Helicoil bigger than expected

#1

Full Member

Thread Starter

Helicoil bigger than expected

Acquired a helicoil kit after struggling to fit a new Deore 12 speed deraileur. The bolt was refusing to selfalign for some reason. Now every time the deraileur is removed I have to clean the threads from the other side with another M10x1 bolt. The bolt still can be tightened up to 10Nm after that.

The question is does the helicoil gets smaller when it gets threaded in? Now it's about 0.5 mm bigger than necessary. Couldn't find any information about it. According to reviews the M10x1 helicoil kit should work for deraileur hangers.

The question is does the helicoil gets smaller when it gets threaded in? Now it's about 0.5 mm bigger than necessary. Couldn't find any information about it. According to reviews the M10x1 helicoil kit should work for deraileur hangers.

Last edited by sysrq; 10-31-23 at 11:13 PM.

#2

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,727

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,590 Times

in

1,436 Posts

Yes.

It's a spring and will shrink in and take it's diameter from the tapped hole. So, as long as you used the correct tap it will produce the right thread.

FWIW, the coils are intentionally wound loose, or oversized, so they press against the outer walls of the hole. If wound tight, they would hold on the screw and migrate as the screw is tightened.

It's a spring and will shrink in and take it's diameter from the tapped hole. So, as long as you used the correct tap it will produce the right thread.

FWIW, the coils are intentionally wound loose, or oversized, so they press against the outer walls of the hole. If wound tight, they would hold on the screw and migrate as the screw is tightened.

Likes For FBinNY:

#3

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,904

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2604 Post(s)

Liked 1,933 Times

in

1,213 Posts

Acquired a helicoil kit after struggling to fit a new Deore 12 speed deraileur. The bolt was refusing to selfalign for some reason. Now every time the deraileur is removed I have to clean the threads from the other side with another M10x1 bolt. The bolt still can be tightened up to 10Nm after that.

Likes For pdlamb:

#5

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

M10 Helicoil kit... @ $35

New Derailleur hanger... @ $20

Watching as Sysrq messes up yet another simple mechanical process... Priceless.

New Derailleur hanger... @ $20

Watching as Sysrq messes up yet another simple mechanical process... Priceless.

#6

Full Member

Thread Starter

It's an integrated deraileur hanger. Hard to avoid any cognitive biases but current social status has only allowed to mess with DIY electronics a bit more, since electronic components are smaller then it's harder to damage them mechanically.

#7

Full Member

Thread Starter

I haven't drilled anything yet since the original threads still can be tightened up to 10Nm, but they can strip completely at the most inconvenient time. Looks like without drill press it will be impossible to drill and tap it straight anyway. Wasn't sure if Dropout Saver is the best choice since you never know when it will start to interfere with chain or cassette, although it doesn't require the hole to be completely straight.

#8

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

care to share the brand and model of the bike frame you're struggling to upgrade to 12 speed?

and i've never seen a "self aligning" der. mount bolt. They are tricky at times. so i sympathize with you on that.

there may be a problem with the thread on the der. bolt... that would explain why you're having to re-tap the hanger so often..

a lack of a clean, evenly formed, chamfer at the entrance of the hanger thread can make threading difficult too.

was the 12 sp. der. purchased as new, or used?

got a magnifying glass? look at the threads on the der. bolt VERY CAREFULLY using that magnifier..... report any defects seen to the forum.

one more question... WHY are you repeatedly Removing then re-installing the rear derailleur? When doing bike builds, and i do quite a few bike builds, i've found installing a der. once, MAYBE twice, to be sufficient.

Last edited by maddog34; 11-01-23 at 12:58 PM.

Likes For maddog34:

#9

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,517

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2747 Post(s)

Liked 3,401 Times

in

2,058 Posts

Unless it's really bad misalignment it should be able to be compensated for in derailleur alignment.

