How to dismantle FH-M730-NT?

#1

Full Member

Thread Starter

How to dismantle FH-M730-NT?

Hi,

Recently, I've found new wheels monted with Deore XT hubs, the M730 of 1986.

Yes but ... NT = Nut Type.

These allow for either 126 mm or 130 mm between the rear dropouts.

I'd like to replace the axle by the Quick Release one. I have all part NOS.

Has anyone encountered and dismantled these Nut Types hubs?

If so, how to proceed?

I tried without success.

This to complete the built of another classic MTB.

Thanks for any tips

Recently, I've found new wheels monted with Deore XT hubs, the M730 of 1986.

Yes but ... NT = Nut Type.

These allow for either 126 mm or 130 mm between the rear dropouts.

I'd like to replace the axle by the Quick Release one. I have all part NOS.

Has anyone encountered and dismantled these Nut Types hubs?

If so, how to proceed?

I tried without success.

This to complete the built of another classic MTB.

Thanks for any tips

#2

Bianchi Goddess

Join Date: Apr 2009

Location: Shady Pines Retirement Fort Wayne, In

Posts: 27,860

Bikes: Too many to list here check my signature.

Mentioned: 192 Post(s)

Tagged: 2 Thread(s)

Quoted: 2930 Post(s)

Liked 2,928 Times

in

1,493 Posts

......

__________________

“One morning you wake up, the girl is gone, the bikes are gone, all that's left behind is a pair of old tires and a tube of tubular glue, all squeezed out"

Sugar "Kane" Kowalczyk

“One morning you wake up, the girl is gone, the bikes are gone, all that's left behind is a pair of old tires and a tube of tubular glue, all squeezed out"

Sugar "Kane" Kowalczyk

Last edited by Bianchigirll; 03-22-23 at 03:05 PM.

#3

Senior Member

I wasn’t aware the Deore XT came in a nutted version.

are these freehub type hubs for a cassette or the older freewheel type?

According to Velobase in ‘86 Deore got the 6 Uniglide cassette but there is no mention of nutted axles.

https://velobase.com/ViewComponent.a...4bcd6&Enum=110

are these freehub type hubs for a cassette or the older freewheel type?

According to Velobase in ‘86 Deore got the 6 Uniglide cassette but there is no mention of nutted axles.

https://velobase.com/ViewComponent.a...4bcd6&Enum=110

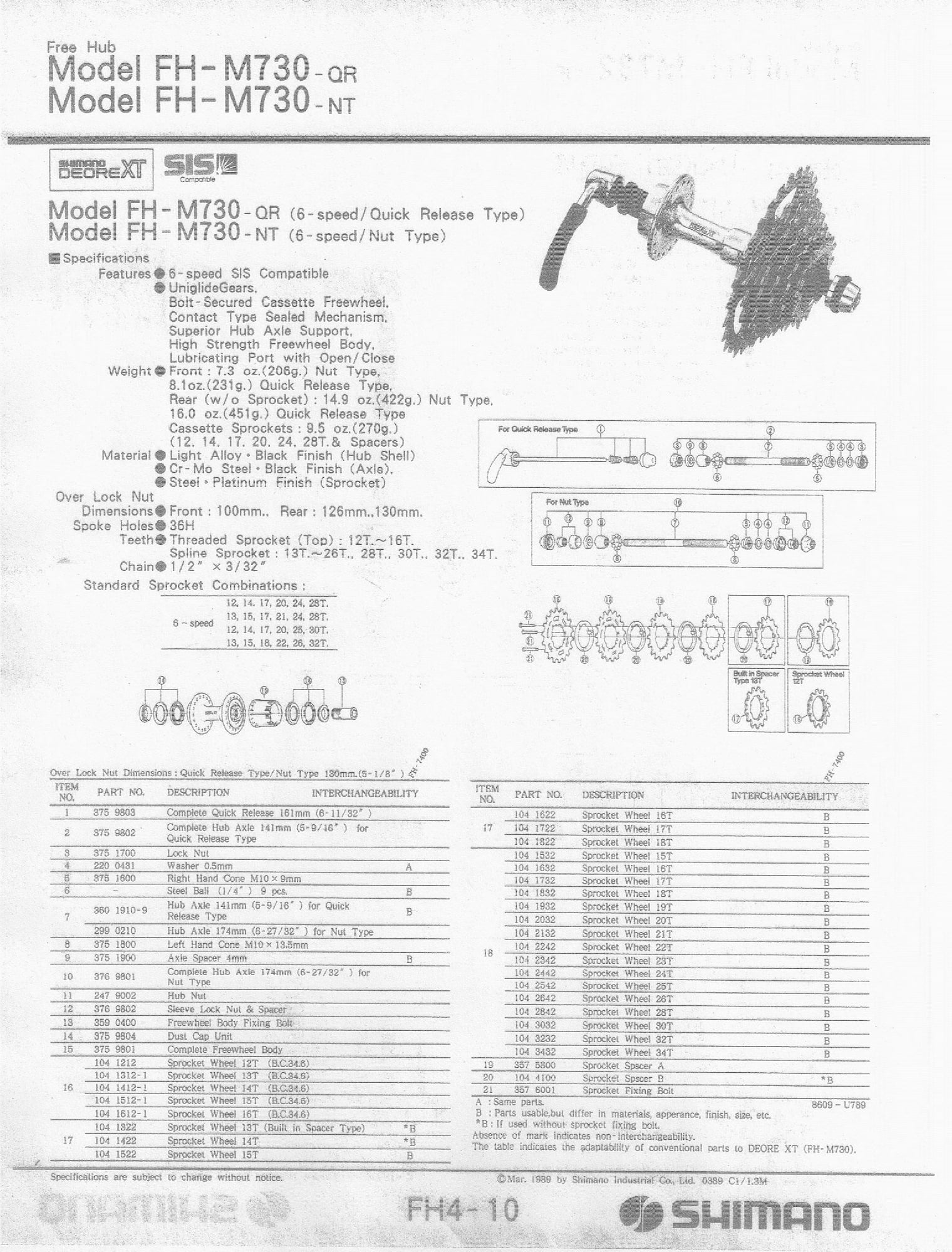

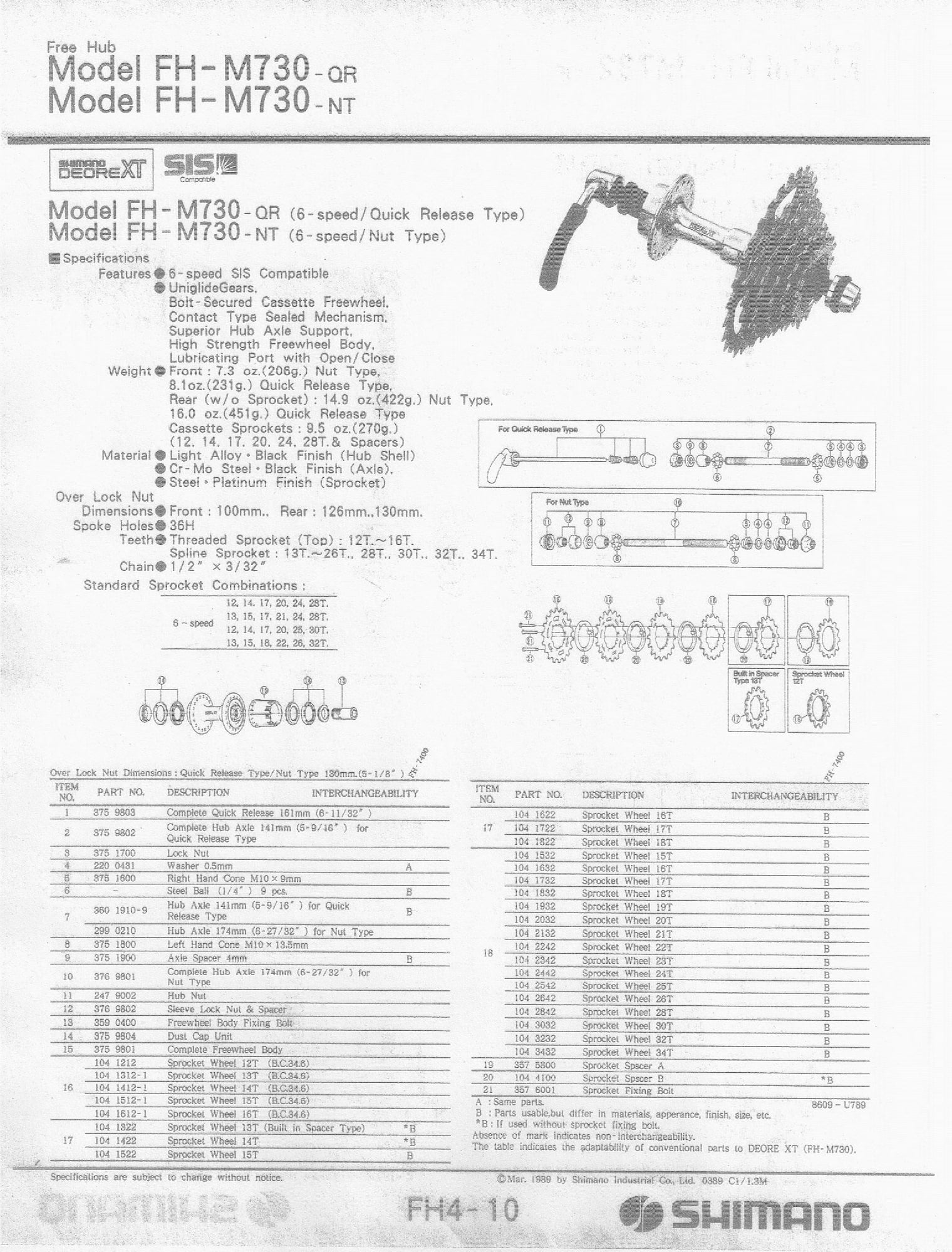

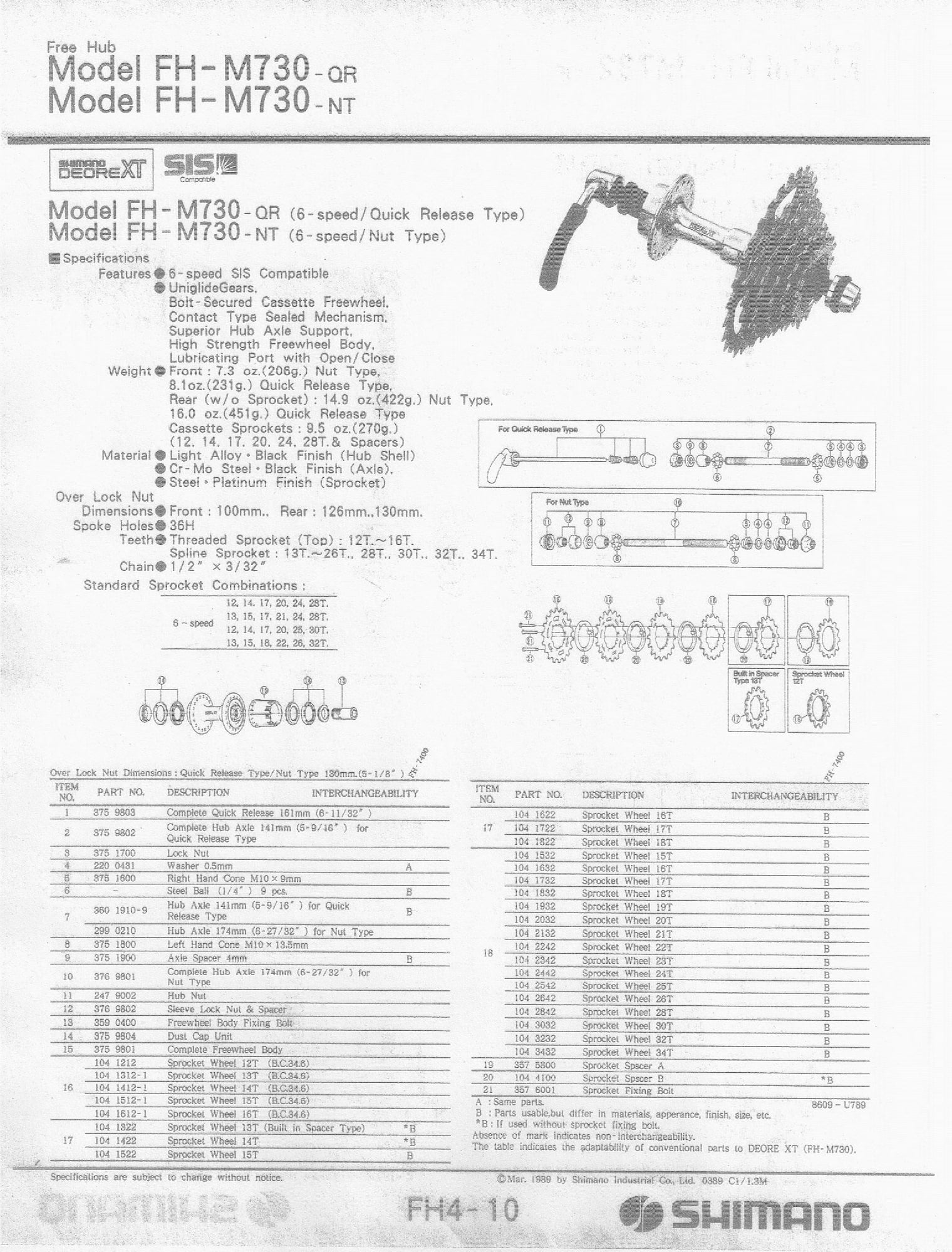

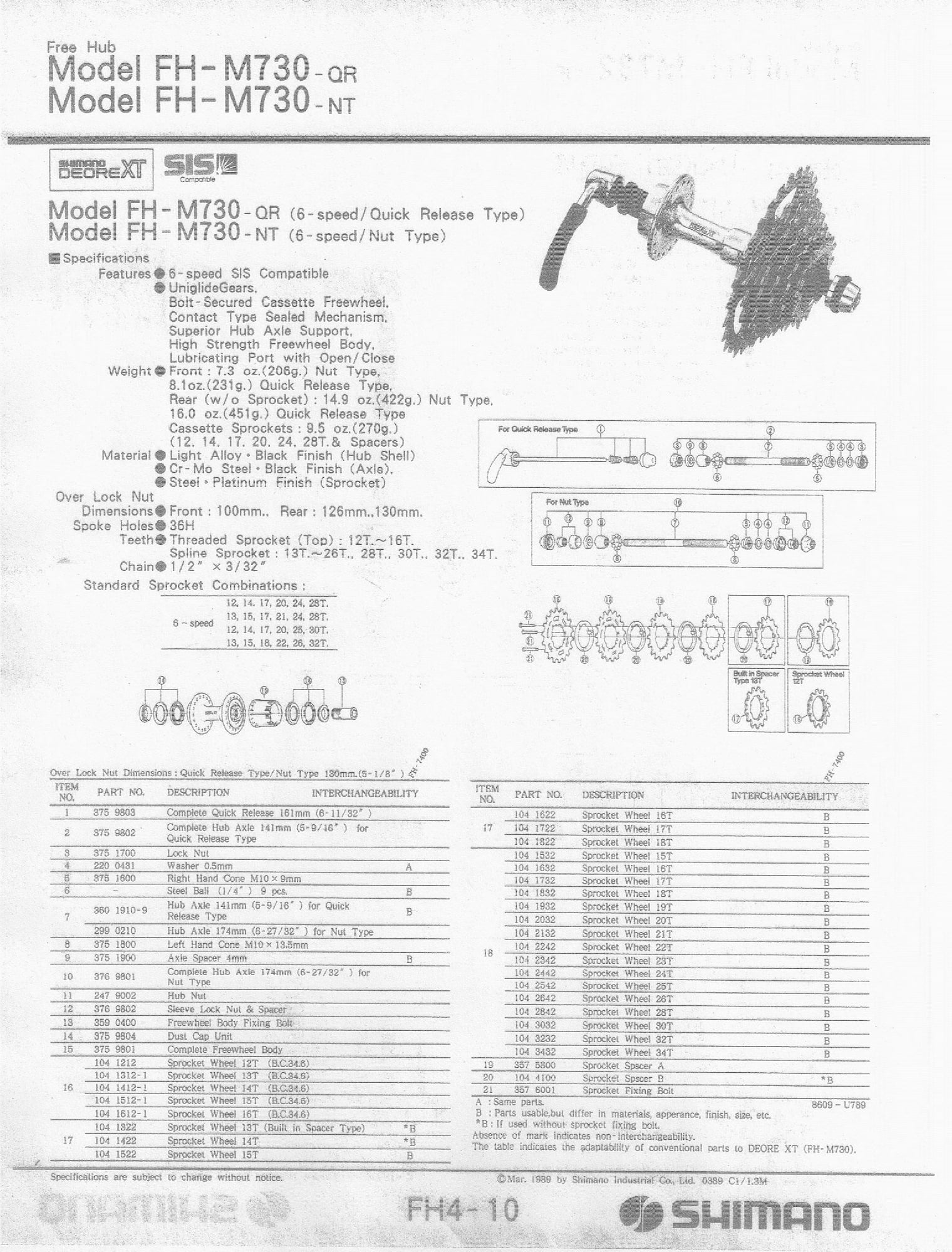

Shimano documentation (EVs) for the FH-M730 indicate it was produced in versions having a 6-speed Uniglide freehub. Contrary to Velobase's listing, Shimano EVs also show it was produced with both nutted and QR axles.

https://si.shimano.com/en/manual/sea..._model=FH-M730

Shimano documentation lists two different EVs; both show both QR and nutted axle versions. I haven't had a chance to look at both EVs in detail, but sometimes multiple EV versions appear to occur due to part number changes during production, color variants, or other such reasons. In this case, certain part numbers and colors appear to have changed between the EVs.

