Underwater bike gears

#26

Senior Member

re chain skipping--you would think this would happen due to an already "on the edge" worn chain and or cassette, quite possibly from a pretty worn out donor bike. We crank down pretty hard on drivetrains and don't have skipping unless there is a wear issue already. One would think that a derailleur tension underwater would be the same, and if it is securely set in the right position for a given cog, being immersed in water wouldnt be a factor (certainly dont have underwater drivetrain experience though)

Liquids and gases/gas mixtures (like air) are both fluids. In any fluid, a moving object experiences form drag. In air, it’s called aerodynamic form drag; in water, it’s called hydrodynamic form drag. While form drag in gases/gas mixtures and liquids are governed by the same basic equation (D = ˝ρCAv^2), in virtually all cases there will be a large difference in scale.

All else being equal (shape, velocity, etc . . . ) form drag varies linearly with the density (“ρ” in the equation above) of the fluid through which an object is passing. It also increases with the square of velocity, so drag becomes far larger proportionally as speed increases. (For those interested, the other terms are “D”: form drag; “A”: frontal area; “v”: velocity; and “C”: coefficient of drag, which varies with the shape of the object concerned.)

Water is roughly 800 times denser than air. If the RD is underwater and exposed to the point it receives relatively unimpeded fluid flow past it, the increased form drag might be enough to be significant. My guess is that the derailleur body would be pushed back more than when in air at the same speed - since it will experience about 800 times more drag force pushing it back than in air at the same speed. Would that extra force move it backwards enough to cause problems? Dunno; that would depend on the strength of the RD's springs. But it's a helluva large increase. In theory, it could.

As noted above, going single speed would eliminate the issue.

But if a single-speed drivetrain won’t do and multi-speed gearing using an RD exposed to flow is necessary, it might be worth fabricating a faring and placing it in front of the RD to shield it somewhat and thus reduce the effect of form drag on the RD. It might even reduce form drag overall slightly (or might not, depending on it's area and shape). Making test runs with and without the faring would show definitively whether or not it was needed and/or helpful.

References: https://physics.info/drag/ (for discussion of form drag); Wikipedia (for comparative density of air and water)

Last edited by Hondo6; 01-19-23 at 10:58 AM. Reason: Technically more precise language; add references.

#27

Senior Member

Hondo, makes for an interesting armchair topic doesnt it? I would have thought the really slow underwater speed wouldnt have an effect, but who knows. Will certainly be something for this group of students to encounter and perhaps have to work around. If going single speed is easy to figure out what gear would be better (guess they could do tests in a tank or something) or just resize a chain for whatever cog works better with the human engine and the reality of moving this thing through the water.

The poster Kooby is the one to ask his or her real life experiences.

still kinda fun just thinking of the ins and the outs isnt it?

The poster Kooby is the one to ask his or her real life experiences.

still kinda fun just thinking of the ins and the outs isnt it?

#28

Senior Member

Hondo, makes for an interesting armchair topic doesnt it? I would have thought the really slow underwater speed wouldnt have an effect, but who knows. Will certainly be something for this group of students to encounter and perhaps have to work around. If going single speed is easy to figure out what gear would be better (guess they could do tests in a tank or something) or just resize a chain for whatever cog works better with the human engine and the reality of moving this thing through the water.

The poster Kooby is the one to ask his or her real life experiences.

still kinda fun just thinking of the ins and the outs isnt it?

The poster Kooby is the one to ask his or her real life experiences.

still kinda fun just thinking of the ins and the outs isnt it?

I have no idea at what speed wind resistance begins to affect a RD's geometry due to wind resistance on the RD body and cage. But I got curious, and played around a bit with a spreadsheet. The calculations were bit surprising.

In the equations for form drag, assuming that the coefficient of drag remains the same for the two fluids everything cancels out if you divide drag in water by drag in air except for density and speed. And the ratio of densities is a constant: 800. Plus, the units for velocity also cancel out. So a quick calculation can let you determine what speeds in water and air have roughly equivalent drag.

Turns out that 1 MPH/kph/whatever in water has the equivalent drag as between 29 and 29 MPH/kph/whatever. That speed probably isn't an issue. But remember, the velocity is squared in the equation.

A velocity of 2 in water calculates out as having drag equivalent to a velocity of between 58 and 59 in air. For 3, the numbers get silly: a velocity of 3 in water has the same drag as a velocity of almost 85(!) in air. I stopped there.

As I said: dunno at what air speed a RD begins to experience enough drag to affect its geometry (and thus shifting) by rotating the cage, and I also have zero idea how fast a human-powered sub can go. But the relative difference in drag is certainly enough to make one wonder if the increased drag in water might have an effect on an exposed derailleur-type drivetrain.

#29

Senior Member

My totally unknowledgeable opinion is that the slow speed underwater will not be an issue to a Rd, but a shield in front of it would certainly deal with the walking speed ish this craft will be going at.

The one underwater ghost shifting example here could very well have been a crappy drivetrain or misadjusted shifter, bent hanger, who knows.

It would be fun if the parent asking the question comes back with a progress report, but thats to be seen.

The one underwater ghost shifting example here could very well have been a crappy drivetrain or misadjusted shifter, bent hanger, who knows.

It would be fun if the parent asking the question comes back with a progress report, but thats to be seen.

#30

Newbie

In our sub, we tested the drivetrain with the RD on land and didn't have problems, but if i recall correctly we didn't test it with resistance on the propeller, so that may have been a problem. Also its possible the RD wasn't in an ideal position and there was less chain wrap on the cassette. I think in our case it may have just been a perfect storm: viscous environment, old chain+cassette, lots of resistance, poor geometry, etc.

#31

Newbie

Well... I went back and found some pictures from our sub...

Definitely the angle the RD is mounted at is not correct, also i think the chain might be too short?

Definitely the angle the RD is mounted at is not correct, also i think the chain might be too short?

Likes For kooby:

#32

Disco Infiltrator

Join Date: May 2013

Location: Folsom CA

Posts: 13,446

Bikes: Stormchaser, Paramount, Tilt, Samba tandem

Mentioned: 72 Post(s)

Tagged: 0 Thread(s)

Quoted: 3126 Post(s)

Liked 2,105 Times

in

1,369 Posts

This is a really cool project.

I did a lot of events like this through my school career though not a submarine specifically. A really efficient RC airplane, various rocket events, a wind tunnel model, a “joule mobile,” a Rube Goldberg contest.

Make pilot safety #1 priority (HPV subs have an original sin) and thorough testing very next. Performance third. Finish the thing weeks in advance and get it running well. If you show up with a craft you just finished you will spend the whole event testing and never get on the board.

I did a lot of events like this through my school career though not a submarine specifically. A really efficient RC airplane, various rocket events, a wind tunnel model, a “joule mobile,” a Rube Goldberg contest.

Make pilot safety #1 priority (HPV subs have an original sin) and thorough testing very next. Performance third. Finish the thing weeks in advance and get it running well. If you show up with a craft you just finished you will spend the whole event testing and never get on the board.

Last edited by Darth Lefty; 01-20-23 at 02:05 AM.

