General Torque Specifications form Park Tool

#1

Full Member

Thread Starter

Join Date: Jan 2022

Location: Albuquerque NM USA

Posts: 492

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 222 Post(s)

Liked 304 Times

in

194 Posts

General Torque Specifications form Park Tool

I stumbled on this webpage from Park Tool. It has recommenced torque settings for all things bike. While I would always try to find specific manufacturer's specifications, sometimes that's just not possible. This seems to be quite a comprehensive list of torque specs. And some are manufacturer specific.

Park Tool Torque Specs

Park Tool Torque Specs

Likes For Mtracer:

#2

Droid on a mission

Join Date: May 2018

Location: Palm Coast, FL

Posts: 1,005

Bikes: Diamondback Wildwood Classic

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 317 Post(s)

Liked 280 Times

in

195 Posts

Should this be up in the Hint and Tricks sticky?

__________________

JoeTBM (The Bike Man) - I'm a black & white type of guy, the only gray in my life is the hair on my head

www.TheBikeMenOfFlaglerCounty.com

www.TheBikeMenOfFlaglerCounty.com

JoeTBM (The Bike Man) - I'm a black & white type of guy, the only gray in my life is the hair on my head

www.TheBikeMenOfFlaglerCounty.com

www.TheBikeMenOfFlaglerCounty.com

Likes For JoeTBM:

#3

Junior Member

While I like the inclusion of so many often hard to find torque figures for numerous fasteners, I find it strange that such an apparently authoritative article doesn't mention whether the torque values given are for dry or oiled or otherwise lubricated threads ( unless I missed it ).

Likes For redshift1:

#4

Senior Member

Thanks. I was just looking online yesterday for torque specs for bottom brackets and crank arm pinch bolts, still couldn't find, in past had to just do by feel. This was in regard to the thread regarding need for a torque wrench. Yeah I said, you can get by without it, but better if you can torque to spec.

#5

Senior Member

While I like the inclusion of so many often hard to find torque figures for numerous fasteners, I find it strange that such an apparently authoritative article doesn't mention whether the torque values given are for dry or oiled or otherwise lubricated threads ( unless I missed it ).

Last edited by Duragrouch; 03-14-24 at 05:04 AM.

#6

Senior Member

Join Date: Apr 2016

Posts: 1,236

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 501 Post(s)

Liked 436 Times

in

335 Posts

While I like the inclusion of so many often hard to find torque figures for numerous fasteners, I find it strange that such an apparently authoritative article doesn't mention whether the torque values given are for dry or oiled or otherwise lubricated threads ( unless I missed it ).

#7

Senior Member

#8

Senior Member

Join Date: Feb 2015

Location: Mission Viejo

Posts: 5,807

Bikes: 1986 Cannondale SR400 (Flat bar commuter), 1988 Cannondale Criterium XTR, 1992 Serotta T-Max, 1995 Trek 970

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1944 Post(s)

Liked 2,164 Times

in

1,323 Posts

I’m guessing that for a bicycle the torque range is for lubrucated/anti-sieze installation; although I’m not certain.

Personally, I use light coat/dab of Phil’s grease, or anti-seize if specified, on threads. I have not had a problem so far torquing to within the range.

John

Last edited by 70sSanO; 03-15-24 at 09:19 PM.

#10

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,640

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4737 Post(s)

Liked 1,533 Times

in

1,004 Posts

Not sure it makes sense. A delivered bike with a seatpost clamp that is marked eg. 6Nm, or stem clamp with some other value. Were the bike's seatpost clamp threads or stem bolts shipped dry or greased when you took delivery of the complete bike?

#11

Full Member

Thread Starter

Join Date: Jan 2022

Location: Albuquerque NM USA

Posts: 492

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 222 Post(s)

Liked 304 Times

in

194 Posts

Concerning wet or dry, I too would like that information. But The generally accepted 40% derating when wet (lubed), while significant, isn't orders of magnitude. I tend to err on the low side of any range of specs given. So, if it is meant dry, then I'm not necessarily exceeding it if lubed, if it has a wide enough range. Or not exceeding it by much.

Also, many of the specs printed on bike parts are a maximum. So, I always tend to stay well below that. Basically I use a torque wrench but if the spec is 5 N-m Max., I'll use 4 N-m unless I have a reason not to. I can't think of anything that has ever become loose on my bikes. So, this approach has been working well for me. I ride mostly road, so might be a different story if I were riding a lot of MTB in rock gardens.

The only time I got bit was tightening some aluminum chain-ring bolts. The aluminum bolts snap VERY easily. The Shimano spec is 12-16 N-m (I know super high). I now know this is a dry number, but didn't at the time I snapped one. There's a lot of debate whether to lube or not lube chain-ring bolts. Many if not most opinions I saw people lubed them to avoid seizing issue later and to perhaps avoid noise. But they torqued to 8 N-m Max.

It also seems a lot of things on the bike are lubed. I try to find manufacturer's specs whenever possible. But sometimes I can't find anything. So, that where a table like the one I linked is way better than nothing.

Also, many of the specs printed on bike parts are a maximum. So, I always tend to stay well below that. Basically I use a torque wrench but if the spec is 5 N-m Max., I'll use 4 N-m unless I have a reason not to. I can't think of anything that has ever become loose on my bikes. So, this approach has been working well for me. I ride mostly road, so might be a different story if I were riding a lot of MTB in rock gardens.

The only time I got bit was tightening some aluminum chain-ring bolts. The aluminum bolts snap VERY easily. The Shimano spec is 12-16 N-m (I know super high). I now know this is a dry number, but didn't at the time I snapped one. There's a lot of debate whether to lube or not lube chain-ring bolts. Many if not most opinions I saw people lubed them to avoid seizing issue later and to perhaps avoid noise. But they torqued to 8 N-m Max.

It also seems a lot of things on the bike are lubed. I try to find manufacturer's specs whenever possible. But sometimes I can't find anything. So, that where a table like the one I linked is way better than nothing.

Likes For Mtracer:

#12

Banned

I helped out in a bike shop in the 1970's and a torque wrench was never used. The bike mechanics knew to use the correct size wrench when tightening anything. The length of the wrench handle limits the amount of torque that can be applied. People bringing their bikes with failed fasteners had used wrenches meant for use on automobiles and not small 8mm bolts on a bike.

Likes For Calsun:

#13

Senior Member

I helped out in a bike shop in the 1970's and a torque wrench was never used. The bike mechanics knew to use the correct size wrench when tightening anything. The length of the wrench handle limits the amount of torque that can be applied. People bringing their bikes with failed fasteners had used wrenches meant for use on automobiles and not small 8mm bolts on a bike.

#14

Senior Member

Join Date: May 2004

Location: Southern California

Posts: 2,191

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 114 Post(s)

Liked 119 Times

in

92 Posts

The Park torque spec is my go-to reference, unless otherwise stated on the component. I've always assumed the Park table was for lubricated threads and I always grease threads. In general, I never liked the idea of wasting energy to overcome friction in the thread and would rather have the energy develop clamping force.

Let me send Park a question about dry v lubed threads and their table. In the past, they've replied to my queries pretty quickly. I'll let you all know what they say.

Let me send Park a question about dry v lubed threads and their table. In the past, they've replied to my queries pretty quickly. I'll let you all know what they say.

#15

Full Member

Thread Starter

Join Date: Jan 2022

Location: Albuquerque NM USA

Posts: 492

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 222 Post(s)

Liked 304 Times

in

194 Posts

The Park torque spec is my go-to reference, unless otherwise stated on the component. I've always assumed the Park table was for lubricated threads and I always grease threads. In general, I never liked the idea of wasting energy to overcome friction in the thread and would rather have the energy develop clamping force.

Let me send Park a question about dry v lubed threads and their table. In the past, they've replied to my queries pretty quickly. I'll let you all know what they say.

Let me send Park a question about dry v lubed threads and their table. In the past, they've replied to my queries pretty quickly. I'll let you all know what they say.

As for greased or not, while you get more tension in the fastener with less applied torque when using grease, I think there may be advantages to un-greased in terms of a bolt loosening. But, I too, tend to grease unless specifically instructed not to do so or it is obvious for some reason to avoid grease (around disc brake rotors for example).

#16

Senior Member

Join Date: Feb 2015

Location: Mission Viejo

Posts: 5,807

Bikes: 1986 Cannondale SR400 (Flat bar commuter), 1988 Cannondale Criterium XTR, 1992 Serotta T-Max, 1995 Trek 970

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1944 Post(s)

Liked 2,164 Times

in

1,323 Posts

The Park torque spec is my go-to reference, unless otherwise stated on the component. I've always assumed the Park table was for lubricated threads and I always grease threads. In general, I never liked the idea of wasting energy to overcome friction in the thread and would rather have the energy develop clamping force.

Let me send Park a question about dry v lubed threads and their table. In the past, they've replied to my queries pretty quickly. I'll let you all know what they say.

Let me send Park a question about dry v lubed threads and their table. In the past, they've replied to my queries pretty quickly. I'll let you all know what they say.

It’s their table, although they might have a mfg’s fallback response which would be tough to track down each specific torque to a prep recommendation.

John

#17

Mostly harmless ™

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

These are my notes - the torques that work well for me, with anti-seize paste (what I always use):

https://bike.bikegremlin.com/14694/b...ening-torques/

https://bike.bikegremlin.com/14694/b...ening-torques/

#18

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,640

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4737 Post(s)

Liked 1,533 Times

in

1,004 Posts

I'm not sure how any table can be reliable. Unless you know for certain that X brand only always uses Y-sized bolts that are made out of Z material. Aren't torque specs at least partially (if not mostly) contingent on the bolt size? And then sometimes torque spec might be also partly contingent on what the part is that is being clamped and not what the clamp and its bolt itself can withstand.

The Park Table, isn't it really out of date?

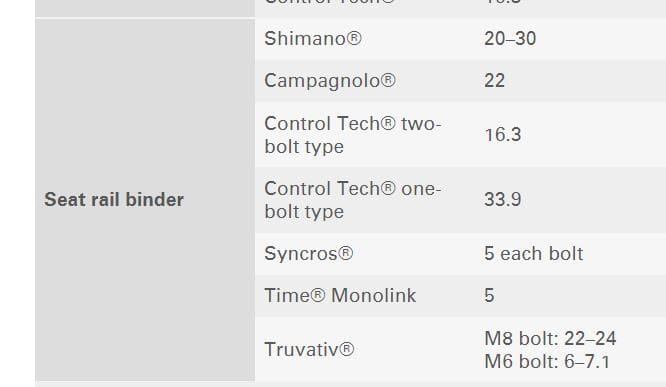

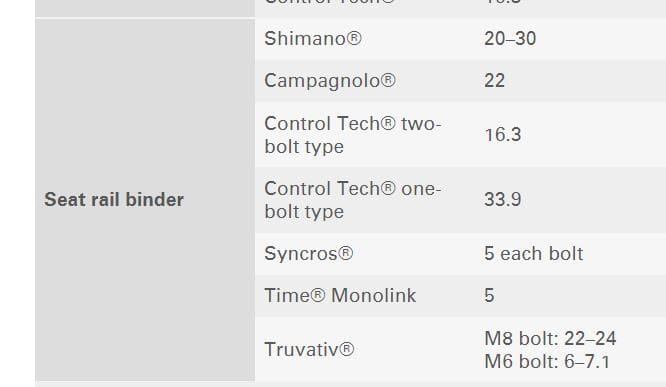

This is the clamping force table for tightening your saddle rails down in the seatpost's clamp? Any of these brands really still in play on any newish bikes? Ranges by brand from 6-34Nm .. seems really wide spread.

The Park Table, isn't it really out of date?

This is the clamping force table for tightening your saddle rails down in the seatpost's clamp? Any of these brands really still in play on any newish bikes? Ranges by brand from 6-34Nm .. seems really wide spread.

#19

Senior Member

Join Date: May 2004

Location: Southern California

Posts: 2,191

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 114 Post(s)

Liked 119 Times

in

92 Posts

"Those are taken from the manufacturer as opposed to being generic like "for a 5x0.8 thread bolt, the max torque is...". So in the manufacturer specified specs you will want to defer to the manufacturer. But you point is valid, we could make a note of that in the chart, otherwise what is the point if you have to go look it up anyway. One note is that there is an assumption that the bolt was prepped from the factory and unless someone did something to the threads (which does happen) to modify the factory prep, if you are servicing the bike post initial assembly, then most people just check the torque, they don't remove the bolt, re-prep it and then reinstall it. Anyway, I will pass this question/suggestion on."

As a side note, on the Park site, https://www.parktool.com/en-us/blog/...hread-concepts, section 4 recommends greasing threaded fasteners unless the manufacturer advises dry threads.

Likes For MudPie:

#20

Senior Member

Join Date: May 2004

Location: Southern California

Posts: 2,191

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 114 Post(s)

Liked 119 Times

in

92 Posts

I stumbled on this webpage from Park Tool. It has recommenced torque settings for all things bike. While I would always try to find specific manufacturer's specifications, sometimes that's just not possible. This seems to be quite a comprehensive list of torque specs. And some are manufacturer specific.

Park Tool Torque Specs

Park Tool Torque Specs

Those are taken from the manufacturer as opposed to being generic like "for a 5x0.8 thread bolt, the max torque is...". So in the manufacturer specified specs you will want to defer to the manufacturer. But you point is valid, we could make a note of that in the chart, otherwise what is the point if you have to go look it up anyway. One note is that there is an assumption that the bolt was prepped from the factory and unless someone did something to the threads (which does happen) to modify the factory prep, if you are servicing the bike post initial assembly, then most people just check the torque, they don't remove the bolt, re-prep it and then reinstall it. Anyway, I will pass this

#21

Full Member

Thread Starter

Join Date: Jan 2022

Location: Albuquerque NM USA

Posts: 492

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 222 Post(s)

Liked 304 Times

in

194 Posts

Your post sparked a debate whether the Park torque values referenced dry or lubricated threads. I sent a query to Park asking for clarification and Pete from customer service replied in a few hours. Here is their reply:

Those are taken from the manufacturer as opposed to being generic like "for a 5x0.8 thread bolt, the max torque is...". So in the manufacturer specified specs you will want to defer to the manufacturer. But you point is valid, we could make a note of that in the chart, otherwise what is the point if you have to go look it up anyway. One note is that there is an assumption that the bolt was prepped from the factory and unless someone did something to the threads (which does happen) to modify the factory prep, if you are servicing the bike post initial assembly, then most people just check the torque, they don't remove the bolt, re-prep it and then reinstall it. Anyway, I will pass this

Those are taken from the manufacturer as opposed to being generic like "for a 5x0.8 thread bolt, the max torque is...". So in the manufacturer specified specs you will want to defer to the manufacturer. But you point is valid, we could make a note of that in the chart, otherwise what is the point if you have to go look it up anyway. One note is that there is an assumption that the bolt was prepped from the factory and unless someone did something to the threads (which does happen) to modify the factory prep, if you are servicing the bike post initial assembly, then most people just check the torque, they don't remove the bolt, re-prep it and then reinstall it. Anyway, I will pass this