Wheelbuilding for a beginner

#1

Full Member

Thread Starter

Join Date: Jan 2022

Posts: 475

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 253 Post(s)

Liked 223 Times

in

118 Posts

Wheelbuilding for a beginner

Hi,

I want to try my hand on wheelbuilding for the first time. While it seems daunting, i feel like lacing it up and giving it basic tention should be doable, if I'll be dilligent about it.

My biggest issue atm, is getting the correct spoke length for a rim/hub combination.

I want to use a 130 mm hub with a 36 spoke count in silver to fit my touring bike aestehtic - something cheap basically with 10speed cassette compatibiltiy. And the corresponding spokes and rims to build it up.

Same for the front wheel (100 mm hub, silver 32/36 spoke count).

Can someone reccomend a hub/spoke/rim combination i can get started with? 100 USD/€ per wheel in total, if possible

Thanks!

I want to try my hand on wheelbuilding for the first time. While it seems daunting, i feel like lacing it up and giving it basic tention should be doable, if I'll be dilligent about it.

My biggest issue atm, is getting the correct spoke length for a rim/hub combination.

I want to use a 130 mm hub with a 36 spoke count in silver to fit my touring bike aestehtic - something cheap basically with 10speed cassette compatibiltiy. And the corresponding spokes and rims to build it up.

Same for the front wheel (100 mm hub, silver 32/36 spoke count).

Can someone reccomend a hub/spoke/rim combination i can get started with? 100 USD/€ per wheel in total, if possible

Thanks!

#2

Bikeable

Join Date: Jan 2011

Posts: 326

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 173 Post(s)

Likes: 0

Liked 104 Times

in

73 Posts

There is something called E.R.D. (short for effective rim diameter). Different rims have different ERD's. You need to look up the ERD for the rims that you plan to use. Next, go to an on line spoke calculator and plug in your rim and hub numbers. Assuming you are talking basic clincher (700c) rims and three cross spoke pattern, it should come out about 292 -294mmish size.

#3

Full Member

Thread Starter

Join Date: Jan 2022

Posts: 475

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 253 Post(s)

Liked 223 Times

in

118 Posts

There is something called E.R.D. (short for effective rim diameter). Different rims have different ERD's. You need to look up the ERD for the rims that you plan to use. Next, go to an on line spoke calculator and plug in your rim and hub numbers. Assuming you are talking basic clincher (700c) rims and three cross spoke pattern, it should come out about 292 -294mmish size.

#4

Senior Member

Join Date: Feb 2007

Posts: 1,415

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 612 Post(s)

Likes: 0

Liked 387 Times

in

270 Posts

I would also recommend reading Sheldon Brown's page on Wheel BuIlding. The devil is in the details.

Likes For Rick:

#5

Senior Member

Join Date: Jul 2013

Location: Nor-Cal

Posts: 3,767

Bikes: lots

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1958 Post(s)

Liked 2,932 Times

in

1,489 Posts

$100.00 for hub/rim/spokes? Good luck.

Likes For cxwrench:

#6

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,464

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 955 Post(s)

Liked 1,619 Times

in

1,039 Posts

Don't know your experience but a good start would be with an old wheel. Take the old wheel and loosen everything up then get it back trued and ready ta go. In doing this you will develop e skills with the tools you have and exponentially increase your change of a successful from scratch wheel build. Fun Fun FUN!!!

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

#7

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,499

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2740 Post(s)

Liked 3,388 Times

in

2,051 Posts

Honestly you can buy wheels cheaper than the parts.

https://www.velomine.com/index.php?m...oducts_id=6527

https://www.velomine.com/index.php?m...oducts_id=6527

#8

Disco Infiltrator

Join Date: May 2013

Location: Folsom CA

Posts: 13,446

Bikes: Stormchaser, Paramount, Tilt, Samba tandem

Mentioned: 72 Post(s)

Tagged: 0 Thread(s)

Quoted: 3126 Post(s)

Liked 2,102 Times

in

1,366 Posts

Musson's book is good. It's totally doable. But really see above. Think why you want to do it. To get a 4.5 lb wheel set that came from the nineties? Nah. Shouldn't you be doing it on something special you couldn't find or afford otherwise?

__________________

Genesis 49:16-17

Genesis 49:16-17

Last edited by Darth Lefty; 07-24-22 at 06:02 PM.

#9

Senior Member

Parts alone will be be about 150 per wheel. You will need a truing stand, spoke tension gauge, and spoke wrench And a cheap digital caliper. So..... there is no payback in doing this for one wheel set. It will take a few builds for you to be "par" with just buying a set of wheels. But where is the fun in that? I borrowed a friend's gear and built my first set 10 years ago. This year was the first year I had to retension the wheel, so that is pretty good for a first try.

For a first build, consider a Deore hub. there are loads of those on eBay. Deore is bomb proof. People scoff at old stuff but the Sun CR-18 rim has been around forever. Durable, relatively cheap, but not always the most round out of the box. And lastly, butted spokes. Unless you are really heavy ( I am 200 lbs) a butted spoke will give you a really resilient wheel.

Its good to learn a skill and have a measure of pride in doing something on your own. Go for it, its fun.

For a first build, consider a Deore hub. there are loads of those on eBay. Deore is bomb proof. People scoff at old stuff but the Sun CR-18 rim has been around forever. Durable, relatively cheap, but not always the most round out of the box. And lastly, butted spokes. Unless you are really heavy ( I am 200 lbs) a butted spoke will give you a really resilient wheel.

Its good to learn a skill and have a measure of pride in doing something on your own. Go for it, its fun.

#11

señor miembro

Join Date: Dec 2018

Location: Pac NW

Posts: 6,601

Bikes: '70s - '80s Campagnolo

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 3869 Post(s)

Liked 6,454 Times

in

3,192 Posts

#12

Senior Member

To each his own. Of course you can use a frame as a stand. I just find that good tools make the job more relaxing. I have trued a wheel on the fly after a broken spoke, the brakes acted as lateral guides. And of course you can tune/tension by ear by plucking spokes like a harp. I have been down the road of doing things without good tools and just prefer the ease of a stand, and the knowledge that a tension gauge gives me a known reading. I would hate to see a beginner have a bad outcome or build and then decide it was a poor choice to try this. Tools last a lifetime. The runout dial gauge for my disc brakes on my cars has paid me back many times. Same for my micrometer. And tools are relatively speaking far less than when I was young. We can scoff at Asian build stuff from China, but lots of stuff is still made in Taiwan and really good quality. And besides, if I don't spend money on a tool, the wife will spend it on curtains or paint or some other pointless item!

#14

Senior Member

Join Date: Feb 2007

Posts: 1,415

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 612 Post(s)

Likes: 0

Liked 387 Times

in

270 Posts

My truing stand is mounted to a table in my bedroom. I use dial indicators and check the tension of the spokes by plucking them and adjust the tension according to how they sound.

#15

Full Member

Thread Starter

Join Date: Jan 2022

Posts: 475

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 253 Post(s)

Liked 223 Times

in

118 Posts

Thanks for all the input! I will be trying my hands on wheelbuilding, and will not get a truing stand/tensiometer right off the bat. A frame will do, from what I can tell initially. From what I can tell,100 $/€ should be within the ballpark for a rear wheel (50 for a hub, 20 for a rim, 20 for spokes and nipples)

Likes For Positron400:

#16

Full Member

Thread Starter

Join Date: Jan 2022

Posts: 475

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 253 Post(s)

Liked 223 Times

in

118 Posts

Wheelbuilding should help me truing rims and the like. Also further down the line I wanna build a 10speed 26 inch rim brake tubeless wheel, and they are terribly hard to come by..

Wheelbuilding should help me truing rims and the like. Also further down the line I wanna build a 10speed 26 inch rim brake tubeless wheel, and they are terribly hard to come by..

Likes For Positron400:

#17

Mostly harmless ™

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

My 2c - not saying it's the best option for everyone:

Shimano mid-range hubs offer a good bang-for-the-buck and are of a decent quality and durability.

Aluminium double-walled rims - whichever you find locally available.

Spokes - for starting, you could go with some cheaper ("Chinese") ones - they will reveal any wheel building defficiency, by breaking.

High-quality swagged spokes can compensate for poor building (even design for that matter), because they are really tough and durable.

Roger Musson's book, mentioned above, is a great idea.

Shimano mid-range hubs offer a good bang-for-the-buck and are of a decent quality and durability.

Aluminium double-walled rims - whichever you find locally available.

Spokes - for starting, you could go with some cheaper ("Chinese") ones - they will reveal any wheel building defficiency, by breaking.

High-quality swagged spokes can compensate for poor building (even design for that matter), because they are really tough and durable.

Roger Musson's book, mentioned above, is a great idea.

#18

Senior Member

I've built all my wheels for the past 40 years. I use a spoke wrench, hold the wheel in my lap, check the true in the frame. I made a dish tool with 2 4-inch wood screws and a flat 1x1 from a discarded TV stand (a stand for eating meals in front of the TV). It's hardwood and perfectly flat, just long enough for a 700c wheel. The hole in the center for the axle fits my hub's.

If I billed for my labor at minimum wage I'd be better off buying made wheels but I like knowing I built them.

If I billed for my labor at minimum wage I'd be better off buying made wheels but I like knowing I built them.

Likes For Arthur Peabody:

#20

Senior Member

Join Date: Feb 2016

Location: SE Wisconsin

Posts: 1,851

Bikes: Lemond '01 Maillot Jaune, Lemond '02 Victoire, Lemond '03 Poprad, Lemond '03 Wayzata DB conv(Poprad), '79 AcerMex Windsor Carrera Professional(pur new), '88 GT Tequesta(pur new), '01 Bianchi Grizzly, 1993 Trek 970 DB conv, Trek 8900 DB conv

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 758 Post(s)

Likes: 0

Liked 809 Times

in

471 Posts

I think those of us that build wheels would be interested in photos and/or specs on the components you source and use for your build(s).

Last edited by fishboat; 07-25-22 at 10:54 AM.

#21

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,895

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2598 Post(s)

Liked 1,924 Times

in

1,208 Posts

I think there's value in learning to build your own wheels, in that you'll be able to maintain your own wheels. Break a spoke? $2 (or euros) instead of $20 labor. Plus you can get back on the road this evening instead of whenever you land in your bike shop repair queue.

As dedhed noted you can buy a machine built wheel for less that the cost of parts. Buy one of those; detension the spokes if you want (but they're usually not up to tension anyway), then develop and practice your tensioning, truing, and stress relieving skills.

As dedhed noted you can buy a machine built wheel for less that the cost of parts. Buy one of those; detension the spokes if you want (but they're usually not up to tension anyway), then develop and practice your tensioning, truing, and stress relieving skills.

#22

Full Member

Thread Starter

Join Date: Jan 2022

Posts: 475

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 253 Post(s)

Liked 223 Times

in

118 Posts

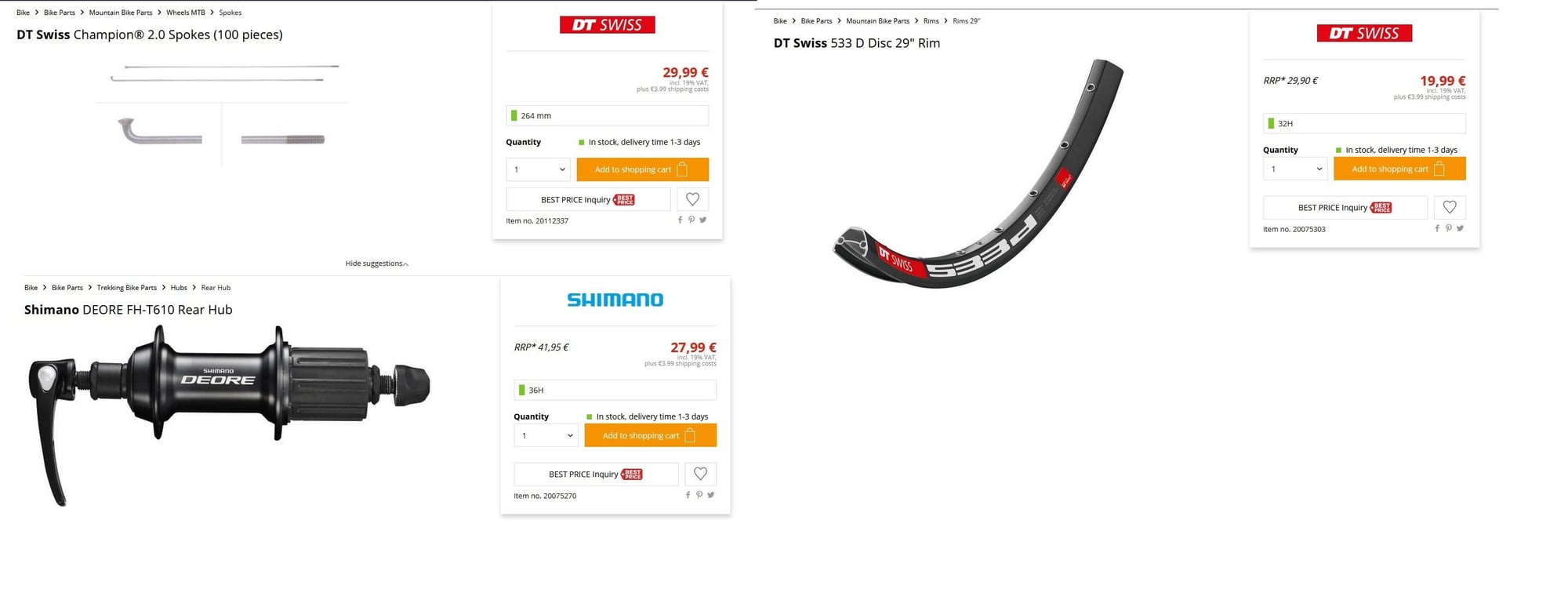

Admittedly, its a hub for rim brakes and the rim is for dics brakes, but i think the argument holds true - found a disc brake hub, which also works out to below 100 €

Last edited by Positron400; 07-25-22 at 09:30 AM.

#23

Senior Member

Join Date: Jul 2013

Location: Nor-Cal

Posts: 3,767

Bikes: lots

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1958 Post(s)

Liked 2,932 Times

in

1,489 Posts

BRAKES. Not breaks.

#25

Senior Member

Join Date: Mar 2012

Posts: 978

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 504 Post(s)

Likes: 0

Liked 637 Times

in

355 Posts

Really? I built a set of wheels in a campground in Rapid City, SD and rode them for roughly 8,000 miles of fully loaded touring. I admit I did use a spoke wrench. But that other stuff, no. I've build well over 100 wheels without a spoke tension gauge or digital calipers. Funny how that works.