Simple carbon fork extension for scooter

#26

Full Member

Join Date: Dec 2009

Posts: 495

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 49 Post(s)

Likes: 0

Liked 13 Times

in

12 Posts

I think you would have been better off just buying aluminum close to the final shape needed and drilled and bolted them to the existing forks. If they worked you could then take them apart and refine the shape a bit.

#27

I like bike

Thread Starter

Join Date: Feb 2021

Location: Merry Land USA

Posts: 662

Bikes: Roubaix Comp 2020

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 267 Post(s)

Liked 283 Times

in

191 Posts

The O.L.D on the wheel would have to be different since the aluminum bolted to the outside would widen the gap, but I could just put some washers on the axle to compensate.

#28

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,835

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2337 Post(s)

Liked 2,813 Times

in

1,536 Posts

While not a frame builder yet, I have built a lot of things over the years (included hacked roller set up so a luge sled could be used for training on roads).

My concern, especially i used for skate style vs classic nordic style, that there will be a lot of lateral forces in play, and with the amount on length added to fit the larger wheels that unless using really thick plate, there will be way to much flex, especially with 16 in wheels

maybe flat, with stiffener welded on outside, but that sound's like it is going beyond OP's current shop toolset

Doesn't hurt to try,

My concern, especially i used for skate style vs classic nordic style, that there will be a lot of lateral forces in play, and with the amount on length added to fit the larger wheels that unless using really thick plate, there will be way to much flex, especially with 16 in wheels

maybe flat, with stiffener welded on outside, but that sound's like it is going beyond OP's current shop toolset

Doesn't hurt to try,

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

#29

Disco Infiltrator

Join Date: May 2013

Location: Folsom CA

Posts: 13,446

Bikes: Stormchaser, Paramount, Tilt, Samba tandem

Mentioned: 72 Post(s)

Tagged: 0 Thread(s)

Quoted: 3126 Post(s)

Liked 2,102 Times

in

1,366 Posts

As you design, don’t conflate stiffness with strength and don’t forget about either. You need more of both just because it’s a longer arm from the platform to the wheel. If you replace steel with carbon the carbon has to be thicker… it’s “stronger” and “stiffer” per weight but much less dense.

__________________

Genesis 49:16-17

Genesis 49:16-17

#30

I like bike

Thread Starter

Join Date: Feb 2021

Location: Merry Land USA

Posts: 662

Bikes: Roubaix Comp 2020

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 267 Post(s)

Liked 283 Times

in

191 Posts

As you design, don’t conflate stiffness with strength and don’t forget about either. You need more of both just because it’s a longer arm from the platform to the wheel. If you replace steel with carbon the carbon has to be thicker… it’s “stronger” and “stiffer” per weight but much less dense.

Or so is my impression of this stuff.. I'm no expert. I am using this page as a reference.

Re: how much stiffness is needed, I don't think it matters all that much as there are not many side-to-side forces on these skates. You are not twisting in NCS, it is not like downhill skiing. Having less stiffness will in fact be good I think, for the up-and-down forces for which some dampening would be good.

Last edited by scottfsmith; 04-08-22 at 08:57 PM.

#31

Senior Member

Join Date: Dec 2019

Posts: 954

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

As you design, don’t conflate stiffness with strength and don’t forget about either. You need more of both just because it’s a longer arm from the platform to the wheel. If you replace steel with carbon the carbon has to be thicker… it’s “stronger” and “stiffer” per weight but much less dense.

It's a bit like if you do the math you will find that in theory you could stand up vertically on a piece of TIG wire. In theory the strength is there. But a tiny perturbation and you won't be loading it straight down any more so of course it will bend.

#32

Senior Member

Join Date: Jan 2013

Location: South Jersey

Posts: 2,262

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 713 Post(s)

Liked 796 Times

in

473 Posts

This seems to have really gone into the weeds with all the theoretical discussion of strength and stiffness. Sometimes you just have to build it and see if it works.

#33

I like bike

Thread Starter

Join Date: Feb 2021

Location: Merry Land USA

Posts: 662

Bikes: Roubaix Comp 2020

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 267 Post(s)

