Retrofriction: care and feeding

#26

Kontact is correct. They will ghost shift under heavy enough force such as a sprint to clear an intersection or standing to pedal on a slope. Once the levers are dialed in and shift repeatedly and cleanly on the workstand, go for a ride and road test them in a parking lot or on a quiet street. Make sure you have the proper sized screwdriver with you to tighten the fixing screw down.

if your retrofrictions ghost shifts, it l's because your clutch spring or internal barrel are worn out or you overlubricted the internals causing the clutch spring to slip easily.....

Last edited by Chombi1; 04-23-24 at 08:45 AM.

#27

I wanted to address how exactly these things work, because I think this debate about the screw has something to do with how we understand how they work:

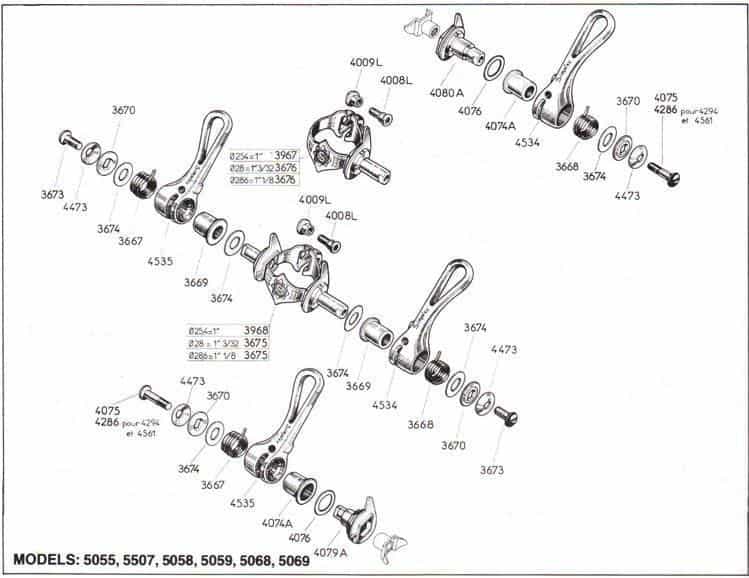

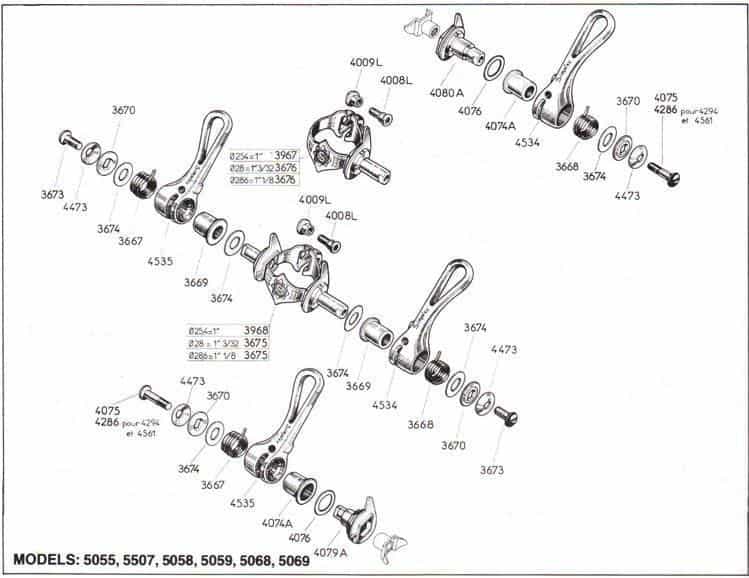

Referring to the shifter in the top of the diagram, we have four parts of real interest:

1. 4080 A - the mounting post that goes over the braze on. This item has a square female base which completely prevents it from rotating.

2. 4074 A - the flared Bushing that slides over the mounting post and is what the clutch spring grips.

3. 4076 - the washer that goes between the mounting post and the flared end of the bushing.

4. 3668 - the clutch spring

What is obvious is that when you pull the lever toward you to downshift on the freewheel, the lever pulls the Spring tip and "unwinds" the Spring, increasing it's inner diameter. This makes the Spring loose on the Bushing, allowing the lever to move without the Bushing moving.

But when the lever is moved forward for an upshift, the Spring inner diameter decreases, and the Spring grips the Bushing.

The Bushing is smooth on the inside and outside. It can turn smoothly under the untensioned Spring, or it can turn on the Post. What prevents it from turning easily on the Post is the mounting screw and washers are pushing it toward the base of the Post. Between them is the 4076 washer.

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post. It also would prevent a great deal of friction wear to the Bushing from forcing the hardened Spring to push over it in upshifts. This explanation would be why the upshift friction can be varied by the mounting screw tension. The shifter is a pretty normal friction shifter in one direction, and relatively friction free in the other.

#1 is the scenario where mounting screw tension is immaterial to the function of the shifter. It has to be quite tight to make sure the Bushing doesn't slip. This scenario seems like it would wear the Bushing and Spring interface quickly.

Am I missing something?

Referring to the shifter in the top of the diagram, we have four parts of real interest:

1. 4080 A - the mounting post that goes over the braze on. This item has a square female base which completely prevents it from rotating.

2. 4074 A - the flared Bushing that slides over the mounting post and is what the clutch spring grips.

3. 4076 - the washer that goes between the mounting post and the flared end of the bushing.

4. 3668 - the clutch spring

What is obvious is that when you pull the lever toward you to downshift on the freewheel, the lever pulls the Spring tip and "unwinds" the Spring, increasing it's inner diameter. This makes the Spring loose on the Bushing, allowing the lever to move without the Bushing moving.

But when the lever is moved forward for an upshift, the Spring inner diameter decreases, and the Spring grips the Bushing.

The Bushing is smooth on the inside and outside. It can turn smoothly under the untensioned Spring, or it can turn on the Post. What prevents it from turning easily on the Post is the mounting screw and washers are pushing it toward the base of the Post. Between them is the 4076 washer.