#4

Disraeli Gears

Pictures of what you're dealing with are necessary. My guess is, at the least, you'll have to replace a solid axle with a hollow one. And guessing further, why would the cones or their threading be any different for solid or hollow axles?

Here is a technical document, if it helps:

I can't seem to find these on Shimano's tech website anymore, for whatever reason -- only have it because I have some M730 hubs, I guess.

Here is a technical document, if it helps:

I can't seem to find these on Shimano's tech website anymore, for whatever reason -- only have it because I have some M730 hubs, I guess.

Last edited by Charles Wahl; 03-22-23 at 07:42 AM.

Likes For Charles Wahl:

#5

Senior Member

Pictures of what you're dealing with are necessary. My guess is, at the least, you'll have to replace a solid axle with a hollow one. And guessing further, why would the cones or their threading be any different for solid or hollow axles?

Here is a technical document, if it helps:

I can't seem to find these on Shimano's tech website anymore, for whatever reason -- only have it because I have some M730 hubs, I guess.

Here is a technical document, if it helps:

I can't seem to find these on Shimano's tech website anymore, for whatever reason -- only have it because I have some M730 hubs, I guess.

#6

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

I'll be gobsmacked if you can't just

The basic procedure is to remove the left side locknut and cone, which allows the axle to be slid out to the right. Then you can take the right side cone and locknut off.

Some Shimano freehubs had the wrench flats on the right cone hidden under the rubber seal, so you may have to push the seal out of the way to access them.

(That's a D-A cone so yours is different and this pic may not help)

Reassembly is the opposite of disassembly, just remember right and left cones are different.

Apologies if I've misunderstood the question.

Mark B

- remove original axle

- install hollow QR axle

- adjust and tighten normally.

The basic procedure is to remove the left side locknut and cone, which allows the axle to be slid out to the right. Then you can take the right side cone and locknut off.

Some Shimano freehubs had the wrench flats on the right cone hidden under the rubber seal, so you may have to push the seal out of the way to access them.

(That's a D-A cone so yours is different and this pic may not help)

Reassembly is the opposite of disassembly, just remember right and left cones are different.

