internally post-stressed bonded aluminum & steel frame

#1

Full Member

Thread Starter

internally post-tensioned bonded aluminum & steel frame

Recent donation at our local bike coop. My guess is it was built by Merida of Tawian. The serial number kinda matches TMar's Asian Serial number guide and the frame resembles another I have that reportedly came from Merida. Sticker reads made in Taiwan in 1988 for BMX products of California. Road bike branded as Mangusta 3000. Bonded aluminum main triangle, steel bb and stays. The seat stay is bolted to the aluminum seat lug.

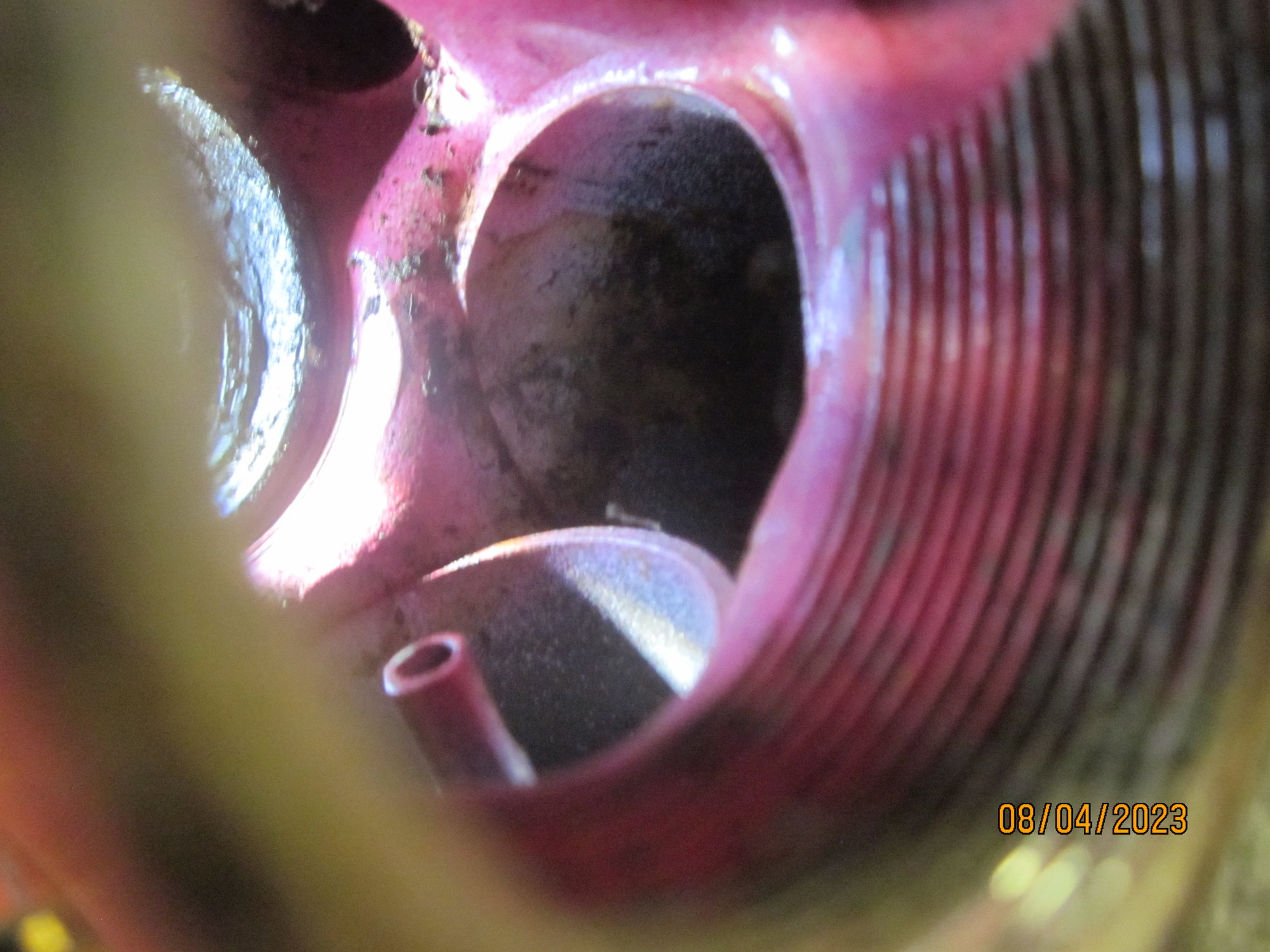

What is unique in this frame is a rod running inside the down tube. Looks to be attached to the head tube and there is a dome shape cup in the down tube near the bb with what looks like a spoke nipple in backwards. There is a hole in the bb shell that aligns with the internal rod. I poked a spoke in to the water bottle blind nut and I can feel the rod and flex it a little bit.

So what is going on? Was this intended to be extra reinforcement to hold the frame together while the glue set up? Or did they think the frame needed some extra strength? I don't know if they used a thermal set glue or an epoxy.

Mangusta 3000 bonded steel & aluminum road bike

internal downtube rod welded or crimped to head tube

crimped or threaded fixin in the downtube

internal downtube rod welded or crimped to head tube

Access hole for post-tension rod nut/crimp

View through the access hole in the bb shell

nut or crimp on the bb end of the internal tension rod

nut or crimp on the bottom end of the internal tension rod

What is unique in this frame is a rod running inside the down tube. Looks to be attached to the head tube and there is a dome shape cup in the down tube near the bb with what looks like a spoke nipple in backwards. There is a hole in the bb shell that aligns with the internal rod. I poked a spoke in to the water bottle blind nut and I can feel the rod and flex it a little bit.

So what is going on? Was this intended to be extra reinforcement to hold the frame together while the glue set up? Or did they think the frame needed some extra strength? I don't know if they used a thermal set glue or an epoxy.

Mangusta 3000 bonded steel & aluminum road bike

internal downtube rod welded or crimped to head tube

crimped or threaded fixin in the downtube

internal downtube rod welded or crimped to head tube

Access hole for post-tension rod nut/crimp

View through the access hole in the bb shell

nut or crimp on the bb end of the internal tension rod

nut or crimp on the bottom end of the internal tension rod

Last edited by rickpaulos; 08-07-23 at 09:43 PM.

#2

Full Member

Thread Starter

Some external photos

Head tube decal

Made in Taiwan for BMX Products Co Camarillo California USA 1988

Precision Aluminum Composite Engineering

some paint bubbling at the bb seams.

Steel seat stays bolted to the aluminum seat lug

Pump peg. Questionable how that will work with the brake cable housing guides under the top tube.

Head tube decal

Made in Taiwan for BMX Products Co Camarillo California USA 1988

Precision Aluminum Composite Engineering

some paint bubbling at the bb seams.

Steel seat stays bolted to the aluminum seat lug

Pump peg. Questionable how that will work with the brake cable housing guides under the top tube.

#3

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,514

Liked 3,807 Times

in

2,595 Posts

That's interesting. If it's aluminum, why is the paint bubbling in so many places?

As far as your questions, it really doesn't have to make sense. The inventor is probably already gone from this world, so we'll probably never know. The marketing for the bike might offer some reasoning that may or may not correspond to the reason why it was done this way.

As far as your questions, it really doesn't have to make sense. The inventor is probably already gone from this world, so we'll probably never know. The marketing for the bike might offer some reasoning that may or may not correspond to the reason why it was done this way.

#4

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,184

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Liked 3,992 Times

in

2,373 Posts

At one time Mangusta was the "high end road" brand that Mongoose (before their sell out) offered. Bonded Al construction and bolted stays as this bike shows. We never ordered any and I can't remember even servicing any since so I have little inside info (bad pun) on this tension rod.

But I can speculate that it is used during the construction to better hold the frame parts in place while the glues cure or it is to make sure the front end of the bike remains close to the rear when the bonding or tubes fail

As to the paint... just like many early Trek bonded frames this frame's joint lines shows paint issues. I suspect this bike's BB shell is steel. Andy

But I can speculate that it is used during the construction to better hold the frame parts in place while the glues cure or it is to make sure the front end of the bike remains close to the rear when the bonding or tubes fail

As to the paint... just like many early Trek bonded frames this frame's joint lines shows paint issues. I suspect this bike's BB shell is steel. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#5

Full Member

Thread Starter

yes, the bb shell is steel. And that is where the paint is bubbling, Where steel bb meets aluminum tubes.

Trek started their bonded frames about the same time. 1986 or 1987. I've talked to a few ex-Trek people about the bonded frames. One guy showed me a sample frame from Merida that Trek had ordered. Trek examined it and decided they could make bonded frames themselves. At one bike club banquet, the guest speaker, head of Trek, bemoaned that their first year of production of bonded frames all failed. They figured out what they did wrong and then the bikes were fine after that. Another ex-Treker described the machine they used to assemble the tubes and lugs and glue into framesets and how they added a clamping jig to hold them as they were sent through an oven to set the glue. Sound like it just took a couple minutes to assemble once all the parts were ready. There have been plenty of other bonded bikes. Raleigh USA Technium bikes made near Seattle for a few years. Vitus of France made light weight race bikes sold under many brand names. One big advantage of gluing is no high heat to affect the metal's strength. Thinner wall tubing can be used because it doesn't have to withstand welding or brazing temps. Pre heat treated tubing is spec'ed for some frames. Lighter and stronger as long as the glue holds and that hasn't been an issue. I had a Raleigh Technium that failed but at that was a brazed joint (steel seat stay to steel dropout). The latest are 3-d printed titanium lugs glued to carbon tubes. Most bonded frames are designed so there is no mitering of tubes. Just square cut to fit cast lugs. Simple too for the average assembly line worker.

Last edited by rickpaulos; 08-08-23 at 10:21 AM.

Likes For rickpaulos:

#6

Senior Member

Interesting

__________________

Bikes: 1996 Eddy Merckx Titanium EX, 1989/90 Colnago Super(issimo?) Piu(?),1990 Concorde Aquila(hit by car while riding), others in build queue "when I get the time"

Bikes: 1996 Eddy Merckx Titanium EX, 1989/90 Colnago Super(issimo?) Piu(?),

#7

Full Member

Thread Starter

#8

Senior Member

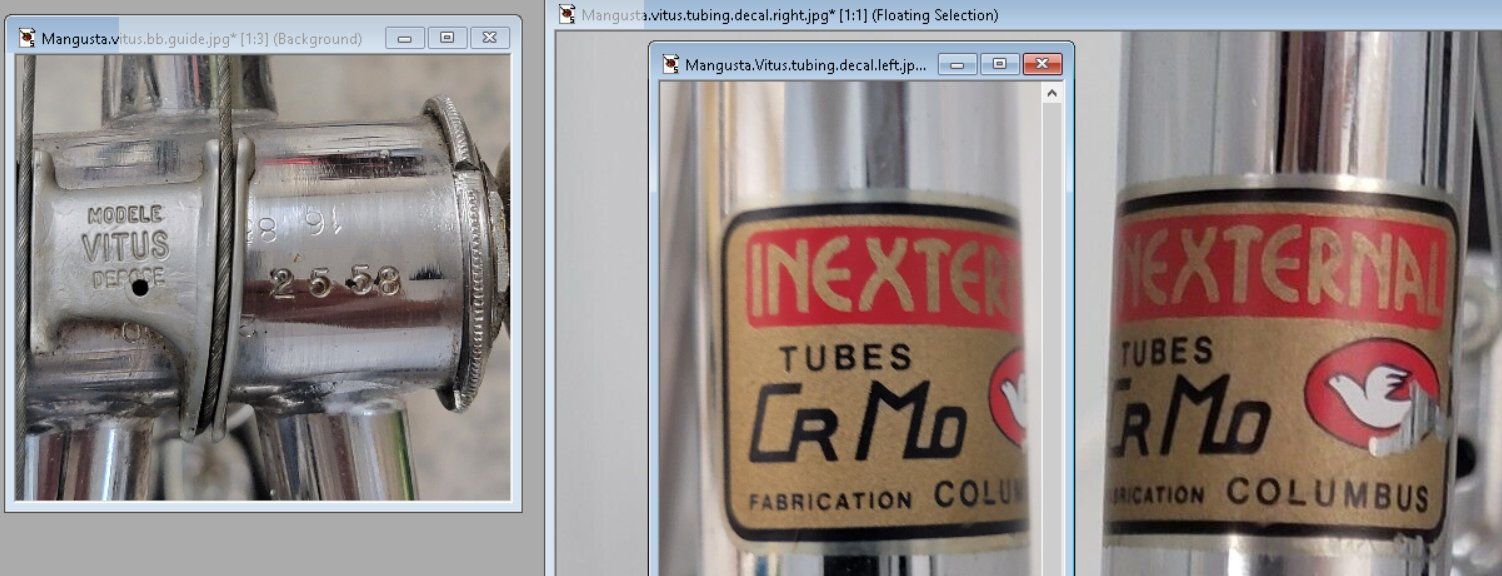

Much like Columbus or Reynolds, Vitus sold steel tubeset to other framebuildes and manufactures. Very likely that the tubeset for this chromed frame was produced by Vitus but the framebuilding performed by another company.

#9

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,514

Liked 3,807 Times

in

2,595 Posts

Interesting that Mangusta offered a Vitus tubed bike. Maybe they bought aluminum tubes from them and bought some steel tubing too? Obviously skipping the normal lugs.

I always wanted some vitus tubing, just for the novelty. I doubt I will ever find any.

I always wanted some vitus tubing, just for the novelty. I doubt I will ever find any.

#10

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,184

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Liked 3,992 Times

in

2,373 Posts

I suspect just like a number of other Euro brand names Mangusta was only a name that was sold (rented for a period?) for specific market(s). Raleigh is perhaps the best known that did this. The USA sales rights were sold to Huffy and they went to a cheaper manufacturer for those "Raleighs" that sold here in the US. Badge labeling and heritage investment.

Still would like to know about that "tension rod" in the down tube. Andy

Still would like to know about that "tension rod" in the down tube. Andy

__________________

AndrewRStewart

AndrewRStewart

#11

Full Member

Thread Starter

from the ebay listing:

Columbus Cro-mo steel tubing. "inexternal" may mean internal lug construction. Seen on other French made bikes.

And a Vitus cable guide on the bb shell.

Columbus Cro-mo steel tubing. "inexternal" may mean internal lug construction. Seen on other French made bikes.

And a Vitus cable guide on the bb shell.

#12

Full Member

Thread Starter

Looking up the etymology of Mangusta:

An exotic car the 1967 De Tomaso Mangusta

Italian luxury yacht maker

town

an old family name.

and the best: french feminine word for mongoose. ding ding ding, we have a winner!

An exotic car the 1967 De Tomaso Mangusta

Italian luxury yacht maker

town

an old family name.

and the best: french feminine word for mongoose. ding ding ding, we have a winner!

#13

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,514

Liked 3,807 Times

in

2,595 Posts

Disappointing that a French manufactured bike would use columbus.

#14

Senior Member

Of course, Atala and a few other Italian companies used Reynolds 531 for some models.

Motobecane used Columbus sometimes. From a old Bike Forums thread:

"I was just perusing the TC/LC on those Bulgier pages. Looks like through 83 both were lugged. In '84 the Le Champion is described as having inexternal brazing but still using SL tubing. I've not heard of Columbus SL that isn't double butted, but I'm not the local expert. Your inquiry is a little vague, so I don't know if any of that helps or not. Are you looking at a particular bike from a particular year?

[edit] a bit more clarification: in 81 the LC was lugged 531 and the TC was SL. In 82 and 83 both were lugged SL. In 84 both were SL; the TC was lugged but the LC was lugless."

Motobecane used Columbus sometimes. From a old Bike Forums thread:

"I was just perusing the TC/LC on those Bulgier pages. Looks like through 83 both were lugged. In '84 the Le Champion is described as having inexternal brazing but still using SL tubing. I've not heard of Columbus SL that isn't double butted, but I'm not the local expert. Your inquiry is a little vague, so I don't know if any of that helps or not. Are you looking at a particular bike from a particular year?

[edit] a bit more clarification: in 81 the LC was lugged 531 and the TC was SL. In 82 and 83 both were lugged SL. In 84 both were SL; the TC was lugged but the LC was lugless."

#15

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,514

Liked 3,807 Times

in

2,595 Posts

Reynolds was around before Columbus, so it's not too surprising the Italians still used Reynolds after Columbus showed up. I don't know why it seems wrong for a French bike to use Columbus but not Reynolds. Maybe it's because they can't agree on how to conjugate verbs so their languages can be different.