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post. It also would prevent a great deal of friction wear to the Bushing from forcing the hardened Spring to push over it in upshifts. This explanation would be why the upshift friction can be varied by the mounting screw tension. The shifter is a pretty normal friction shifter in one direction, and relatively friction free in the other.

#1 is the scenario where mounting screw tension is immaterial to the function of the shifter. It has to be quite tight to make sure the Bushing doesn't slip. This scenario seems like it would wear the Bushing and Spring interface quickly.

Am I missing something?

#28

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Maryland, USA

Posts: 2,657

Bikes: Drysdale/Gitane/Zeus/Masi/Falcon/Palo Alto/Raleigh/Legnano

Liked 757 Times

in

463 Posts

That's why I don't lubricate the internals of my retrofrictions, I just clean them out periodicslly with WD40 to flush our dust and dirt that might get in them, giving the clutch spring the max ability to grip onto the inner barrel to prevents ghost shifting. I had been installing ajd using Retrofrictions since I discovered them for myself in the early 80's and had enough experience to know them in and out....

if your retrofrictions ghost shifts, it l's because your clutch spring or internal barrel are worn out or you overlubricted the internals causing the clutch spring to slip easily.....

if your retrofrictions ghost shifts, it l's because your clutch spring or internal barrel are worn out or you overlubricted the internals causing the clutch spring to slip easily.....

If the "your clutch spring or internal barrel are worn out", not sure I'd know from a visual inspection, nor what the options are save watching for a replacement set (I think I saw some on For Sale but those are clamp-on and didn't I read they do NOT interchange?)

The bottle of thread locker beckons like it's some controlled substance I'm trying to kick... where's the HotLine I am supposed to call for that particular addition?

__________________

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

#30

Full Member

Join Date: Sep 2017

Location: Oklahoma City

Posts: 269

Bikes: 1984 Chas Roberts Audax tubing?, 1985 Roberts SLX, Mercian 531, 1984 Torpado SLX, 1981/82 Peugeot PSV-10, 1978 Charlie Roberts full touring, 1970 Charlie Roberts 531 road.

Liked 195 Times

in

75 Posts

Still not thrilled with performance; I have the shifters off the boss and soaking in WD40 (I dunno, leave them in for an hour or so?) and will report back on whether it improves anything.

If the "your clutch spring or internal barrel are worn out", not sure I'd know from a visual inspection, nor what the options are save watching for a replacement set (I think I saw some on For Sale but those are clamp-on and didn't I read they do NOT interchange?)

The bottle of thread locker beckons like it's some controlled substance I'm trying to kick... where's the HotLine I am supposed to call for that particular addition?

If the "your clutch spring or internal barrel are worn out", not sure I'd know from a visual inspection, nor what the options are save watching for a replacement set (I think I saw some on For Sale but those are clamp-on and didn't I read they do NOT interchange?)

The bottle of thread locker beckons like it's some controlled substance I'm trying to kick... where's the HotLine I am supposed to call for that particular addition?

#31

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Maryland, USA

Posts: 2,657

Bikes: Drysdale/Gitane/Zeus/Masi/Falcon/Palo Alto/Raleigh/Legnano

Liked 757 Times

in

463 Posts

I wanted to address how exactly these things work, because I think this debate about the screw has something to do with how we understand how they work:

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post.

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post.

Well, having been told not to dismantle, I pulled the assemblies off the frame (and I had already crimped tips on the cables so I did not want to undo that!

Always do those last on a project!) and, at the ends of the cables, dipped into a cup of WD40 and swished. Then I figured, let technology do the work -- put the shifters and WD40 in a very small pesto jar left over from lunch, stuck that in the ultrasonic cleaner balanced on a TV table (bike is in a stand, so too high to reach the floor with the cables in place) and gave everything about 6 minutes. The WD40 discolored but not opaque black. Reassembled, they feel great. On the stand. Without riding the bike.

Always do those last on a project!) and, at the ends of the cables, dipped into a cup of WD40 and swished. Then I figured, let technology do the work -- put the shifters and WD40 in a very small pesto jar left over from lunch, stuck that in the ultrasonic cleaner balanced on a TV table (bike is in a stand, so too high to reach the floor with the cables in place) and gave everything about 6 minutes. The WD40 discolored but not opaque black. Reassembled, they feel great. On the stand. Without riding the bike.The clamp on Do Not interchange with the frame mounted ones, I.e. they’re French after all. Had one of the springs break, they have a little tiny catch on the end, and that can rust and finally break, releasing the pressure, and you are in the smallest cog (of it’s the rear derailleur).

__________________

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

Likes For tiger1964:

#32

Full Member

Join Date: Sep 2017

Location: Oklahoma City

Posts: 269

Bikes: 1984 Chas Roberts Audax tubing?, 1985 Roberts SLX, Mercian 531, 1984 Torpado SLX, 1981/82 Peugeot PSV-10, 1978 Charlie Roberts full touring, 1970 Charlie Roberts 531 road.

Liked 195 Times

in

75 Posts

Had two sets of braze on shifters overhauled by Wayne Bingham, he replaced the set with the broken spring, as well as another set off eBay.Fr. He might have more springs. Here’s his Facebook page. By now, most people know that I closed my shop Velo Classique at the end of last year. It's now being reborn, although in a very scaled down fashion, as Atelier Velo Classique (that's Classic Bike Workshop in French). It's still a work in progress, but coming together nicely. The veloclassique@gmail address is still active, and the best way to contact me if you'd like to make an appointment, or just want to stay in touch. There is a new webpage in the works too, and there will be postings of things for sale both here and there as all that gets organized.

I want to thank all those that supported Velo Classique while in our two different locations in Purcellville for 14 years. I do miss the shop, but I'm looking forward to what lies ahead too. I have a lot of new ideas, so stay tuned.

I want to thank all those that supported Velo Classique while in our two different locations in Purcellville for 14 years. I do miss the shop, but I'm looking forward to what lies ahead too. I have a lot of new ideas, so stay tuned.

#33

Full Member

Join Date: Sep 2017

Location: Oklahoma City

Posts: 269

Bikes: 1984 Chas Roberts Audax tubing?, 1985 Roberts SLX, Mercian 531, 1984 Torpado SLX, 1981/82 Peugeot PSV-10, 1978 Charlie Roberts full touring, 1970 Charlie Roberts 531 road.

Liked 195 Times

in

75 Posts

https://peugeotcoursepb12.wordpress....-installation/

a good article on the shift levers, mentioning Wayne having replacement springs.

a good article on the shift levers, mentioning Wayne having replacement springs.

#34

Of course, all friction shifters have a washer like that, but those shifters are constantly wiggling them back and forth. The Simplex shifter only ever tries to turn in a single direction, so no wiggling.

Last edited by Kontact; 05-23-24 at 08:02 PM.

#35

car dodger

Bumping this thread to add a bit of info that I couldn't find via web search. I recently experienced low gear slipping due to the retrofriction screw not being tight enough, of course I didn't have a big screwdriver with me so I walked a few steep hills and managed the rest of the ride. When I got home I tightened the screw and it held low gear fine, just a bit more resistance when pushing the lever forward. Then I looked into replacing the o/g screws with button head 3mm allen screws. I have braze on shifters, they take 20mm long M5 screws. (The length is what I had trouble figuring out online). I found some at the hardware store. Also, unbranded (mavic?) retrofriction shifters have slightly different pull vs simplex branded retrofriction shifters, I had to adjust the limit screws when I switched from one to the other.

__________________

1989 Schwinn Paramount OS

1980 Mclean/Silk Hope Sport Touring

1983 Bianchi pista

1976 Fuji Feather track

1979 raleigh track

"I've consulted my sources and I'm pretty sure your derailleur does not exist"

1989 Schwinn Paramount OS

1980 Mclean/Silk Hope Sport Touring

1983 Bianchi pista

1976 Fuji Feather track

1979 raleigh track

"I've consulted my sources and I'm pretty sure your derailleur does not exist"

#36

Bumping this thread to add a bit of info that I couldn't find via web search. I recently experienced low gear slipping due to the retrofriction screw not being tight enough, of course I didn't have a big screwdriver with me so I walked a few steep hills and managed the rest of the ride. When I got home I tightened the screw and it held low gear fine, just a bit more resistance when pushing the lever forward. Then I looked into replacing the o/g screws with button head 3mm allen screws. I have braze on shifters, they take 20mm long M5 screws. (The length is what I had trouble figuring out online). I found some at the hardware store. Also, unbranded (mavic?) retrofriction shifters have slightly different pull vs simplex branded retrofriction shifters, I had to adjust the limit screws when I switched from one to the other.

if the shifter is slipping badly, it could be a worn out inner shifter drum or clutch spring or even over lubrication of the clutch spring that's keeping it from gripping the inner shifter drum.

__________________

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

#37

As surely noted already in this thread, the resistajce from the Retrofriction levers all comes from the cltch spring. If sny resistance is provided by the pivot anchor screws, it 8s incidental and just results from differing tolerances from the actual design of the shifter.

if the shifter is slipping badly, it could be a worn out inner shifter drum or clutch spring or even over lubrication of the clutch spring that's keeping it from gripping the inner shifter drum.

if the shifter is slipping badly, it could be a worn out inner shifter drum or clutch spring or even over lubrication of the clutch spring that's keeping it from gripping the inner shifter drum.

#38

Senior Member

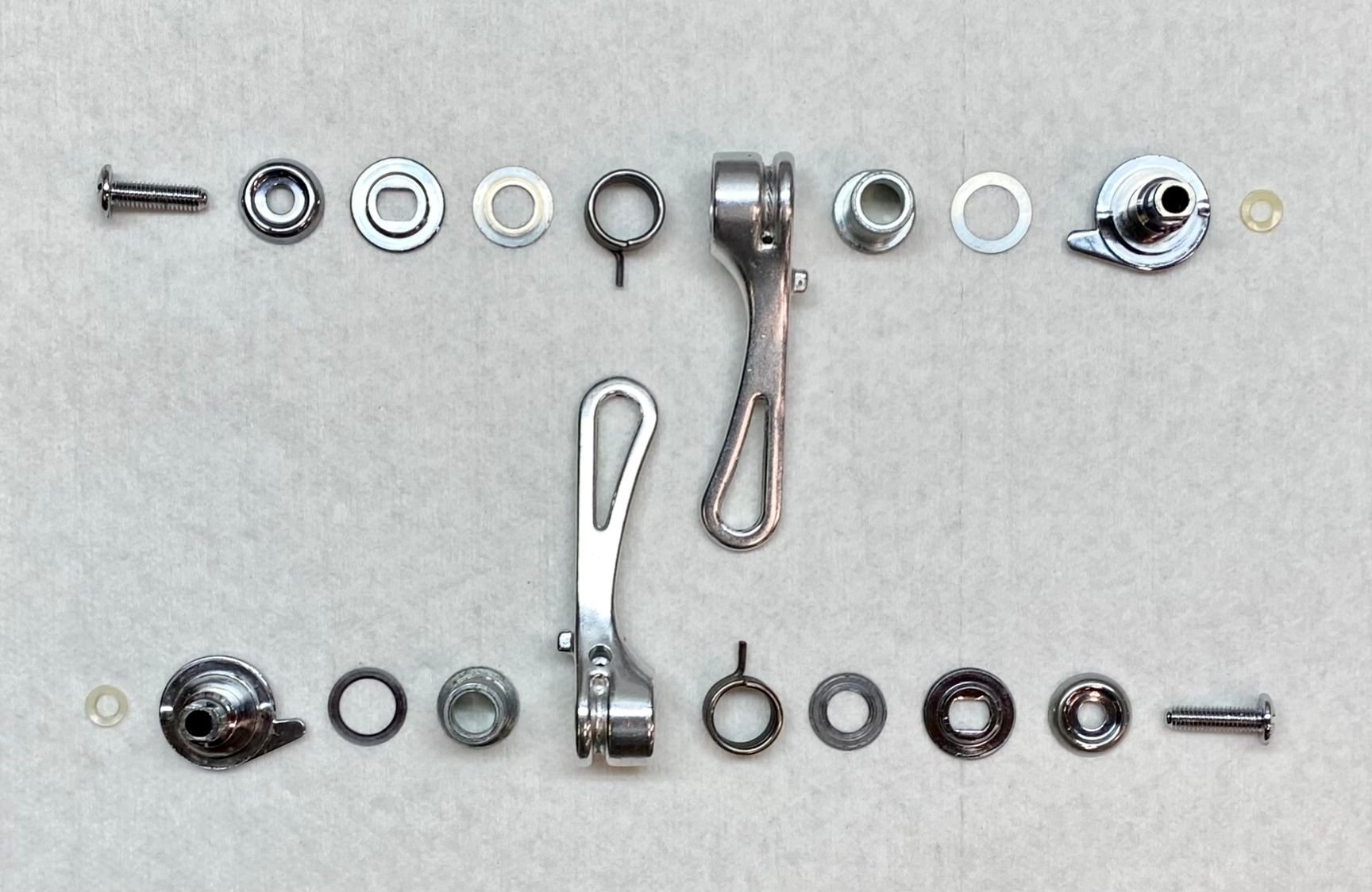

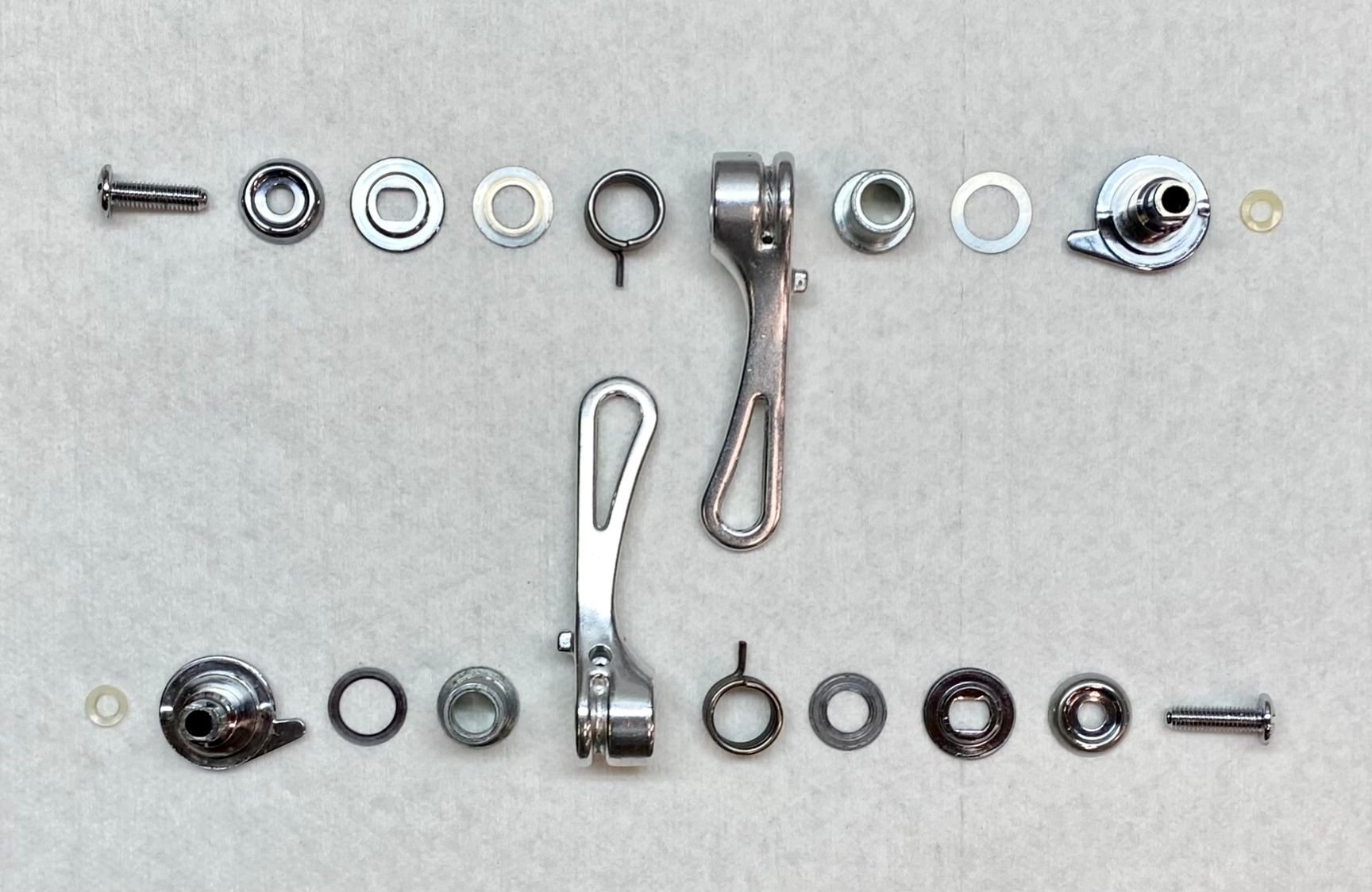

FYI - the springs are a bit fidgety to remove, but it can be done. Despite these being NOS, they were disassembled and everything got a very light coat of grease as they were reassembled. I don’t trust 30-year-old grease, even if it was never used. They’ve worked perfectly since and have never slipped. Also, these must be a later model as they have hex screws vs the slotted screws.

__________________

My collection: 1947 Ciclo Piave, 1955 Liberia, 1969 Colnago Super, 1972 Legnano Olimpiade Record Specialissima, 1980 Mercian Vincitore, 1983 Gitane Interclub, 1985 Peugeot PGN10, 1986 Bianchi Vittoria, 1987 De Rosa Professional, 1989 Vitus 979, 1990 Bianchi Axis, 1990 Specialized Sirrus, 2001 Colnago Dream B-Stay, 2007 Trek 1000

My collection: 1947 Ciclo Piave, 1955 Liberia, 1969 Colnago Super, 1972 Legnano Olimpiade Record Specialissima, 1980 Mercian Vincitore, 1983 Gitane Interclub, 1985 Peugeot PGN10, 1986 Bianchi Vittoria, 1987 De Rosa Professional, 1989 Vitus 979, 1990 Bianchi Axis, 1990 Specialized Sirrus, 2001 Colnago Dream B-Stay, 2007 Trek 1000

#39

I had been using and working on Simplex retrofriction shifters since the early 80's (Had them on 90% of all my bikes.) and figured it all out way back then.

What first convinced me on how it works is I noticed that even if the lever has a bit of side to side play (Which means the mounting screw is not bearing down tight on tue lever body to provide friction.) when already mounted on the shifter boss, the lever still provides the resistance/friction it needs to function, without the lever getting pulled back by the derailleur springs. Which means, the mounting screws were not meant to provide any resistance friction, like conventional shift levers do. It is all coming from the clutch spring. It's a very simple concept if you figure it out.....

#40

Disraeli Gears

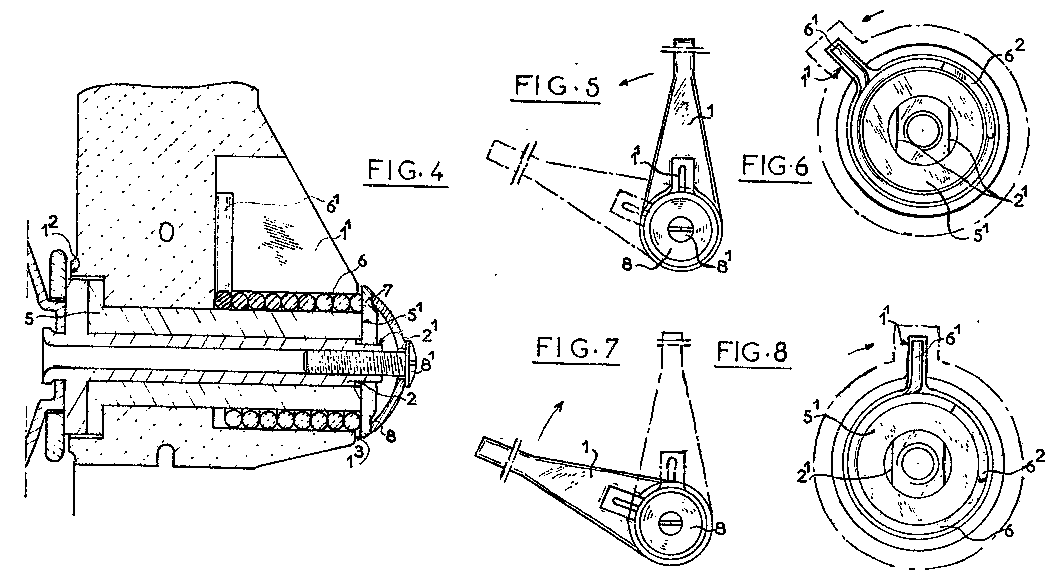

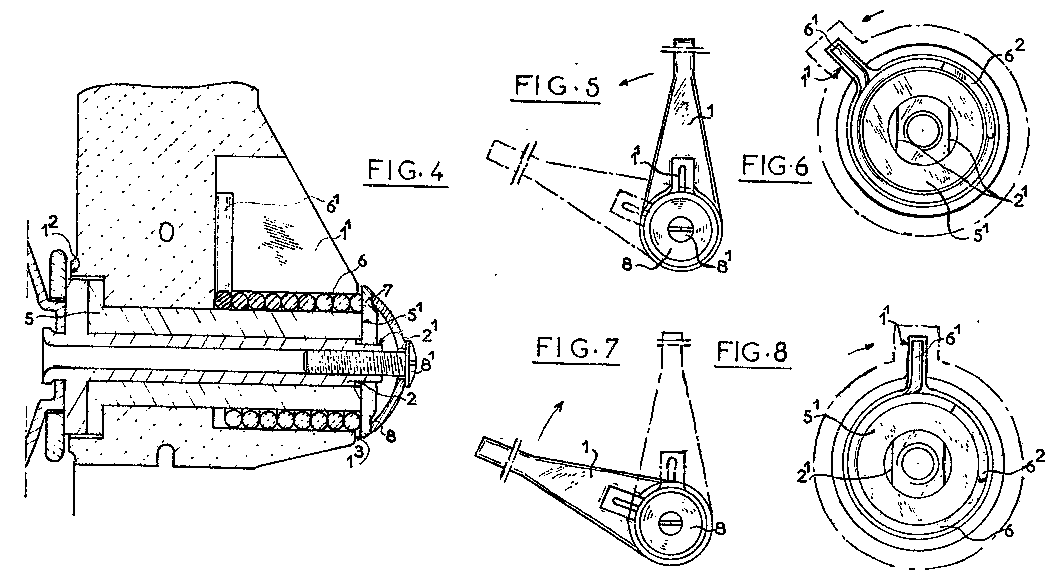

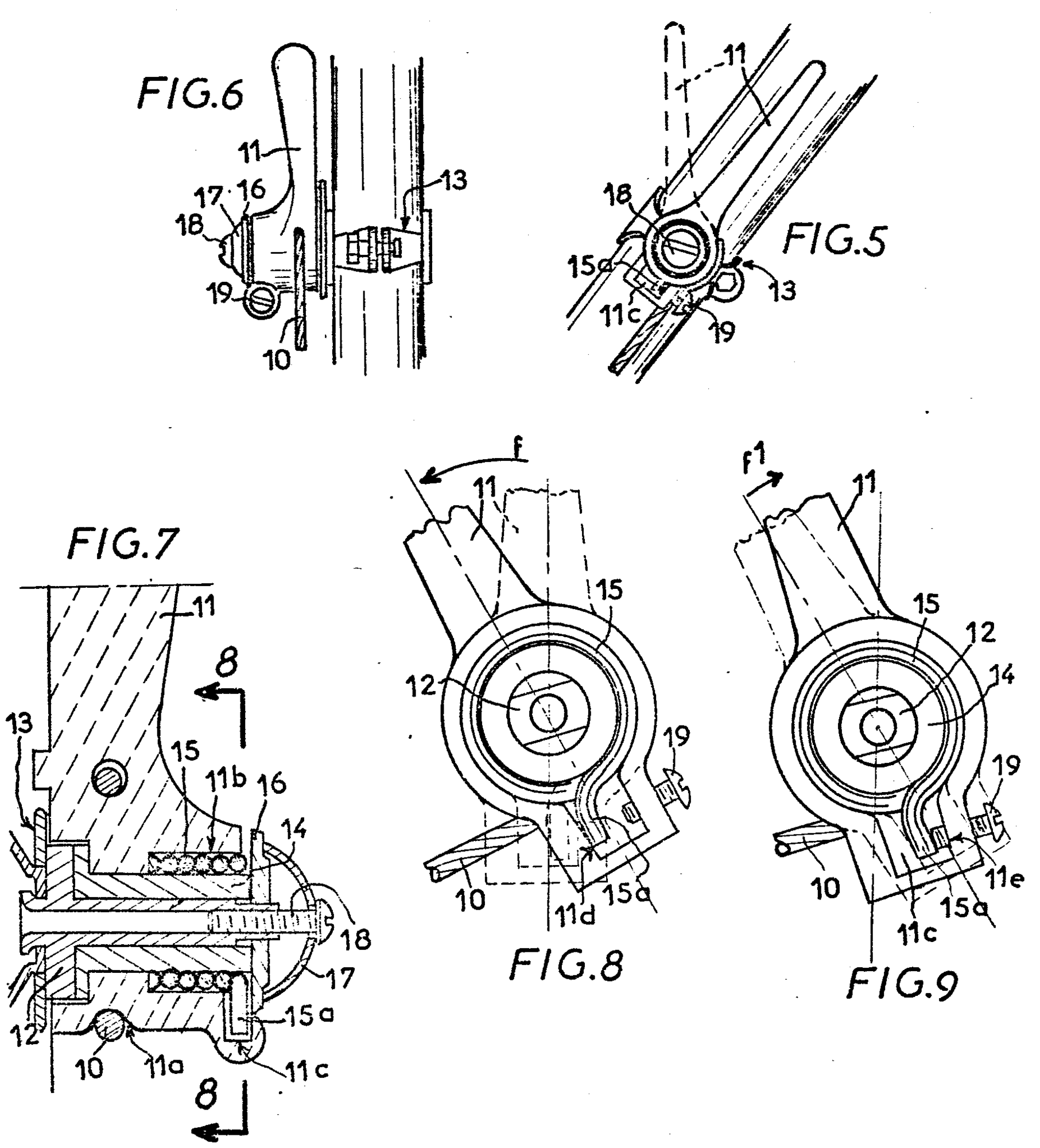

Re adjustability: I have these PNG images in my tech files, probably from a BF thread, filenames "Simplex retrofriction patent drawing" and "Simplex retrofriction patent drawing, later". Note the screw #19 in the "later" one (which I don't think is later, but earlier because it's on a single-side band mount, and I have one of those on a bike, with that screw, and it's not only single-sided, but has the earlier lever without the "lightening" opening).

Patent dwg 1: note that the spring's "tang" is on the downtube side, rather than on the retaining screw's side.

Patent dwg 2, labeled "later" but probably earlier? The spring's tang is on the outside now. It seems to me that the function of screw #19 is to provide some adjustment of how tightly wound the spring is.

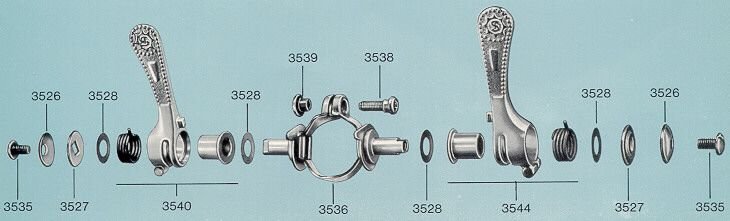

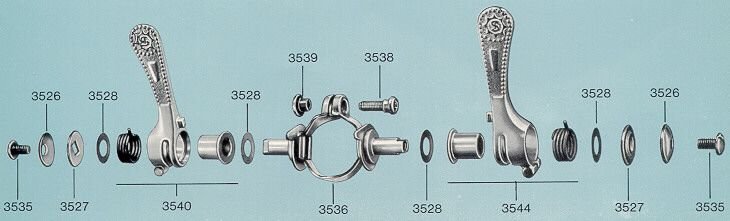

The exploded view below shows a band-on double lever with the same feature. I'll note that I have in my parts stash a NOS band-on almost exactly like the assembly shown, and it doesn't have the screw or the appendage to receive it. And, oddly, the exploded view doesn't even show the screw as part of the lever.

Instead, my double-band-on assembly has levers with the inside spring tang engagement and no adjustment screw, like the diagram below:

My guess is that Simplex changed the design at some point, and eliminated the adjustment screw.

Another interesting thing I found, reviewing my tech files, is that there were two versions of the braze-on fixing: the first having the older "Simplex/Cyclo" boss without flats found on a lot of older bikes (but on some Peugeots right into the 80s), and requiring the (near unobtainable) M5x1.0 fixing screw; and the second for a Campagnolo-style shifter boss with the flats, and fixed with an M5x0.8 screw:

Only the rightmost image in the middle row (the dual band-on assembly that I mention above) and the two in the bottom row are retrofriction levers, and the bottom row illustrates braze-on levers of the two different types.

Just to add my 2 cents to this discussion: I don't ever find a need to "adjust" my retrofriction lever on the one bike going that has one. It just works (and it's got the adjustment screw!).

Patent dwg 1: note that the spring's "tang" is on the downtube side, rather than on the retaining screw's side.

Patent dwg 2, labeled "later" but probably earlier? The spring's tang is on the outside now. It seems to me that the function of screw #19 is to provide some adjustment of how tightly wound the spring is.

The exploded view below shows a band-on double lever with the same feature. I'll note that I have in my parts stash a NOS band-on almost exactly like the assembly shown, and it doesn't have the screw or the appendage to receive it. And, oddly, the exploded view doesn't even show the screw as part of the lever.

Instead, my double-band-on assembly has levers with the inside spring tang engagement and no adjustment screw, like the diagram below:

My guess is that Simplex changed the design at some point, and eliminated the adjustment screw.

Another interesting thing I found, reviewing my tech files, is that there were two versions of the braze-on fixing: the first having the older "Simplex/Cyclo" boss without flats found on a lot of older bikes (but on some Peugeots right into the 80s), and requiring the (near unobtainable) M5x1.0 fixing screw; and the second for a Campagnolo-style shifter boss with the flats, and fixed with an M5x0.8 screw:

Only the rightmost image in the middle row (the dual band-on assembly that I mention above) and the two in the bottom row are retrofriction levers, and the bottom row illustrates braze-on levers of the two different types.

Just to add my 2 cents to this discussion: I don't ever find a need to "adjust" my retrofriction lever on the one bike going that has one. It just works (and it's got the adjustment screw!).

Last edited by Charles Wahl; 08-03-24 at 08:41 PM.

Likes For Charles Wahl:

#41

the clutch spring grips the internal drum for resistance in a one way action. This is dine through twisting the spring in the direction where the coils tightens up and itoosens up the other way providing zero resistance. That how the whole Retrofriction design concept works.

I had been using and working on Simplex retrofriction shifters since the early 80's (Had them on 90% of all my bikes.) and figured it all out way back then.

What first convinced me on how it works is I noticed that even if the lever has a bit of side to side play (Which means the mounting screw is not bearing down tight on tue lever body to provide friction.) when already mounted on the shifter boss, the lever still provides the resistance/friction it needs to function, without the lever getting pulled back by the derailleur springs. Which means, the mounting screws were not meant to provide any resistance friction, like conventional shift levers do. It is all coming from the clutch spring. It's a very simple concept if you figure it out.....

I had been using and working on Simplex retrofriction shifters since the early 80's (Had them on 90% of all my bikes.) and figured it all out way back then.

What first convinced me on how it works is I noticed that even if the lever has a bit of side to side play (Which means the mounting screw is not bearing down tight on tue lever body to provide friction.) when already mounted on the shifter boss, the lever still provides the resistance/friction it needs to function, without the lever getting pulled back by the derailleur springs. Which means, the mounting screws were not meant to provide any resistance friction, like conventional shift levers do. It is all coming from the clutch spring. It's a very simple concept if you figure it out.....

Without tension on that barrel, the lever would not hold any position against derailleur cable tension. The spring clutch grabs that barrel securely, and when you push forward the spring twists the barrel with it. When you pull back on the clutch, the spring opens and moves without the barrel. The barrel only moves forward, the spring only releases rearward. The spring release has no real friction, which is what we like about 'retrofriction', but the spring grabs and drives the barrel when pushed forward, and that's the friction that counters the derailleur.

You seem to be suggesting that the clutch spring, that does such a wonderful job gliding backwards, is then tearing the barrel up by being forced to drag forwards despite its tension. How long do you think a system that relies on the grip of a hardened steel spring is going to last if you are overwhelming that grip to get the lever to move? That's crazy.

Forward movement happens with the barrel slides around mounting post 3533 against the friction provided by inner washer 3532 and outer washer 3528. And the tension screw, through washers 3527 and 3526, provides that friction on the inner washers to the barrel.

The play you are noting is the interface between the barrel and the lever/spring clutch assemblies.

Last edited by Kontact; 08-04-24 at 09:29 AM.

#42

This gentleman explains it exactly the same way I have. He calls the "barrel" a "top hat", but that part is what the friction is applied to, and why the shifter has no friction until mounted. Until mounted, the top hat is free to move either direction. After assembly on a braze-on the barrel is trapped between the mounting bolt tension and the spring clutch. Push one way and you overcome mounting bolt friction by grabbing the barrel with the spring, push it the other way and you release the clutch and the barrel doesn't move.

In essence, retrofriction is a friction shifter surrounded by a clutch that allows you to move the lever in one direction without engaging the friction. But the other direction it is entirely conventional friction. Adjusting the mounting bolt tension only affects the friction barrel - it has nothing to do with the spring clutch or how it holds.

Unless you overtighten the tension screw.

In essence, retrofriction is a friction shifter surrounded by a clutch that allows you to move the lever in one direction without engaging the friction. But the other direction it is entirely conventional friction. Adjusting the mounting bolt tension only affects the friction barrel - it has nothing to do with the spring clutch or how it holds.

Unless you overtighten the tension screw.

Last edited by Kontact; 08-04-24 at 10:10 AM.

#43

You have described how the spring clutch releases, but not where the friction comes from. And it comes from the screw tension put on the perfectly round barrel that is shown as item 5 in the patent drawings or far left barrel in assembly 3534 in the parts break down.

Without tension on that barrel, the lever would not hold any position against derailleur cable tension. The spring clutch grabs that barrel securely, and when you push forward the spring twists the barrel with it. When you pull back on the clutch, the spring opens and moves without the barrel. The barrel only moves forward, the spring only releases rearward. The spring release has no real friction, which is what we like about 'retrofriction', but the spring grabs and drives the barrel when pushed forward, and that's the friction that counters the derailleur.

You seem to be suggesting that the clutch spring, that does such a wonderful job gliding backwards, is then tearing the barrel up by being forced to drag forwards despite its tension. How long do you think a system that relies on the grip of a hardened steel spring is going to last if you are overwhelming that grip to get the lever to move? That's crazy.

Forward movement happens with the barrel slides around mounting post 3533 against the friction provided by inner washer 3532 and outer washer 3528. And the tension screw, through washers 3527 and 3526, provides that friction on the inner washers to the barrel.

The play you are noting is the interface between the barrel and the lever/spring clutch assemblies.

Without tension on that barrel, the lever would not hold any position against derailleur cable tension. The spring clutch grabs that barrel securely, and when you push forward the spring twists the barrel with it. When you pull back on the clutch, the spring opens and moves without the barrel. The barrel only moves forward, the spring only releases rearward. The spring release has no real friction, which is what we like about 'retrofriction', but the spring grabs and drives the barrel when pushed forward, and that's the friction that counters the derailleur.

You seem to be suggesting that the clutch spring, that does such a wonderful job gliding backwards, is then tearing the barrel up by being forced to drag forwards despite its tension. How long do you think a system that relies on the grip of a hardened steel spring is going to last if you are overwhelming that grip to get the lever to move? That's crazy.

Forward movement happens with the barrel slides around mounting post 3533 against the friction provided by inner washer 3532 and outer washer 3528. And the tension screw, through washers 3527 and 3526, provides that friction on the inner washers to the barrel.

The play you are noting is the interface between the barrel and the lever/spring clutch assemblies.

Did you ever wonder why Simplex just provided the shufters with the most rudimentary mounting screws with such shallow slots and nut a wing nut or a D ring screw? It's because they do not exoect it to be tightened periodically for maintsining friction for the shifters as with other friction shifters. It gets screwed on tight enough to keep the levers on the boss once and that's it. You would not jave to touch it till you have to take off the shift levers for any sort of servicing.....

If you insist on using your Retrofrictions like any othe friction levers, go ahead. It's too bad as you are not tsking advantage of the original design of the levers..... I give up trying to explain this over and over again...

if you want to see how it should work, I have ten bikes I can show you with it installed and working properly.....

Last edited by Chombi1; 08-04-24 at 01:15 PM.

#44

have you actually opened up one of these shifters and looked at the spring and barrel separatseparif you look at one that had been used for a long time, you will see how the spring will eventually wear grooves on the barrel from gripping it and providing d the resistance friction. Tue internal barrel does not move eith the lever as it is keyed to the base of the lever mounting boss. The internal barrel takes all of the friction duties along with the spring the mou ting screw and the face washers under it, just retains the lever and internal barrel on the shifter boss with minimal pressure. If you somehow add pressure to the shifter assembly to create friction, you are not utilizing the Retrofriction feature as it was designed which is zero friction when pulling the lever back and friction when pushing it forwards to resist the derailleur springs. This makes the action as light and as smooth as possible as you only have friction in one direction, which is resisting the derailleur spring. If you add friction through the mounting screws and washer somehow. You are uselessly making the action of the lever heavier in both directions. The springs and barrel do wear out eventually after years of use, just like any other shifter. It can be fixed by replacing the internal barrel and/or spring, which I had successfully done on a couple of my Retrofriction shifter sets. You can also just switch springs and internal barrels around with other Retrofriction sets and it could work, if the wear grooves on the barrel does not match up exactly with the spring coil pattern.

But the friction doesn't come from the spring rubbing on the barrel, unless YOU overtightened the screw to where the barrel can't move and now your destroying it with the spring.

So I don't know if you just don't understand what you're looking at, or have been overtightening all your shifters - causing them to wear out prematurely. But the fact that the lever has no friction until tightened down should be a clue to you how they work: If all their functions were internal to the spring mechanism, they would work without a mounting screw - just like an index shifter does.

Misunderstanding something for a long time doesn't turn it into understanding. The video guy and I have you outvoted.

#45

car dodger

Okay here is an update, I sort of fixed my well-used simplex branded shifters that had low gear slipping issues by tightening the mounting screws. But I didn't like the increased friction feel they now had. So I replaced them with an apparently less used pair of unbranded retrofriction shifters I had, and swapped out the screws for allen head button screws. I tightened them to just snug or maybe a hair more. Rode up the steepest hill around and they held fine!

Then I cleaned the shifters I took off and replaced those screws with button head screws. If anyone needs some button head screws to swap out I have a good supply now! Also tried to clean up the flaked off chrome on the caps with a chrome pen...it looks "just okay". See pics -

Also, how do you simulate a really steep hill on the work stand?

Then I cleaned the shifters I took off and replaced those screws with button head screws. If anyone needs some button head screws to swap out I have a good supply now! Also tried to clean up the flaked off chrome on the caps with a chrome pen...it looks "just okay". See pics -

Also, how do you simulate a really steep hill on the work stand?

#46

Okay here is an update, I sort of fixed my well-used simplex branded shifters that had low gear slipping issues by tightening the mounting screws. But I didn't like the increased friction feel they now had. So I replaced them with an apparently less used pair of unbranded retrofriction shifters I had, and swapped out the screws for allen head button screws. I tightened them to just snug or maybe a hair more. Rode up the steepest hill around and they held fine!

Then I cleaned the shifters I took off and replaced those screws with button head screws. If anyone needs some button head screws to swap out I have a good supply now! Also tried to clean up the flaked off chrome on the caps with a chrome pen...it looks "just okay". See pics -

Also, how do you simulate a really steep hill on the work stand?

Then I cleaned the shifters I took off and replaced those screws with button head screws. If anyone needs some button head screws to swap out I have a good supply now! Also tried to clean up the flaked off chrome on the caps with a chrome pen...it looks "just okay". See pics -

Also, how do you simulate a really steep hill on the work stand?

If not, the spring clutch is slipping

#47

car dodger

Well I did take them completely apart (except for the springs) and cleaned everything with wd40, not sure if that would improve anything and it will be a while before I find out I guess.

__________________

1989 Schwinn Paramount OS

1980 Mclean/Silk Hope Sport Touring

1983 Bianchi pista

1976 Fuji Feather track

1979 raleigh track

"I've consulted my sources and I'm pretty sure your derailleur does not exist"

1989 Schwinn Paramount OS

1980 Mclean/Silk Hope Sport Touring

1983 Bianchi pista

1976 Fuji Feather track

1979 raleigh track

"I've consulted my sources and I'm pretty sure your derailleur does not exist"

#48

The thin brass washers under the screw heads which are unique to retrofriction shifters, are meant to provide a slip0ery surface between the screw head and the lever body.....not friction. Brass is commonly provided between sliding surfaces as sort of dry lubrication.....

__________________

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

#49

The thin brass washers under the screw heads which are unique to retrofriction shifters, are meant to provide a slip0ery surface between the screw head and the lever body.....not friction. Brass is commonly provided between sliding surfaces as sort of dry lubrication.....

You don't know what you're talking about.