Liked 283 Times

in

191 Posts

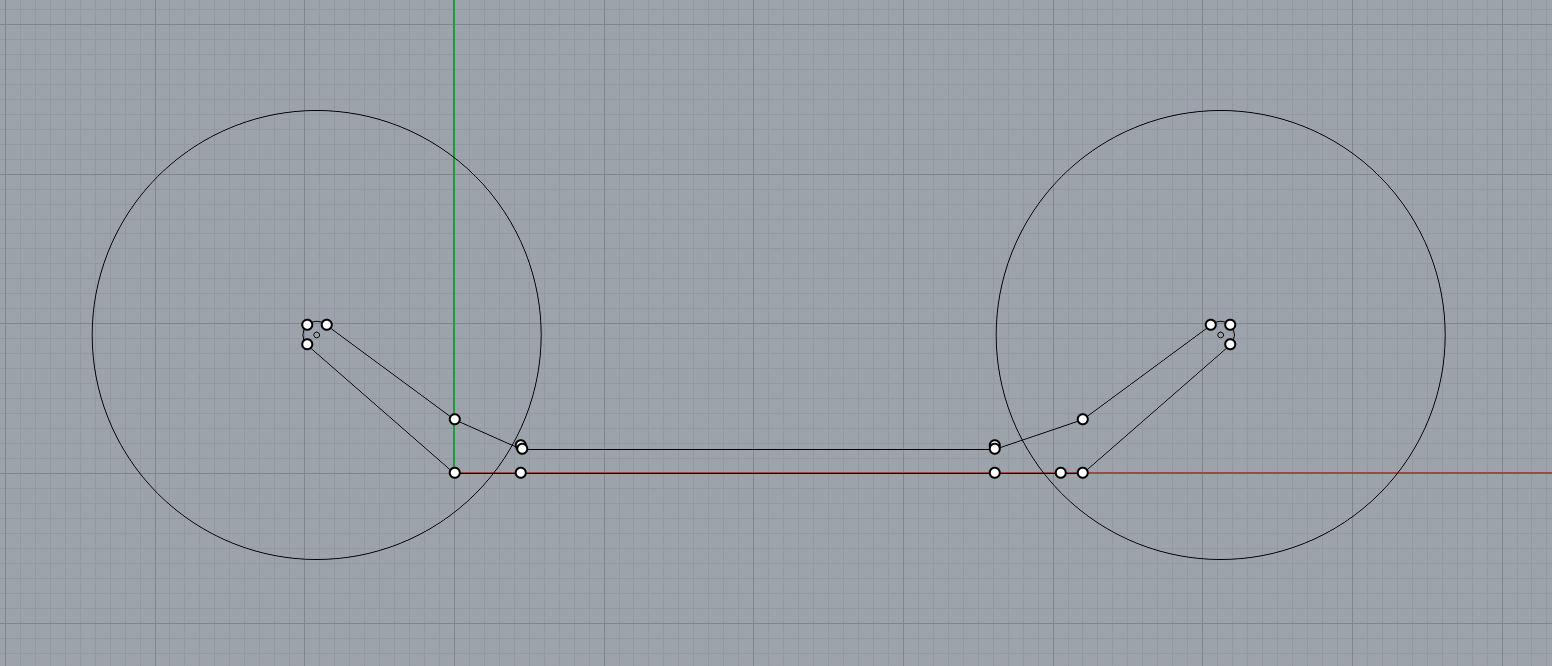

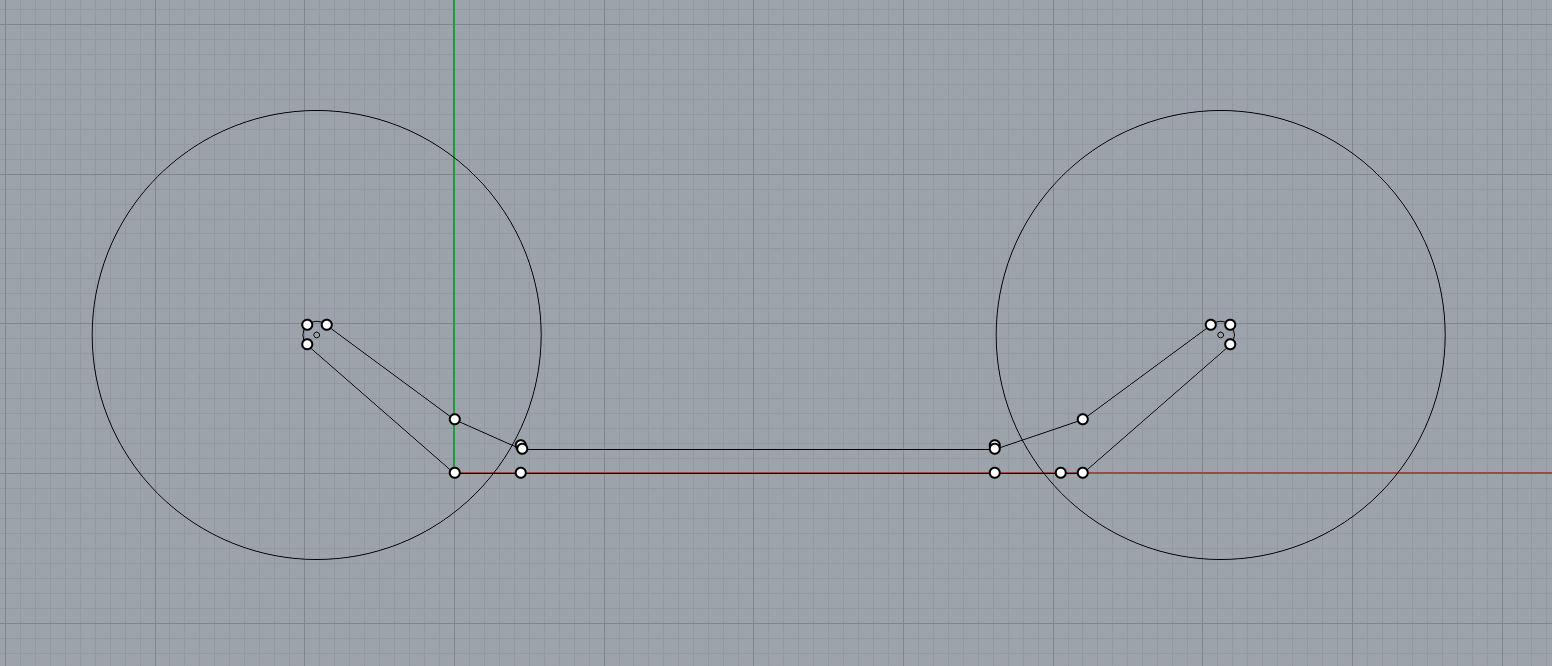

Indeed. I decided to order some full side panels in aluminum and use those to prototype. Its $12 a panel including materials, cutting, shipping, and tax .. it seems worth the cost to get a realistic prototype. Here is my simple design if you are curious. I had to learn a few more features of my CAD program to get this done.