#33

Senior Member

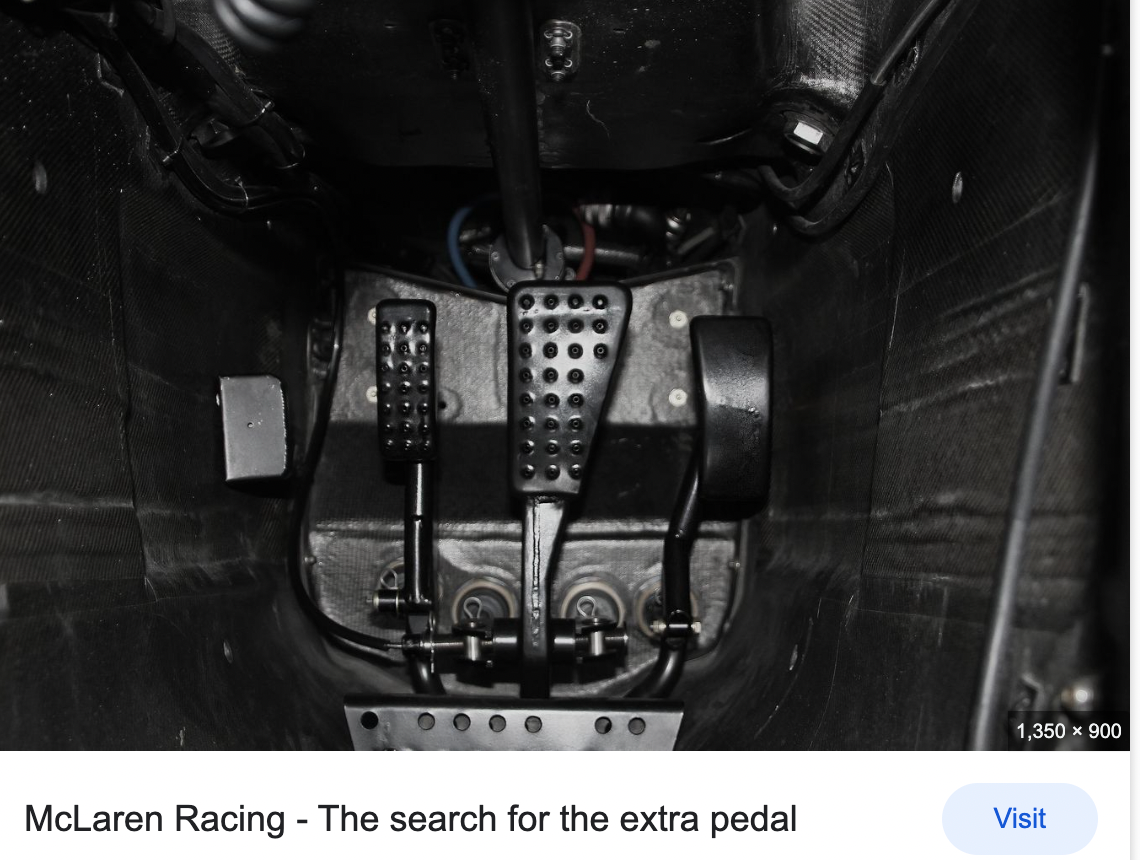

*It makes me recall this from Formula One, anyone else follow F1 and the "fourth pedal" that a photographer finally snapped a photo of when one of the Maclarens broke down on track and he stuck his camera with flash into the cockpit and snapped the shot that brought their neat braking system to light?

https://www.mclaren.com/racing/insid...pedal-3153421/

We can see that the chain was not routed through both rd pulleys, so theres that already thats a factor (or not) but the fact that the rd is mounted onto a solid block of aluminum that doesnt allow for proper positioning could have been the problem also.

When I mentioned the derailleur hanger, I hadn't visualized how the drivetrain setup would be like, but I wonder if a hanger type setup would allow more adjustment, ie slight bending of a steel piece, to get the rd right.

Mind you, I'm sure you guys did the alignment measurements of this block that the rd was attached to, but who knows. Also, I don't know what factor running the chain only through one jockey wheel was, but if possible, keeping the drivetrain in the same working configuration as on a bike would seem like the least problematic method, as its a known factor in how it works.

After all this interesting talk, I suspect the parent who asked this question came to a "bicycle forum" just to get an answer about the bearings and lube, and perhaps got put off by the speculating by all of us, and / or the one grumpy guy here.

to the parent, if you see this, suggest to your son and team to really look at the basics of a working bike in regards to rd placement, chain alignment distances in regard to crankset and cassette, and try to mimic this setup as best as possible while dealing with the space constraints and gear transfer stuff going on to turn a propshaft.

If they go single speed, then just have some prelengthened chains for different cogs until they figure out what gear is more appropriate. A bike store could even give them some old chains to use that will serve the purpose well enough.

Last edited by djb; 01-20-23 at 09:35 AM. Reason: added in Formula 1 reveal photo from 1997

#34

Newbie

Thread Starter

Join Date: Jan 2023

Posts: 8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Liked 0 Times

in

0 Posts

Is this for the International Submarine races at the David Taylor model basin in Carderock? I did that back in high school, we went with a bike drivetrain too. For the bearings, we just made sure to wash them off, sprayed them with WD-40 and put some fresh grease in before we left for the races. They lasted the whole weekend without any problems. I think the water they used in that basin was pretty fresh, so corrosion wasnt a big issue.

On a side note: we had problems with the chain skipping on the rear cassette of our bike drivetrain, so i reccomend increasing chain tension if you are using a derailleur, or better yet: go single speed and avoid the problem altogether.

On a side note: we had problems with the chain skipping on the rear cassette of our bike drivetrain, so i reccomend increasing chain tension if you are using a derailleur, or better yet: go single speed and avoid the problem altogether.

Thanks so much for replying! We have no idea what to expect. Any other ibsights into what typically goes wrong? Was control an issue?

#35

Newbie

Also, having a good cart to transport the sub from the waiting area to the basin will save you a lot of energy and frustration.

I will probably be going to this year's edition of ISR, so I hope to see your son's team there!

Likes For kooby:

#36

Newbie

Thread Starter

Join Date: Jan 2023

Posts: 8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Liked 0 Times

in

0 Posts

Yeah, control absolutely was a problem for us. Our control fins were way too small, they would have worked well at higher speeds, but we never managed to get the sub up to those speeds. I think they were about 10x10 inches for each fin? Our quick-fix was to cut up some plastic boxes and use duct tape to attach them to the fins to increase their size. I think a good fin size should be 12x24 inches.Also, having a good cart to transport the sub from the waiting area to the basin will save you a lot of energy and frustration. I will probably be going to this year's edition of ISR, so I hope to see your son's team there!

#37

Newbie

Thread Starter

Join Date: Jan 2023

Posts: 8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Liked 0 Times

in

0 Posts

The first decision is whether you're considering a dry boat (air filled) or a flooded design. The following is for s dry boat. The secret is in having a decent design that keeps the bearings dry. Simply put you have the support bearings inside the hull, with a plain bearing, or nylon sleeve as the through hull. I can't upload a sketch, so try to visualize. You attach the framework to the hull with the shaft supported by ball bearings, then extending through thd hull using a bushing with rubber or plastic seals on the outer edge. There will be some weepage, depending on depth and pressurization. If you're pressurizing the boat, then slight over pressure will bleed air out and prevent water from entering. Or you can use a box inside the thru-hull, and feed a small trickle of air so there's a positive outflow. The basic design can be refined but the key is a between the bearing and a 2-3" sleeve as the through hull. BTW the biggest challenge will be managing air. Whethet you opt to breath through a mask, try to recruit someone familiar with the physiology of underwater exercise, because it's different than on the surface.

#38

Newbie

Thread Starter

Join Date: Jan 2023

Posts: 8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Liked 0 Times

in

0 Posts

Fresh water won't be too hard on the hub or chain. Note that rhe damage happens while things stay wet for hours after leaving the water. So, marine grease, then use a heat gun or powerful hair dryer after each set of runs so the wet time is minimized. You can also buy zinc powder, and blend it into the grease to add some extra time against corrosion. FWIW, my road bike/touring bike has been submerged multiple times in floods and 1 lake. No damage or rust despite no special precautions or maintenance.‐------------Just out of curiosity ---- how long is the event?. I'm a diver and know what hard effort does to sir consumption.

#39

Newbie

Thread Starter

Join Date: Jan 2023

Posts: 8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Liked 0 Times

in

0 Posts

Hi, actual Subsea Vehicle Pilot/Tech here: Unless this thing is staying underwater for weeks at a time, you don’t need to go to any extreme measures. Especially if it’s fresh water, galvanic corrosion happens way slower In fresh , and way slower than you all think it does, even in seawater. Like it was mentioned above, it’ll be the most vulnerable to corrosion if it’s left wet after it comes out of the water. Rinse it when it comes out, and use compressed air (even a leaf blower) to get the water out of the nooks and crannies.We also use a lot of wd40 on surfaces we don’t want water settling on (after we hit it with the air) we use a lot of solid bronze bushings, with ceramic on the high-speed stuff like the thruster prop shafts. You’ll probably not need to withstand 200hp at 300 rpm, so the standard bearings in the hubs/cranks will be fine. I’d pack them full of blue “trailer” grease to keep the water out. We use that on a lot out here. Adding a zerk to keep them topped off is a good idea, just so you don’t have to tear them down every time you want to add grease. If there’s a chain involved, we like White Lightning “Epic” chain lube (mfgr recommended) or in a pinch, the white lithium grease that comes in a spray can. It’s really more about getting lube between the side plates, than on the rollers. Good luck with the project!

#40

Newbie

Thread Starter

Join Date: Jan 2023

Posts: 8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Liked 0 Times

in

0 Posts

I know this is a bike forum, so I will not go further with any sub questions, but here is one of the episodes where we chop up his old mountain bike for the drivetrain. If interested in the non bike-related progress you can check out the youtube channel. Thx for all the help!

#41

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,696

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5774 Post(s)

Liked 2,571 Times

in

1,423 Posts

Not for your application. Time is on your side here. Whatever water damage occurs will be too slow to matter.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#42

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,696

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5774 Post(s)

Liked 2,571 Times

in

1,423 Posts

Thanks, but I was more focused on the time length of individual heats & the air consumption considerations.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#43

Dirty Heathen

Join Date: Oct 2015

Location: MC-778, 6250 fsw

Posts: 2,182

Bikes: 1997 Cannondale, 1976 Bridgestone, 1998 SoftRide, 1989 Klein, 1989 Black Lightning #0033

Mentioned: 19 Post(s)

Tagged: 0 Thread(s)

Quoted: 889 Post(s)

Liked 906 Times

in

534 Posts

I'd plan for the bearings to get 'wet' Depending on what kind of bearing it is, simply filling the housing with grease would be sufficient; there's no 'space' for the water to go if it gets past the seals, but I doubt you'll be seeing the kind of water pressure or shaft speed that UHD-310 is seeing up in post #23

For a 'sealed cartridge' bearing, hosing it down with White Lightning 'Epic' or 'Wet' should be enough to keep the bearings happy for the duration of a trial heat.

Remember, get all the water out / off of it as soon as it's out of the pool for the day. WD-40 is good for getting water off of surfaces and out of cracks, but it also tends to 'thin out' other grease and lube, so be ready to re-lube after everything is dried off.

Good Luck!

#44

Senior Member

Probably not worth the headache. Trying to run a 'dry' bearing, means sooner or later, you'll be lubricating those bearings with....water. You could, I suppose; but it'd mean constructing an entire new bearing housing, since you can't just stick a seal on the outside of the existing hub / crank spindle.

I'd plan for the bearings to get 'wet' Depending on what kind of bearing it is, simply filling the housing with grease would be sufficient; there's no 'space' for the water to go if it gets past the seals, but I doubt you'll be seeing the kind of water pressure or shaft speed that UHD-310 is seeing up in post #23

For a 'sealed cartridge' bearing, hosing it down with White Lightning 'Epic' or 'Wet' should be enough to keep the bearings happy for the duration of a trial heat.

Remember, get all the water out / off of it as soon as it's out of the pool for the day. WD-40 is good for getting water off of surfaces and out of cracks, but it also tends to 'thin out' other grease and lube, so be ready to re-lube after everything is dried off.

Good Luck!

I'd plan for the bearings to get 'wet' Depending on what kind of bearing it is, simply filling the housing with grease would be sufficient; there's no 'space' for the water to go if it gets past the seals, but I doubt you'll be seeing the kind of water pressure or shaft speed that UHD-310 is seeing up in post #23

For a 'sealed cartridge' bearing, hosing it down with White Lightning 'Epic' or 'Wet' should be enough to keep the bearings happy for the duration of a trial heat.

Remember, get all the water out / off of it as soon as it's out of the pool for the day. WD-40 is good for getting water off of surfaces and out of cracks, but it also tends to 'thin out' other grease and lube, so be ready to re-lube after everything is dried off.

Good Luck!

its probable that these folks wont have any experience opening up a bottom bracket (bb) nor have the tools, so to the parent--if at all possible, ask around if someone you know has the tools and experience, and they could open up the bike before it is chopped up and cram it full of marine grease.

I'm sure you'll all be having lots of other things to think about as the project progresses, and if lucky, a well packed bottom bracket bearing will be fine enough as is for the duration of the project if it is packed well with grease.

to the parent, look up the types of bottom bracket bearings, so when you get a donor bike to chop up, you'll have an idea of what to do to grease it if the team ends up doing it yourselves. Its a fairly simple job, it just comes down to having the right tools to do it, depending on the bb type.

this is an old style loose ball bearing type bearing, its still common on low end bikes, which might be what you end up as a donor bike.

and a sealed bottom bracket type

hopefully you can find a helpful bike person with the tools who is happy to help out.

Likes For djb: