Who did "this" to crown race sholders

#1

Stop reading my posts!

Thread Starter

Who did "this" to crown race sholders

I bought a frameset that has almost no identifying features: it was supposedly a prop for a trade show but seems perfectly ride-able.

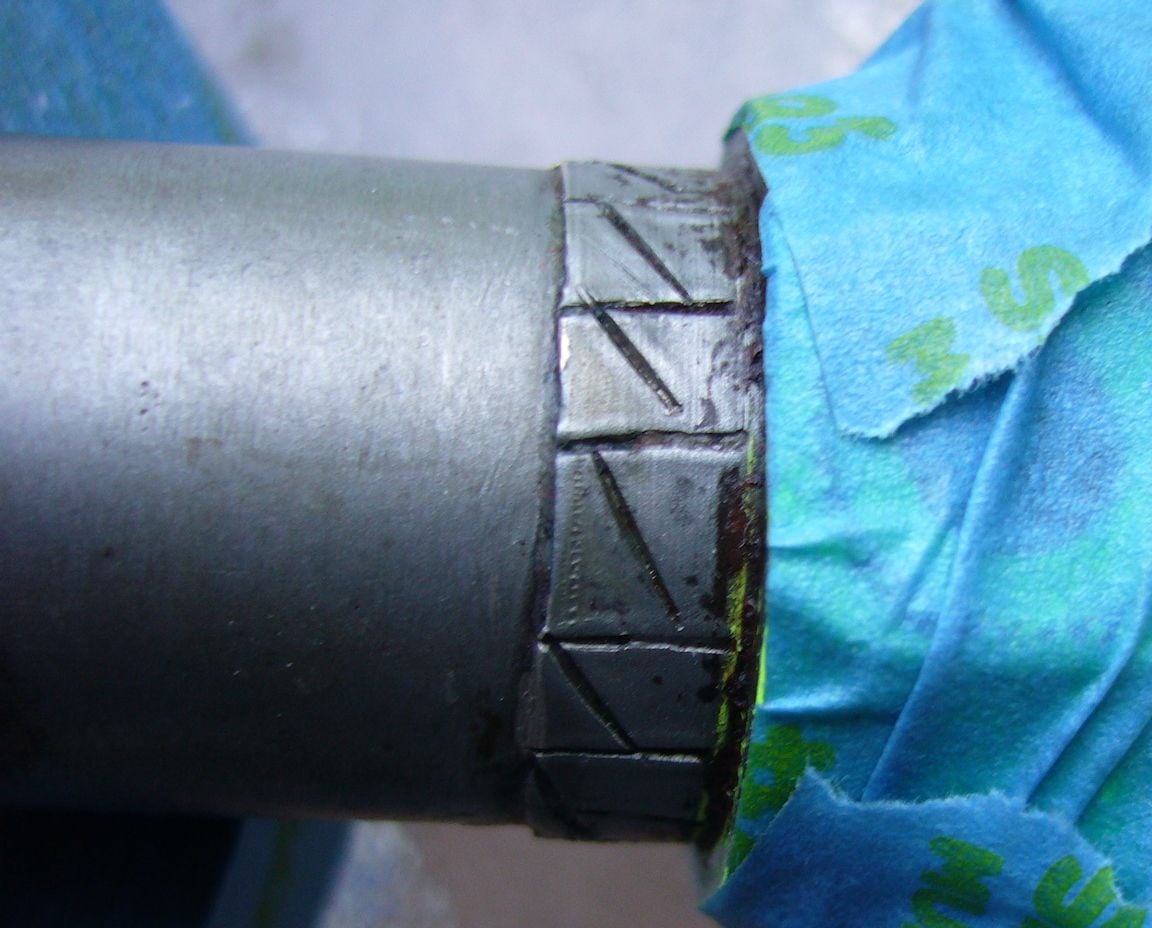

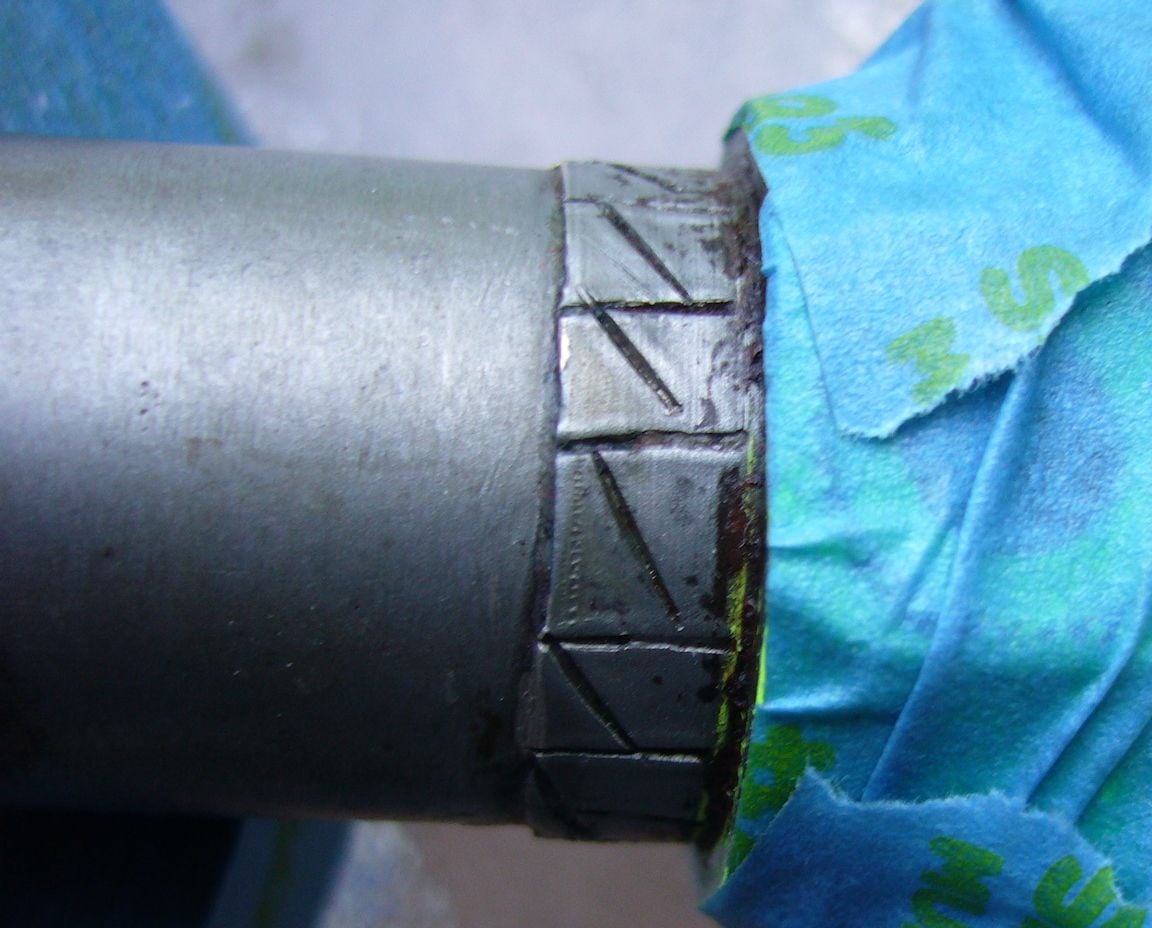

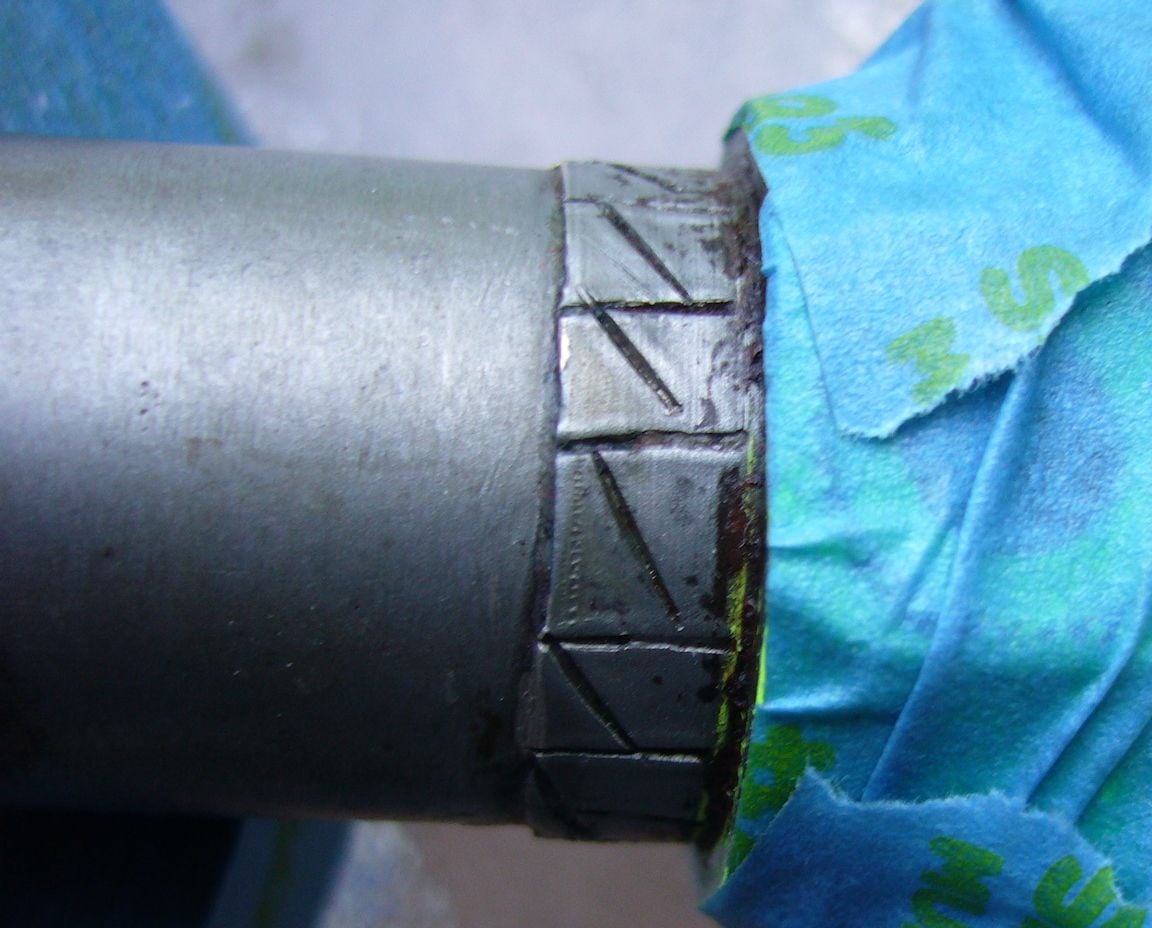

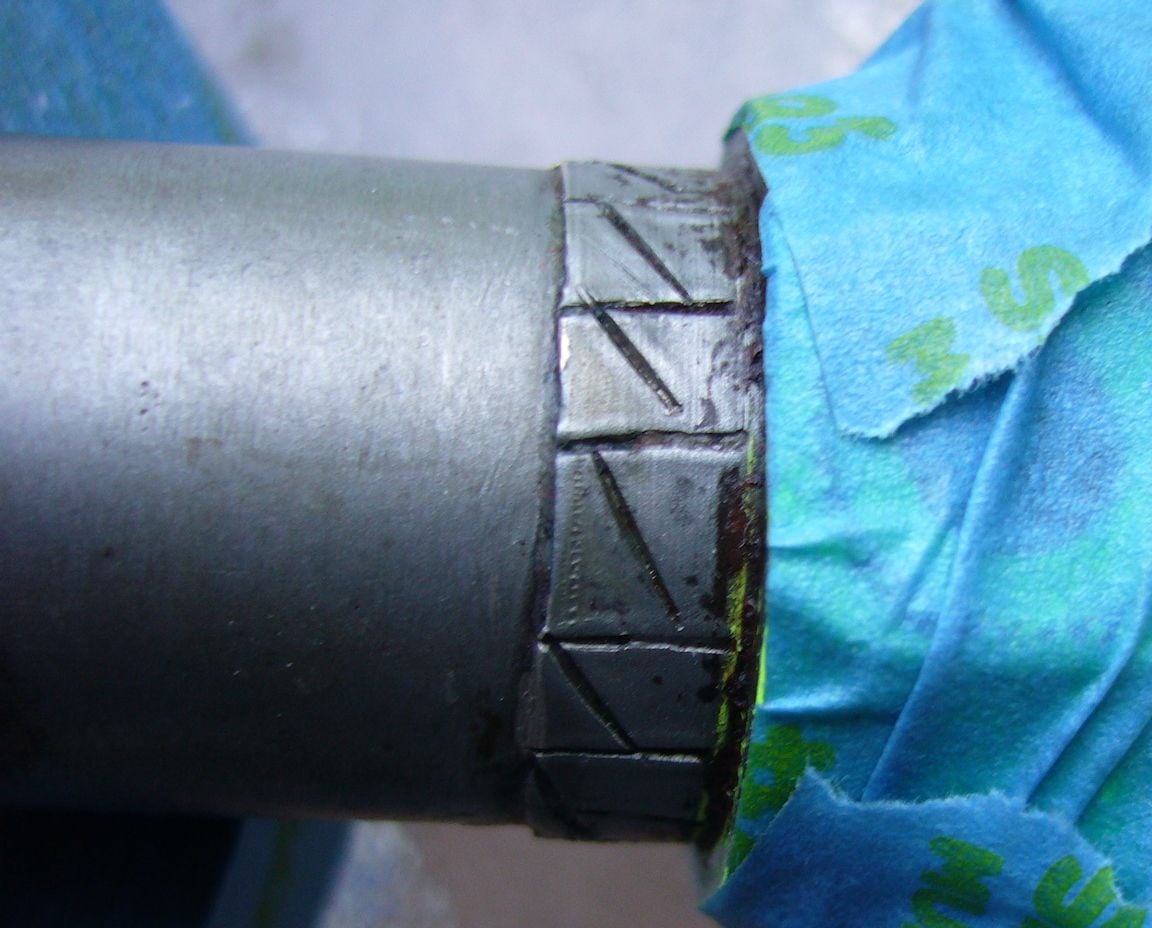

Anyhow could have been built in the East Coast of USA, might be Tig-welded or (less likely} fillet-brazed...but this treatment of the crown race collar is nothing I have seen before.

Might have needed "peening" for a tight press-fit, but I have only seen frame builders (or shop-dogs) use a sharp punch for that, this looks to be a small chisel.

Any guesses?

Anyhow could have been built in the East Coast of USA, might be Tig-welded or (less likely} fillet-brazed...but this treatment of the crown race collar is nothing I have seen before.

Might have needed "peening" for a tight press-fit, but I have only seen frame builders (or shop-dogs) use a sharp punch for that, this looks to be a small chisel.

Any guesses?

#2

Senior Member

I use an automatic center punch, and hit four quadrants, then in between, then above/below those if it's still loose. The automatic part makes it less likely to need re-facing after the fact.

That looks...interesting, and none-too-accurate, at that.

That looks...interesting, and none-too-accurate, at that.

#3

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,359

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Liked 1,409 Times

in

934 Posts

Four quadrants or five should be plenty enough to center the race, but with Loctite applied to take the actual load, lest the peening get knocked down and allow the crown race to start moving.

A heavy application of peening, as shown, is more appropriate if no Loctite is used.

Even Schwinn's knurling failed me after just a thousand miles before I added Loctite to the joining.

A heavy application of peening, as shown, is more appropriate if no Loctite is used.

Even Schwinn's knurling failed me after just a thousand miles before I added Loctite to the joining.

#4

Senior Member

I bought a frameset that has almost no identifying features: it was supposedly a prop for a trade show but seems perfectly ride-able.

Anyhow could have been built in the East Coast of USA, might be Tig-welded or (less likely} fillet-brazed...but this treatment of the crown race collar is nothing I have seen before.

Might have needed "peening" for a tight press-fit, but I have only seen frame builders (or shop-dogs) use a sharp punch for that, this looks to be a small chisel.

Any guesses?

Anyhow could have been built in the East Coast of USA, might be Tig-welded or (less likely} fillet-brazed...but this treatment of the crown race collar is nothing I have seen before.

Might have needed "peening" for a tight press-fit, but I have only seen frame builders (or shop-dogs) use a sharp punch for that, this looks to be a small chisel.

Any guesses?

Likes For Schweinhund:

#5

Junior Member

It appears that whoever built the fork did not have tooling to finish the crown race seat. How did it become undersized to start with? The diameter of fork crown race seats are usually slightly oversize diameter and cut to size simultaneously when surfacing the seat.

Likes For stoneageyosh:

#6

www.theheadbadge.com

Join Date: Sep 2005

Location: Southern Florida

Posts: 28,602

Bikes: https://www.theheadbadge.com

Liked 4,543 Times

in

2,143 Posts

What diameter is it at present? 26.4 slotted out to 27.0? Have any photos of the rest?

I am curious if the craftsmanship matches the crown - whether the corner cutting shown here is evident in other areas of the frame, or whether this might be someone else's post-build attempt to shove a JIS headset onto it.

-Kurt

I am curious if the craftsmanship matches the crown - whether the corner cutting shown here is evident in other areas of the frame, or whether this might be someone else's post-build attempt to shove a JIS headset onto it.

-Kurt

Likes For cudak888:

Likes For Charles Wahl:

#8

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 13,431

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Liked 4,422 Times

in

2,843 Posts

It sounds to me like this bike was built specifically for the (or several) trade show(s). I used to build boats. Boats for shows had to look really good. The boats that we were knew were going to the World Championships or get sailed across oceans got radically more care in the unseen places. Show bikes? Finish matters. Lug work matters. Headset fit doesn't. I also bet that show bikes are like show boats - almost always built in a real hurry. Delivering it late simply doesn't work.

This isn't always the case. Some new models/products at shows are real gems.

This isn't always the case. Some new models/products at shows are real gems.

#9

Senior Member

#10

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,834

Bikes: It's complicated.

Liked 6,298 Times

in

2,424 Posts

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

Likes For gugie:

#11

Stop reading my posts!

Thread Starter

well. I know this is both annoying and coy, but want to keep the identity concealed for a little while so no bigger revealing pix just yet.

It seems to be very well made without any lugs, has Campagnolo shorty DOs (portacantena no less) and fork ends, BSC BB threading and takes 27.2 seatpost, the cable routing under BB shell with a standard plastic guide, Allen bolt brakes, 126 OLN rear spacing, fork crown is a familiar Italian make with "window" cutouts in the external sockets.

But here's the real oddity: aside from 2 vent holes in the fork blades there are NO holes in ANY of the tubes or stays (even between the BB shell and 3 mains, the TT and seat tube, the head tube and TT or DT...nada)

What do you framebuilders think about that? Big red flag or just odd?

Edit: also just found the digital calipers and with the Stonehenge Nordic Runes it's barely measuring 26.4, taking multiple readings I get between 26.1 and 26.4

It seems to be very well made without any lugs, has Campagnolo shorty DOs (portacantena no less) and fork ends, BSC BB threading and takes 27.2 seatpost, the cable routing under BB shell with a standard plastic guide, Allen bolt brakes, 126 OLN rear spacing, fork crown is a familiar Italian make with "window" cutouts in the external sockets.

But here's the real oddity: aside from 2 vent holes in the fork blades there are NO holes in ANY of the tubes or stays (even between the BB shell and 3 mains, the TT and seat tube, the head tube and TT or DT...nada)

What do you framebuilders think about that? Big red flag or just odd?

Edit: also just found the digital calipers and with the Stonehenge Nordic Runes it's barely measuring 26.4, taking multiple readings I get between 26.1 and 26.4

Last edited by unworthy1; 05-23-23 at 03:10 PM.

Likes For unworthy1:

#12

Senior Member

My/most of the Serottas that I've seen have the vents brazed closed with silver. The process is interesting, and usually not done on any but an expensive frame.

If done poorly, moisture can be trapped in the tube.

If done poorly, moisture can be trapped in the tube.

#13

Senior Member

Stein does a good job.

took delivery of one of his headset wrenches this year. Nice tool.

I want to fabricate a tool to possibly roll out top tube dents similar to this knurling tool in concept.

#14

blahblahblah chrome moly

But here's the real oddity: aside from 2 vent holes in the fork blades there are NO holes in ANY of the tubes or stays (even between the BB shell and 3 mains, the TT and seat tube, the head tube and TT or DT...nada)

What do you framebuilders think about that? Big red flag or just odd?

What do you framebuilders think about that? Big red flag or just odd?

The other is a ~1970 PX-10, also with the seat tube rust perforated, from the inside out. Not a lack of a drain hole in the BB there, since that's a lugged frame, but they unwisely put a cork in the seat tube below the seatpost, and that's where the water puddled and did its dirty work.

Moral of the story is this: water will get into the seat tube(s), and needs a way out. Well, I live in Seattle, so maybe folks in Arizona, who never ever get caught in a downpour, can ignore this advice. But on any frame without a drain at the bottom of the ST, I would drill one. Remember, bikes get water inside when being transported on a car rack too, not only from riding.

Edit: also just found the digital calipers and with the Stonehenge Nordic Runes it's barely measuring 26.4, taking multiple readings I get between 26.1 and 26.4

Mark B

#15

Stop reading my posts!

Thread Starter

Yep^ I have a bottle of Loctite Green and know how to use it!

#16

Stop reading my posts!

Thread Starter

funny thing but the seller mentioned that Ben Serotta may have been the builder of this frame...but maybe he was just name-dropping

#17

Senior Member

The chainstay sockets had been sized with a tool that pushed a ridge ahead of it, a rust stain shows where the puddle was.

Both sides were like this, fortunately the bike was from a dry climate and it was hardly more than a stain:

After a few minutes with a rotary-tool:

Always worth pulling the bb of any bike you just bought...

Likes For oneclick:

#18

www.theheadbadge.com

Join Date: Sep 2005

Location: Southern Florida

Posts: 28,602

Bikes: https://www.theheadbadge.com

Liked 4,543 Times

in

2,143 Posts

#19

Stop reading my posts!

Thread Starter

I'm tempted to just drill some holes in "the usual places" so I can at least squirt some rust-proof juice up in them...but I have bigger fish to fry for a time, so may just sell this frameset to somebody else as-is.

Even with a right-angle drill attachment it will be tricky to make a clean job of that...could be more trouble than it's worth, too.

The seller told me this (Very Bright day-glo yellow frame) was used by Mavic for trade-show use displaying Mavic components...could be but it has BSC/ISO BB threading so...who knows?

I know yellow was the Mavic color but this is Hyper yellow, not sure if they ever went to day-glo (even if just for promo events) but maybe somebody here knows.

If I don't sell it this weekend I'll take pix and share them here, which be be the next flog-opportunity!

Even with a right-angle drill attachment it will be tricky to make a clean job of that...could be more trouble than it's worth, too.

The seller told me this (Very Bright day-glo yellow frame) was used by Mavic for trade-show use displaying Mavic components...could be but it has BSC/ISO BB threading so...who knows?

I know yellow was the Mavic color but this is Hyper yellow, not sure if they ever went to day-glo (even if just for promo events) but maybe somebody here knows.

If I don't sell it this weekend I'll take pix and share them here, which be be the next flog-opportunity!

#20

Stop reading my posts!

Thread Starter