Question on spoke length calculation

#1

Senior Member

Thread Starter

Question on spoke length calculation

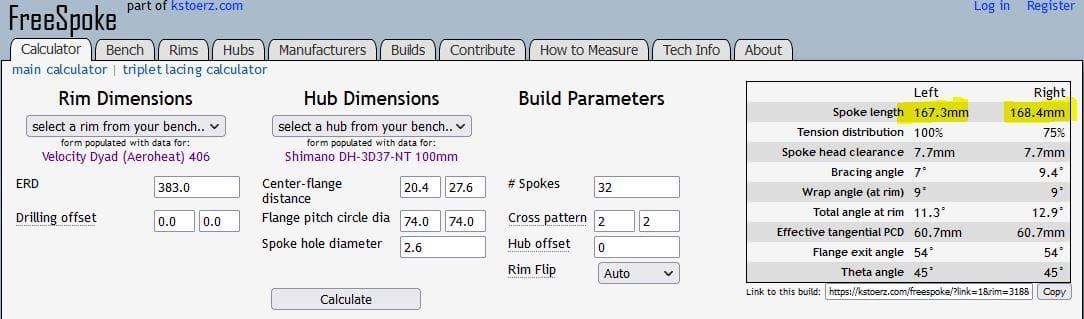

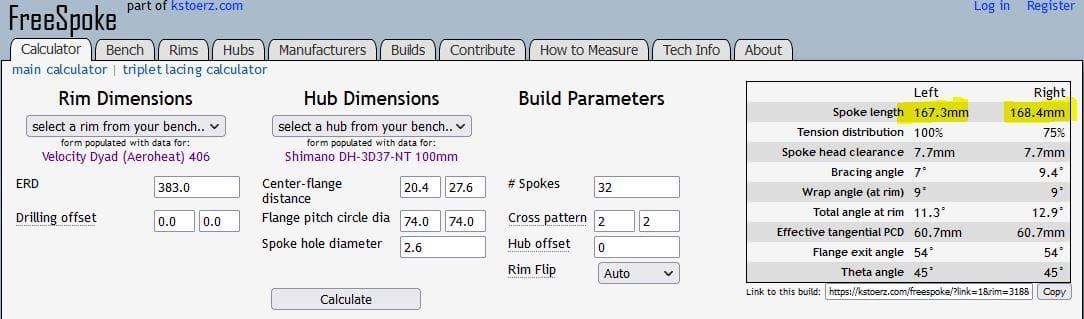

I want to put a hub dynamo in one of my wheels. The hub dynamo is a Shimano DH-3D37 which has a 3.6mm offset. The rim is a Velocity Dyad 406 (20"). According to a tire spoke calculator the difference in spoke length between left and right side is about 1.1mm.

167.3mm on the left and 168.4mm on the right side. I think with this small of a delta I can order the same length spoke for both sides. I was thinking about 168.0mm for each side. That should give me enough room on either side. Any concerns here doing that?

Below is also a photo from the calculator out put which can be found here:

https://www.kstoerz.com/freespoke/

Thanks

167.3mm on the left and 168.4mm on the right side. I think with this small of a delta I can order the same length spoke for both sides. I was thinking about 168.0mm for each side. That should give me enough room on either side. Any concerns here doing that?

Below is also a photo from the calculator out put which can be found here:

https://www.kstoerz.com/freespoke/

Thanks

#2

Really Old Senior Member

I'd 168 on both.

You have a double wall rim, so you don't have concerns about a spoke being so long it protrudes into the rim strip.

.4mm short is only .016".

If using thinner spokes, they may stretch a "couple/few" extra .1mm.

You have a double wall rim, so you don't have concerns about a spoke being so long it protrudes into the rim strip.

.4mm short is only .016".

If using thinner spokes, they may stretch a "couple/few" extra .1mm.

Likes For Bill Kapaun:

#3

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,707

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5781 Post(s)

Liked 2,576 Times

in

1,427 Posts

I second Bill's suggestion to split the difference and use the same spoke for both sides, but with one caveat.

I don't know if you measured the ERD, or pulled it from a spec sheet, but that is the most critical dimension. Most of the calculators will bring the end of the spoke out to the ERD entered. If the thickness of the nipple head isn't allowed for, that means that the spoke will end at the BOTTOM of the nipple head, not 0-1mm shy of the top.

My advice is to measure the ERD yourself, either allowing for the nipple heads, or if measuring from the nipple seat add 2-3mm (according to rounding) to the calculated length.

I don't know if you measured the ERD, or pulled it from a spec sheet, but that is the most critical dimension. Most of the calculators will bring the end of the spoke out to the ERD entered. If the thickness of the nipple head isn't allowed for, that means that the spoke will end at the BOTTOM of the nipple head, not 0-1mm shy of the top.

My advice is to measure the ERD yourself, either allowing for the nipple heads, or if measuring from the nipple seat add 2-3mm (according to rounding) to the calculated length.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#4

Senior Member

Thread Starter

I second Bill's suggestion to split the difference and use the same spoke for both sides, but with one caveat.

I don't know if you measured the ERD, or pulled it from a spec sheet, but that is the most critical dimension. Most of the calculators will bring the end of the spoke out to the ERD entered. If the thickness of the nipple head isn't allowed for, that means that the spoke will end at the BOTTOM of the nipple head, not 0-1mm shy of the top.

My advice is to measure the ERD yourself, either allowing for the nipple heads, or if measuring from the nipple seat add 2-3mm (according to rounding) to the calculated length.

I don't know if you measured the ERD, or pulled it from a spec sheet, but that is the most critical dimension. Most of the calculators will bring the end of the spoke out to the ERD entered. If the thickness of the nipple head isn't allowed for, that means that the spoke will end at the BOTTOM of the nipple head, not 0-1mm shy of the top.

My advice is to measure the ERD yourself, either allowing for the nipple heads, or if measuring from the nipple seat add 2-3mm (according to rounding) to the calculated length.

https://www.velocityusa.com/product/rims/dyad-406

#5

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,903

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2604 Post(s)

Liked 1,930 Times

in

1,211 Posts

I second Bill's suggestion to split the difference and use the same spoke for both sides, but with one caveat.

I don't know if you measured the ERD, or pulled it from a spec sheet, but that is the most critical dimension. Most of the calculators will bring the end of the spoke out to the ERD entered. If the thickness of the nipple head isn't allowed for, that means that the spoke will end at the BOTTOM of the nipple head, not 0-1mm shy of the top.

My advice is to measure the ERD yourself, either allowing for the nipple heads, or if measuring from the nipple seat add 2-3mm (according to rounding) to the calculated length.

I don't know if you measured the ERD, or pulled it from a spec sheet, but that is the most critical dimension. Most of the calculators will bring the end of the spoke out to the ERD entered. If the thickness of the nipple head isn't allowed for, that means that the spoke will end at the BOTTOM of the nipple head, not 0-1mm shy of the top.

My advice is to measure the ERD yourself, either allowing for the nipple heads, or if measuring from the nipple seat add 2-3mm (according to rounding) to the calculated length.

Likes For pdlamb:

#6

Full Member

Join Date: Jun 2022

Location: San Diego, California USA

Posts: 353

Bikes: 1974 Masi GC, 1982 Trek 728 (aka 720), 1992 Trek Multitrack 750

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 122 Post(s)

Liked 221 Times

in

140 Posts

I second Bill's suggestion to split the difference and use the same spoke for both sides, but with one caveat.

I don't know if you measured the ERD, or pulled it from a spec sheet, but that is the most critical dimension. Most of the calculators will bring the end of the spoke out to the ERD entered. If the thickness of the nipple head isn't allowed for, that means that the spoke will end at the BOTTOM of the nipple head, not 0-1mm shy of the top.

My advice is to measure the ERD yourself, either allowing for the nipple heads, or if measuring from the nipple seat add 2-3mm (according to rounding) to the calculated length.

I don't know if you measured the ERD, or pulled it from a spec sheet, but that is the most critical dimension. Most of the calculators will bring the end of the spoke out to the ERD entered. If the thickness of the nipple head isn't allowed for, that means that the spoke will end at the BOTTOM of the nipple head, not 0-1mm shy of the top.

My advice is to measure the ERD yourself, either allowing for the nipple heads, or if measuring from the nipple seat add 2-3mm (according to rounding) to the calculated length.

kindest regards

Larry

Likes For HelpSingularity:

#7

Newbie

Join Date: Jan 2010

Location: Upstate NY

Posts: 28

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 8 Post(s)

Likes: 0

Liked 17 Times

in

11 Posts

Not to introduce any more confusion or controversy, but I usually use spoke nipple washers with a no-eyelet rim like a Dyad. Washers add about 1mm to the required spoke length. Based on the Freespoke numbers, and using washers, I would probably go with 168 on the left and 170 on the right. And the washers are probably overkill anyway. But that’s just me.

And — based on 40-odd years of wheel building — I strongly agree that there’s no substitute for measuring the ERD yourself. Roger Musson (wheelpro.co.uk) has a good template for doing this using a printed scale and a couple of junk spokes cut to length.

And — based on 40-odd years of wheel building — I strongly agree that there’s no substitute for measuring the ERD yourself. Roger Musson (wheelpro.co.uk) has a good template for doing this using a printed scale and a couple of junk spokes cut to length.

#9

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

While some Al rims of an aero shape have their special spoke "washers" most all other rims have a flat enough spoke bed to allow the nipple to seat well. Most of these rims are made with a thick enough spoke bed to not need the stress relieving aspect of a nipple washer. I consider the Dyad to be one of these rims not needing a washer for structural reasons (can't say I have ever seen a cracked Dyad rim). BUT using a washer as a low friction device (a thrust washer of sorts) is not a bad choice. Al rims with no eyelet will have more friction/grip on the nipples. So when tensioning up the spokes some of the effort to turn nipples is from this friction. This added friction can mislead the truer/builder in thinking that the spokes are reaching a good tension level, when the spokes are still lower in tension then ideal.

I also agree with the others who welcome back Francis. He has greater patients and tolerance for those who post than I do. Although I think we share the same goals in trying to help them. Andy

I also agree with the others who welcome back Francis. He has greater patients and tolerance for those who post than I do. Although I think we share the same goals in trying to help them. Andy

__________________

AndrewRStewart

AndrewRStewart

#10

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

Likes For Andrew R Stewart:

#11

Newbie

Join Date: Jan 2010

Location: Upstate NY

Posts: 28

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 8 Post(s)

Likes: 0

Liked 17 Times

in

11 Posts

While some Al rims of an aero shape have their special spoke "washers" most all other rims have a flat enough spoke bed to allow the nipple to seat well. Most of these rims are made with a thick enough spoke bed to not need the stress relieving aspect of a nipple washer. I consider the Dyad to be one of these rims not needing a washer for structural reasons (can't say I have ever seen a cracked Dyad rim). BUT using a washer as a low friction device (a thrust washer of sorts) is not a bad choice. Al rims with no eyelet will have more friction/grip on the nipples. So when tensioning up the spokes some of the effort to turn nipples is from this friction. This added friction can mislead the truer/builder in thinking that the spokes are reaching a good tension level, when the spokes are still lower in tension then ideal.

I also agree with the others who welcome back Francis. He has greater patients and tolerance for those who post than I do. Although I think we share the same goals in trying to help them. Andy

I also agree with the others who welcome back Francis. He has greater patients and tolerance for those who post than I do. Although I think we share the same goals in trying to help them. Andy

#12

Senior Member

Thread Starter

Thanks everyone with the idea to use washers to reduce friction. I have never used them so far but it makes total sense to me. So far I have built less than 10 wheels and my experience is limited. My biggest concern is always to get the best tension. I do have the park tool tension meter but this tool does not really work on small wheels with double cross pattern.