#10

Senior Member

Join Date: Mar 2010

Posts: 1,660

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1248 Post(s)

Liked 1,323 Times

in

674 Posts

If the threads are sketchy, you can use a Loctite Form-A-Thread Stripped Thread Repair Kit and then restrain yourself from mounting and unmounting your derailleur constantly. By the way, how were you planning on drilling out the non-removable hanger using a drill press?

#11

Full Member

Thread Starter

meh... i'll bite....nothing better to do as i wait for an appointment callback.

care to share the brand and model of the bike frame you're struggling to upgrade to 12 speed?

and i've never seen a "self aligning" der. mount bolt. They are tricky at times. so i sympathize with you on that.

there may be a problem with the thread on the der. bolt... that would explain why you're having to re-tap the hanger so often..

a lack of a clean, evenly formed, chamfer at the entrance of the hanger thread can make threading difficult too.

was the 12 sp. der. purchased as new, or used?

got a magnifying glass? look at the threads on the der. bolt VERY CAREFULLY using that magnifier..... report any defects seen to the forum.

one more question... WHY are you repeatedly Removing then re-installing the rear derailleur? When doing bike builds, and i do quite a few bike builds, i've found installing a der. once, MAYBE twice, to be sufficient.

care to share the brand and model of the bike frame you're struggling to upgrade to 12 speed?

and i've never seen a "self aligning" der. mount bolt. They are tricky at times. so i sympathize with you on that.

there may be a problem with the thread on the der. bolt... that would explain why you're having to re-tap the hanger so often..

a lack of a clean, evenly formed, chamfer at the entrance of the hanger thread can make threading difficult too.

was the 12 sp. der. purchased as new, or used?

got a magnifying glass? look at the threads on the der. bolt VERY CAREFULLY using that magnifier..... report any defects seen to the forum.

one more question... WHY are you repeatedly Removing then re-installing the rear derailleur? When doing bike builds, and i do quite a few bike builds, i've found installing a der. once, MAYBE twice, to be sufficient.

The frame is Throrn Audax Mk3.

Last edited by sysrq; 11-01-23 at 05:36 PM.

#12

With a mighty wind

Join Date: May 2015

Posts: 2,595

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 1088 Post(s)

Liked 862 Times

in

490 Posts

If the threads are sketchy, you can use a Loctite Form-A-Thread Stripped Thread Repair Kit and then restrain yourself from mounting and unmounting your derailleur constantly. By the way, how were you planning on drilling out the non-removable hanger using a drill press?

I removed a washer and that gave me purchase on some good threads deeper in. Itís been working perfectly since.

I still know that a bunch of threads are missing and it worries me. Would this Loctite thread repair work here? Itís usually best to loosen these bolts to align the calipers then tighten. Will it hold up to that?

I figured Iíd helicoil it sometime this winter but this is a totally different idea. Iím curious.

#13

Senior Member

Putting my 2 cents worth of experience in on this one. I have installed hanger savers about a dozen times over the years on steel frames. There is no need to worry too much about drilling the hole straight as the bit will follow the hole that already exists. When tapping the new threads into the new hole, that is where experience in handling a manual tap comes in. I personally use a drill now, but the first few taps I did it manually with a tap handle. It is not rocket science here, just a hole and a tap.

#14

Full Member

Thread Starter

meh... i'll bite....nothing better to do as i wait for an appointment callback.

care to share the brand and model of the bike frame you're struggling to upgrade to 12 speed?

and i've never seen a "self aligning" der. mount bolt. They are tricky at times. so i sympathize with you on that.

there may be a problem with the thread on the der. bolt... that would explain why you're having to re-tap the hanger so often..

a lack of a clean, evenly formed, chamfer at the entrance of the hanger thread can make threading difficult too.

was the 12 sp. der. purchased as new, or used?

got a magnifying glass? look at the threads on the der. bolt VERY CAREFULLY using that magnifier..... report any defects seen to the forum.

one more question... WHY are you repeatedly Removing then re-installing the rear derailleur? When doing bike builds, and i do quite a few bike builds, i've found installing a der. once, MAYBE twice, to be sufficient.

care to share the brand and model of the bike frame you're struggling to upgrade to 12 speed?

and i've never seen a "self aligning" der. mount bolt. They are tricky at times. so i sympathize with you on that.

there may be a problem with the thread on the der. bolt... that would explain why you're having to re-tap the hanger so often..

a lack of a clean, evenly formed, chamfer at the entrance of the hanger thread can make threading difficult too.

was the 12 sp. der. purchased as new, or used?

got a magnifying glass? look at the threads on the der. bolt VERY CAREFULLY using that magnifier..... report any defects seen to the forum.

one more question... WHY are you repeatedly Removing then re-installing the rear derailleur? When doing bike builds, and i do quite a few bike builds, i've found installing a der. once, MAYBE twice, to be sufficient.

#15

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

you answered the first question twice, failed to answer two more questions, then answered the last question..

the frame is no prize. Taiwan built out of what is most likely low grade chrome moly.. close to two kilos weight, minus the fork.

is the skewer the one you mention in another thread? the one you poured loctite onto, then couldn't get loose?

have you looked at the threads on the der. bolt with a magnifying glass yet?

tip: The "thread Drop" technique...... get the der. bolt centered on the hanger, properly aligned... turn the der. bolt counter-clockwise before threading it into the hanger... at some point, you will feel the bolt kind of Drop into place into the hanger... then begin turning it clockwise.... the "drop" is the entry ramp of the bolt thread dropping into the entry ramp of the hanger's thread... i advise practicing this method on a larger thread nut/bolt combo.. it will be easier to feel and learn, with no bad consequences.

and fine rate threads are always tricky.

I learned the Thread Drop tip watching my dad put the gas tank cap onto his 1929 Ford Model A Pickup... the 1930 Model A pickup came with a larger, much lower rate thread... The customers complained to Ford about those stupid fine threads on the '27 Model A.. it took Ford 3 years to change their bad design.. My dad later took the time to Cut the filler off that tank and replace it with a 1931 Cap/filler neck, salvaged from a wrecked car. Model A tanks filled at the Center of the area between the Engine Hood and the windshield... On hot days, you had to lean onto the hood to get to the cap.... on a Black Truck... in the Sun... with gas fumes wafting up into your face.... and then fight with those super-fine rate threads on a somewhat flexible thin walled filler neck.........

derailleur hanger bolt threads are, By Far, easier to deal with.

the frame is no prize. Taiwan built out of what is most likely low grade chrome moly.. close to two kilos weight, minus the fork.

is the skewer the one you mention in another thread? the one you poured loctite onto, then couldn't get loose?

have you looked at the threads on the der. bolt with a magnifying glass yet?

tip: The "thread Drop" technique...... get the der. bolt centered on the hanger, properly aligned... turn the der. bolt counter-clockwise before threading it into the hanger... at some point, you will feel the bolt kind of Drop into place into the hanger... then begin turning it clockwise.... the "drop" is the entry ramp of the bolt thread dropping into the entry ramp of the hanger's thread... i advise practicing this method on a larger thread nut/bolt combo.. it will be easier to feel and learn, with no bad consequences.

and fine rate threads are always tricky.

I learned the Thread Drop tip watching my dad put the gas tank cap onto his 1929 Ford Model A Pickup... the 1930 Model A pickup came with a larger, much lower rate thread... The customers complained to Ford about those stupid fine threads on the '27 Model A.. it took Ford 3 years to change their bad design.. My dad later took the time to Cut the filler off that tank and replace it with a 1931 Cap/filler neck, salvaged from a wrecked car. Model A tanks filled at the Center of the area between the Engine Hood and the windshield... On hot days, you had to lean onto the hood to get to the cap.... on a Black Truck... in the Sun... with gas fumes wafting up into your face.... and then fight with those super-fine rate threads on a somewhat flexible thin walled filler neck.........

derailleur hanger bolt threads are, By Far, easier to deal with.

Last edited by maddog34; 11-01-23 at 07:32 PM.

#16

Senior Member

Join Date: Mar 2010

Posts: 1,660

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1248 Post(s)

Liked 1,323 Times

in

674 Posts

Ive got a Cane Creek Helm MK2 fork that I over torqued and stripped during a trailside realignment with the disc caliper. I was a bit surprised I was able to do that with a folding tool but I did.

I removed a washer and that gave me purchase on some good threads deeper in. Itís been working perfectly since.

I still know that a bunch of threads are missing and it worries me. Would this Loctite thread repair work here? Itís usually best to loosen these bolts to align the calipers then tighten. Will it hold up to that?

I figured Iíd helicoil it sometime this winter but this is a totally different idea. Iím curious.

I removed a washer and that gave me purchase on some good threads deeper in. Itís been working perfectly since.

I still know that a bunch of threads are missing and it worries me. Would this Loctite thread repair work here? Itís usually best to loosen these bolts to align the calipers then tighten. Will it hold up to that?

I figured Iíd helicoil it sometime this winter but this is a totally different idea. Iím curious.

#17

Full Member

Thread Starter

you answered the first question twice, failed to answer two more questions, then answered the last question..

the frame is no prize. Taiwan built out of what is most likely low grade chrome moly.. close to two kilos weight, minus the fork.

is the skewer the one you mention in another thread? the one you poured loctite onto, then couldn't get loose?

have you looked at the threads on the der. bolt with a magnifying glass yet?

tip: The "thread Drop" technique...... get the der. bolt centered on the hanger, properly aligned... turn the der. bolt counter-clockwise before threading it into the hanger... at some point, you will feel the bolt kind of Drop into place into the hanger... then begin turning it clockwise.... the "drop" is the entry ramp of the bolt thread dropping into the entry ramp of the hanger's thread... i advise practicing this method on a larger thread nut/bolt combo.. it will be easier to feel and learn, with no bad consequences.

and fine rate threads are always tricky.

I learned the Thread Drop tip watching my dad put the gas tank cap onto his 1929 Ford Model A Pickup... the 1930 Model A pickup came with a larger, much lower rate thread... The customers complained to Ford about those stupid fine threads on the '27 Model A.. it took Ford 3 years to change their bad design.. My dad later took the time to Cut the filler off that tank and replace it with a 1931 Cap/filler neck, salvaged from a wrecked car. Model A tanks filled at the Center of the area between the Engine Hood and the windshield... On hot days, you had to lean onto the hood to get to the cap.... on a Black Truck... in the Sun... with gas fumes wafting up into your face.... and then fight with those super-fine rate threads on a somewhat flexible thin walled filler neck.........

derailleur hanger bolt threads are, By Far, easier to deal with.

the frame is no prize. Taiwan built out of what is most likely low grade chrome moly.. close to two kilos weight, minus the fork.

is the skewer the one you mention in another thread? the one you poured loctite onto, then couldn't get loose?

have you looked at the threads on the der. bolt with a magnifying glass yet?

tip: The "thread Drop" technique...... get the der. bolt centered on the hanger, properly aligned... turn the der. bolt counter-clockwise before threading it into the hanger... at some point, you will feel the bolt kind of Drop into place into the hanger... then begin turning it clockwise.... the "drop" is the entry ramp of the bolt thread dropping into the entry ramp of the hanger's thread... i advise practicing this method on a larger thread nut/bolt combo.. it will be easier to feel and learn, with no bad consequences.

and fine rate threads are always tricky.

I learned the Thread Drop tip watching my dad put the gas tank cap onto his 1929 Ford Model A Pickup... the 1930 Model A pickup came with a larger, much lower rate thread... The customers complained to Ford about those stupid fine threads on the '27 Model A.. it took Ford 3 years to change their bad design.. My dad later took the time to Cut the filler off that tank and replace it with a 1931 Cap/filler neck, salvaged from a wrecked car. Model A tanks filled at the Center of the area between the Engine Hood and the windshield... On hot days, you had to lean onto the hood to get to the cap.... on a Black Truck... in the Sun... with gas fumes wafting up into your face.... and then fight with those super-fine rate threads on a somewhat flexible thin walled filler neck.........

derailleur hanger bolt threads are, By Far, easier to deal with.

The Thorn Audax Mk3 was advertised as being heat treated and as good as Raynolds frame.

They probably found a way how to make a better profit.

#18

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

The Dropout Saver might actually work better since the dropout slot part is thicker than the rest on Thorn Audax Mk3 frame leaving a lot of clearance around cassette lockring. On the other hand if the hole diameter required for Dropout saver is bigger than helicoil then it might take out too much material, so helicoil might be safer.

The Thorn Audax Mk3 was advertised as being heat treated and as good as Raynolds frame.

They probably found a way how to make a better profit.

The Thorn Audax Mk3 was advertised as being heat treated and as good as Raynolds frame.

They probably found a way how to make a better profit.

https://www.ebay.com/itm/18536650788...acd6b7f423c255

SMH.... i'm out... NEXT!

Last edited by maddog34; 11-02-23 at 02:18 AM.

#19

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,517

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2747 Post(s)

Liked 3,401 Times

in

2,058 Posts

use one of these... i have... it will require a 15/32 drill bit, if i recall correctly. you'll want to check on that specification..... they work great.

https://www.ebay.com/itm/18536650788...acd6b7f423c255

SMH.... i'm out... NEXT!

https://www.ebay.com/itm/18536650788...acd6b7f423c255

SMH.... i'm out... NEXT!

https://wheelsmfg.com/presses-tools/dropout-savers.html

#20

Full Member

Join Date: Jul 2023

Location: "Driftless" WI

Posts: 388

Bikes: 1972 Motobecane Grand Record, 2022 Kona Dew+

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 146 Times

in

107 Posts

If so, it won't - trust me on this. Helicoils are intended to be installed in a smooth-sided bore of a diameter indicated on the packaging they came in. M10x1 'coil needs a 10.25mm hole for aluminum, magnesium, steel and plastic for proper installation.

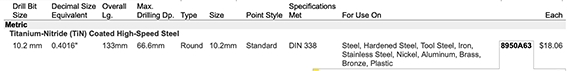

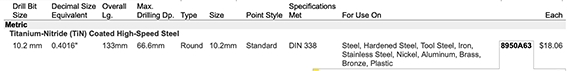

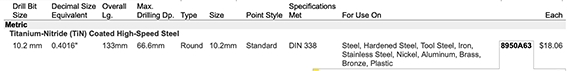

You could use an X (10.0838mm so will be tight!) or a Y drill (10.2616mm dia.) as a 10.25mm bit might be tough to find. McMaster has 10.2mm for ~ US $27 (shipped) which ought to work OK if you're careful doing the job.

Or have I missed something?

Likes For spclark:

#21

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

So you ran an M10x1 Helicoil into an M10x1-threaded hole that still has viable threads innit and you expect the Helicoil to accept the original M10x1 bolt?

If so, it won't - trust me on this. Helicoils are intended to be installed in a smooth-sided bore of a diameter indicated on the packaging they came in. M10x1 'coil needs a 10.25mm hole for aluminum, magnesium, steel and plastic for proper installation.

You could use an X (10.0838mm so will be tight!) or a Y drill (10.2616mm dia.) as a 10.25mm bit might be tough to find. McMaster has 10.2mm for ~ US $27 (shipped) which ought to work OK if you're careful doing the job.

Or have I missed something?

If so, it won't - trust me on this. Helicoils are intended to be installed in a smooth-sided bore of a diameter indicated on the packaging they came in. M10x1 'coil needs a 10.25mm hole for aluminum, magnesium, steel and plastic for proper installation.

You could use an X (10.0838mm so will be tight!) or a Y drill (10.2616mm dia.) as a 10.25mm bit might be tough to find. McMaster has 10.2mm for ~ US $27 (shipped) which ought to work OK if you're careful doing the job.

Or have I missed something?

i've bought multiple High end Reynolds and Columbus Frames for less than Sysrq has spent on that stripped hanger thread in his basic taiwan built chrome moly frame....

Last edited by maddog34; 11-02-23 at 12:41 PM.

#22

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

A good LBS should have one in stock rather than getting one shipped from eastern europe.

https://wheelsmfg.com/presses-tools/dropout-savers.html

https://wheelsmfg.com/presses-tools/dropout-savers.html

and actually... i found yet another overpriced widget i can make... and still make a decent profit on, at around half the price..

#23

With a mighty wind

Join Date: May 2015

Posts: 2,595

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 1088 Post(s)

Liked 862 Times

in

490 Posts

That loctite kit is $35-$42 depending on the source.

A helicoil kit is $15 to $45 depending on the brand.

I think the advantage of the goop kit must be simplicity. And if it doesnít work, I could try again.

Iíd wager that the helicoil is substantially stronger and more permanent. Iíd have to drill out the remaining threads and if I did it wrong, I donít know where that would leave me. Which is a pretty big disadvantage.

Its amazing how fruitless online searches for the effectiveness of this stuff are. Maybe one test, that puts it even with JB Weld. 2 or 3 people who left a positive review if used in a hole with some good threads left. Very little else.

Thats why I asked.

#24

Senior Member

Join Date: Mar 2010

Posts: 1,660

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1248 Post(s)

Liked 1,323 Times

in

674 Posts

Thats a possibility.

That loctite kit is $35-$42 depending on the source.

A helicoil kit is $15 to $45 depending on the brand.

I think the advantage of the goop kit must be simplicity. And if it doesnít work, I could try again.

Iíd wager that the helicoil is substantially stronger and more permanent. Iíd have to drill out the remaining threads and if I did it wrong, I donít know where that would leave me. Which is a pretty big disadvantage.

Its amazing how fruitless online searches for the effectiveness of this stuff are. Maybe one test, that puts it even with JB Weld. 2 or 3 people who left a positive review if used in a hole with some good threads left. Very little else.

Thats why I asked.

That loctite kit is $35-$42 depending on the source.

A helicoil kit is $15 to $45 depending on the brand.

I think the advantage of the goop kit must be simplicity. And if it doesnít work, I could try again.

Iíd wager that the helicoil is substantially stronger and more permanent. Iíd have to drill out the remaining threads and if I did it wrong, I donít know where that would leave me. Which is a pretty big disadvantage.

Its amazing how fruitless online searches for the effectiveness of this stuff are. Maybe one test, that puts it even with JB Weld. 2 or 3 people who left a positive review if used in a hole with some good threads left. Very little else.

Thats why I asked.

#25

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

Thats a possibility.

That loctite kit is $35-$42 depending on the source.

A helicoil kit is $15 to $45 depending on the brand.

I think the advantage of the goop kit must be simplicity. And if it doesn’t work, I could try again.

I’d wager that the helicoil is substantially stronger and more permanent. I’d have to drill out the remaining threads and if I did it wrong, I don’t know where that would leave me. Which is a pretty big disadvantage.

Its amazing how fruitless online searches for the effectiveness of this stuff are. Maybe one test, that puts it even with JB Weld. 2 or 3 people who left a positive review if used in a hole with some good threads left. Very little else.

Thats why I asked.

That loctite kit is $35-$42 depending on the source.

A helicoil kit is $15 to $45 depending on the brand.

I think the advantage of the goop kit must be simplicity. And if it doesn’t work, I could try again.

I’d wager that the helicoil is substantially stronger and more permanent. I’d have to drill out the remaining threads and if I did it wrong, I don’t know where that would leave me. Which is a pretty big disadvantage.

Its amazing how fruitless online searches for the effectiveness of this stuff are. Maybe one test, that puts it even with JB Weld. 2 or 3 people who left a positive review if used in a hole with some good threads left. Very little else.

Thats why I asked.