Apologies if I've misunderstood the question.

Mark B

Last edited by bulgie; 03-22-23 at 01:53 PM.

#7

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

But by the time this hub was made, solid axles in M10 x 1mm were indeed a thing, made by a few manu's besides Shimano too, such as Suntour and Specialized. What changed in between was MTBs. They (1st Stumpjumper for example) originally came with solid axles, on the mistaken belief that those are stronger. (I obviously don't believe they are.) Certainly with a freehub, hollow axles are strong enough, and the OEMs quickly figured that out and stopped putting nutted hubs on MTBs. So nutted MTBs were a "thing" for only a couple years in the early to mid- '80s

Mark B

#8

Phyllo-buster

Join Date: Jan 2010

Location: Nova Scotia

Posts: 8,847

Bikes: roadsters, club bikes, fixed and classic

Mentioned: 133 Post(s)

Tagged: 0 Thread(s)

Quoted: 2298 Post(s)

Liked 2,055 Times

in

1,255 Posts

Fitchel & Sachs made a 10mm axle in the 60's and 70's but the threading is non-standard.

#9

Senior Member

I say "most" because the solid-axle version used very different locknuts (see the EV for details) than the QR version, which also had a NDS spacer. Dunno for sure how well the solid-axle locknuts would work with QR dropouts, but they appear different enough on the EVs that I'd guess they might not "play nice".

#10

Full Member

Thread Starter

Shimano came with a surprising variety of cones but this is not an issue.

I'm a bag of M730 hollow axles and another one with the cones.

The part #12 (sleeve lock nut & spacer) has 2 positions to allow for the 2 lenghts.

I can't remove it.

Is there a trick?

And the Uniglide can take 7 speeds

I'm a bag of M730 hollow axles and another one with the cones.

The part #12 (sleeve lock nut & spacer) has 2 positions to allow for the 2 lenghts.

I can't remove it.

Is there a trick?

And the Uniglide can take 7 speeds

#11

Full Member

Thread Starter

Shimano came with a surprising variety of cones but this is not an issue.

I've a bag of M730 hollow axles and another one with the cones.

The part #12 (sleeve lock nut & spacer) has 2 positions to allow for the 2 lenghts.

I can't remove it.

Is there a trick?

And the Uniglide can take 7 speeds

I've a bag of M730 hollow axles and another one with the cones.

The part #12 (sleeve lock nut & spacer) has 2 positions to allow for the 2 lenghts.

I can't remove it.

Is there a trick?

And the Uniglide can take 7 speeds

#12

Senior Member

If I recall correctly, yes - Shimano 6-speed Uniglide and 7-speed Uniglide used the same length freehub and will take either a 6- or 7-speed Uniglide cassette.

But also if I recall correctly, Shimano 7-speed hadn't yet been released for Deore when this hub was first produced by Shimano (I believe that happened the next year). That's IMO probably why the EVs refer to it as a 6-speed hub.

#13

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

As to removing part #12, any chance of a close-up pic? I've worked on those hubs and I don't remember any difficulty, but it was a long time ago and my memory is unreliable.

Mark B

#14

Disraeli Gears

As I said before, and as @bulgie just said: photo(s) needed to figure out what you're having trouble with. As @bulgie said, the standard way to remove an axle on a rear hub is to loosen & remove the cone & locknut on the left (non-drive) side, which are accessible (drive side are not, sufficiently). Reverse order is how the bearings are adjusted: fully tighten cone and locknut on the right side, reassemble freehub to the hub, install bearings on right, grease, and feed axle through, install bearings on left, install cone, adjust with locknut. Fiddle with QR (tightening, loosening) and the left side cone-locknut adjustment as needed to get the right free-turning/bearing preload/whatever that floats your boat.

If there's a trick, I have no idea what it might be. I have some M730 hubs, but they've always been QR type -- no Shimano engineering wackiness on those.

If there's a trick, I have no idea what it might be. I have some M730 hubs, but they've always been QR type -- no Shimano engineering wackiness on those.

#15

Full Member

Thread Starter

I should have said that I must have done this with hundreds of hubs, Campagnolo, Shimano, FB, Miche, Porthor, Suntour, Simplex, Sturmey, etc...

The self extending locknut doesn't let go and I was wondering if some pecularities were preventing me to do it as usually.

For uneducated public, these are best advices

#16

Junior Member

Shimano still makes nutted cassette hubs, the TX models. The axle is 10mm x 26tpi, which is what they use on their QR hubs too. I've bought these hubs just to get the axle and axle nuts, as a wheels mfg. 10mm x 26tpi solid axle is something like 30 dollars retail, and axle nuts in that threading are essentially impossible to find. Save the axle nuts from your old hub!!

#17

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

Shimano still makes nutted cassette hubs, the TX models. The axle is 10mm x 26tpi, which is what they use on their QR hubs too. I've bought these hubs just to get the axle and axle nuts, as a wheels mfg. 10mm x 26tpi solid axle is something like 30 dollars retail, and axle nuts in that threading are essentially impossible to find. Save the axle nuts from your old hub!!

Nowadays 26 tpi pretty much only means Campy. Luckily 26 tpi is close enough to 1 mm that your thinner parts like locknuts are interchangeable (class B fit). I find cones to be too thick though, they start to thread on, but then the accumulated error becomes too much and they bind up.

Campy dropouts also have 26 tpi threads where the derailer screws in, so technically a Japanese mech is a class B fit on any frame with Campy dropouts. In practice though, the soft steel of the dropout just sorta flows as necessary to fit the 1 mm thread. Just don't go back and forth between 1 mm and 26 tpi; after a few back-and-forths, you might strip the threads.

Am I fulla beans? Can we get some confirmation, anyone else ever find 26 tpi on a Japanese part?

Mark B

#18

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

I'd try heating the nut that won't budge, like with a heat gun or small propane torch. Heat till the oil smokes, not until glowing!

I find heat to be almost like magic for freeing stuck parts. Even a blow-drier can help, better than nothing.

An axle vise (like in my pic in post #6) is also recommended, for gripping the axle tightly enough to really reef on, without hurting the threads. Soft jaws in your vise (copper, plastic, aluminum) are not as perfect as a dedicated axle vise, but good enough if used judiciously.

Mark B

I find heat to be almost like magic for freeing stuck parts. Even a blow-drier can help, better than nothing.

An axle vise (like in my pic in post #6) is also recommended, for gripping the axle tightly enough to really reef on, without hurting the threads. Soft jaws in your vise (copper, plastic, aluminum) are not as perfect as a dedicated axle vise, but good enough if used judiciously.

Mark B

#19

Junior Member

I agree that 10mm x 26tpi is truly weird and shouldn't exist. It was very frustrating when I was trying to find a solid axle for a parallax-era Shimano cassette hub, couldn't use an M10x1 axle, checked the cones on a gauge, and found that it was 10mm x 26tpi. I bought the nutted TX500 and was able to use its axle with the parallax hub's hardware, then rebuilt the TX500 with the QR axle from the parallax hub. This was three years ago, I mostly work on older bikes and don't know what Shimano's doing now, if they switched to standard metric axles then I'm glad!

#20

Disraeli Gears

Thanks Charles.

I should have said that I must have done this with hundreds of hubs, Campagnolo, Shimano, FB, Miche, Porthor, Suntour, Simplex, Sturmey, etc...

The self extending locknut doesn't let go and I was wondering if some pecularities were preventing me to do it as usually.

I should have said that I must have done this with hundreds of hubs, Campagnolo, Shimano, FB, Miche, Porthor, Suntour, Simplex, Sturmey, etc...

The self extending locknut doesn't let go and I was wondering if some pecularities were preventing me to do it as usually.

#21

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

I agree that 10mm x 26tpi is truly weird and shouldn't exist. It was very frustrating when I was trying to find a solid axle for a parallax-era Shimano cassette hub, couldn't use an M10x1 axle, checked the cones on a gauge, and found that it was 10mm x 26tpi. I bought the nutted TX500 and was able to use its axle with the parallax hub's hardware, then rebuilt the TX500 with the QR axle from the parallax hub. This was three years ago, I mostly work on older bikes and don't know what Shimano's doing now, if they switched to standard metric axles then I'm glad!

