of material and spoke tension. I would argue that a wheel with even tension across all the spokes in a 3 cross pattern will be much stronger than a poorly build 4 cross wheel.

4) If this is your first time building a wheel, I would recommend going with brass nipples. They are much stronger and less prone to corrosion. Alloy nipples are lighter and can come in any color to match your bike, but at a strength disadvantage. The nipples that I like to build with right now are the Sapim polyax. Any of the name brand spokes in plain gauge 2 mm should serve you fine, just make sure you get stainless steel ones.

Some of the more well know spoke manufacturers

DT Swiss

Wheelsmith

Sapim

2)There are shops (both online and local), that can measure, cut and thread whatever length spokes that you need.

3) 4 cross is not going to give you a much stronger wheel then a 3 cross, it is stronger, but not by much. The strength of the wheel, ultimately comes down to quality of material and spoke tension. I would argue that a wheel with even tension across all the spokes in a 3 cross pattern will be much stronger than a poorly build 4 cross wheel.

4) If this is your first time building a wheel, I would recommend going with brass nipples. They are much stronger and less prone to corrosion. Alloy nipples are lighter and can come in any color to match your bike, but at a strength disadvantage. The nipples that I like to build with right now are the Sapim polyax. Any of the name brand spokes in plain gauge 2 mm should serve you fine, just make sure you get stainless steel ones.

Some of the more well know spoke manufacturers

DT Swiss

Wheelsmith

Sapim

__________________

All dogs want to be lap dogs doesn't matter the size

-Animal loving friend

All dogs want to be lap dogs doesn't matter the size

-Animal loving friend

#3

Senior Member

Join Date: Apr 2010

Location: Mountain View, CA USA and Golden, CO USA

Posts: 6,341

Bikes: 97 Litespeed, 50-39-30x13-26 10 cogs, Campagnolo Ultrashift, retroreflective rims on SON28/PowerTap hubs

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 550 Post(s)

Liked 325 Times

in

226 Posts

So I'm planning to replace the hubs in my front and rear wheels. I'm replacing them with hubs that have cartridge bearings as well as disc rotor mounts. This is for my Trek 7200 and I realize it's a low-mid range bike, but I'm doing this because I like to "learn" and I'm pretty mechanical.

Anyway the Hubs are Novatec D881SB (front) and D812SB (rear). The Rims are Matrix 750. Based on my research I'm getting the following numbers for the wheel.

Matrix 750 ERD = 544.3mm

Anyway the Hubs are Novatec D881SB (front) and D812SB (rear). The Rims are Matrix 750. Based on my research I'm getting the following numbers for the wheel.

Matrix 750 ERD = 544.3mm

ERD varies with different batches and as the rim extrusion dies wear.

Anyway when the calculations come out the spokes for the front are coming out in fractions. 262.8 on the left and 265.4 on the right. Are you supposed to round up? So 263 v.s. 262.8? Also rond down on 265.4 to just 265?

How was ERD measured? With spokes threaded to the nipple slot bottom or top? How worn were the extruder dies? Have tolerances change any because of a factory move?

Was the online calculator aiming for the same nipple engagement? How is it accounting for elongation under tension? Use spocalc.xls that just applies the trigonometry.

What gauge spoke do you plan on using? 2.0mm straight gauge have negligible elongation. 2.0/1.5mm butted grow nearly 1mm front/drive side and 0.5mm NDS.

What sizes do your spokes come in and do you feel like having some cut to length? Usually they come in either even or odd lengths.

Aim for the slot bottom, use a stiff spoke, round down, and you may break nipples because your spokes are too short.

Aim for the slot top, use a light spoke, round up, and you may run out of threads before reaching full tension.

Also, in terms of spoke type are there any considerations I should take. This is going to be for a 3 cross pattern. I'm planning to get black color spokes. These wheels will also have a brake rotor and yes my frame has the appropriate mounts for the caliper. Do these require special considerations in terms of the cross pattern (4 instead of 3)? Also since I'm building these wheels, what are some good spoke types/brands. It seems most of the spokes I'm seeing on ebay are generally stainless with brass nipples.

Big hubs or small wheels can cause the spokes to meet the rim at too much angle for the nipple to pivot and handle. Subtract a cross to compensate.

32 hole second generation (carbon window era) PowerTap hubs should be laced cross-2.

Last edited by Drew Eckhardt; 08-31-19 at 02:19 PM.

Likes For Drew Eckhardt:

#4

Senior Member

Thread Starter

Join Date: Nov 2017

Posts: 122

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 79 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Measure it. Put two spokes in opposite holes, thread nipples to your target depth, measure across the elbows with your calipers, and add double the spoke length.

ERD varies with different batches and as the rim extruder dies wear.

It depends.

Where is the online calculator aiming in the nipple? Slot bottom or top?

What gauge spoke do you plan on using? 2.0mm straight gauge have negligible elongation. 2.0/1.5mm butted grow nearly 1mm front/drive side and 0.5mm NDS.

What sizes do your spokes come in and do you feel like having some cut to length? Usually they come in either even or odd lengths.

Aim for the slot bottom, use a stiff spoke, round down and you may break nipples because your spokes are too short.

Aim for the slot top, use a light spoke, round up and you may run out of threads before reaching full tension.

The maximum cross pattern comes from the number of holes in the hub and its diameter. Usually 32 spokes in 700C / 27" wheels dictate cross 3.

Big hubs or small wheels can cause the spokes to meet the rim at too much angle for the nipple to pivot and handle. Subtract a cross to compensate.

32 hole second generation (carbon window era) PowerTap hubs should be laced cross-2.

ERD varies with different batches and as the rim extruder dies wear.

It depends.

Where is the online calculator aiming in the nipple? Slot bottom or top?

What gauge spoke do you plan on using? 2.0mm straight gauge have negligible elongation. 2.0/1.5mm butted grow nearly 1mm front/drive side and 0.5mm NDS.

What sizes do your spokes come in and do you feel like having some cut to length? Usually they come in either even or odd lengths.

Aim for the slot bottom, use a stiff spoke, round down and you may break nipples because your spokes are too short.

Aim for the slot top, use a light spoke, round up and you may run out of threads before reaching full tension.

The maximum cross pattern comes from the number of holes in the hub and its diameter. Usually 32 spokes in 700C / 27" wheels dictate cross 3.

Big hubs or small wheels can cause the spokes to meet the rim at too much angle for the nipple to pivot and handle. Subtract a cross to compensate.

32 hole second generation (carbon window era) PowerTap hubs should be laced cross-2.

1). What is Slot bottom or top. I used two calculators.

https://www.prowheelbuilder.com/spokelengthcalculator

AND

https://leonard.io/edd/

The second one has the mfg of both my wheels and hubs.

I entered the values in both calculators and I got a 1/10th of a mm difference.

2). The first hub has a 2.0 mm spoke hole. However the rear hub has a 2.6mm spoke hole. This is actually a question I missed. Does the extra 0.6mm matter? I'm not really seeing 2.6mm but I do see all 2.0mm spokes. All my spokes will be J-bent spokes.

3). I'm figuring that I should round up because I read that usually they give you 8 - 10 mm of spoke thread. So if I have spoke sticking out I can grind/cut each spoke down by a bit?

The Matrix 750 are double walled rims where the nipple head rest on the most inner wall.

Thanks

#5

Senior Member

Join Date: Apr 2010

Location: Mountain View, CA USA and Golden, CO USA

Posts: 6,341

Bikes: 97 Litespeed, 50-39-30x13-26 10 cogs, Campagnolo Ultrashift, retroreflective rims on SON28/PowerTap hubs

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 550 Post(s)

Liked 325 Times

in

226 Posts

The second one has the mfg of both my wheels and hubs.

Drop that into the spocalc.xls spreadsheet which makes no assumptions.

Published ERD should only affect which way you round. If your rim is a little bigger than the published numbers, round down if you can so you won't run out of thread swapping a new rim that doesn't run big. If it's smaller favor rounding up.

Get that right and when you bend or wear out the rim, you tape a new on to it in three places, move spokes over one at a time, remove the old rim, tension, and true.

2). The first hub has a 2.0 mm spoke hole. However the rear hub has a 2.6mm spoke hole. This is actually a question I missed. Does the extra 0.6mm matter? I'm not really seeing 2.6mm but I do see all 2.0mm spokes. All my spokes will be J-bent spokes.

3). I'm figuring that I should round up because I read that usually they give you 8 - 10 mm of spoke thread. So if I have spoke sticking out I can grind/cut each spoke down by a bit?

If the nipple has 8mm of thread and spoke has 9mm, it's physically impossible for the spoke to extend more than 1mm past the top.

That's a standard 12mm DT nipple on the bottom. It can't thread any farther on to the spoke. If you end up in that situation, you'll need to settle for whatever tension it's at which might not be enough to keep the wheel true, or remove the nipples, drill them out for more clearance, and start over.

This is what happens when the spokes are too short. They need to be long enough to go all the way through the rim bed, so they're squeezing the nipple into it not putting it in tension.

You need to avoid both problems.

I think nipples should be made with less thread now that quality bikes all use double walled rims. Dropping to 6mm of thread on a 12mm nipple would give you an extra 2mm of tolerance. With only 1-1.5 bolt diameters required for full strength, 4mm of engagement would be plenty when a spoke was as short as it could be without risking nipple breakage.

Last edited by Drew Eckhardt; 08-31-19 at 02:41 PM.

#6

Senior Member

the spokes go longer in tension; the rim goes shorter in compression.

elastic modulus of the spoke: ~179GPa

elastic modulus of the rim: ~72GPa

but the strain-stress curve is not a line but a curve so these figures are just approximations.

the rim should have at least 900kgf circumferential compression: 16*(120+79)*0.9/3.1415=912kgf

120+79 is DS+NDS average tension estimation;

0.9 is the radial factor rough estimation as the spokes are not straight but have x+y+z components (vectorial).

if the rim has about 88sqmm (~450g weight, 2.7 density) then 912*9.8/88=101.5MPa;

101.5MPa/70GPa*311mm=0.44mm shorter radius of the rim.

how much the spoke is elongated under tension is more obvious: 79*9.8*/3.1415/179000*290=0.4mm longer spoke for a plain gauge spoke.

about 0.5mm longer spoke for a 1.8mm gauge spoke. and that is for a non drive side spoke which has 79kgf tension and 290mm length.

that's why people round down spoke length and that's why spoke calculators should take these things into account.

you should be able to do the math and find out if one online spoke calculator does round down and how much it does so.

use the sine/cosine functions...

the most important thing to note: butted spokes having more elastic elongation, you can calculate how much exactly. spoke length calculators could ask you the spoke gauge as well...

elastic modulus of the spoke: ~179GPa

elastic modulus of the rim: ~72GPa

but the strain-stress curve is not a line but a curve so these figures are just approximations.

the rim should have at least 900kgf circumferential compression: 16*(120+79)*0.9/3.1415=912kgf

120+79 is DS+NDS average tension estimation;

0.9 is the radial factor rough estimation as the spokes are not straight but have x+y+z components (vectorial).

if the rim has about 88sqmm (~450g weight, 2.7 density) then 912*9.8/88=101.5MPa;

101.5MPa/70GPa*311mm=0.44mm shorter radius of the rim.

how much the spoke is elongated under tension is more obvious: 79*9.8*/3.1415/179000*290=0.4mm longer spoke for a plain gauge spoke.

about 0.5mm longer spoke for a 1.8mm gauge spoke. and that is for a non drive side spoke which has 79kgf tension and 290mm length.

that's why people round down spoke length and that's why spoke calculators should take these things into account.

you should be able to do the math and find out if one online spoke calculator does round down and how much it does so.

use the sine/cosine functions...

the most important thing to note: butted spokes having more elastic elongation, you can calculate how much exactly. spoke length calculators could ask you the spoke gauge as well...

#7

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

the spokes go longer in tension; the rim goes shorter in compression.

elastic modulus of the spoke: ~179GPa

elastic modulus of the rim: ~72GPa

but the strain-stress curve is not a line but a curve so these figures are just approximations.

the rim should have at least 900kgf circumferential compression: 16*(120+79)*0.9/3.1415=912kgf

120+79 is DS+NDS average tension estimation;

0.9 is the radial factor rough estimation as the spokes are not straight but have x+y+z components (vectorial).

if the rim has about 88sqmm (~450g weight, 2.7 density) then 912*9.8/88=101.5MPa;

101.5MPa/70GPa*311mm=0.44mm shorter radius of the rim.

how much the spoke is elongated under tension is more obvious: 79*9.8*/3.1415/179000*290=0.4mm longer spoke for a plain gauge spoke.

about 0.5mm longer spoke for a 1.8mm gauge spoke. and that is for a non drive side spoke which has 79kgf tension and 290mm length.

that's why people round down spoke length and that's why spoke calculators should take these things into account.

you should be able to do the math and find out if one online spoke calculator does round down and how much it does so.

use the sine/cosine functions...

the most important thing to note: butted spokes having more elastic elongation, you can calculate how much exactly. spoke length calculators could ask you the spoke gauge as well...

elastic modulus of the spoke: ~179GPa

elastic modulus of the rim: ~72GPa

but the strain-stress curve is not a line but a curve so these figures are just approximations.

the rim should have at least 900kgf circumferential compression: 16*(120+79)*0.9/3.1415=912kgf

120+79 is DS+NDS average tension estimation;

0.9 is the radial factor rough estimation as the spokes are not straight but have x+y+z components (vectorial).

if the rim has about 88sqmm (~450g weight, 2.7 density) then 912*9.8/88=101.5MPa;

101.5MPa/70GPa*311mm=0.44mm shorter radius of the rim.

how much the spoke is elongated under tension is more obvious: 79*9.8*/3.1415/179000*290=0.4mm longer spoke for a plain gauge spoke.

about 0.5mm longer spoke for a 1.8mm gauge spoke. and that is for a non drive side spoke which has 79kgf tension and 290mm length.

that's why people round down spoke length and that's why spoke calculators should take these things into account.

you should be able to do the math and find out if one online spoke calculator does round down and how much it does so.

use the sine/cosine functions...

the most important thing to note: butted spokes having more elastic elongation, you can calculate how much exactly. spoke length calculators could ask you the spoke gauge as well...

...then there's application.

Spoke calculator should simply provide a calculated length result.

Because a DT Swiss double butted 2.0 / 1.8 / 2.0 will behave differently than a CNspoke MAC double butted 2.0 / /1.8 / 2.0 than a HT double butted 2.0 / 1.8 / 2.0.

For two reasons...three if "black".

And the differences are repeated for 2.0 / 1.7 / 2.0 and 2.0 / 1.6 / 2.0 and 2.0 / 1.5 / 2.0, etc, etc.

Aim for the bottom of the screwdriver slot in your ERD, for a 12mm standard profile nipple...you already have elongation covered in 99% of cases.

Quit making a molehill out of an anthill folks.

=8-|

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

Likes For mrrabbit:

#9

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,701

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5776 Post(s)

Liked 2,574 Times

in

1,425 Posts

Doesn't make a difference. The head, which is what matters, is always in the same place.

OTOH if the spoke is really short the thread might show with a 12mm nipple, so go with 14 for purely cosmetic reasons.

BTW, had you read that thread before posting you'd have been that far ahead of the game.

#11

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,701

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5776 Post(s)

Liked 2,574 Times

in

1,425 Posts