16 speed Brompton with shimano nexus 8

#51

Senior Member

Join Date: Jul 2008

Location: San Mateo

Posts: 130

Bikes: 3 Bromptons, M2L-X, S6L-X/BWR. S6R/SRAM/Schlimpf, Novara Roadbike

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

So the front derailleur, I've fit that in the past, I got an adapter from Steve Perry, I don't think it will be produced to the same volume as the made-in-China Dahon type, but I paired with a Campag Mirage Triple and a friction shifter I fit to the handlebars. The adapter, its design is so simple and the metal used so sturdy looking, I think it will last a lifetime. I've removed mine as I moved to Schlumpf but I'm keeping as I think its a timeless design that I might reuse.

I used that in a tour I posted to in this forum the drawback was I used it with the Brompton crankset, which simply isn't rigid enough or strong enough being Aluminium, so a compact Shimano as shown here would probably be better stronger. The problem is getting the large jump in chainring size with anything off-the-shelf, I built a 28T/50 and a 30T/54T and used with the SP+Mirage and it shifted reliable, but would flex left/right annoying under any load so I had to shift to inner chainring early to reduce the flexing. It worked though. A BWR though has more capacity in the rear so it needs less in the front a rigid off-the-shelf 39T/53T would give 26"-106"

Another drawback with these front derailleurs is they don't allow a trouser guard - an issue for a folder for commuting - that tended to make mine go on folding touring bikes meaning a compact folder, its expense, tied into a package you could not really use for short work trips or shopping trips using home clothing (long socks rolled up forgives a lot!). One approach is to keep "commuting mode" the Brompton with the double-chainring with a trouser-guard as manual-shift, and only for "touring mode" fit the FD and its shifter and remove the trouser-guard.

I'm currently riding a Brompton BWR 44T with 29"-88" and a Brompton SRAM with 56T Schlumpf Mountain Drive with a 18"-97" , because I spent the $ in the past it was all a lot cheaper then ... (the Schlumpf is 60% higher cost now).

I used that in a tour I posted to in this forum the drawback was I used it with the Brompton crankset, which simply isn't rigid enough or strong enough being Aluminium, so a compact Shimano as shown here would probably be better stronger. The problem is getting the large jump in chainring size with anything off-the-shelf, I built a 28T/50 and a 30T/54T and used with the SP+Mirage and it shifted reliable, but would flex left/right annoying under any load so I had to shift to inner chainring early to reduce the flexing. It worked though. A BWR though has more capacity in the rear so it needs less in the front a rigid off-the-shelf 39T/53T would give 26"-106"

Another drawback with these front derailleurs is they don't allow a trouser guard - an issue for a folder for commuting - that tended to make mine go on folding touring bikes meaning a compact folder, its expense, tied into a package you could not really use for short work trips or shopping trips using home clothing (long socks rolled up forgives a lot!). One approach is to keep "commuting mode" the Brompton with the double-chainring with a trouser-guard as manual-shift, and only for "touring mode" fit the FD and its shifter and remove the trouser-guard.

I'm currently riding a Brompton BWR 44T with 29"-88" and a Brompton SRAM with 56T Schlumpf Mountain Drive with a 18"-97" , because I spent the $ in the past it was all a lot cheaper then ... (the Schlumpf is 60% higher cost now).

Last edited by NigelHealy; 12-29-11 at 12:11 AM.

#52

Senior Member

Join Date: Jul 2008

Location: San Mateo

Posts: 130

Bikes: 3 Bromptons, M2L-X, S6L-X/BWR. S6R/SRAM/Schlimpf, Novara Roadbike

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

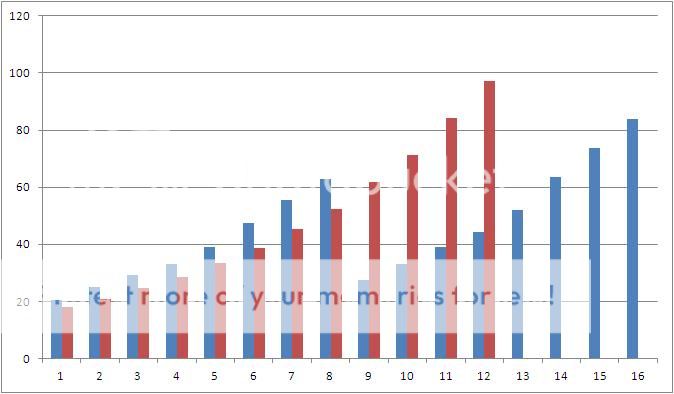

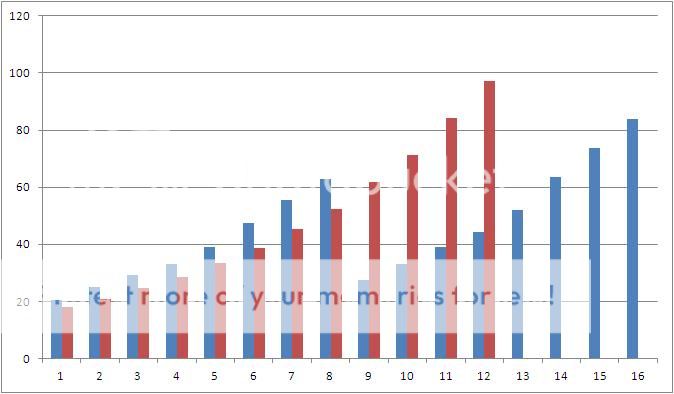

FYI this is the described Nexus 8 with the 39T/53T front mech vs a Shlumpf on the 6speed SRAM (upto 2008).

So the 16speed produces 10 unique gears (8 plus 2 higher/lower) from 20"-84" vs the Schlumpf 12 unique gears 18"-97". The jump between gears on the 16sp is varying between 13%-21% with average 17%, the Schlumpf is 15%-18% average 17%.

From my touring experience loaded with equipment in mountain country, you do need 20" low and then as high a gear as you can get above 70" to help on downhills. If someone liked the idea of adding a frontmech but not the Nexus and used say the BWR. then relative to the 1sp Brompton, then Brompton is charging £120 for the BWR and you can compare with the cost of the Nexus. The stock rear cogs of 13T/16T with a 39T/53T produces 26"-106" so make it 20" calls for say a 30T/48T for 20"-96", but one should always aim for a gear about 70" as that is the most popular for flat lightly-loaded and that would need say a 30T/44T 20"-88" or 30T/54T 20"-108".

So the 16speed produces 10 unique gears (8 plus 2 higher/lower) from 20"-84" vs the Schlumpf 12 unique gears 18"-97". The jump between gears on the 16sp is varying between 13%-21% with average 17%, the Schlumpf is 15%-18% average 17%.

From my touring experience loaded with equipment in mountain country, you do need 20" low and then as high a gear as you can get above 70" to help on downhills. If someone liked the idea of adding a frontmech but not the Nexus and used say the BWR. then relative to the 1sp Brompton, then Brompton is charging £120 for the BWR and you can compare with the cost of the Nexus. The stock rear cogs of 13T/16T with a 39T/53T produces 26"-106" so make it 20" calls for say a 30T/48T for 20"-96", but one should always aim for a gear about 70" as that is the most popular for flat lightly-loaded and that would need say a 30T/44T 20"-88" or 30T/54T 20"-108".

#53

Banned

I read Herr Schlumpf is trying to shift production out of CH,

because the Swiss Franc is becoming more expensive,

higher value in currency exchanges,

So, selling into Euro and Dollar countries , results in those big price increases.

so he is setting up an arrangement in Germany.

because the Swiss Franc is becoming more expensive,

higher value in currency exchanges,

So, selling into Euro and Dollar countries , results in those big price increases.

so he is setting up an arrangement in Germany.

#54

Newbie

Join Date: Dec 2011

Location: Whitley Bay, England

Posts: 1

Bikes: 1993 Univega - Old Faithful, Trek Valencia Plus - Problem Child, Trex 7.3FX, Brompton

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Great work!

Looks like just what I need - big hills on my commute & advancing years (I'm 58) demand more gears to save wear on the old knees.

More information on how you did it & any tips would be very welcome please

Ken

More information on how you did it & any tips would be very welcome please

Ken

#56

Senior Member

Join Date: Aug 2011

Location: Paris, France

Posts: 2,497

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 573 Post(s)

Liked 118 Times

in

99 Posts

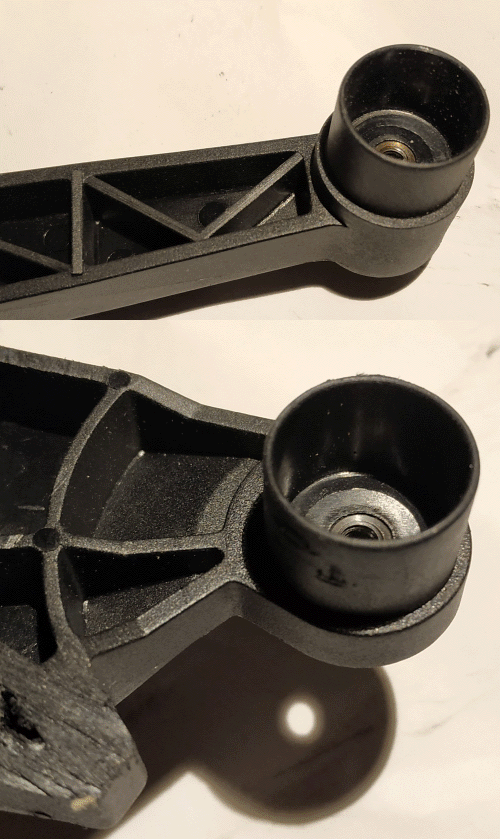

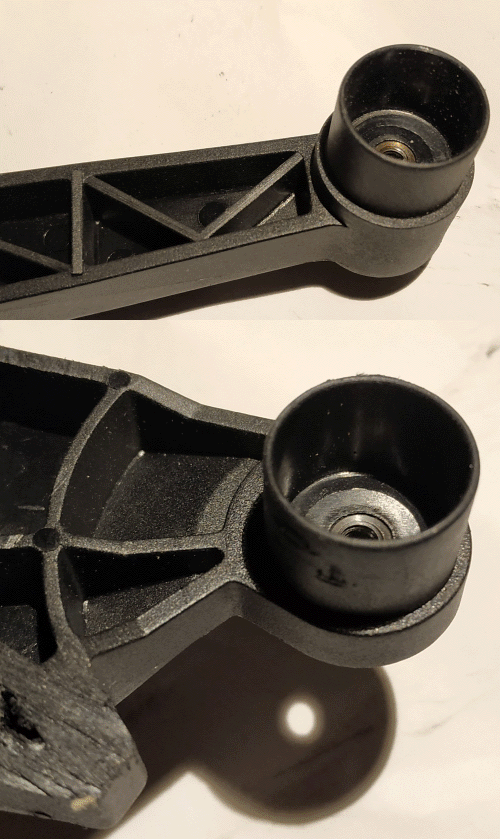

Reviving an old thread with a question about Brompton's 1/3 speed chain tensioner: How do you think the idlers (jockey wheels) were pushed inward to have a correct chain line and keep the idler wheels away from the cassette joint bracket?

Underneath, I guess the Sturmey Archer lock washers were used to get the bracket to be horizontal: Neither the blue/green nor the black/grey pairs of washers from Shimano match that setup.

Underneath, I guess the Sturmey Archer lock washers were used to get the bracket to be horizontal: Neither the blue/green nor the black/grey pairs of washers from Shimano match that setup.

#57

Schwinnasaur

I am not sure I understand your question or problem. It looks like you now have the wheel in and the frame and wheel are in the correct alignment. It looks that way.

When I added a third gear to my Brompton and tightened everything up I experienced an interference with the chain as it went over the jockey wheel contacting something (I don't remember but contacting on its side as it shifted. I think it was contacting the bottom of the derailleur. I solved the problem with a thin spacer.

When you shift, the pusher moves the chain for one gear to the other. The jockey moves vertically depending on the size of the gear. It slides horizontally on the shaft. The spring in the derailleur causes this by tensioning the chain. The chain like a string wants to be straight under tension.

When I added a third gear to my Brompton and tightened everything up I experienced an interference with the chain as it went over the jockey wheel contacting something (I don't remember but contacting on its side as it shifted. I think it was contacting the bottom of the derailleur. I solved the problem with a thin spacer.

When you shift, the pusher moves the chain for one gear to the other. The jockey moves vertically depending on the size of the gear. It slides horizontally on the shaft. The spring in the derailleur causes this by tensioning the chain. The chain like a string wants to be straight under tension.

#58

Senior Member

Join Date: Aug 2011

Location: Paris, France

Posts: 2,497

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 573 Post(s)

Liked 118 Times

in

99 Posts

It's a picture I found on the Net.

It seems to be using the 1/3 speed Brompton tensioner, with some serious spacers added to remedy the chain line: The idlers are sitting between the wheel and the cassette joint bracket, as they should be.

I wonder how it's done;

It seems to be using the 1/3 speed Brompton tensioner, with some serious spacers added to remedy the chain line: The idlers are sitting between the wheel and the cassette joint bracket, as they should be.

I wonder how it's done;

#59

Schwinnasaur

My guess would be that it is a custom rear frame section or purchased that way from Kinetics or such.

Can you get your dropouts concentric and perpendicular to where your wheel can fit in?

Can you get your dropouts concentric and perpendicular to where your wheel can fit in?

#60

Senior Member

Join Date: Aug 2011

Location: Paris, France

Posts: 2,497

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 573 Post(s)

Liked 118 Times

in

99 Posts

No, it's the original that was "simply" cold-set.

But then, the tensioner has to tweaked as shown so that the idlers are moved inward to match the location of the cog.

That's what I need to solve before asking a local bike shop to give it a shot.

But then, the tensioner has to tweaked as shown so that the idlers are moved inward to match the location of the cog.

That's what I need to solve before asking a local bike shop to give it a shot.

#61

Schwinnasaur

One thing I noticed is that on your last picture, the derailleur on that Brompton is different looking than mine or the one that is shown separately in your picture. Look at the lower jockey wheel. It has a long metal shaft that allows it to extend back to the correct position. That is likely true of the upper jockey too, but it is hard to see due the orientation of the picture. Those parts look custom but you may be able to extend yours with off the shelf hardware. I would have to mine apart to see. I have taken them apart once but just too deep clean and that a long time and I forgotten what their components look like.

If they cold set your Brompton you should ask the shop to get it in the orientation of the one in your picture. In the last picture of your bike, it was bodged.

If they cold set your Brompton you should ask the shop to get it in the orientation of the one in your picture. In the last picture of your bike, it was bodged.

#63

Senior Member

Join Date: Sep 2005

Location: Michigan

Posts: 3,706

Bikes: Trek 730 (quad), 720 & 830, Bike Friday NWT, Brompton M36R & M6R, Dahon HAT060 & HT060, ...

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 840 Post(s)

Liked 336 Times

in

251 Posts

I extended axles in my tensioner after going from 2 to 3 cogs. It is just a bolt with a piece of stainless steel tube slipped on. I.e., I used longer bolts and longer tube pieces. If you go too far, you start hitting the spokes.

#64

Senior Member

Join Date: Aug 2011

Location: Paris, France

Posts: 2,497

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 573 Post(s)

Liked 118 Times

in

99 Posts

Won't the axle break because of the leverage, since it's no longer resting within the body?

Of I could just use a non-Brompton short cage rear derailleur, as some have done:

Of I could just use a non-Brompton short cage rear derailleur, as some have done:

#65

Senior Member

Join Date: Aug 2011

Location: Paris, France

Posts: 2,497

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 573 Post(s)

Liked 118 Times

in

99 Posts

Looks like that's exactly what Brommieplus did to fit the Sturmey Archer X-RF8 gear hub:

https://www.brommieplus.com/portal_c...&cnt_id=344818

https://www.brommieplus.com/portal_c...&cnt_id=344818

#68

Senior Member

Join Date: Sep 2005

Location: Michigan

Posts: 3,706

Bikes: Trek 730 (quad), 720 & 830, Bike Friday NWT, Brompton M36R & M6R, Dahon HAT060 & HT060, ...

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 840 Post(s)

Liked 336 Times

in

251 Posts

At some point there might be indeed too much leverage. However, there is not much space there anyway. My modestly extended axles have worked for years now.

As to the regular derailleur for Brompton, I tried that route too, but it ended up being more of a loss than gain. Basically, the original Brompton tensioner is very good in gathering the chain slack. When I added 30T difference between the largest and smallest ring in the front, the Brompton tensioner managed to eat that up. The tensioners in regular derailleurs are meager in comparison. I tried chain catchers, etc., but it was pointless. Basically, you may get away with a a regular derailleur in the back of Brompton, but then forget multiple rings in the front.

I explored also the option of a Suntour rear derailleur under the chainstay of Brompton, going then for 2 tensioners, original + Suntour, but it was impossible to make it compatible with folding.

As to the regular derailleur for Brompton, I tried that route too, but it ended up being more of a loss than gain. Basically, the original Brompton tensioner is very good in gathering the chain slack. When I added 30T difference between the largest and smallest ring in the front, the Brompton tensioner managed to eat that up. The tensioners in regular derailleurs are meager in comparison. I tried chain catchers, etc., but it was pointless. Basically, you may get away with a a regular derailleur in the back of Brompton, but then forget multiple rings in the front.

I explored also the option of a Suntour rear derailleur under the chainstay of Brompton, going then for 2 tensioners, original + Suntour, but it was impossible to make it compatible with folding.

#69

Senior Member

Join Date: Aug 2011

Location: Paris, France

Posts: 2,497

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 573 Post(s)

Liked 118 Times

in

99 Posts

Thanks for the feeback.

What I don't understand, is how the original chain tensioner could work with the sleeves not resting on anything unless the idlers haven't been pushed out too much (ie.part of them still rests on the original location).

Was some kind of O-ring added in there to sort of hold the sleeve in place and avoid play? And even then, is it enough?

What I don't understand, is how the original chain tensioner could work with the sleeves not resting on anything unless the idlers haven't been pushed out too much (ie.part of them still rests on the original location).

Was some kind of O-ring added in there to sort of hold the sleeve in place and avoid play? And even then, is it enough?

#70

Schwinnasaur

Everything is resting on something .(If not everything would get tired Bolts and sleeves are cantilevered off the derailleur. The jockey wheels can slide and rotate on the sleeves. The forces on the jockey wheels are mainly from the tensioner spring and the chain. The chain is not putting that much force on them. When you pedal most of the force goes into the sprockets and a little bit goes into rotating the jockey wheels which does not take much. .

Bolts and sleeves are cantilevered off the derailleur. The jockey wheels can slide and rotate on the sleeves. The forces on the jockey wheels are mainly from the tensioner spring and the chain. The chain is not putting that much force on them. When you pedal most of the force goes into the sprockets and a little bit goes into rotating the jockey wheels which does not take much. .

The jockey wheel needs to slide on the sleeve but not much, enough to make the shift. In my case I have three narrow cogs instead of the stock two thicker ones but basically using the same space and stock derailleur system. The modified ones in your picture are trying extend beyond 3 gears so they need modify the derailleur to have more horizontal travel. In your case the horizontal range is fine but you need to modify the derailleur so that the jockey wheels are where they are supposed to be. The horizontal range is fine but the you need more distance over due widening the rear fork. Or am I completely missing the problem?

Bolts and sleeves are cantilevered off the derailleur. The jockey wheels can slide and rotate on the sleeves. The forces on the jockey wheels are mainly from the tensioner spring and the chain. The chain is not putting that much force on them. When you pedal most of the force goes into the sprockets and a little bit goes into rotating the jockey wheels which does not take much. .

Bolts and sleeves are cantilevered off the derailleur. The jockey wheels can slide and rotate on the sleeves. The forces on the jockey wheels are mainly from the tensioner spring and the chain. The chain is not putting that much force on them. When you pedal most of the force goes into the sprockets and a little bit goes into rotating the jockey wheels which does not take much. .The jockey wheel needs to slide on the sleeve but not much, enough to make the shift. In my case I have three narrow cogs instead of the stock two thicker ones but basically using the same space and stock derailleur system. The modified ones in your picture are trying extend beyond 3 gears so they need modify the derailleur to have more horizontal travel. In your case the horizontal range is fine but you need to modify the derailleur so that the jockey wheels are where they are supposed to be. The horizontal range is fine but the you need more distance over due widening the rear fork. Or am I completely missing the problem?

#71

Senior Member

Join Date: Aug 2011

Location: Paris, France

Posts: 2,497

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 573 Post(s)

Liked 118 Times

in

99 Posts

What does the sleeve rest on once the jockey wheel has been moved outward?

I happened on the following page, although the idea did occur to me to head for a fablab and "3D print" a couple of parts to fill the now-hollow sections through which to screw the sleeves + bolts:

I happened on the following page, although the idea did occur to me to head for a fablab and "3D print" a couple of parts to fill the now-hollow sections through which to screw the sleeves + bolts:

#73

Schwinnasaur

The jockey wheel is supported at inside end by sitting on the metal sleeve. Think of that side as a bearing. I think you have the wheel sitting on plastic sitting on the metal sleeve. In the worse case it is being carried by the bolt. I would have to take mine apart. What would work best for you would be have a piece or round stock aluminum the same diameter as the outside of the derailleurs sleeve stepped down where it goes inside the sleeve and center drilled to the same diameter size to fit the metal sleeve. The length determined by where it needs to be. In your case under the cog. I think I could make the piece just on a drill press but a lathe would do better. I forgot but you are just thinking of doing one cog. Correct?

#74

Senior Member

Join Date: Aug 2011

Location: Paris, France

Posts: 2,497

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 573 Post(s)

Liked 118 Times

in

99 Posts

No, both jockeys must be modified since they both move (when using the derailleur, and now to match the new chain line with the Nexus).

Looks like a 3D printer would be easier than finding someone to carve one half of a metal tube, as AussieOnABrompton did.

Besides the chain tensioner, another issue is that only the 15mm nut used on the SturmeyArcher hub fits the chain tensioner… while Shimano uses 17mm nuts.

And to make it more interesting, the axle on the SA hub is apparently 10mm while Shimano uses 9.525mm (3/8") on the Alfine. It seems tight enough on the Nexus, but who knows.

So it looks like I'll keep the SA lock washers + nuts, and see how it goes.

Looks like a 3D printer would be easier than finding someone to carve one half of a metal tube, as AussieOnABrompton did.

Besides the chain tensioner, another issue is that only the 15mm nut used on the SturmeyArcher hub fits the chain tensioner… while Shimano uses 17mm nuts.

And to make it more interesting, the axle on the SA hub is apparently 10mm while Shimano uses 9.525mm (3/8") on the Alfine. It seems tight enough on the Nexus, but who knows.

So it looks like I'll keep the SA lock washers + nuts, and see how it goes.

#75

Schwinnasaur

Yes both jockey wheels need to move. When I say one cog, I am saying you do not need to add to or change the range, like the one in the picture.

I looked at AussieOnABrompton. You might find a spacer, aluminum or plastic. One of those might move you over to where to movement range might let you position correctly with some cutting or grinding to space you right.

Did AussieOnABrompton cold set the rear frame?

I looked at AussieOnABrompton. You might find a spacer, aluminum or plastic. One of those might move you over to where to movement range might let you position correctly with some cutting or grinding to space you right.

Did AussieOnABrompton cold set the rear frame?

Last edited by Schwinnsta; 03-04-21 at 08:11 PM. Reason: Changed to the text