I too have no idea what they've been doing for the last 25 or so years. 8-speed is as far as I got with "current" Shimano, and that's only on the tandem, most of my bikes are 5- 6- or 7-speed.

I'm not saying you didn't find one that was 26 tpi, but I'd be more likely to believe that a previous owner had swapped in a Campy, than believe Shimano ever made a 26 tpi cone.

#22

Full Member

Thread Starter

Here comes the pictures...

For the story, the wheelset is intended for Bugs Bunny.

Marin Suntour by bagheerabe, on Flickr

Marin Suntour by bagheerabe, on Flickr

A Marin that I'm rebuilding mostly in Suntour XC Pro ... except when I don't find the parts New...

and since Suntour Cassette are an extinct specie, I spared on finding cheap Nos Grease Guard hubs!

Here on a wheelset with XTR M900 hubs that will go on another project.

So here the FH-M730-NT hub

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr

FH, surely like Rear Hub and NT , Nut Type.

Deore XT M730 NT by bagheerabe, on Flickr with a little bit of shop dust...

Deore XT M730 NT by bagheerabe, on Flickr with a little bit of shop dust...

These "sleeve lock nut and spacer" can be set to a 126 mm wheel width like here

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr

OR...

Can be extended to a 130 mm wheel width ...

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr

HOW?

(and now you will understand that I succeeded to dismantle it)

With concentric ... sleeve.

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr

You can see that the internal part has an exagonal shape

And ...

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr

The outer part has a matching exagonal shape that can be locked (sort of) in extended position.

So now gone to the parts bin.

Welcome the QR axle-cone

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr

Thanks for the help.

For the story, the wheelset is intended for Bugs Bunny.

Marin Suntour by bagheerabe, on Flickr

Marin Suntour by bagheerabe, on FlickrA Marin that I'm rebuilding mostly in Suntour XC Pro ... except when I don't find the parts New...

and since Suntour Cassette are an extinct specie, I spared on finding cheap Nos Grease Guard hubs!

Here on a wheelset with XTR M900 hubs that will go on another project.

So here the FH-M730-NT hub

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on FlickrFH, surely like Rear Hub and NT , Nut Type.

Deore XT M730 NT by bagheerabe, on Flickr with a little bit of shop dust...

Deore XT M730 NT by bagheerabe, on Flickr with a little bit of shop dust...These "sleeve lock nut and spacer" can be set to a 126 mm wheel width like here

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on Flickr Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on FlickrOR...

Can be extended to a 130 mm wheel width ...

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on FlickrHOW?

(and now you will understand that I succeeded to dismantle it)

With concentric ... sleeve.

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on FlickrYou can see that the internal part has an exagonal shape

And ...

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on FlickrThe outer part has a matching exagonal shape that can be locked (sort of) in extended position.

So now gone to the parts bin.

Welcome the QR axle-cone

Deore XT M730 NT by bagheerabe, on Flickr

Deore XT M730 NT by bagheerabe, on FlickrThanks for the help.

Likes For Munny:

#23

Disraeli Gears

Congratulations! Like many Shimano "improvements", an invention in search of a necessity. I still don't understand how it locks in the 130 mm position, so as to be secure enough; but maybe I don't need to know. And, thank you for the photos.

#24

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

Excellent, thanks for documenting that super weird part. Mind = blown.

Like Charles Wahl , I'm mystified how it works, but it's such an obscure niche, I don't need to know. Chalk it up to one o' those unsolved mysteries.

Mark B

Like Charles Wahl , I'm mystified how it works, but it's such an obscure niche, I don't need to know. Chalk it up to one o' those unsolved mysteries.

Mark B

#25

Full Member

Thread Starter

You lenghtened it by pulling and twisting of a few degrees at the extended lenght.

The outer sleeve has 2 flats to allow it to be hold while tightening the external nut but such a little twisting movement is enough to unlock it.

Mmm... no!

Likes For Munny: