Framebuilder Question: Never seen a weld on this area before

#1

Junior Member

Thread Starter

Join Date: Sep 2020

Posts: 14

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 8 Times

in

4 Posts

Framebuilder Question: Never seen a weld on this area before

cheers everybody,

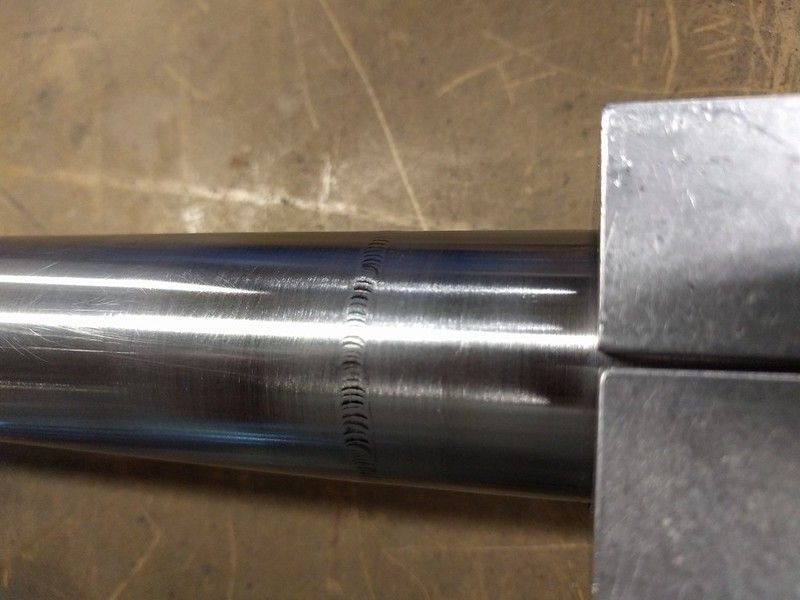

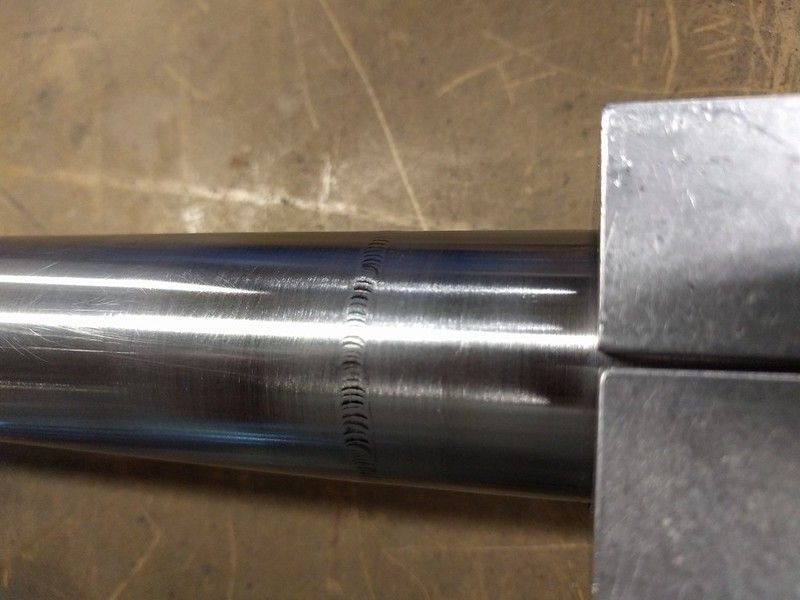

recently I stumbled upon quite a nice steel frame on the net. however I realised that the seat tube was welded in an interesting way that I have never seen before.

maybe someone can explain to me why they chose to weld the seat tube like they did.

thanks in advance

:-)

recently I stumbled upon quite a nice steel frame on the net. however I realised that the seat tube was welded in an interesting way that I have never seen before.

maybe someone can explain to me why they chose to weld the seat tube like they did.

thanks in advance

:-)

Last edited by vxchtx; 11-13-21 at 10:20 AM.

#2

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,396

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

That's there because many sizes of tubes are not available in convenient sizes to fit easily available seat posts. Or more likely, the tubes that fit the easily available seat posts are too heavy. So builders weld in a collar.

You can shop all the seat tube collars that paragon machine makes on this page https://www.paragonmachineworks.com/...t+tube+collars

You can shop all the seat tube collars that paragon machine makes on this page https://www.paragonmachineworks.com/...t+tube+collars

Likes For unterhausen:

#3

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,073

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4201 Post(s)

Liked 3,857 Times

in

2,305 Posts

Not an uncommon way to get the top of the seat tube to a spec ID, as Eric mentions. Seen a lot of TI frames and some steel ones done this way. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#4

Senior Member

Join Date: Jan 2013

Location: South Jersey

Posts: 2,266

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 714 Post(s)

Liked 800 Times

in

475 Posts

I use seat collars like that to make some of my MTB seat tubes to fit dropper posts or to make a seat tube out of a tube intended for a different purpose. I sometimes use a tube intended to be a bent downtube for a seat tube and that leaves me with a 34.9mm tube with a .6mm wall where I cut the tube to the proper length for a seat tube. In order to get the tube to fit a 30.9 or 31.6 seat post and have enough strength to weld the top tube and seat stays to it, I attach a 4" section of a much thicker walled tube to the top of it.

This is a 4" section of 4130 tube that I turned with a step to fit the inside of the 34.9 x .6mm wall tube and the interior dimension to fit a 31.6 seat tube.

That tube section fusion welded into the seat tube. If the fit is tight enough, it can be fusion welded and the weld just about disappears under powder coat.

This is the finished frame with that seat tube.

This is a 4" section of 4130 tube that I turned with a step to fit the inside of the 34.9 x .6mm wall tube and the interior dimension to fit a 31.6 seat tube.

That tube section fusion welded into the seat tube. If the fit is tight enough, it can be fusion welded and the weld just about disappears under powder coat.

This is the finished frame with that seat tube.

Likes For dsaul: